Method for highly selectively catalyzing epoxidation between olefin and air by cobalt-loaded zeolite molecular sieve

A zeolite molecular sieve and high-selectivity technology, applied in organic chemistry and other fields, can solve the problem of low selectivity of epoxidation, and achieve the effect of low catalyst cost, high conversion rate and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

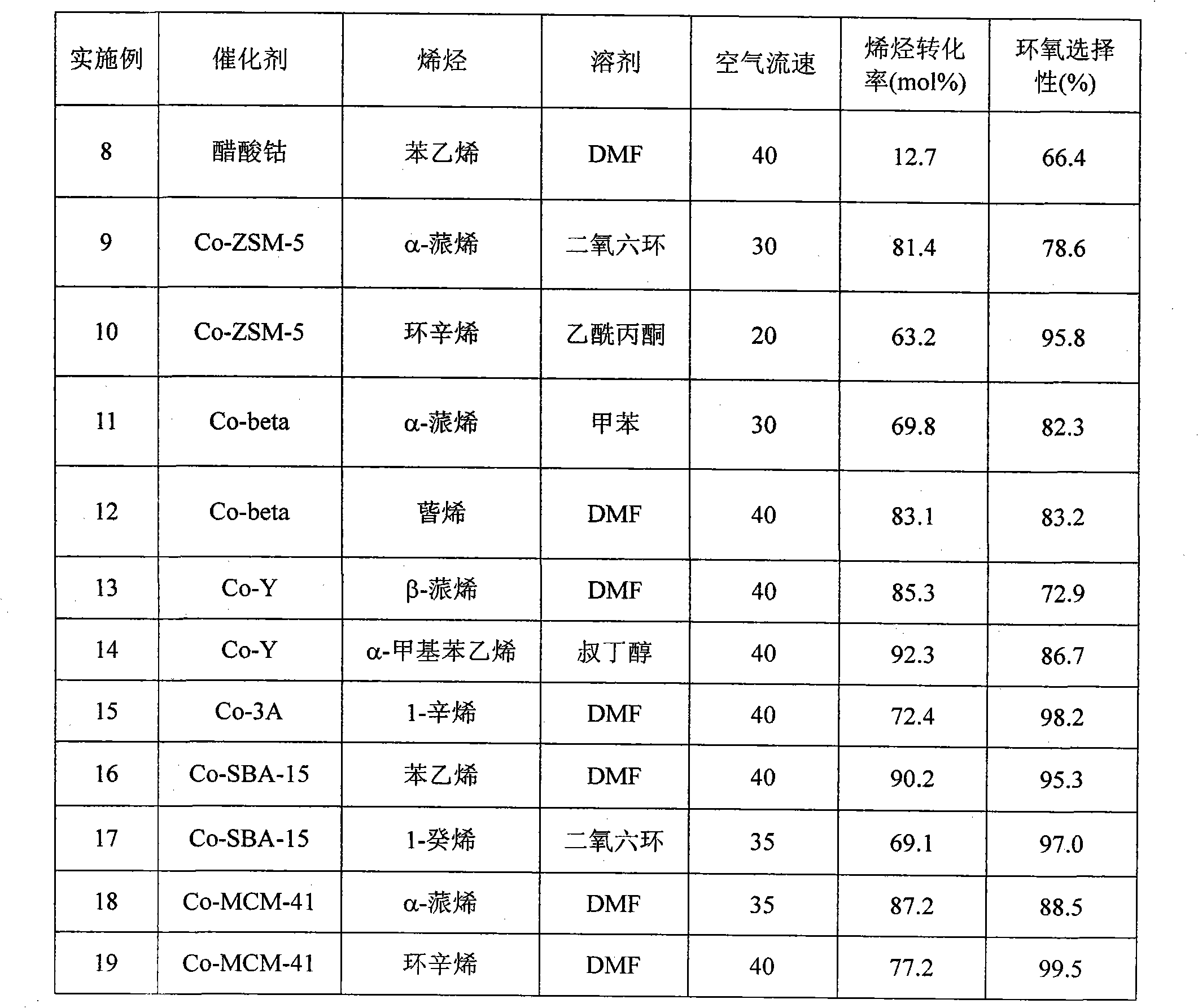

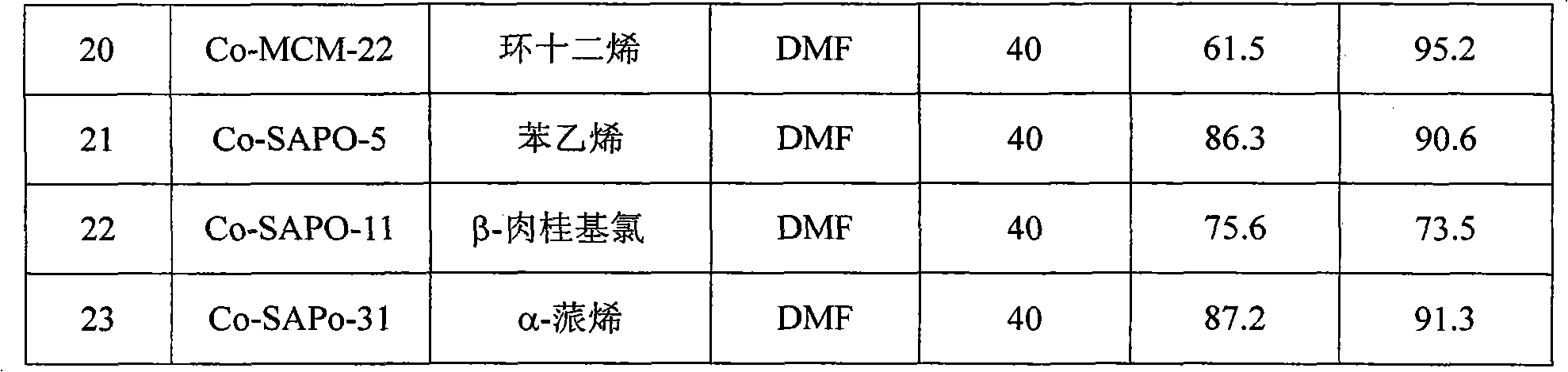

Examples

Embodiment 1

[0025] Weigh cobalt acetate, cobalt nitrate, cobalt sulfate, and cobalt chloride at a certain loading ratio, dissolve them in 200mL of water, then add 5g of ZSM-5, perform ion exchange at 90°C for 10h, and filter with suction to obtain a solid. After drying, Co-ZSM-5 (with a cobalt loading of 1.0-5.0%) is obtained.

Embodiment 2

[0027] The preparation steps of other cobalt-loaded zeolite molecular sieves are the same as in Example 1, and the molecular sieves are selected from one of 4A, 3A, Y, beta, SBA-15, MCM-41, MCM-22, SAPO-5, SAPO-11, and SAPO-31. species, the prepared catalysts were Co-4A, Co-3A, Co-Y, Co-beta, Co-SBA-15, Co-MCM-41, Co-MCM-22, Co-SAPO-5, Co- SAPO-11, Co-SAPO-31.

Embodiment 3

[0029] In a 50ml two-necked round bottom flask, successively add 10g of solvent DMF, 100mg of Co-ZSM-5 (1.5% cobalt load) catalyst, 3mmol styrene, 0.3mmol tert-butyl hydroperoxide (65% aqueous solution) , and then connected to a low-temperature condenser (the temperature is kept at -15°C) and the flow rate is 30ml / min of dry air, the reactor is warmed up to 90°C for 5h under rapid magnetic stirring, then the reaction is stopped and filtered after cooling to room temperature , quantitative analysis was carried out by chromatography after adding internal standard chlorobenzene in the filtrate. The conversion rate of styrene is 88.4 mol%, and the selectivity of epoxide is 95.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com