Patents

Literature

238 results about "Selective catalytic oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of ferromanganese composite oxide catalyst for simultaneous denitrification and mercury removal and preparation method thereof

InactiveCN102294248AImprove anti-poisoning performanceHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsBULK ACTIVE INGREDIENTHigh activity

The invention discloses a ferromanganese composite oxide catalyst for simultaneous denitrification and mercury removal, the active components of which are MnO2 and Fe2O3, wherein the molar ratio of Mn / Fe is 0.5-5, the catalyst is compounded on the carrier TiO2, and its active components are The total mass fraction of the component is 5% to 40%, and CuO, CeO2, V2O5 and other oxide auxiliary components can also be added, and the addition amount is 0% to 10% of the total mass fraction. The invention also discloses a preparation method of the catalyst, which adopts an impregnation method or a co-precipitation method. The catalyst of the present invention has high activity and selectivity for the catalytic oxidation of nitrogen oxides and mercury, and its temperature adaptability window is wide, which can effectively improve the anti-poisoning performance of the catalyst, and has strong adaptability to harsh operating conditions, and can It is widely used in the catalytic oxidation of pollutants in the flue gas selective catalytic oxidation denitrification and demercuration process, and at the same time, the preparation method of the catalyst of the present invention is simple in process and low in cost.

Owner:ZHEJIANG UNIV

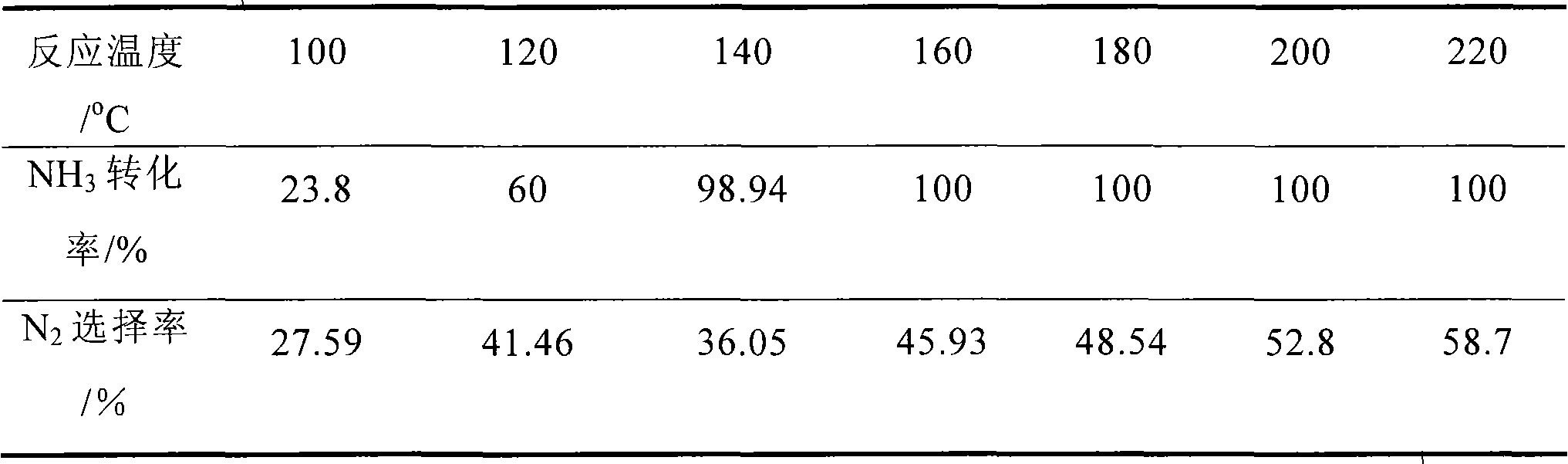

Preparation method and application of nanometer ceria-zirconia solid solution-based catalyst for selectively catalytically oxidizing ammonia

InactiveCN101966451ALow priceHigh low temperature activityDispersed particle separationCatalyst activation/preparationManganeseBULK ACTIVE INGREDIENT

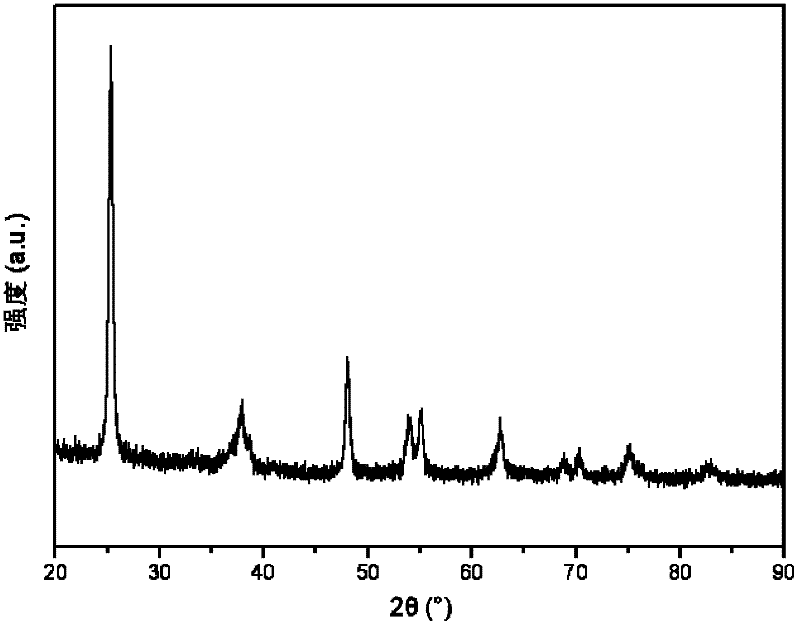

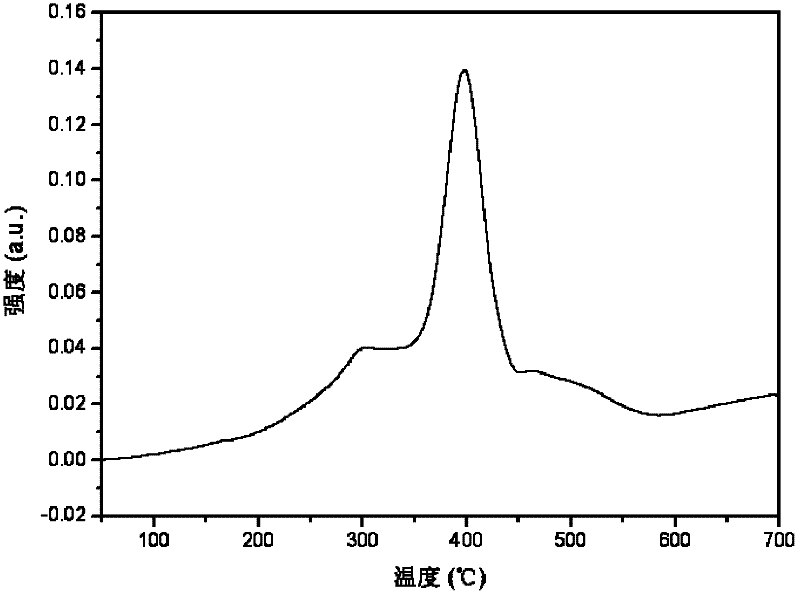

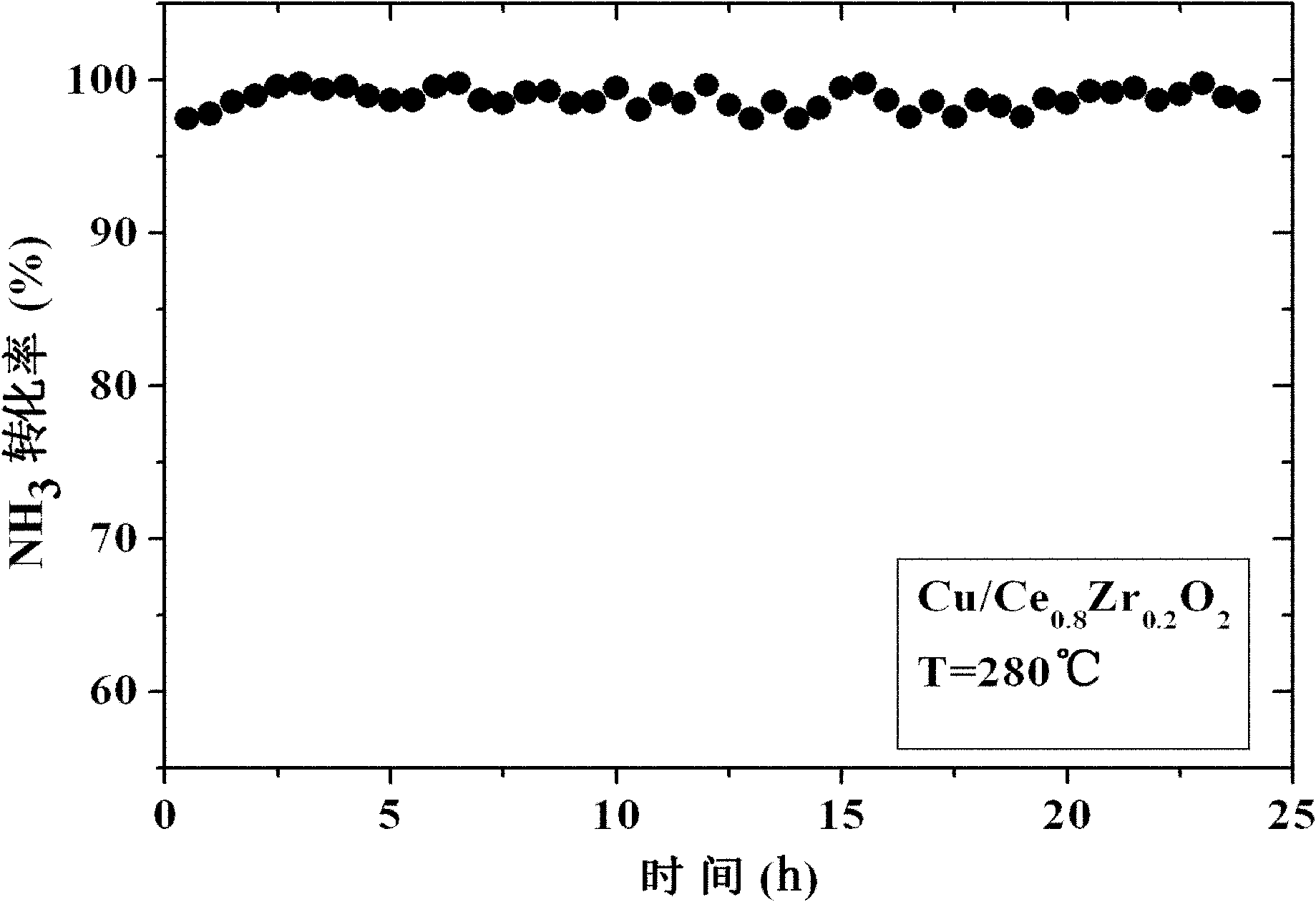

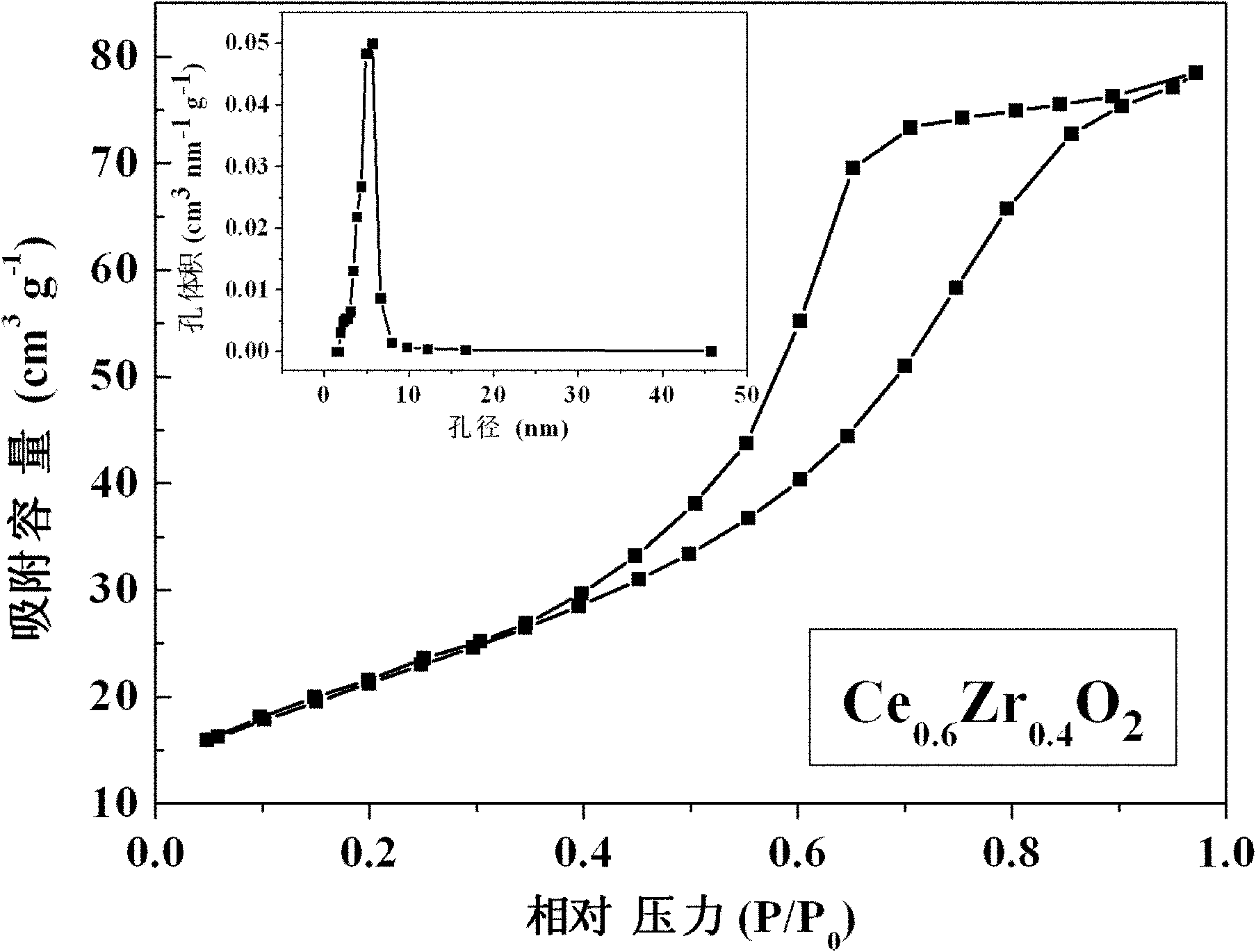

The invention relates to a preparation method and application of a nanometer ceria-zirconia solid solution-based catalyst for selectively catalytically oxidizing ammonia. The preparation method is characterized in that: a carrier of the prepared catalyst is ceria-zirconia solid solution, and the active ingredients are copper, silver, manganese, iron and the like; and the carrier is prepared by an anionic surfactant method, and the active ingredients are loaded on the ceria-zirconia solid solution by a deposit-precipitation method or impregnation method. The raw material used in the method is not toxic or harmful, and the prepared catalyst has the characteristics of large specific area, mesoporous structure and the like. The catalyst prepared by the method has the advantages of high low-temperature activity, 100 percent of conversion rate when NH3 is at 280 DEG C, good N2 selectivity, wide temperature window, high stability, catalysates of N2 and H2O and no secondary pollution. If the prepared catalyst is pulped and loaded to a honey-comb shaped metal wire mesh or a honey-comb ceramic, the catalyst can be applied to ammonia pollution treatment in tail gas of the practical industry and has wide application prospect.

Owner:DALIAN UNIV OF TECH

Dehydrogenation catalyst applicable to raw gas rich in carbon monoxide, and preparation and application thereof

InactiveCN102974344AEasy to operateHigh activityCarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsDehydrogenationCerium

The invention relates to gas purification techniques and specifically to a dehydrogenation catalyst applicable to raw gas rich in carbon monoxide and preparation and application thereof. Palladium is used as an active component of the catalyst, auxiliary agents for the catalyst are two to four selected from the group consisting of silver, zinc, lanthanum, cerium, samarium, praseodymium, iron, stannum, manganese, calcium, magnesium, tungsten and molybdenum, and a carrier of the catalyst is alumina. The catalyst realizes selective catalytic oxidation removal of hydrogen in the raw gas rich in carbon monoxide by directing using synergism of palladium and oxides of a plurality of the auxiliary agents. Components of the catalyst comprise, based on the weight of the carrier, 0.05 to 1% of the active component and 0.5 to 5% of the total auxiliary agents. According to the invention, the catalyst has high activity and stability even when the application amount of a precious metal is small; through usage of the catalyst in a gas source rich in carbon monoxide, outlet hydrogen content is less than 100 ppm, outlet oxygen content is less than 0.1%, and purifying indexes of hydrogen and oxygen in reaction tail gas still accord with requirements after continuous operation for 1000 hours.

Owner:DALIAN CATALYTIC ENG TECH

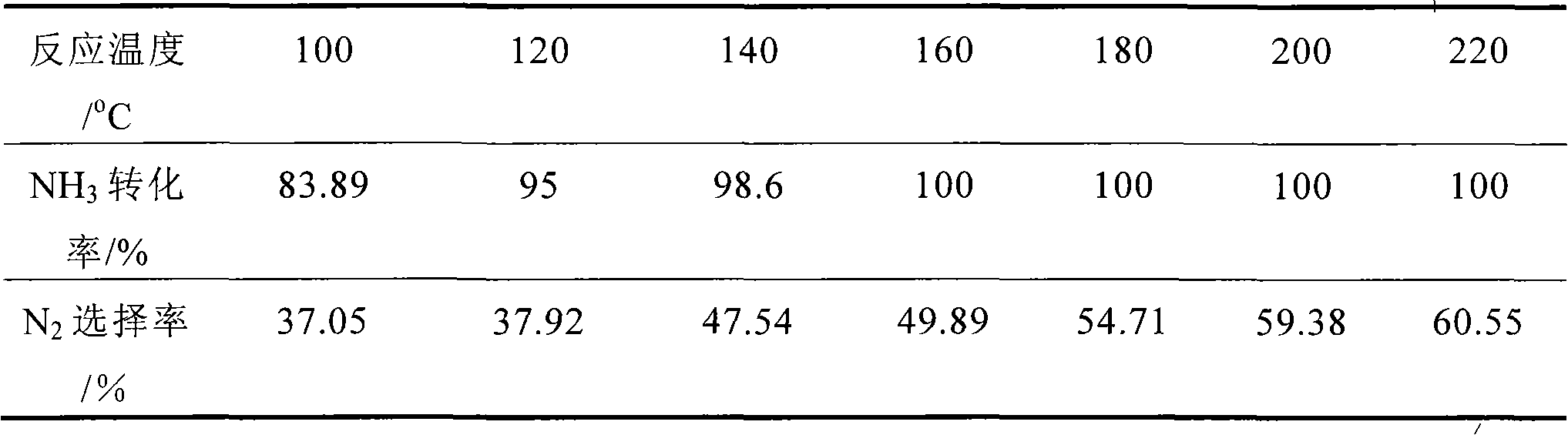

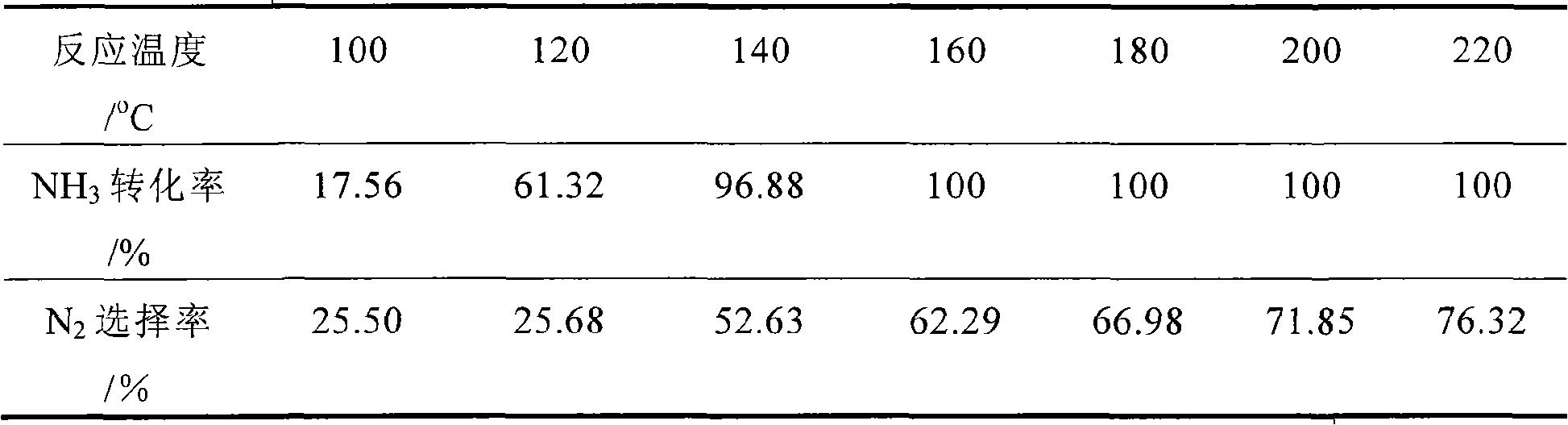

Low-temperature ammonia selective oxidation catalyst

ActiveCN101554587ARaw materials are readily availableEasy to prepareNitrogen preparationDispersed particle separationCeriumNitrogen gas

The invention provides a low-temperature ammonia selective oxidation catalyst which is used for eliminating ammonia gas pollution generated in the field of industry, agriculture, traffic, architecture, and the like, and selectively catalyzing and oxidizing the ammonia into pollution-free nitrogen and water under lower temperature. The oxidation catalyst can completely convert the ammonia under the temperature above 160 DEG C, and has the nitrogen selectivity of nearly 80 percent, good low-temperature oxidbillity, high catalytic efficiency and high stability. The oxidation catalyst contains porous inorganic oxide carrier, silver as an active component and cerium as an accessory ingredient, wherein the porous inorganic oxide carrier can be silicon dioxide, aluminium oxide, zirconia, lanthana, zinc oxide or titanium dioxide or the mixture of more than one of the oxide; the active component is formed by loading silver which a metal element with the weight conversion value of 1-15 percent on the inorganic oxide carrier; and the accessory ingredient is formed by simultaneously loading cerium and silver with the metal element weight conversion value of 5-50 percent on the inorganic oxide carrier.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

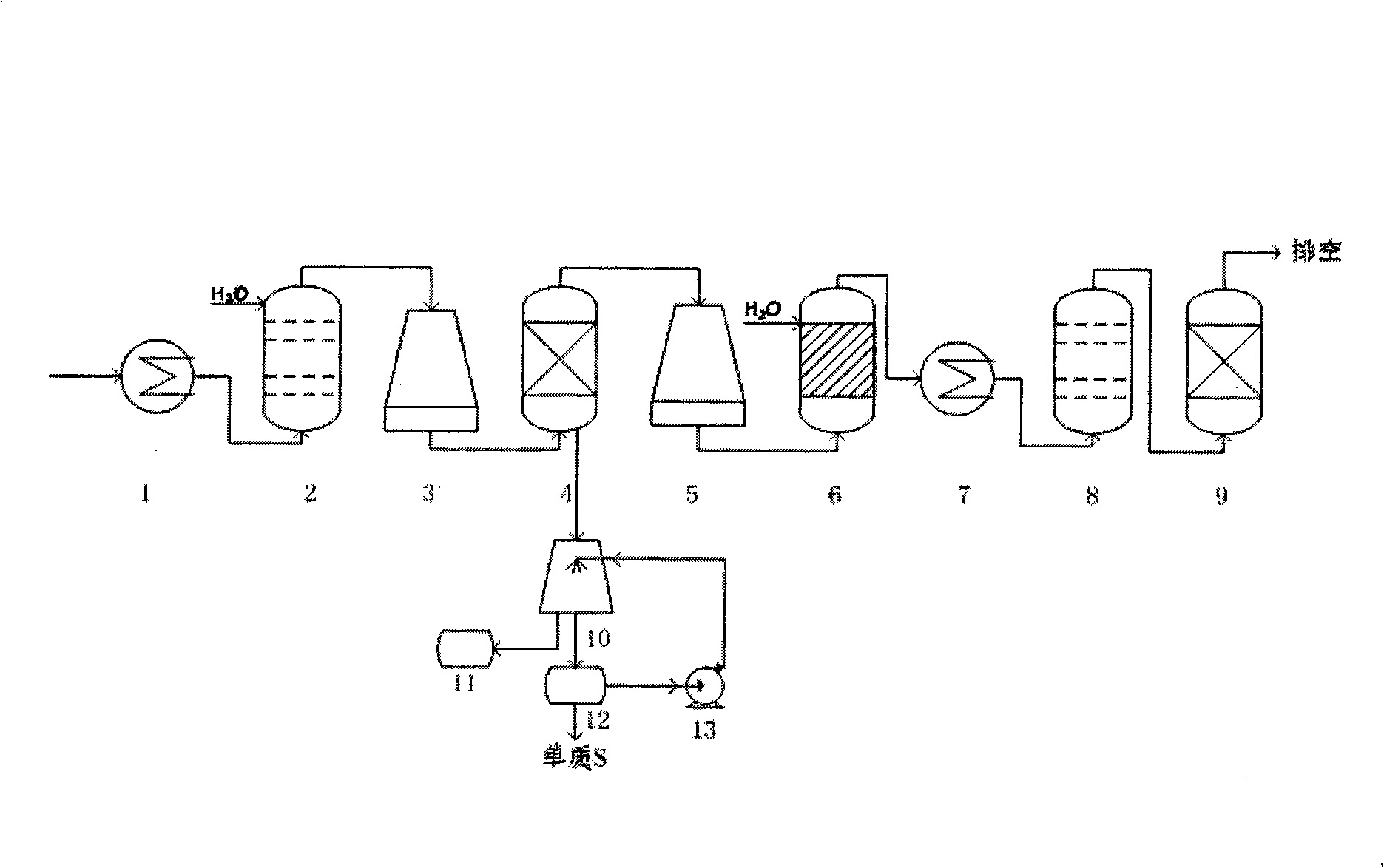

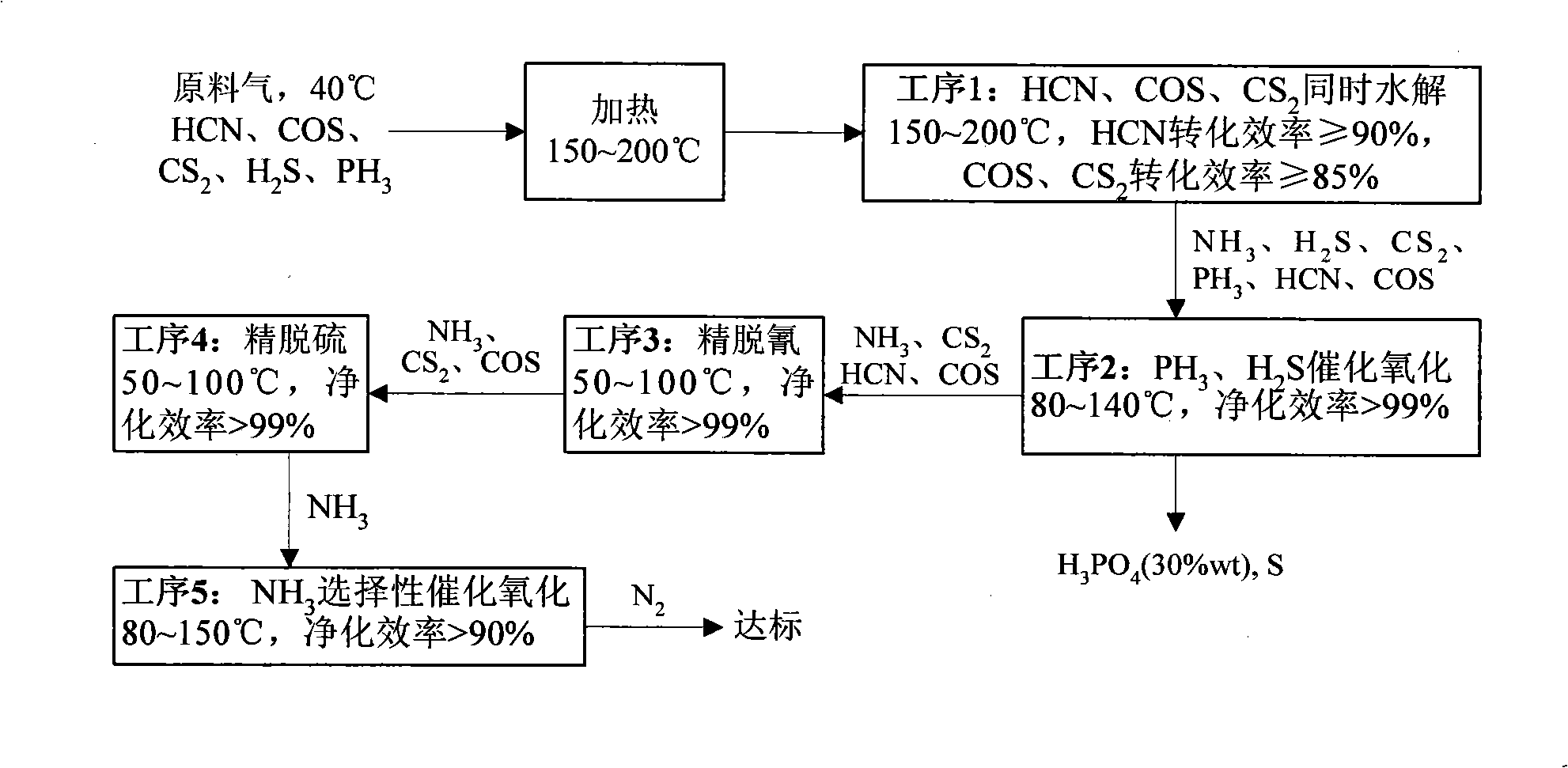

Low-temperature micro-oxygen purification method for removing harmful gas in yellow phosphorus tail gas

InactiveCN101352653AEliminate pollutionLow running costDispersed particle separationPurification methodsResource utilization

The invention provides a micro-oxygen purifying method used for removing harmful gas in yellow phosphorus tail gas, which is characterized in that mixed gas containing HCN, PH, H2S, COS and CS2, with the speed of 1000-5000 / h is heated to 150-200 DEG C by a heat exchanger and sent to a catalytic hydrolysis reactor; more than 90% of HCN and 85% of COS and CS2 can be respectively hydrolysed as NH3, CO, H2S and CO2; subsequently, the mixed gas enters a selective catalytic oxidation reaction; PH3 and H2S are catalysed and oxidated as P2O5 and S; harmful gas in the mixed gas which is disposed twice is removed further in a fine decyanation reactor and the sulfide thereof is removed by a fine desulfurization reactor; NH3 is selectively catalysed and oxidated as N2, thus purifying the mixed gas. The method of the invention leads the violent toxic matter to be converted into non-toxic matter, generates no secondary pollution, recovers the outgrowth sulphur, improves the utilization ratio of the resource, eliminates the environmental pollution due to waste gas exhausting, and has the advantages of simple process, few investment and low running expense.

Owner:KUNMING UNIV OF SCI & TECH

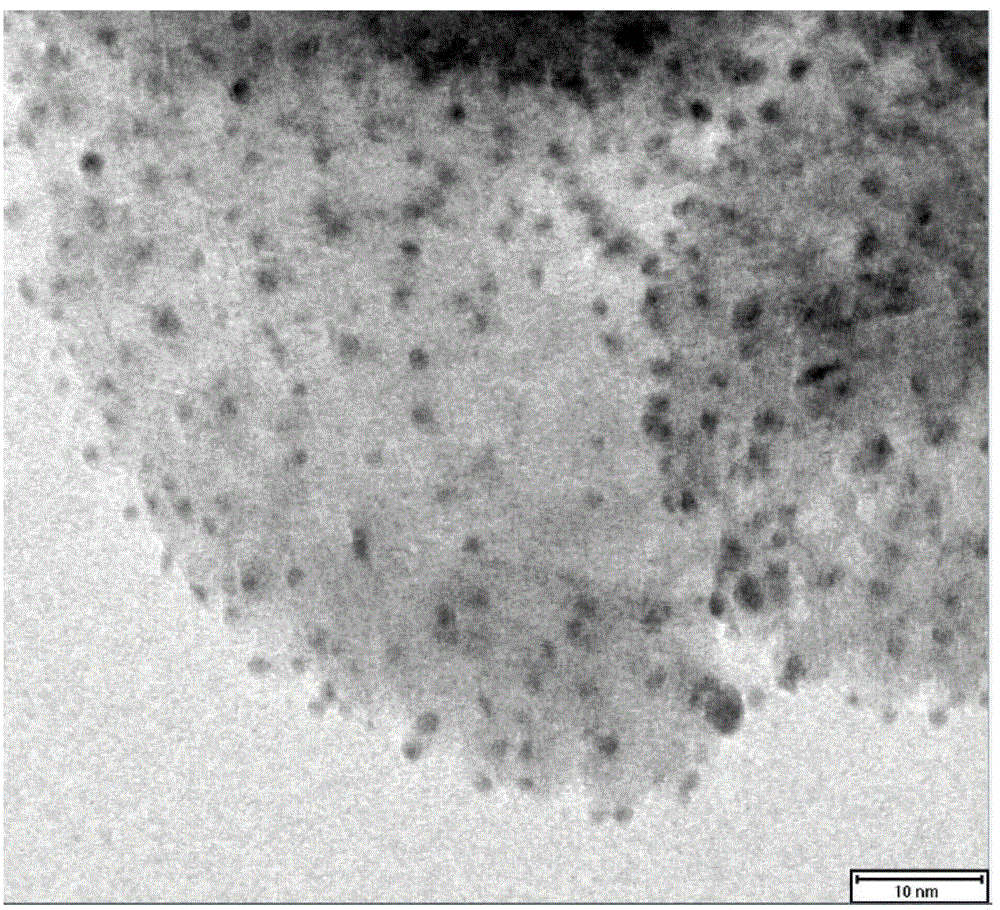

Application of gold/mesoporous carbon catalyst in glucose selective oxidation reaction to prepare gluconic acid

InactiveCN101805256AImprove stabilityActivity does not decayOrganic compound preparationCarboxylic compound preparationReaction temperatureGluconic acid

The invention provides a method for preparing gluconic acid through a selective catalytic oxidation reaction by taking glucose as a raw material and gold / mesoporous carbon as a catalyst. Conditions are that: the catalyst is the carbon-loaded gold catalyst with a regular mesoporous structure, and the concentration of glucose is 0.01 to 2M; oxygen is used as an oxidant, and the velocity range of the oxygen is 100 to 1,000 ml.min<-1>; and the reaction temperature range of the glucose selective oxidation reaction is between 25 and 80 DEG C, reaction pressure is normal pressure and reaction time is 0.5 to 120h. In the invention, an action of the mesoporous carbon-loaded nano gold for the glucose selective catalytic oxidation is used, the glucose with a certain concentration is converted into the gluconic acid at normal temperature and normal pressure, so that energy consumption of the reaction process is low, the catalyst is stable and can be recycled and the method is a method for preparing the green gluconic acid.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

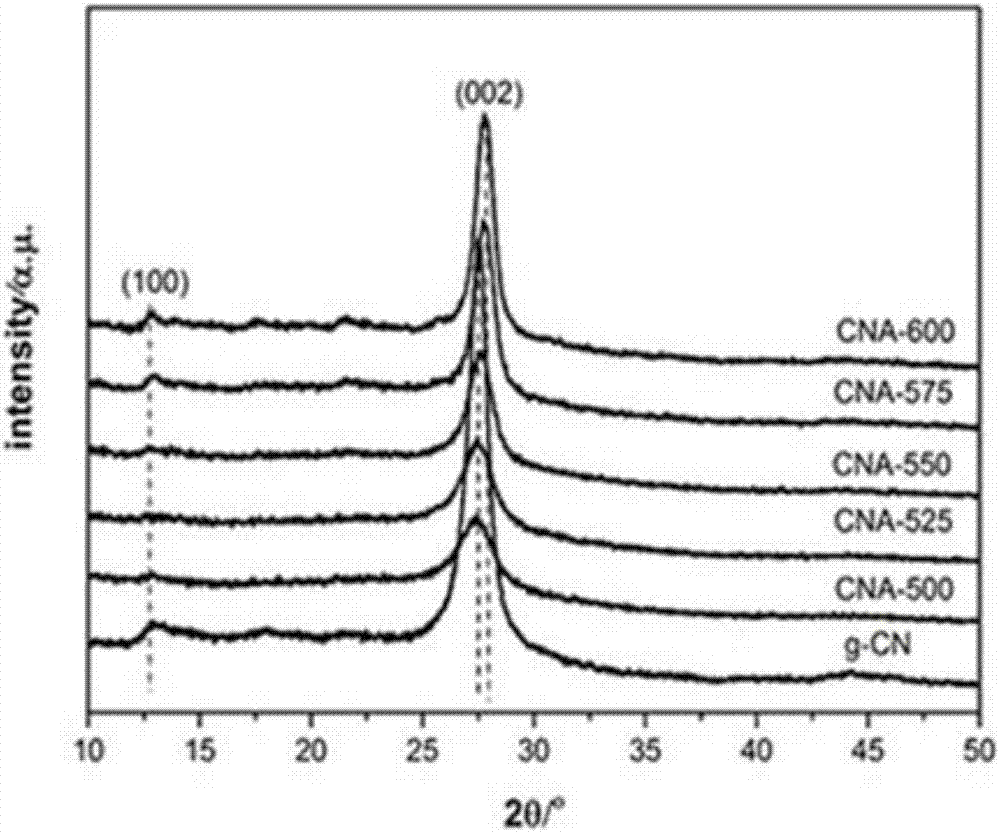

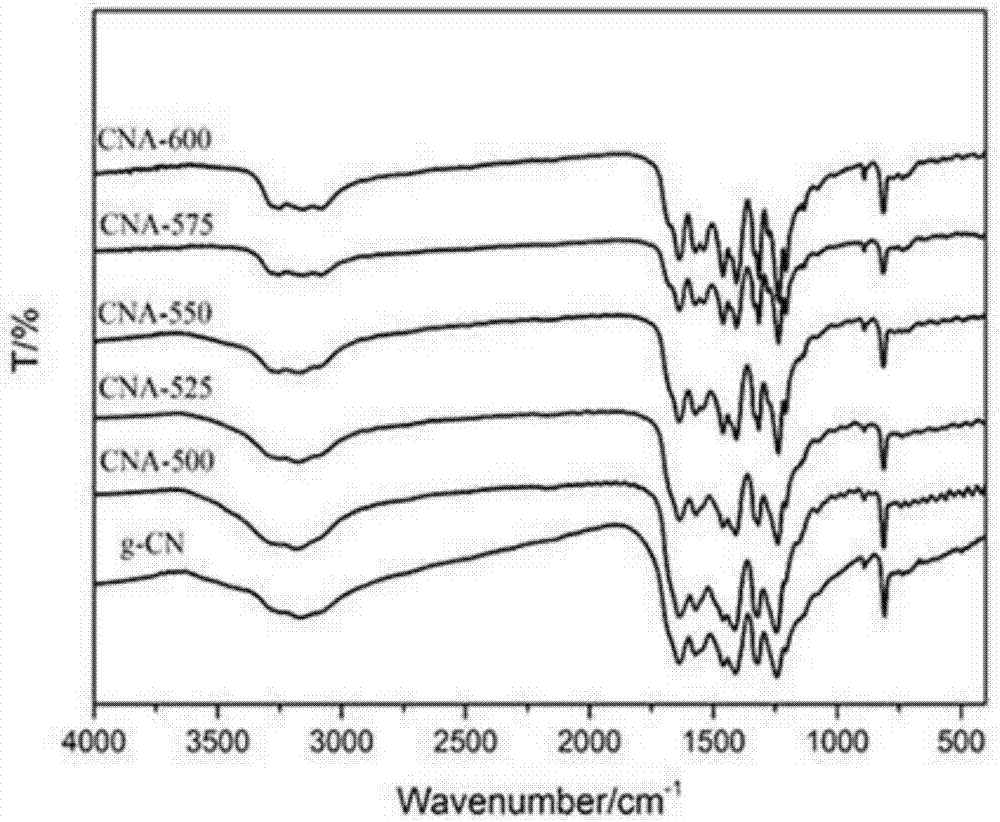

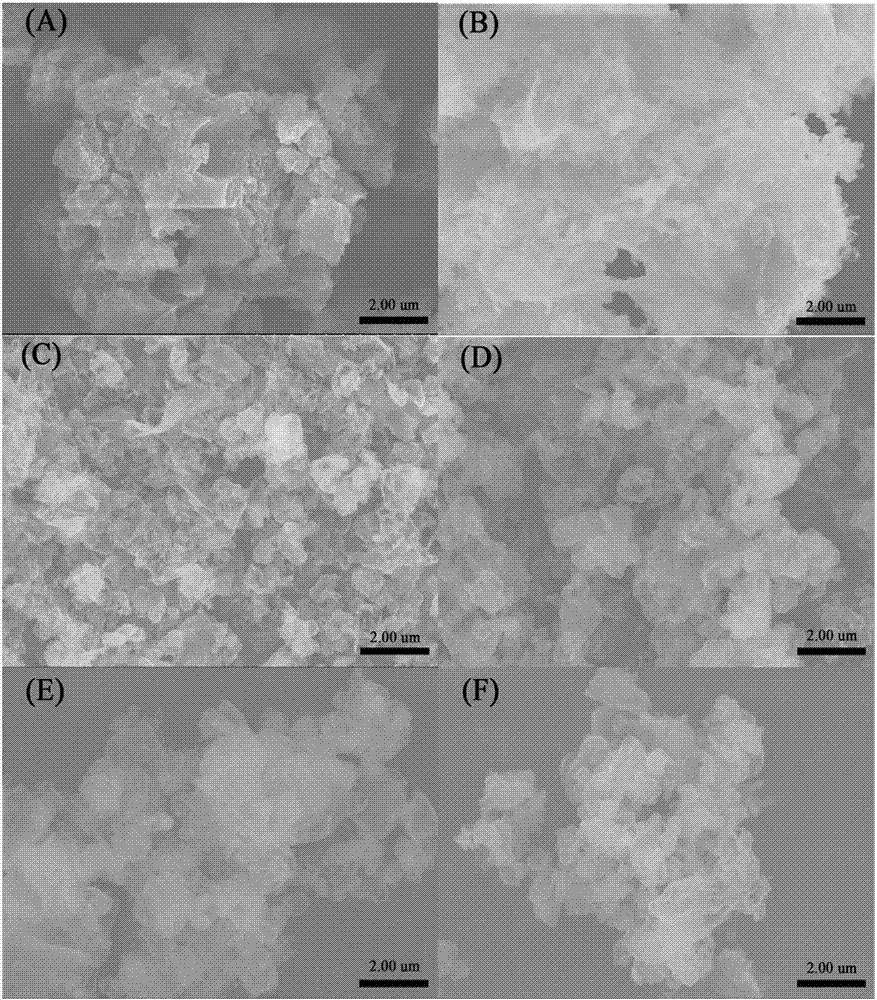

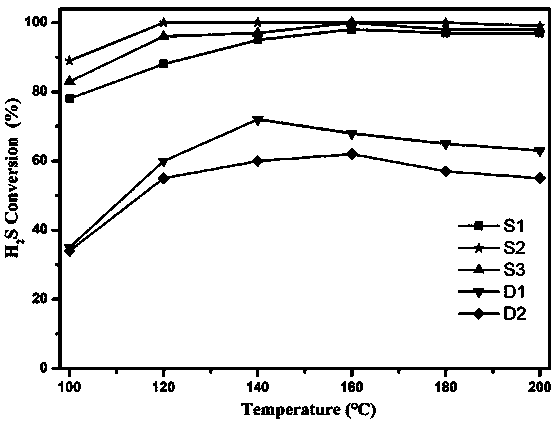

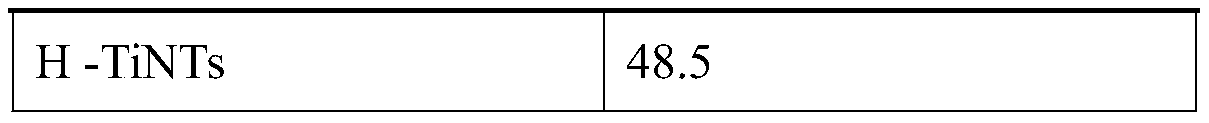

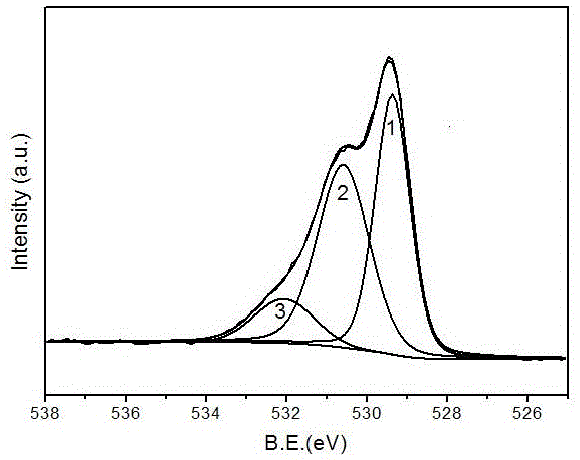

Method for preparing graphite phase carbon nitride catalyst and application of graphite phase carbon nitride catalyst in H2S oxidation

ActiveCN106902856AImprove performanceEasy to preparePhysical/chemical process catalystsSulfur preparation/purificationAir atmosphereCarbon nitride

The invention discloses a method for preparing a graphite phase carbon nitride catalyst. The method comprises the following specific steps: grinding thiocyanuric acid serving as a precursor into powder, and putting into a heating device; then, heating the thiocyanuric acid powder to 500-600 DEG C in an air atmosphere, and performing thermal polymerization reaction for 2 hours; and cooling to room temperature after the reaction is completed so as to finally prepare the graphite phase carbon nitride catalyst having a nano-plate structure. The graphite phase carbon nitride catalyst has a plate nano-laminate structure with high specific surface area, and has excellent catalytic activity and selectivity when applied to selective catalytic oxidation of H2S.

Owner:FUZHOU UNIV ASSET MANAGEMENT CO LTD

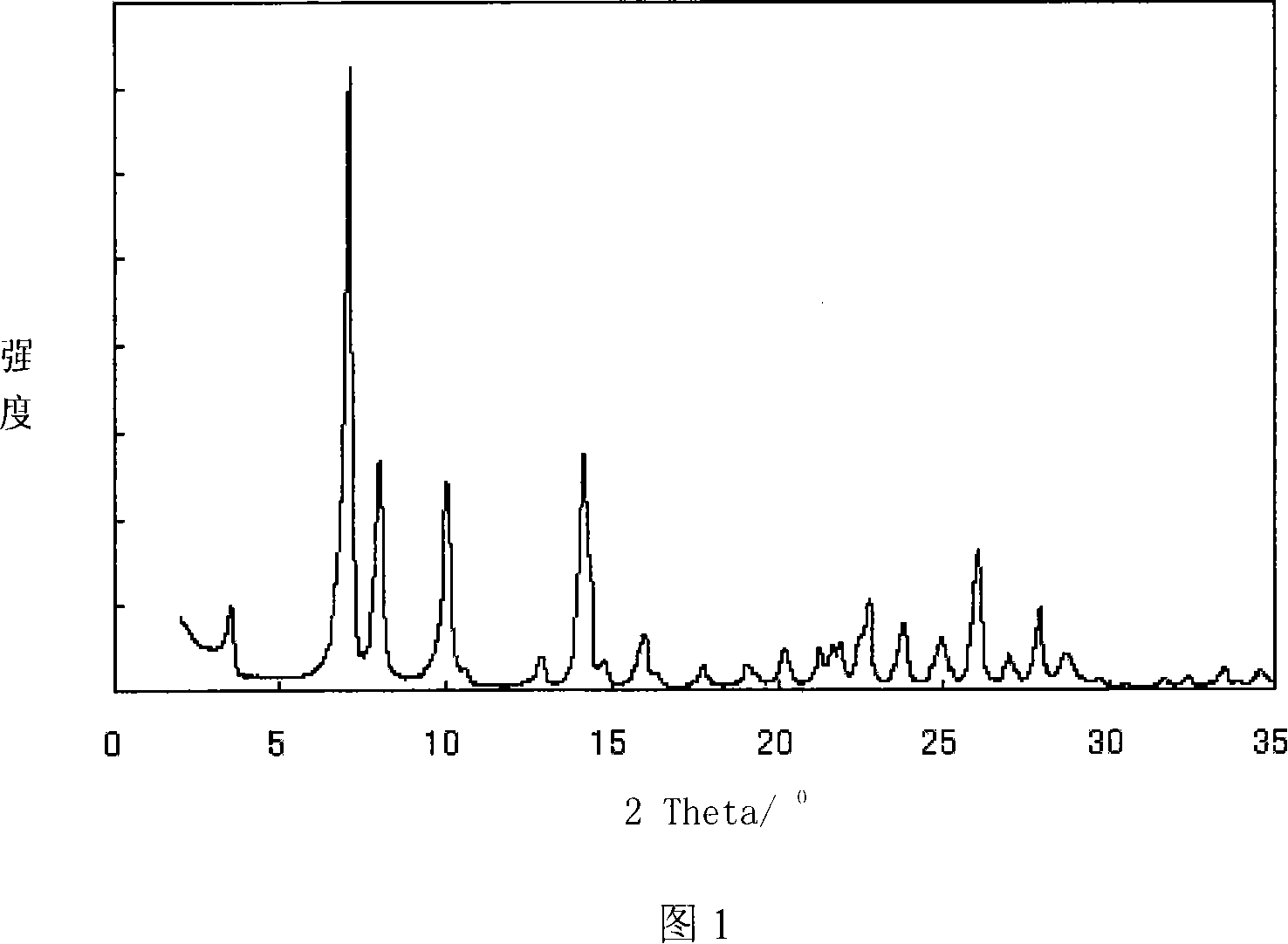

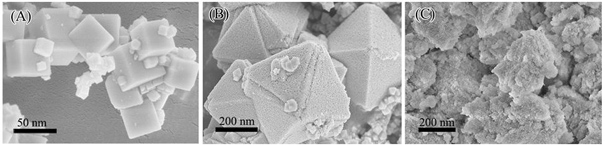

Titanium-silicon molecular screen with MWW structure and its synthesis and application

InactiveCN101148260AReduce surface defectsImprove catalytic performanceMolecular sieve catalystsOximes preparationMolecular sieveInorganic Chemical

The present invention is one kind of Ti-Si molecular sieve in MWW structure and its synthesis and application, and belongs to the field of inorganic chemical technology. The Ti-Si molecular sieve in MWW structure with Ti, Si and O as the skeleton elements and without B adverse to selective catalytic oxidation is prepared through synthesizing intermediate crystal material and roasting directly or after acid treatment. It is suitable for use as the catalytic oxidation catalyst, and has less surface faults, great specific surface area up to 450 sq m / g, high catalytic oxidation performance and other advantages.

Owner:EAST CHINA NORMAL UNIV

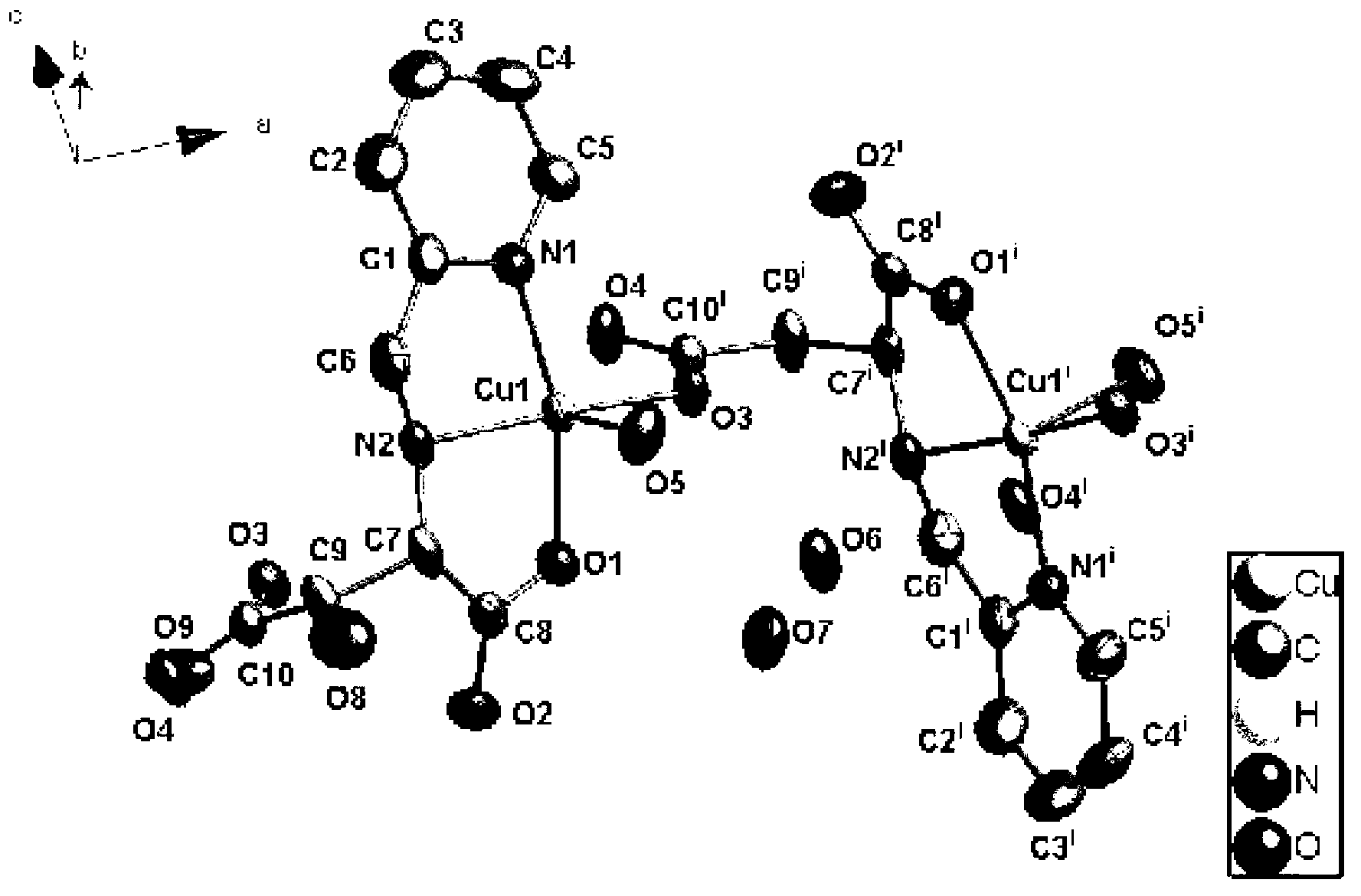

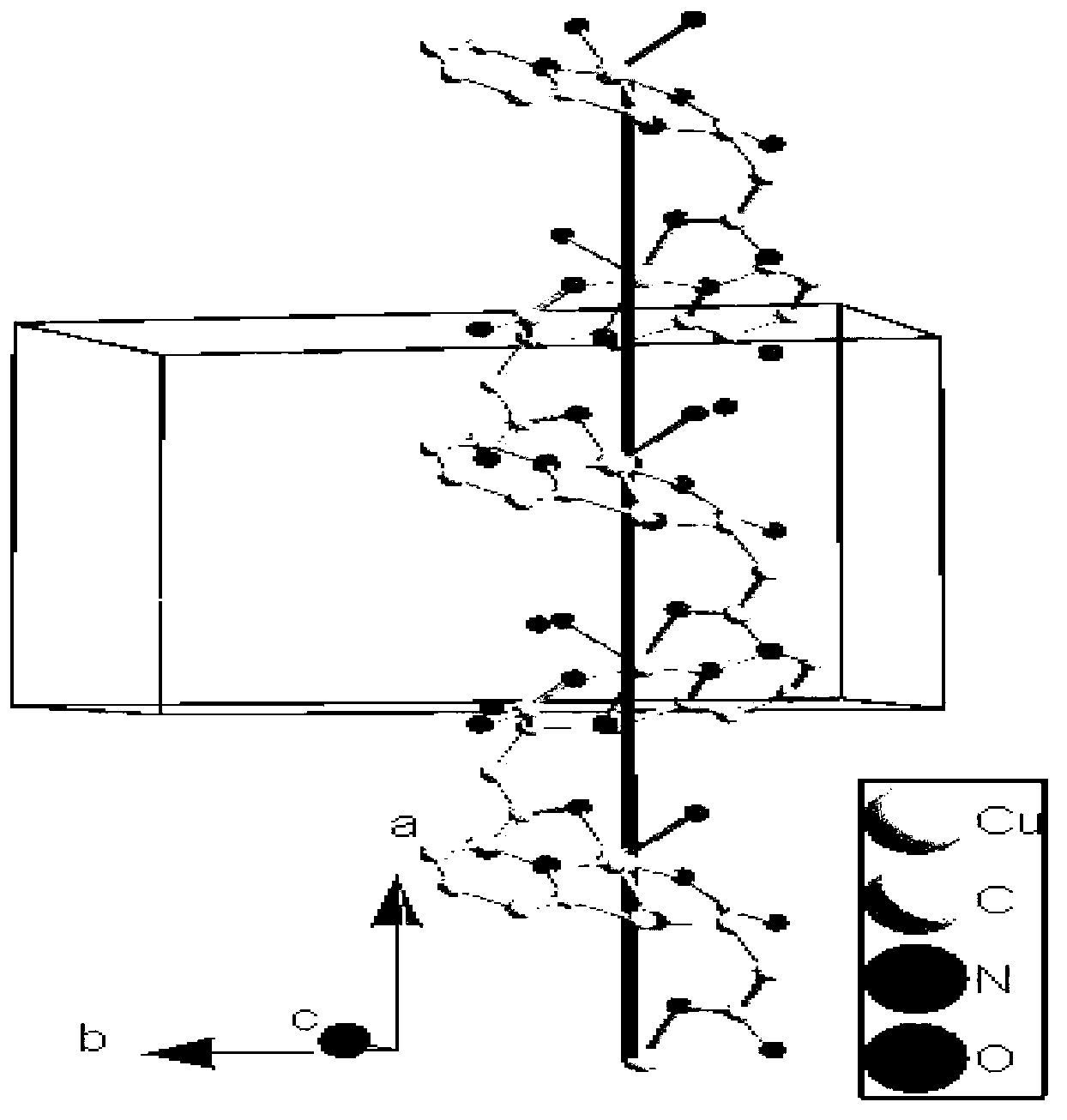

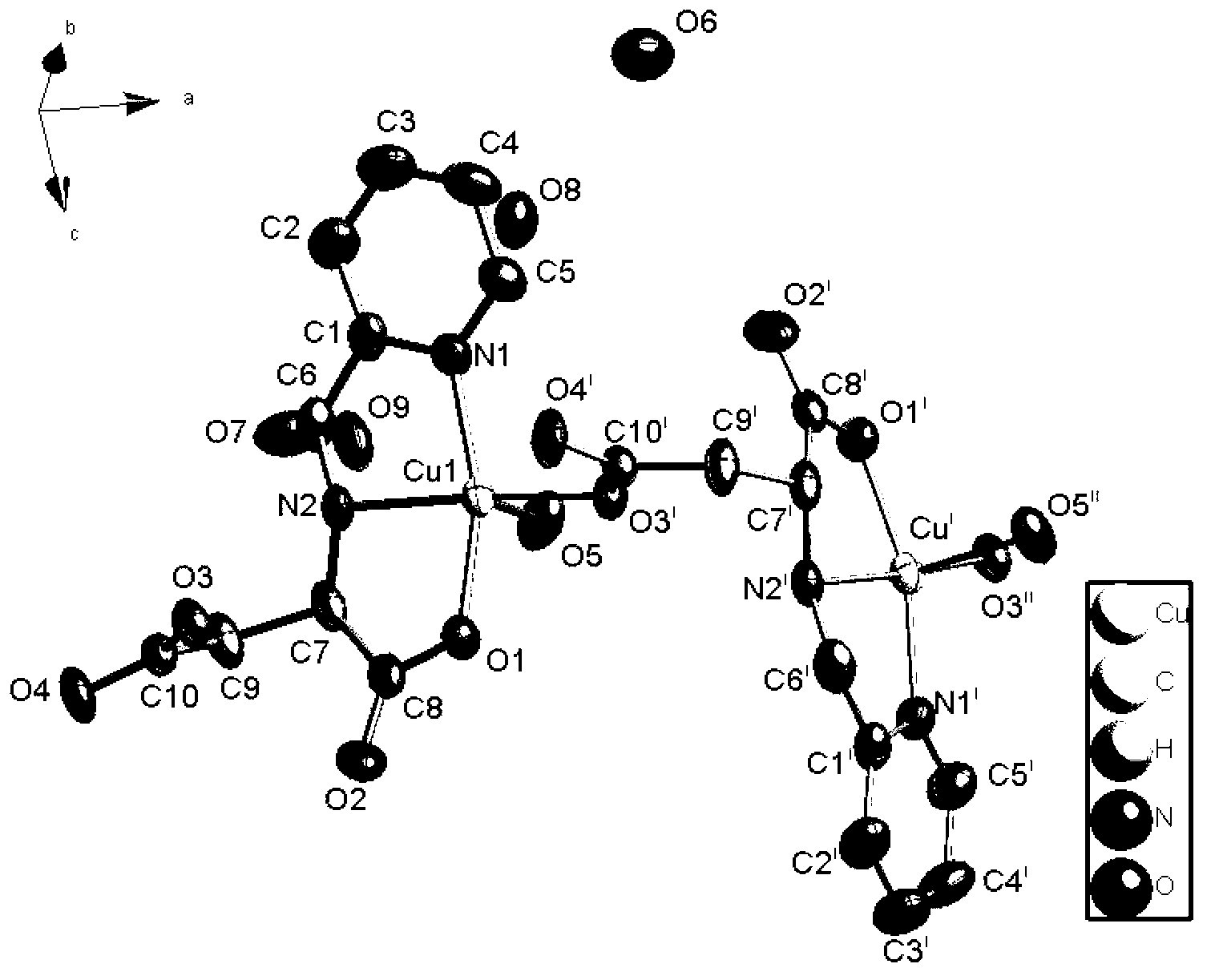

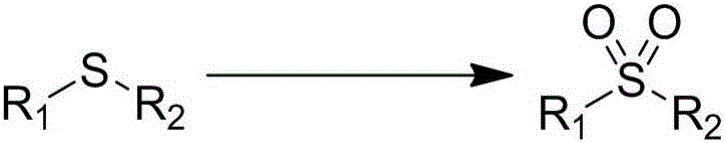

Cuprum (II) coordination compound catalyst of selective catalytic oxidation thioether and preparation method of cuprum (II) coordination compound catalyst

ActiveCN103012442AImprove thermal stabilityHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMethyl groupSelective catalytic oxidation

The invention discloses a cuprum (II) coordination compound catalyst of selective catalytic oxidation thioether and a preparation method of the cuprum (II) coordination compound catalyst, and relates to the technical field of transition metal coordination polymers. The chemical formula of the coordination compound is as shown in the specification, wherein pasp is an N-(2-picolyl)-L(D)-aspartic acid negative ion ligand. A preparation process of the cuprum (II) coordination compound catalyst comprises the steps that cupric salt and N-(2-picolyl)-L(D)-aspartic acid are adopted as reaction raw materials to react in a volatilization condition at a room temperature, and a homochiral crystalline material is obtained. A synthetic method is mild in condition, high in yield, convenient to operate, and good in reproducibility. The reaction of adopting a sample of the coordination compound catalyst to oxidize different thioethers into corresponding sulphoxides is high in yield, and the cuprum (II) coordination compound catalyst is simple to prepare and facilitates large-scale popularization.

Owner:CHANGZHOU UNIV

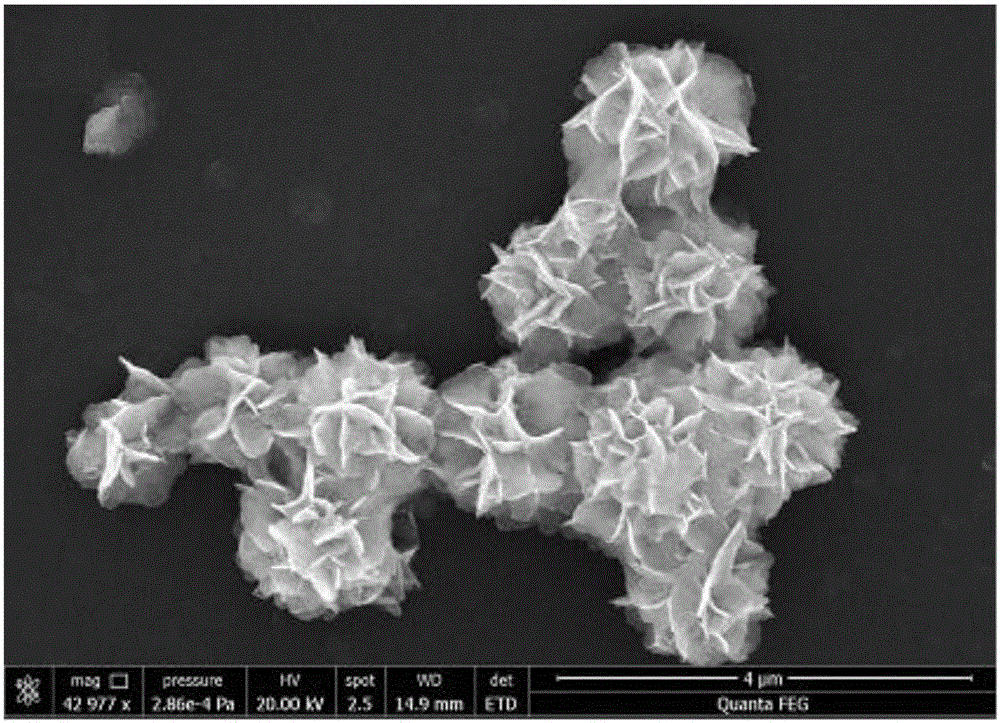

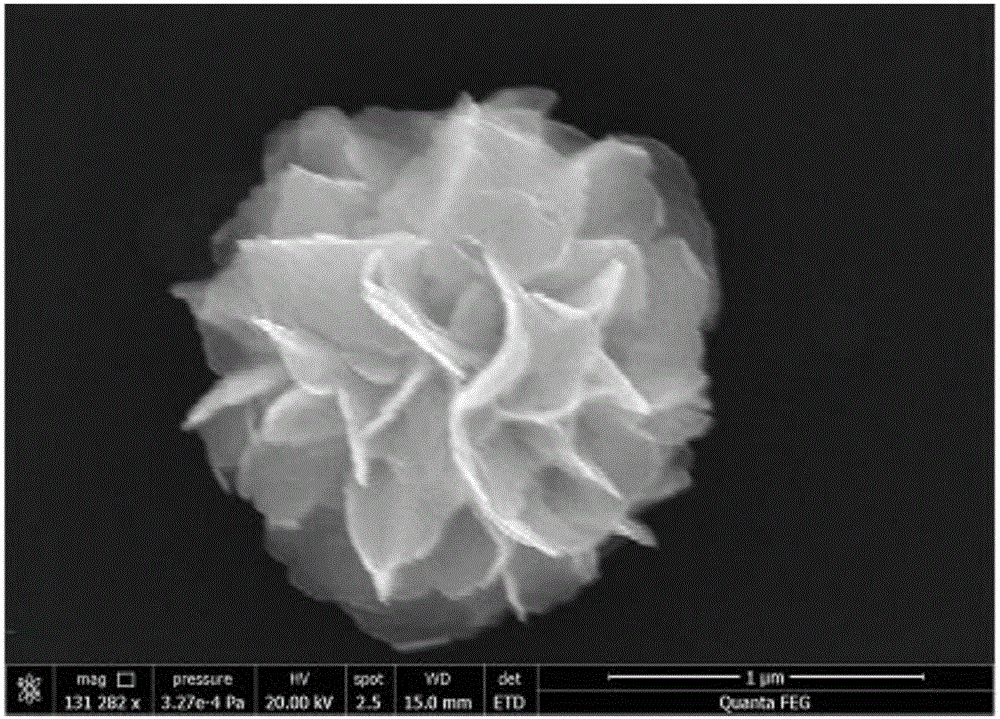

Preparing method for flower-shaped BiOI microspheres

InactiveCN105148950AHigh purityMild conditionsWater/sewage treatment by irradiationDispersed particle separationMicrosphereNew energy

The invention relates to a preparing method for flower-shaped BiOI microspheres, and belongs to the field of nanometer photocatalytic material preparing. The preparing method includes the following specific preparing steps that bismuth nitrate is added into nitric acid to obtain a solution A; ionic liquid [Bmin]I and nonionic surfactants PVP are added into distilled water, heated and stirred to form micro-emulsion B; then the solution A and the micro-emulsion B are mixed to be poured into a high pressure kettle, the pH is controlled to range from 1 to 4, centrifuging, washing and drying are carried out after a hydrothermal reaction, and the flower-shaped BiOI microspheres are obtained. According to the preparing method, an ionic liquid micro-emulsion method is adopted for the first time, no organic solvent is added, and the environment-friendly requirement is met; ionic liquid is used as an iodine source and solvents, is also used as an oil phase to form micro-emulsion drops and has the important effect on forming of the flower-shaped BiOI microspheres; the prepared flower-shaped BiOI microspheres have the high application value in the fields of pollution treatment, new energy preparing, selectivity catalytic oxidation and the like.

Owner:NANJING UNIV

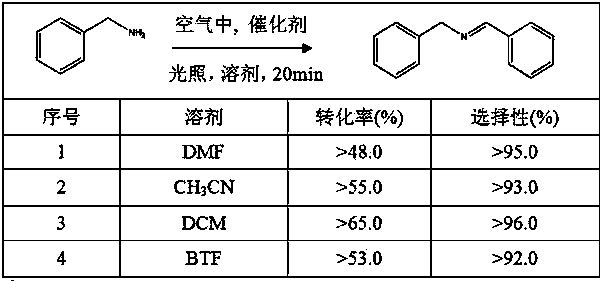

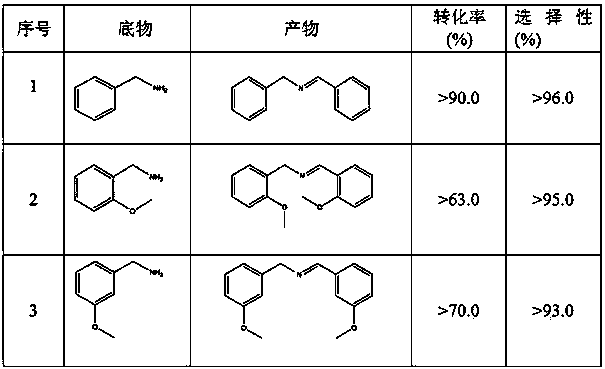

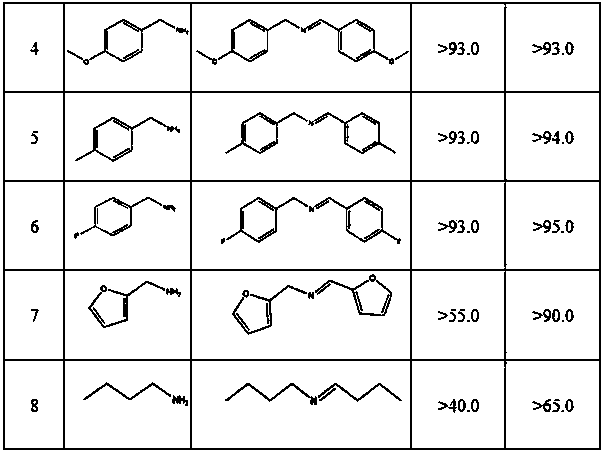

Photocatalyst for selectively catalytically oxidizing and coupling amine to generate imine

InactiveCN103908971ASimple manufacturing methodEfficient responsePhysical/chemical process catalystsImino compound preparationPtru catalystOrganic chemistry

The invention discloses a photocatalyst for selectively catalytically oxidizing and coupling amine to generate imine, belonging to the technical field of organic chemistry and photocatalysis. The photocatalyst is ZnIn2S4. The photocatalyst has high conversion rate and selectivity on selective amine oxide type compounds in air. Meanwhile, a method for preparing the catalyst is simple, convenient and feasible and is good for large-scale industrial popularization.

Owner:FUZHOU UNIV

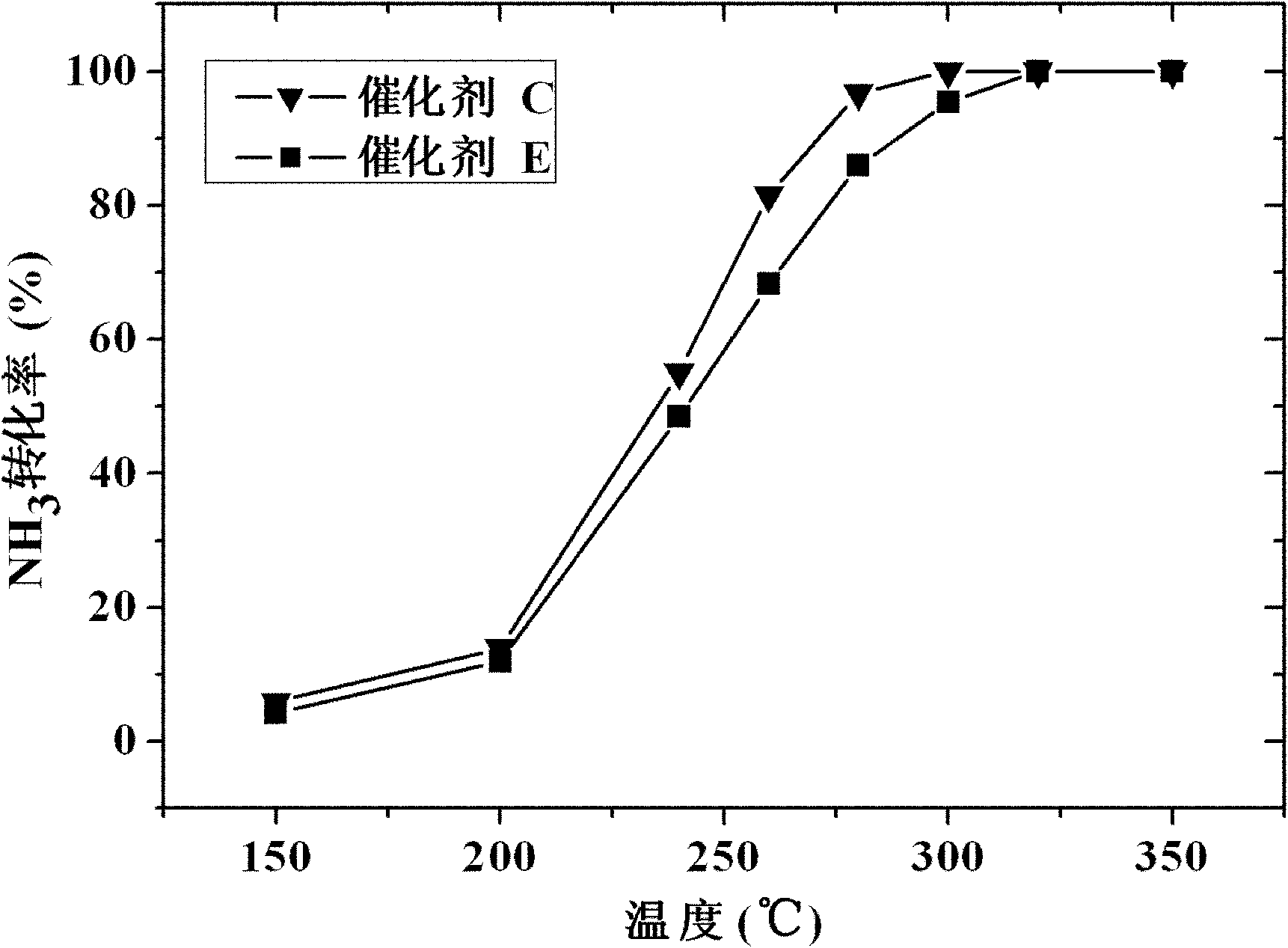

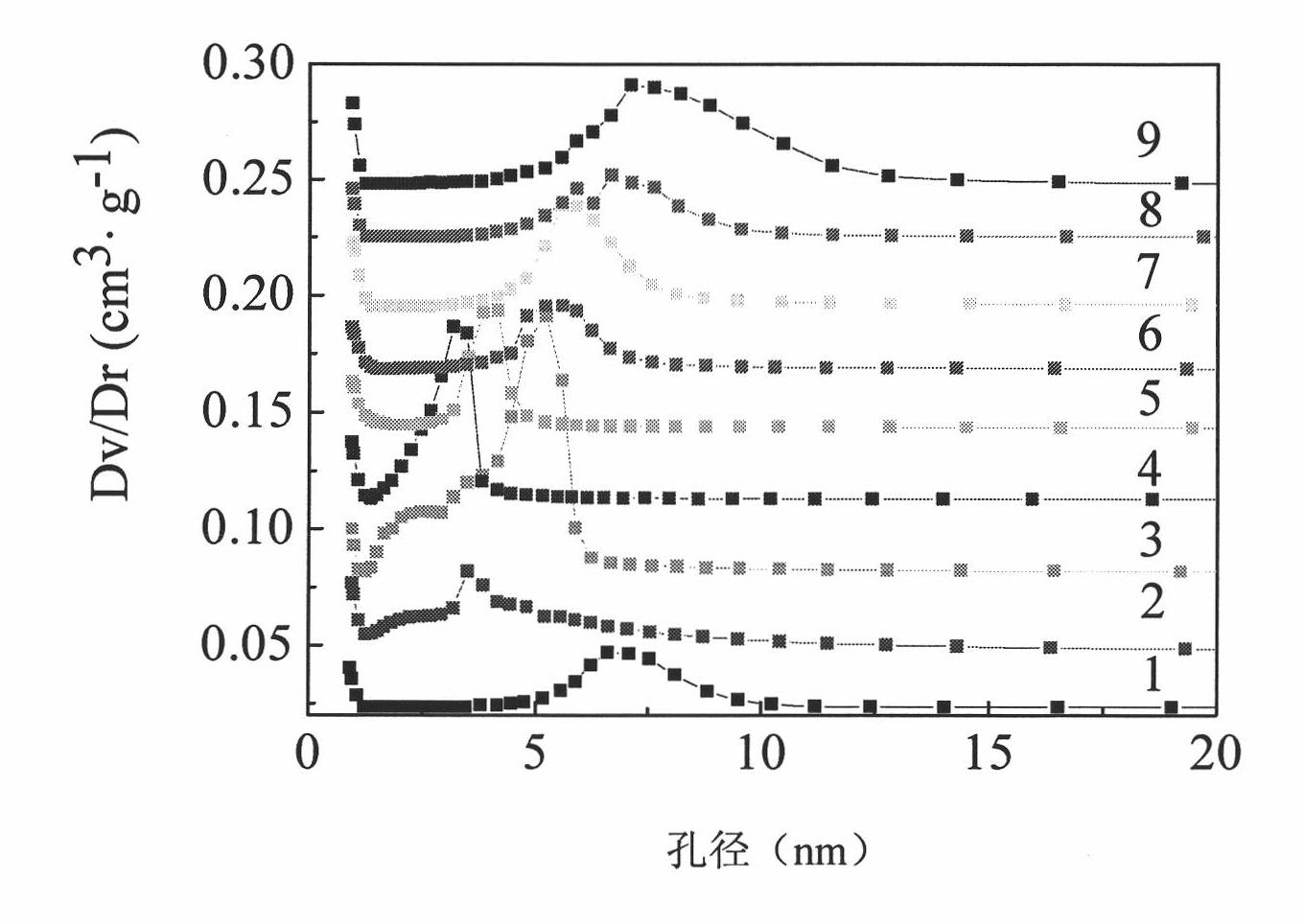

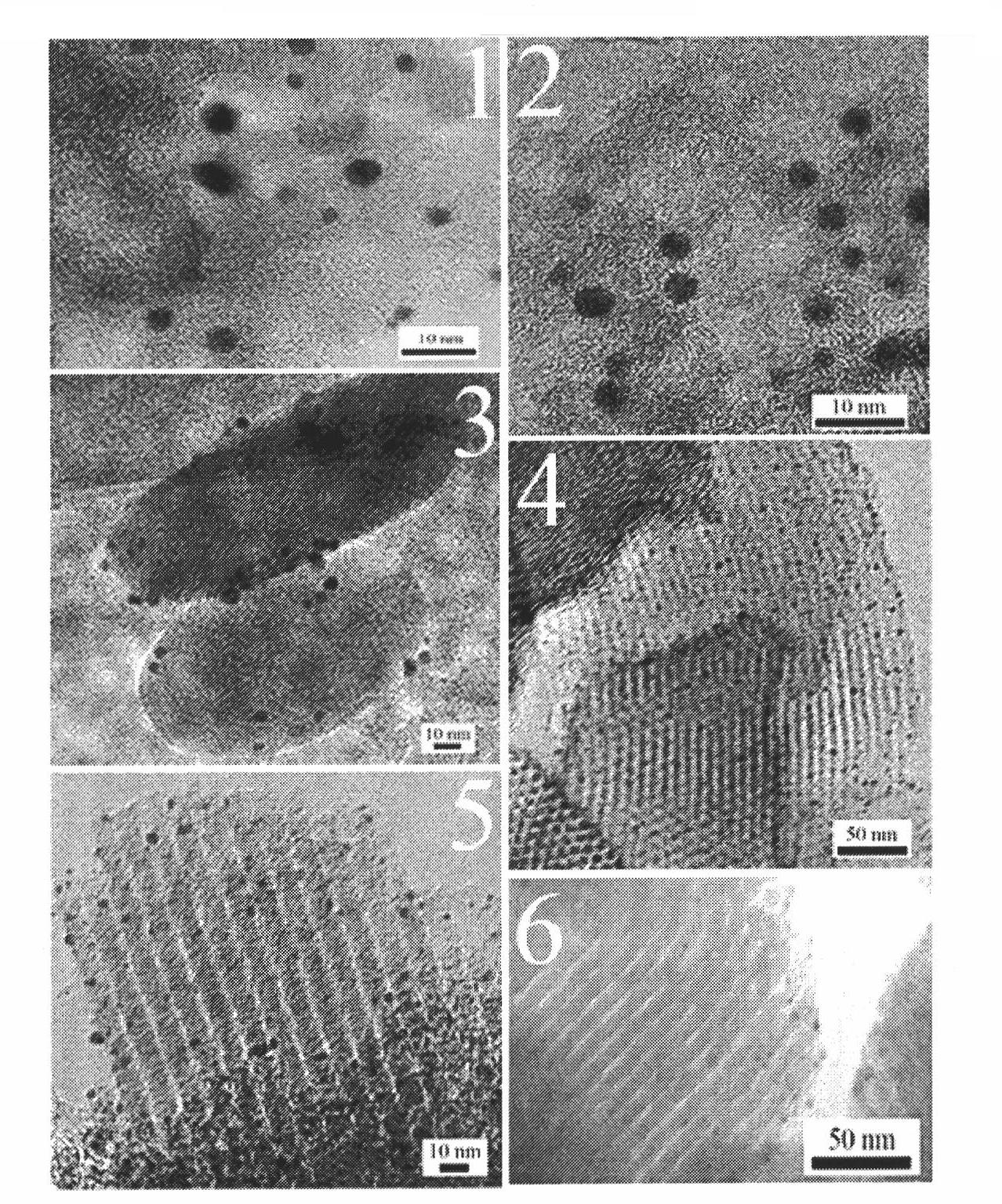

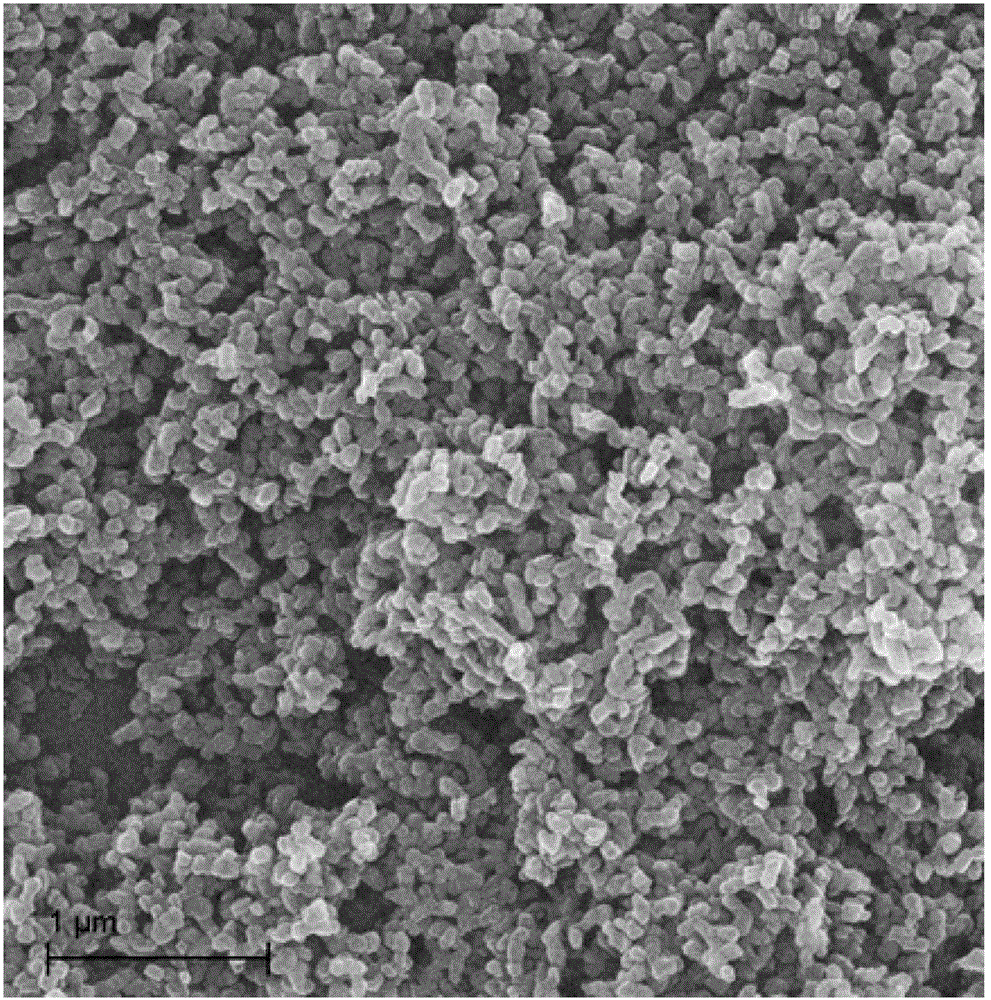

Mesoporous molecular sieve-based catalyst used for ammonia removing, and preparation method and applications thereof

InactiveCN104888839AMaximize Catalytic EfficiencyMaximize catalytic selectivityMolecular sieve catalystsDispersed particle separationMolecular sieveEvaporation

The invention discloses a mesoporous molecular sieve-based catalyst used for ammonia removing, and a preparation method and applications thereof. The mesoporous molecular sieve-based catalyst comprises a mesoporous molecular sieve and at least one active ingredient; specific surface area of the mesoporous molecular sieve-based catalyst ranges from 400 to 750m<2>*g<-1>; the at least one active ingredient is embedded into pore passages of the mesoporous molecular sieve; particle size of the active ingredient ranges from 2 to 50nm; the active ingredient is a transition metal oxide; transition metal loading amount of the transition metal oxide accounts for 2 to 8wt% of the total weight of the mesoporous molecular sieve-based catalyst. According to the preparation method, different mesoporous molecular sieve carriers are prepared via in situ synthesis, and the mesoporous molecular sieve-based catalyst is obtained via loading of a certain amount of the active ingredient via dipping-rotary evaporation. When the mesoporous molecular sieve-based catalyst is used for an ammonia selective catalytic oxidation removing system, 100% catalytic efficiency can be achieved at 300 DEG C, energy consumption is reduced, and at the same time, catalyst catalytic efficiency and N2 selectivity are increased.

Owner:BEIJING UNIV OF CHEM TECH

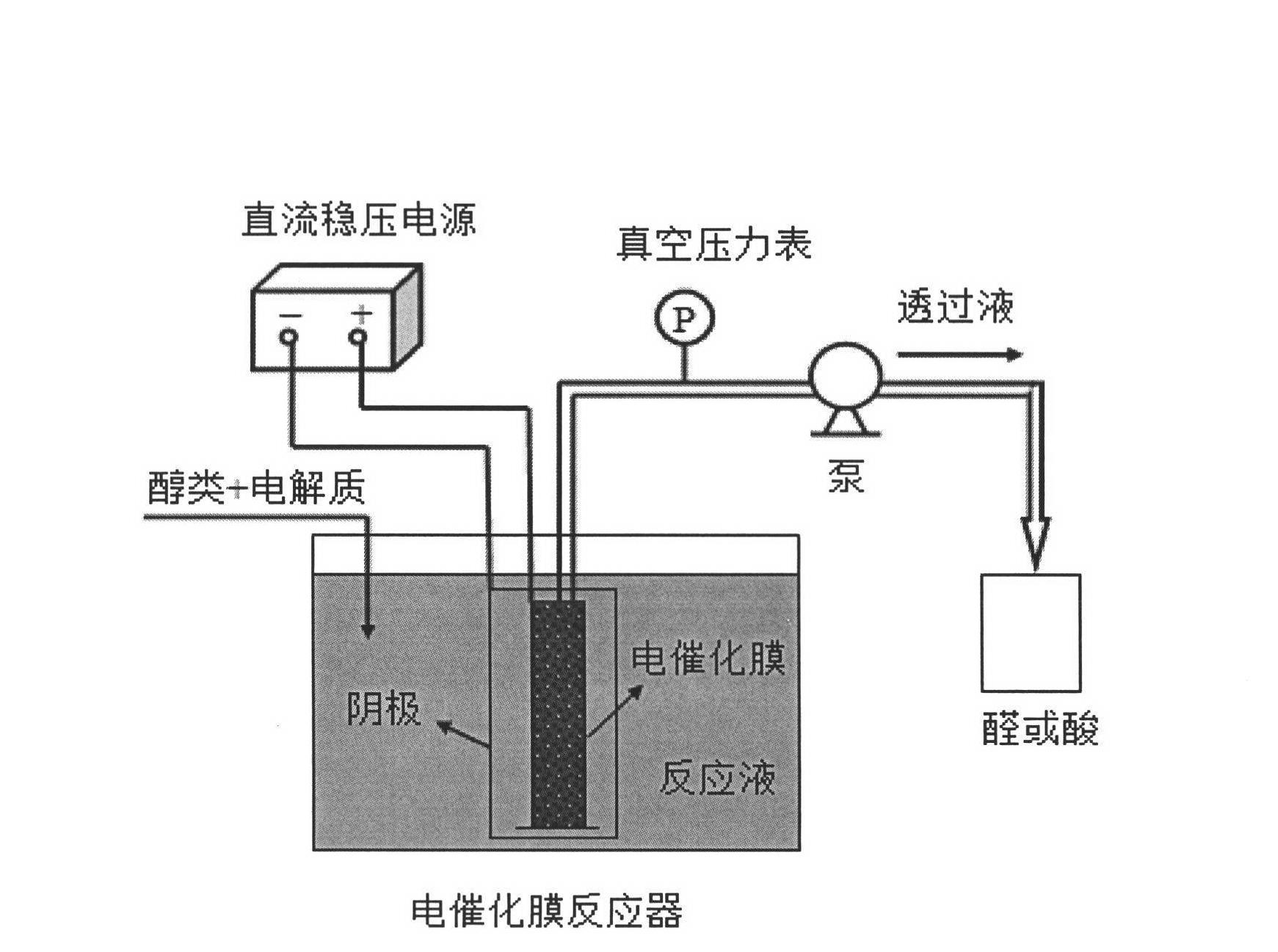

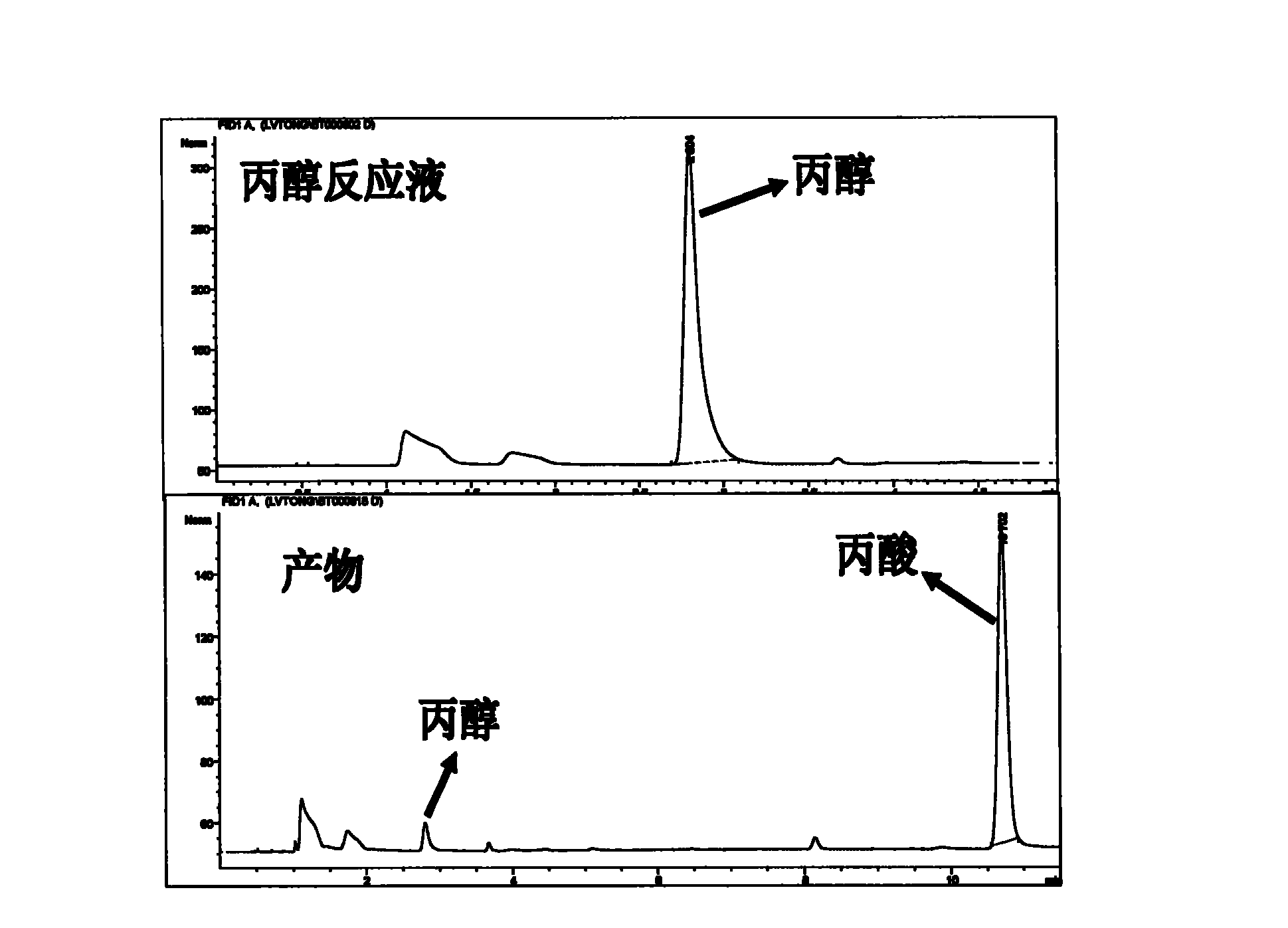

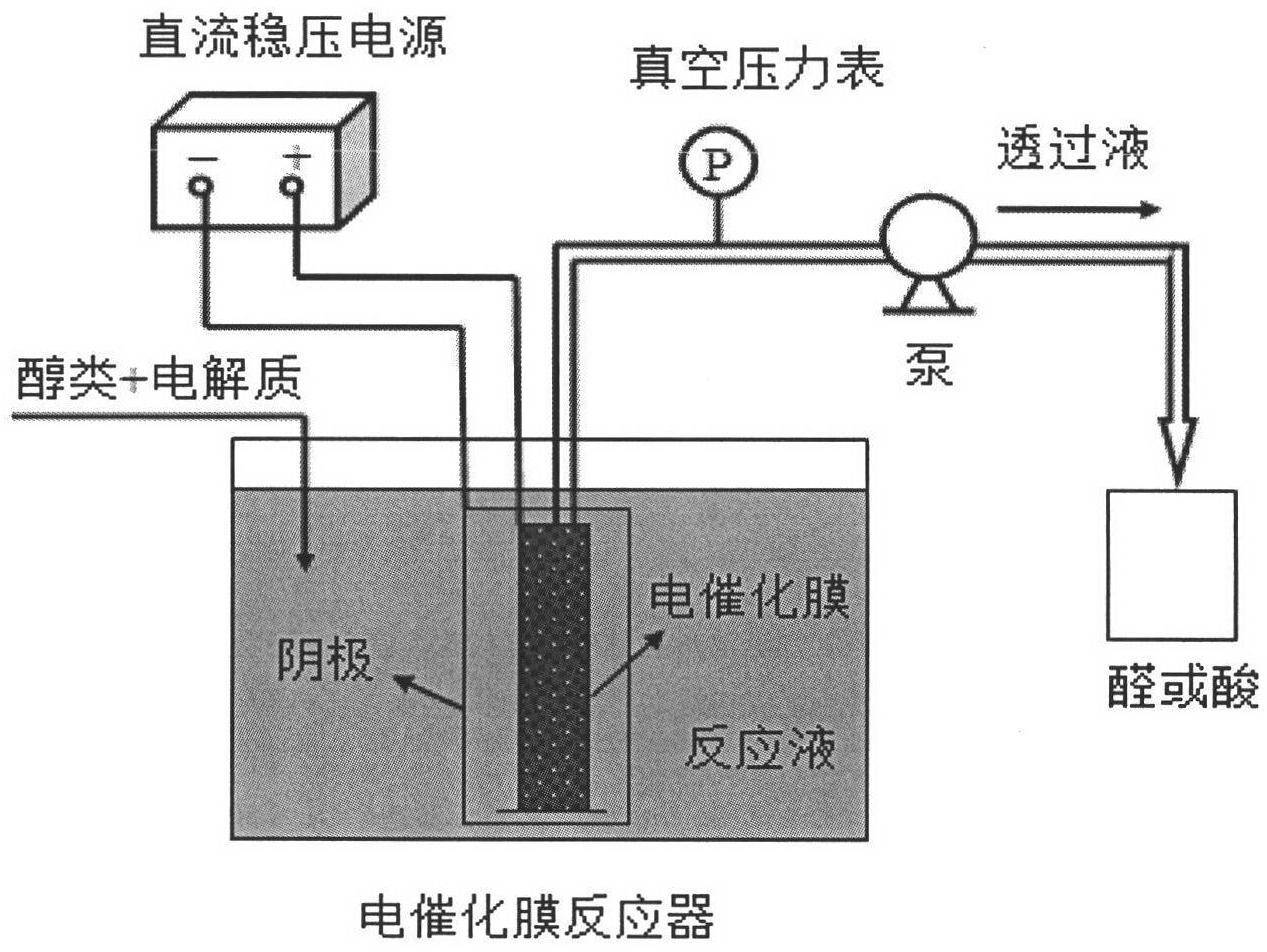

Method for preparing aldehydes or acids by selectively performing catalytic oxidation on alcohols by electro-catalysis membrane

ActiveCN102492957ASeparation in timeHigh selectivityElectrolysis componentsElectrolytic organic productionOrganic synthesisLow voltage

The invention relates to the technical field of electro-catalysis selective oxidation synthesis, in particular to a method for preparing corresponding aldehydes or acids by performing catalytic oxidation on alcohols by an electro-catalysis membrane effectively at high selectivity. Electro-catalytic oxidation and a membrane separation technology are coupled, a system that aldehydes or acids are synthesized by using alcohols is used as a research system, and the electro-catalysis membrane used as an anode and an auxiliary electrode are connected through a guide line and a direct-current stabilized power supply to form an electro-catalysis membrane reactor. In an aqueous solution containing alcohol reactants and electrolyte, operation parameters comprising working voltage and current density in the membrane reactor are controlled and adjusted, and the surface of the membrane is introduced to generate reactive oxygen species such as hydroxyl radicals and the like under the action of a low-voltage electric field (1-6V), so the aldehydes or acids can be controllably and efficiently prepared by using the alcohols. Compared with the conventional process, the method has the advantages of low energy consumption, high selectivity, controllable process and the like, is easy to operate, can be industrially implemented, and can be widely used for catalytic oxidation controllable preparation in an organic synthesis field.

Owner:TIANJIN POLYTECHNIC UNIV

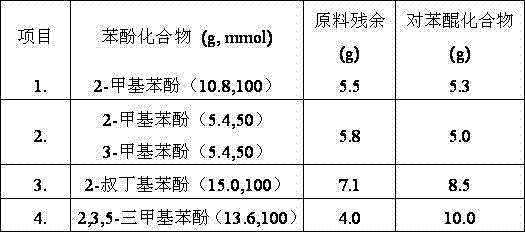

Method for preparing p-benzoquinone compound through selective catalytic oxidation of phenol compound

The invention provides a method for preparing a p-benzoquinone compound through selective catalytic oxidation of a phenol compound. The method is characterized in that the p-benzoquinone compound is highly selectively prepared through a reaction of a raw material the phenol compound in a liquid medium under mild conditions under the action of a transition metal compound primary catalyst and a stellate molecule cocatalyst with oxygen or an oxygen-containing gas as an oxidant.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

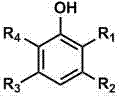

Process for producing methyl benzoic acid by paraxylene

InactiveCN101177393AReduce manufacturing costImprove production stabilityOrganic compound preparationCarboxylic compound preparationBenzoic acidBenzaldehyde

The invention relates to a production process for methyl benzol methanoic acid using paraxylene;, comprising following steps: a selective catalyze oxidation reaction is implemented on the paraxylene and the oxygen in the air; solid-liquid separation is implemented on the reactant, so that methyl benzaldehyde, carboxyl benzaldehyde, terephthalic acid and other high-melting and crystallizable subsidiary products can be removed; the paraxylene of the reactant is removed in the paraxylene distillation apparatus; a vacuum distillation is implemented on the material in a gap rectifying tower; so that the light-component impurities can be removed further; in the rectifying tower of methyl benzol methanoic acid crude product, the top of the tower is implemented on an impurity removal separation for refining the methyl benzol methanoic acid; the refined methyl benzol methanoic acid liquidoid is arranged into a cooling crystallizer for cooling and crystallization so as to get methyl benzol methanoic acid crystallization product with uniform particles. The invention has the advantages of safety and reliability, high yield, low production cost and environmental friendliness.

Owner:YANGZHOU LIUSHI CHEM

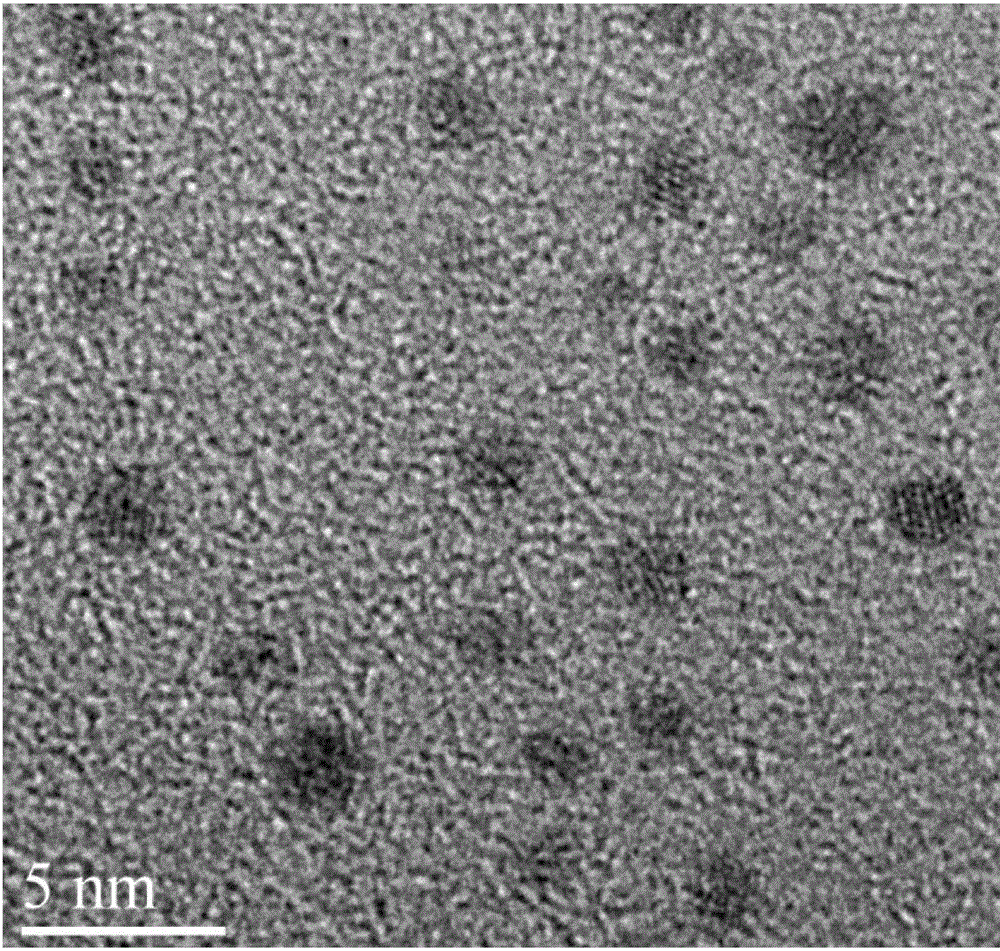

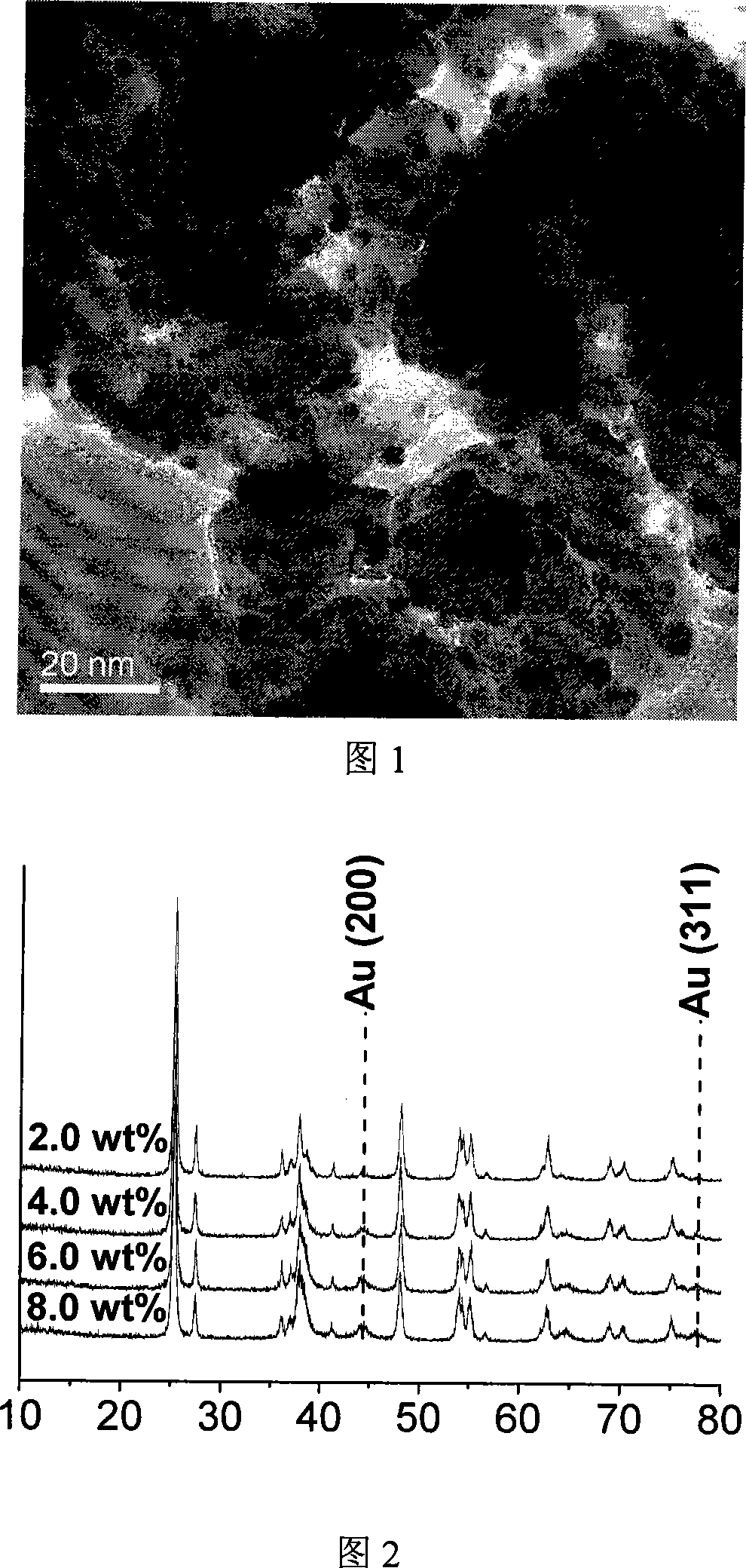

High-activity hydrotalcite loaded gold nanocluster catalyst and preparation method thereof

InactiveCN103143376AIntrinsically alkalineHigh activityPhysical/chemical process catalystsOrganic compound preparationAlkalinityAlcohol

The invention relates to a high-activity hydrotalcite loaded gold nanocluster catalyst and a preparation method thereof, and belongs to the technical field of catalysts. The catalyst has a chemical formula: AuNCs / (M<2+>)(M<3+>)-LDH, wherein the AuNCs is a gold nanocluster, and the (M<2+>)(M<3+>)-LDH is hydrotalcite. The hydrotalcite has the structural formula: [(M<2+>)1-x(M<3+>)x(OH)<2>]<x+>(A<n->)x / n.mH2O), wherein the M<2+> is any one or two of Mg<2+>, Ni<2+> and Cu<2+> which are divalent metal ions, M<3+> is any one of Fe<3+>, Cr<3+> and Al<3+> which are trivalent metal ions, x ranges between 0.2 and 0.33, A<n-> is one of CO3<2->, NO<3->, Cl<-> and SO4<2-> which are anions, and m is the number of carried interlayer water. The AuNCs-SR serves as a precursor, the carboxyl on the AuNCs-SR as a ligand interacts with a laminate with positive charges on the (M<2+>)(M<3+>)-LDHm, AuNCs-SR is connected to the (M<2+>)(M<3+>)-LDHm in an anchoring way, and the ligand is removed by calcinating to obtain the catalyst with the chemical formula of AuNCs / (M<2+>)(M<3+>)-LDH. The catalyst has intrinsic alkalinity and hereby has excellent activity in the selective catalytic oxidation reaction of alcohol by selective catalysis under the alkaline-additive free condition.

Owner:BEIJING UNIV OF CHEM TECH

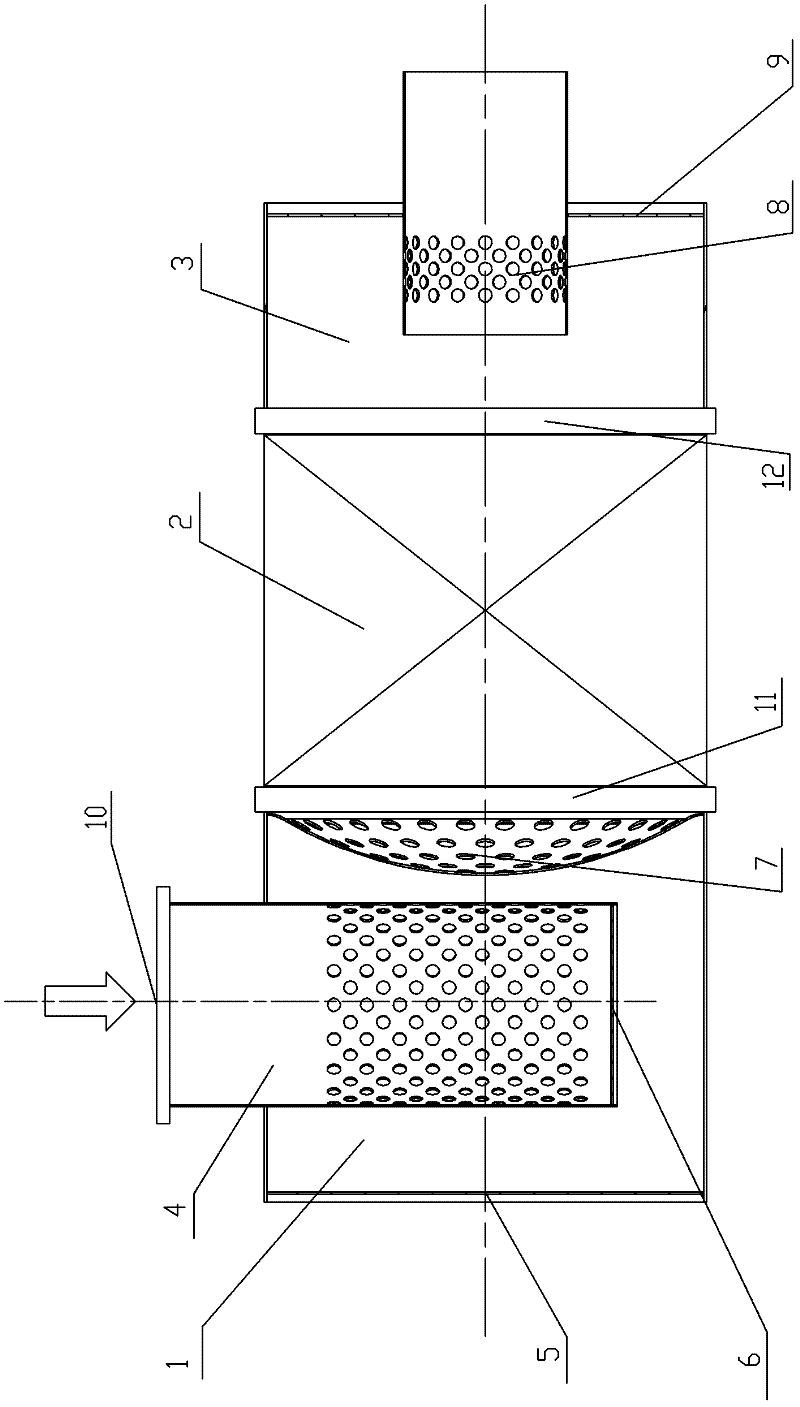

SCR (Selective Catalytic Reduction) catalytic conversion muffler

InactiveCN102410069ASmooth dischargePass smoothlyExhaust apparatusSilencing apparatusCatalytic transformationEngineering

The invention discloses an SCR (Selective Catalytic Reduction) catalytic conversion muffler, which comprises a front cavity body, a carrier cavity body, a back cavity body and an air outlet pipe that are sequentially and coaxially connected, wherein a catalyst carrier is arranged in the carrier cavity body; a catalyst is coated on the catalyst carrier; a porous air inlet pipe is vertically arranged on the front cavity body; through holes which are uniformly and circumferentially arranged are arranged on the pipe wall of the porous air inlet pipe located in the front cavity body. The SCR catalytic conversion muffler is characterized in that the bottom of the porous air inlet pipe is hung in the air; and a closed end cover is arranged at the bottom of the porous air inlet pipe. According to the SCR catalytic conversion muffler disclosed by the invention, a urea solution is effectively prevented from crystallizing, and the atomization degree of the urea solution is improved. Meanwhile, the air inlet pipe is vertically arranged so that the overall structure of the catalytic conversion muffler is more compact, the condition that the catalytic reduction reaction is affected by deposited particles in an exhaust gas flow blocking a carrier passage is avoided. While the porous air inlet pipe effectively reduces system noises, the distribution uniformity of reactants in the carrier can be remarkably improved, thereby effectively improving the catalytic conversion of tail gas.

Owner:HANGZHOU YINLUN TECH CO LTD +1

Metal-free H2S selective catalytic oxidation catalyst and preparation method thereof

InactiveCN108786877AEasy to prepareLow costDispersed particle separationSulfur preparation/purificationTube furnaceMetal free

The invention discloses a metal-free H2S selective catalytic oxidation catalyst and a preparation method thereof. A target catalyst can be obtained by taking green and pollution-free sugar as a main carbon source, pretreating by using a simple mechanical mixing method, and putting a mixture into a tubular furnace with an inert atmosphere for slow roasting. In addition, the catalyst shows the characteristics of high activity and high stability in the test of H2S selective catalytic oxidation performance. The preparation method of the catalyst disclosed by the invention has the advantages of simplicity, low cost, easiness in raw material obtaining, easiness in operation and broad application prospect.

Owner:FUZHOU UNIV

Diesel oil high-efficiency selective catalytic oxidation desulfurization method

ActiveCN110218576AAvoid efficiencyReduce qualityRefining with oxygen compoundsCatalyst activation/preparationSulfur containingSelective catalytic oxidation

The invention relates to a diesel oil high-efficiency selective catalytic oxidation desulfurization method. A titanium nanometer material catalyst and an oxidant are contacted with the diesel oil to selectively catalyze oxidation of the diesel oil to remove the second component under the condition that the first component competes for oxygen consumption. The diesel oil comprises a first componentand a second component; the first component comprises one or more of olefins, aromatic hydrocarbon, or cycloalkanes; the second component is a sulfur-containing compound comprising mercaptan, thioether, thiophene, benzothiophene, dibenzothiophene or 4,6-dimethyldibenzothiophenes. The titanium nanometer material catalyst prepared by the invention selectively removes sulfur-containing compounds suchas dimethyl dibenzothiophene (DMDBT) and other macromolecules in diesel oil under the condition of competitive oxidation of complex components such as olefins, cycloalkanes and aromatic hydrocarbons,the desulfurization efficiency of the diesel oil reaches 98.2%, and has good application prospect in the field of oxidative desulfurization of diesel oil.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

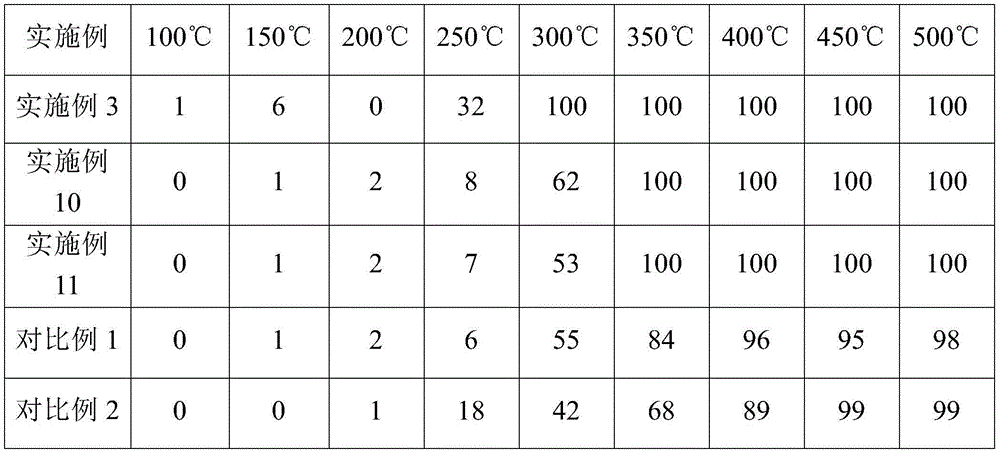

Method for preparing efficient oxidation catalyst through plasma-assisted sol gel method

ActiveCN105056940ASimple preparation processLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentFlue gas

The invention relates to a method for preparing an efficient oxidation catalyst through a plasma-assisted sol gel method. Active particles in plasma are used for decomposing organic matter and nitrate in gel at normal temperature, and the oxidation catalyst with the active components being MnOx or MnCeOx is prepared. The method has the advantages that firstly, catalytic oxidation is performed on nitrogen oxide, and high activity and selectivity are achieved; secondly, a wide temperature adaptation window is arranged; thirdly, the preparation technology is simple, cost is low, and the method can be widely used for the preparation process of denitration catalysts performing selective catalytic oxidation on flue gas.

Owner:ZHEJIANG UNIV

Monolithic catalyst and preparation and application thereof

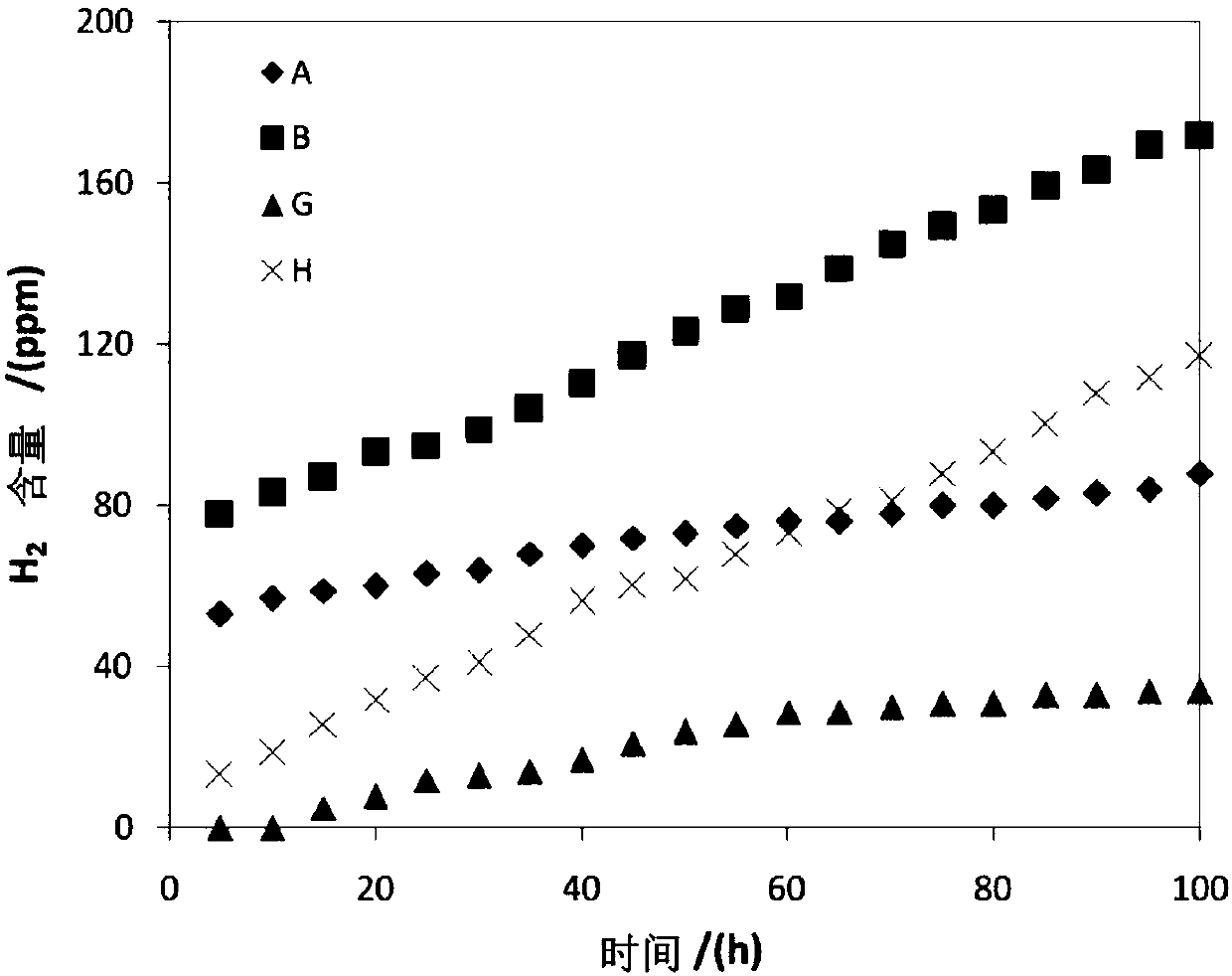

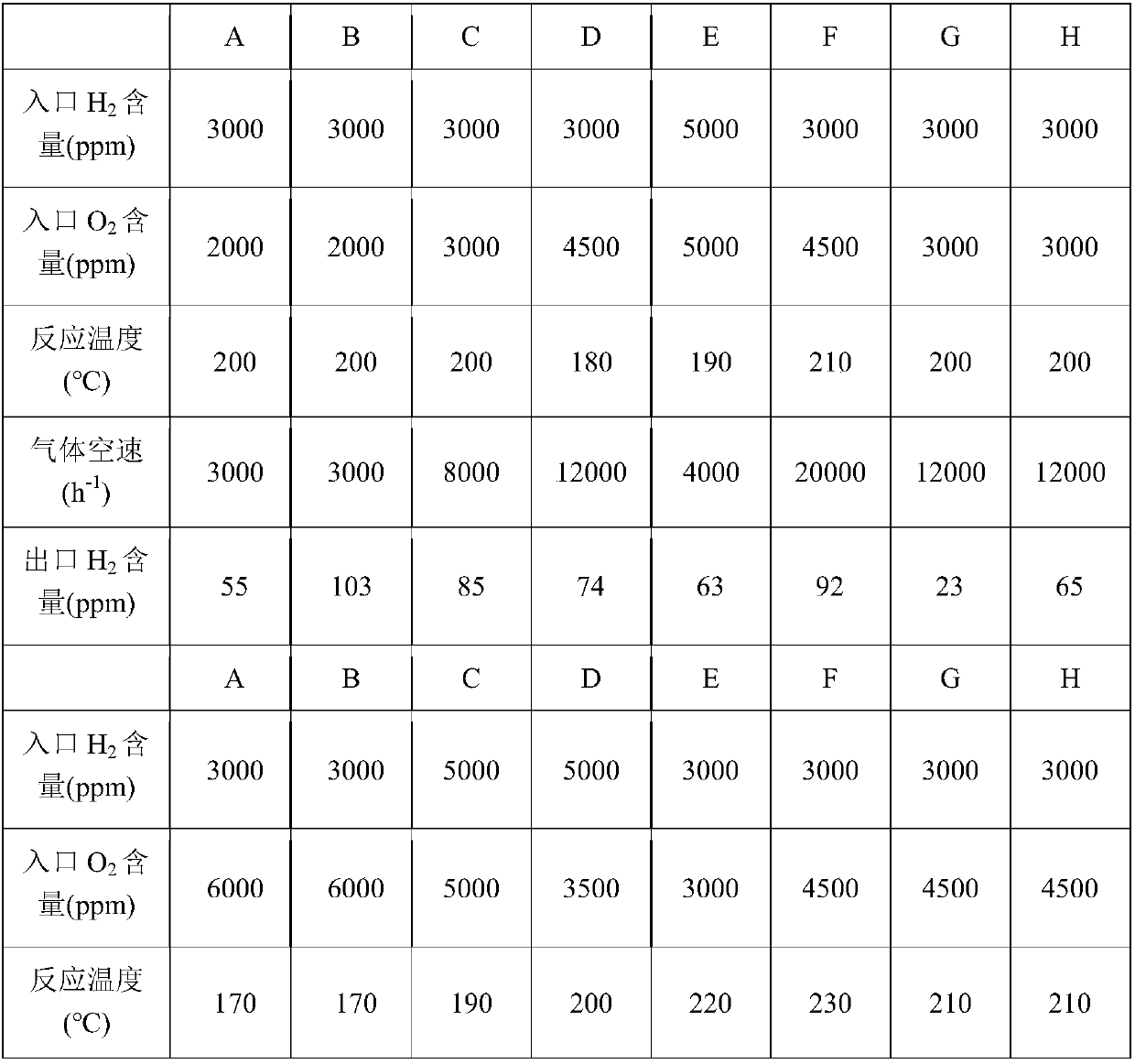

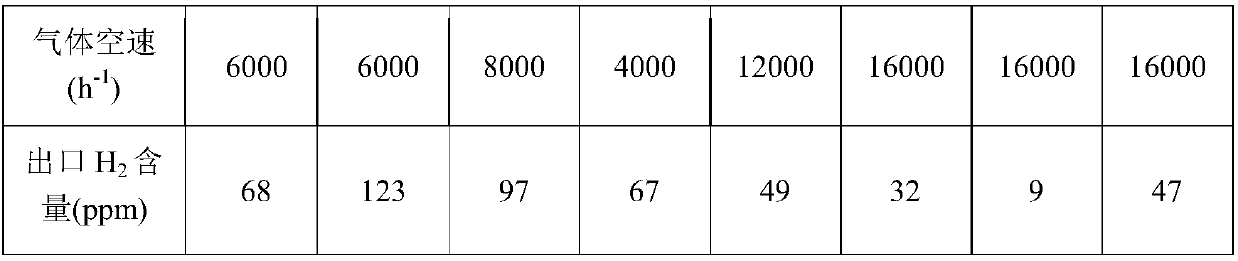

ActiveCN107694562AHigh metal dispersionImprove hydrogenation activityMolecular sieve catalystsCatalyst activation/preparationOxalateHigh concentration

The invention provides a high-dispersion monolithic catalyst for selectively catalytic oxidization of H2 in the atmosphere of high-concentration CO and a preparation method and application of the high-dispersion monolithic catalyst. The catalyst is suitable for a fixed bed reactor and has a multilayer structure, wherein the multilayer structure includes but not limited to a shell layer, an activecomponent layer, a carrier coating and a honeycomb carrier layer. The catalyst can be applied to the process of the selectively catalytic oxidization of H2 in the atmosphere of the high-concentrationCO, wherein the ratio of H2 to O2 in feed gas is 1:1 to 1:3, the reaction temperature is 150-250 DEG C, and the pressure is 0.3-0.6 MPa; besides, when the airspeed is 3000-20000h<-1>, the content of output H2 is less than 100 ppm, so that the reaction requirements of subsequent vapor catalytic coupling synthesis of oxalate by using CO are met.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

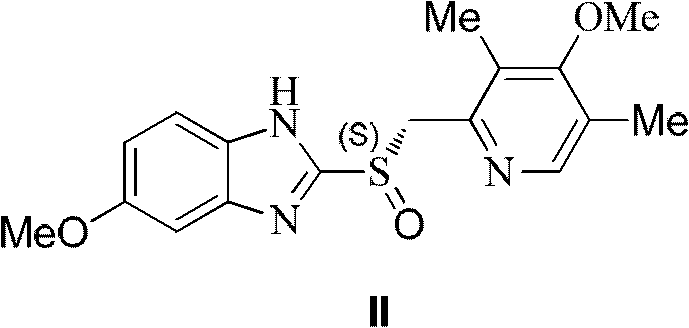

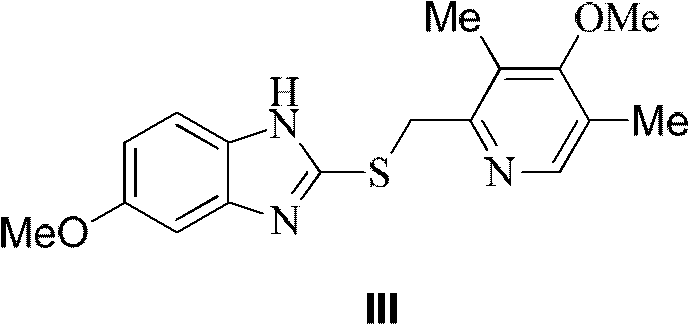

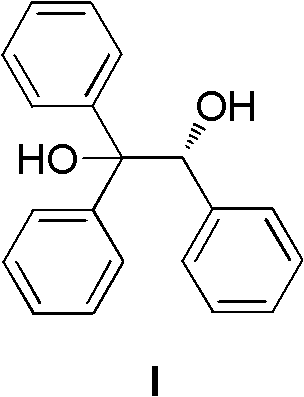

Preparation method for high-enantioselectivity synthesized (S)-omeprazole and salt thereof

The invention relates to a preparation method for high-enantioselectivity synthesized (S)-omeprazole. The method comprises under catalysis of a complex formed by chiral alcohol ligand (R)-(+)-1, 1, 2-triphenyl-1, 2, glycol and alkoxy titanium, utilizing an oxidant to a prochiral compound omeprazole thioether to perform selective catalytic oxidation to obtain optically pure enantiomer (S)-5-methoxy-2-[[(4-methoxy-3, 5-dimethyl-2-pyridyl)-methyl] sulfinyl]-1H-benzimidazole ((S)-omeprazole). (S)-omeprazole further reacts with alkali to form salt, and (S)-omeprazole metal salt with medical values is obtained. The preparation method is economical and simple and convenient to operate, optical purity and chemical purity of a product are high, and the preparation method is suitable for industrialized production.

Owner:SHANGHAI HUILUN BIOLOGICAL TECH CO LTD +1

Method for preparing aldehydes or ketones compounds by selective catalytic oxidation of alcohols compounds

InactiveCN101205175AEasy to separateEasy to useCarbonyl compound preparation by oxidationAlcoholReaction temperature

The invention relates to a method for selectively catalyzing and oxidating the alcohol compounds to prepare the aldehyde or ketone compounds, which comprises the steps that the highly active supported nanometer gold catalysts, water or water and cosolvent and alcohol compounds are put in an autoclave, the oxygen or air is pumped in the autoclave so as to carry out the reaction among the mixtures for 6 to 8 hours on the conditions of a reaction pressure ranging from 0.2 to 1.2MPa and a reaction temperature ranging from 100 to 130 DEG C; then the organic phase is separated and the aldehyde or ketone compounds is obtained. The conversion rate of the alcohol compounds ranges from 80 per cent to 83 per cent and the selectivity of the aldehyde or ketone products reaches 90 per cent to 100 per cent. The invention has the advantages of simple process, low production cost, environmental friendliness, easy separation and cycling use of the catalysts, etc.

Owner:DALIAN UNIV OF TECH

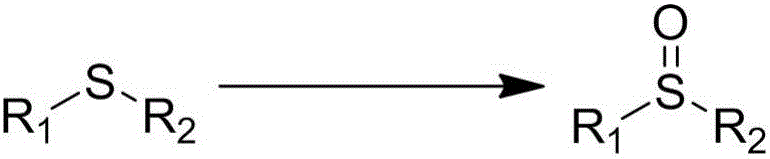

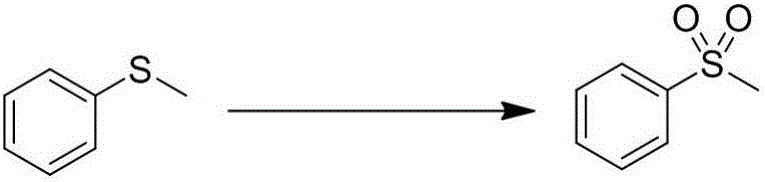

Sulfocompound selective catalytic oxidation reaction system in aqueous phase

InactiveCN105949018AReduce dosageGood choiceSulfonyl/sulfinyl group formation/introductionOrganic compound preparationRoom temperatureEthyl acetate

The invention provides a sulfocompound selective catalytic oxidation reaction system in an aqueous phase. A catalyst, a sulfocompound and 30% hydrogen peroxide are stirred for 1.5-2 hours under room temperature in the aqueous phase according to the molar ratio of the catalyst to the sulfocompound to the 30% hydrogen peroxide being 1 to 400 to 1200, wherein the conversion rate is greater than 97%, and the selectivity of the product namely sulphone is greater than 94%; the catalyst, the sulfocompound and the 30% hydrogen peroxide are stirred for 6 hours under the room temperature in the aqueous phase according to the molar ratio of the catalyst to the sulfocompound to the 30% hydrogen peroxide being 1 to 1666 to 1666, wherein the conversion rate is greater than 90%, and the selectivity of the product namely sulphoxide is greater than 80%. According to the reaction system disclosed by the invention, after the reaction is completed, extraction is performed with ethyl acetate, after an organic phase is separated, the catalyst dispersed in the aqueous phase can be directly used for the next catalytic reaction, and the catalytic activity, the conversion rate and the selectivity are all kept. The sulfocompound selective catalytic oxidation reaction system disclosed by the invention has the advantages that water is used as a solvent, the reaction condition is mild, the catalytic activity is high, the selectivity of products is good, the consumption of the catalyst is low, and the catalyst can be repeatedly used.

Owner:NANYANG NORMAL UNIV

Method for removing sulfur by selectively catalytic oxidation of diesel oil

InactiveCN1670131AHigh yieldRaw materials are easy to getRefining with oxygen compoundsDistillationHydrodesulfurization

The invention relates a method for diesel oil selective catalytic oxidation desulfuration. The method comprising the steps of: (1) mixing catalyse zinc benzoate with diesel oil according to the concentration of 1400~2000ug / g; (2) add catalyst boracic acid and diesel oil to diesel oil with 1~10 mass %; (3) add the diesel oil mixed with the two catalyst into high-pressure autoclave; (4) feed oxygen and agitate under 130~180Deg. C for 20~150min, separate oxidation diesel oil and zinc benzoate after cooling, water scrubbing and reclaiming boracic acid; (5) use extracting agent with 60~90 mass % N, N-dimethyltoluamide and 10~40 mass % ethyl alcohol, under 20~80Deg. C, mix oxidation diesel oil and the extracting agent with volume ratio of 4~6, stewing phase-splitting; (6) use carclazyte adsorption processing extracting diesel oil and get the refining straight distillation diesel oil; (7) After distilling, the extracting agent phase can be reused.

Owner:SOUTHWEST PETROLEUM UNIV

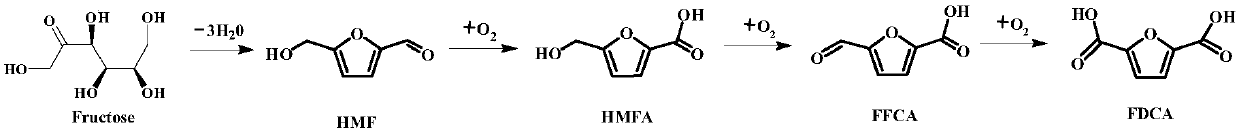

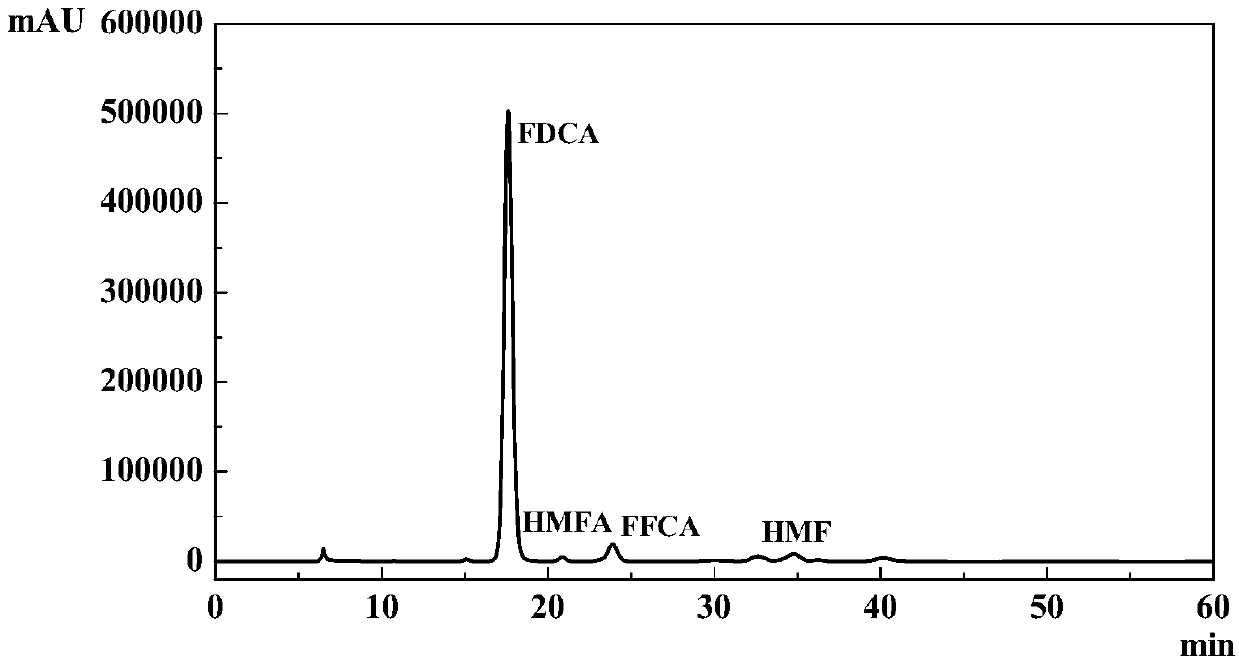

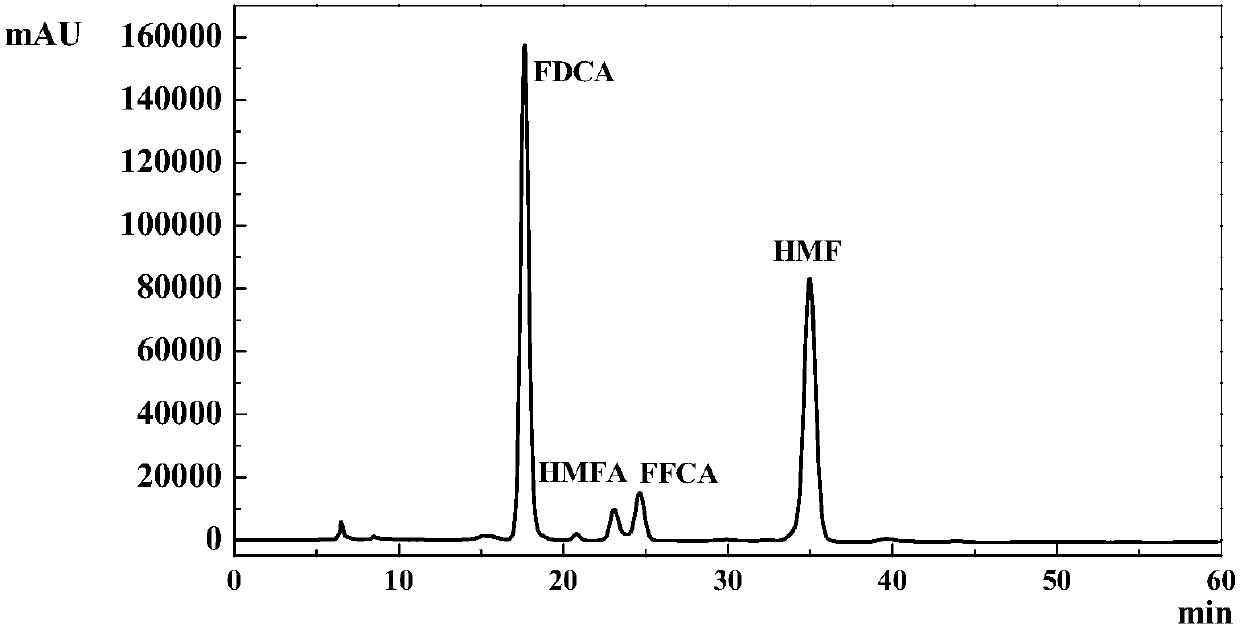

One-pot and one-step method for preparing 2,5-furandicarboxylic acid from fructose

The invention relates to a One-pot and one-step method for preparing a polymer monomer 2,5-furandicarboxylic acid from relatively cheap fructose as a raw material, through catalytic dehydration and selective catalytic oxidation in a non-alkaline reaction system. According to the method, solid acid and chlorinated salt are used as a dehydration catalyst, single oxides or composite oxides of non-noble metals such as cerium, iron and zirconium are used as an oxidation catalyst, ionic liquid is used as a solvent, air or oxygen is used as an oxidant, a separating step is not required, and under a certain reaction condition, the 2,5-furandicarboxylic acid is prepared through one-step catalytic conversion of the fructose. The cheap fructose is used as the raw material, so that the cost of the rawmaterial is greatly reduced; the cheap non-noble metal oxidation catalyst is used for replacing the conventional noble metal oxidation catalyst, so that the cost of the catalyst is greatly reduced; the ionic liquid is used as the solvent, so that introduction of the separating step (removal of the dehydration catalyst and purification of HMF) and strong alkali is avoided, and thus the preparationprocess of 2,5-furandicarboxylic acid is simpler, more economical and more environmentally-friendly.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

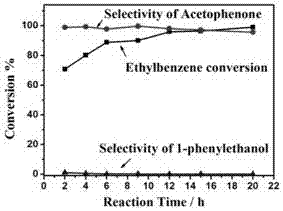

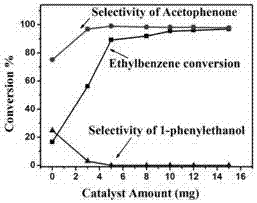

Process for high selective catalytic oxidizing of ethylbenzene to produce acetophenone

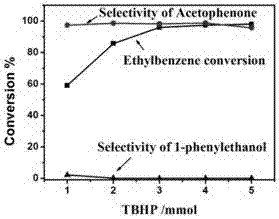

InactiveCN107879907AHigh catalytic activityHigh selectivityCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsAlkanePorphyrin

The invention belongs to the field of fine chemical engineering, and relates to a process for high selective catalytic oxidizing of ethylbenzene to produce acetophenone and provides a process and a concept of catalytically oxidizing ethylbenzene to prepare acetophenone by taking a peroxide as an oxidizing agent and a cobalt metal carbon nitride compound as a catalyst. The process comprises the following steps: roasting carbon black loaded metal cobalt porphyrin in a nitrogen atmosphere to prepare a metal cobalt nitrogen and carbon catalyst; and carrying out highly selective catalytic oxidization on ethylbenzene to prepare acetophenone by taking tert-butyl hydroperoxide as the oxidizing agent and water as a solvent through reaction at a certain temperature. The process has relatively high catalytic activity and good selectivity in catalytically oxidizing ethylbenzene to prepare acetophenone under an organic solvent-free condition. The process is mild in reaction condition, environment-friendly, easy for product quality control and suitable for the fields of selective alkane oxidization reactions and synthesis of medical intermediates and the like.

Owner:HUNAN UNIV

Method for synergistically catalyzing and oxidizing cycloalkane by porphyrin cobalt (II)/zinc (II) salt

InactiveCN110563555AHigh selectivityLow selectivityPreparation by oxidation reactionsOrganic compound preparationAlkaneAfter treatment

The invention discloses a method for synergistically catalyzing and oxidizing cycloalkane by porphyrin cobalt (II) / zinc (II) salt. The method comprises the following steps: dispersing porphyrin cobalt(II) and a zinc (II) salt in cycloalkane, sealing the reaction system, carrying out heating to 100-130 DEG C while stirring, introducing oxygen to 0.2-3 MPa, keeping a set temperature and oxygen pressure, carrying out stirring for reacting for 3-24 hours, and then carrying out after-treatment on the reaction solution to obtain product naphthenic alcohol and naphthenic ketone. According to the method disclosed by the invention, the naphthenic alcohol and the naphthenic ketone are high in selectivity, and generation of aliphatic diacid is effectively inhibited; a cocatalyst is cheap and is easily available, and synthesis cost of the naphthenic alcohol and naphthenic ketone is low; the aliphatic diacid is low in selectivity, so that continuity of a cycloalkane oxidation process and separation of products are facilitated; and the method has a potential of solving the problem that naphthenic alcohol and naphthenic ketone are easily and deeply oxidized to generate aliphatic diacid in industrial cycloalkane catalytic oxidation processes. The method is a novel efficient feasible method for selective catalytic oxidation of cycloalkane.

Owner:ZHEJIANG UNIV OF TECH

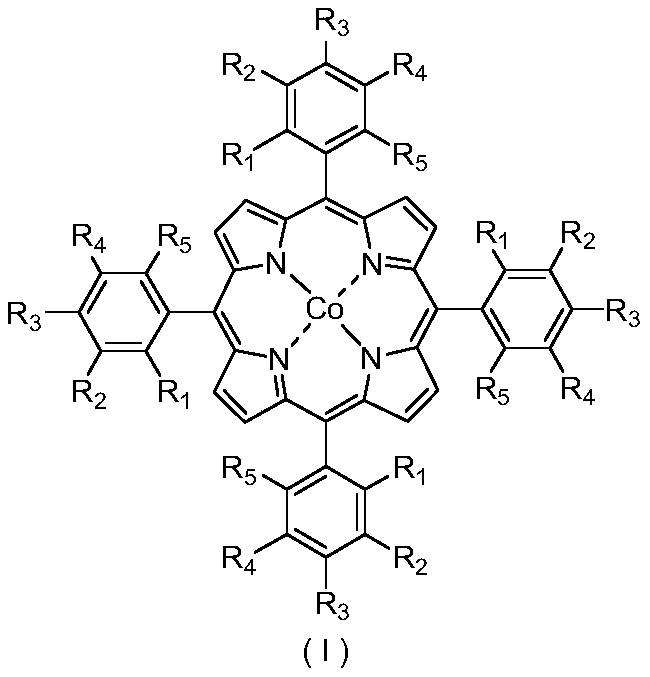

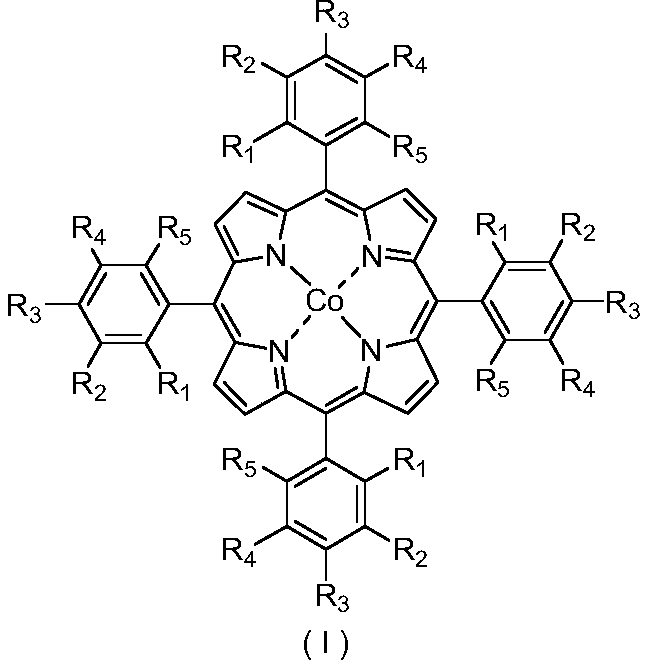

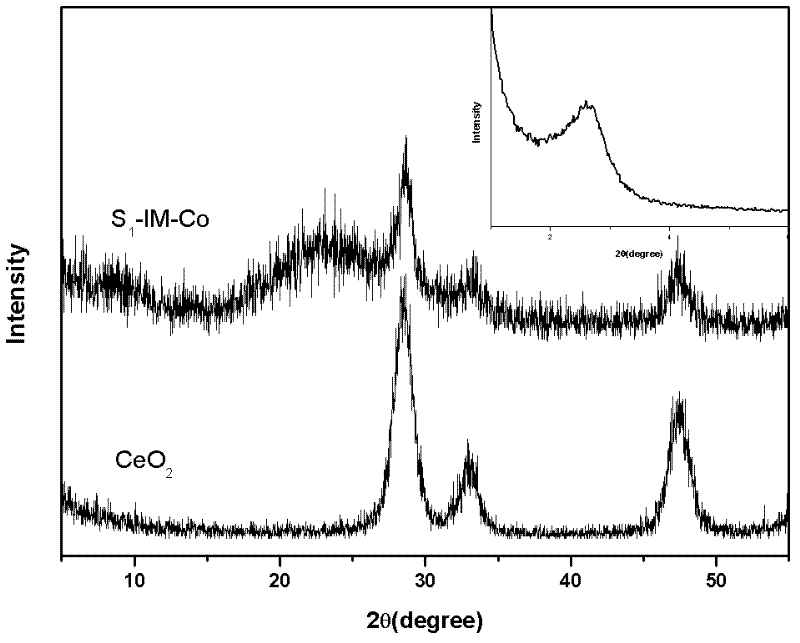

Preparation method of core-shell structure CeO2@SiO2 load metalloporphyrin catalyst prepared by double wrapping method

InactiveCN102407160AAvoid churnImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaneDiphenylmethane

The invention relates to a preparation method of core-shell structure CeO2@SiO2 load metalloporphyrin catalyst prepared by double wrapping method, and provides a system for forming the core-shell structure CeO2@SiO2 load metalloporphyrin multi-phase catalyst by double wrapping method. The preparation method comprises the following steps of: stirring and dispersing nanometer cerium oxide particles with surfaces modified by sodium citrate, and adding tetraethyl orthosilicate (TEOS) dropwise to obtain once wrapped core-shell structure CeO2@SiO2; stirring and dispersing the once wrapped core-shell structure CeO2@SiO2 and hexadecyl ammonium bromide; adding mixed solution of the TEOS and 3-aminopropyl triethoxy silicane (APTES) to obtain doubly wrapped core-shell structure CeO2@SiO2; and linking cobalt monocarboxyl porphyrin (CoTMCPP) to a doubly wrapped core-shell structure CeO2@SiO2 carrier by amidation reaction so as to obtain the core-shell structure CeO2@SiO2 load metalloporphyrin catalyst prepared by double wrapping method. The catalyst provided by the invention has higher catalytic activity and stability for selective catalytic oxidation reaction of molecular oxygen on diphenylmethane in the absence of solvent, and the preparation method is simple and product quality is easily controlled, so that the catalyst is suitable for use in the fields such as selective oxidation reaction of hydrocarbon alkyl and synthesis of medicine intermediate and the like.

Owner:HUNAN UNIV

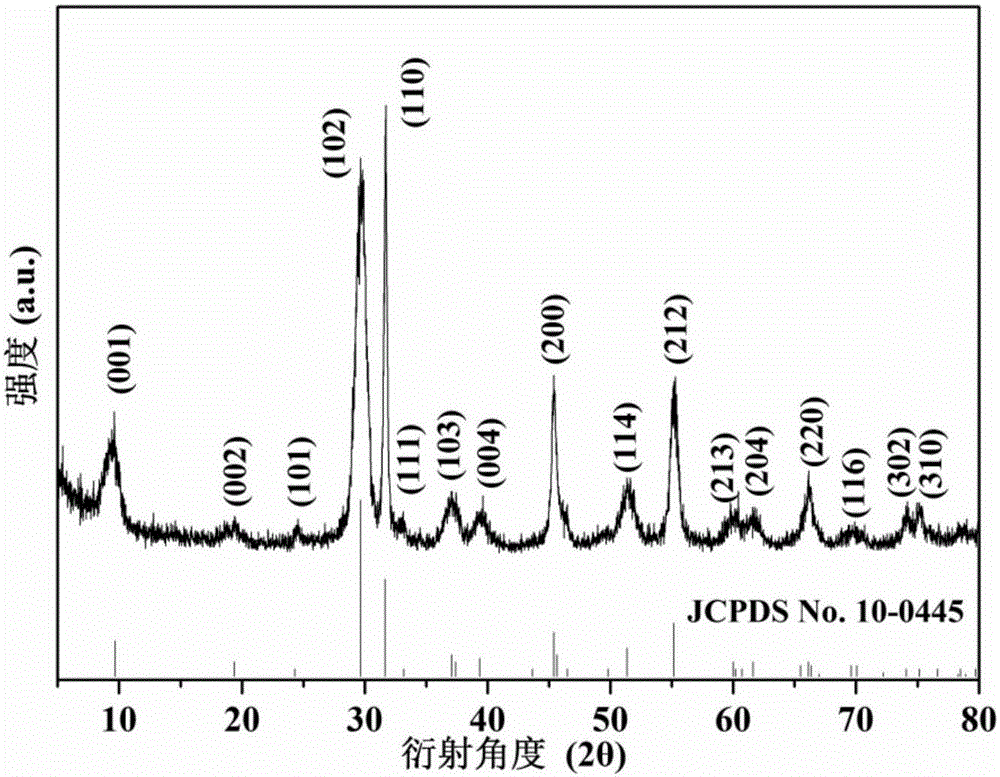

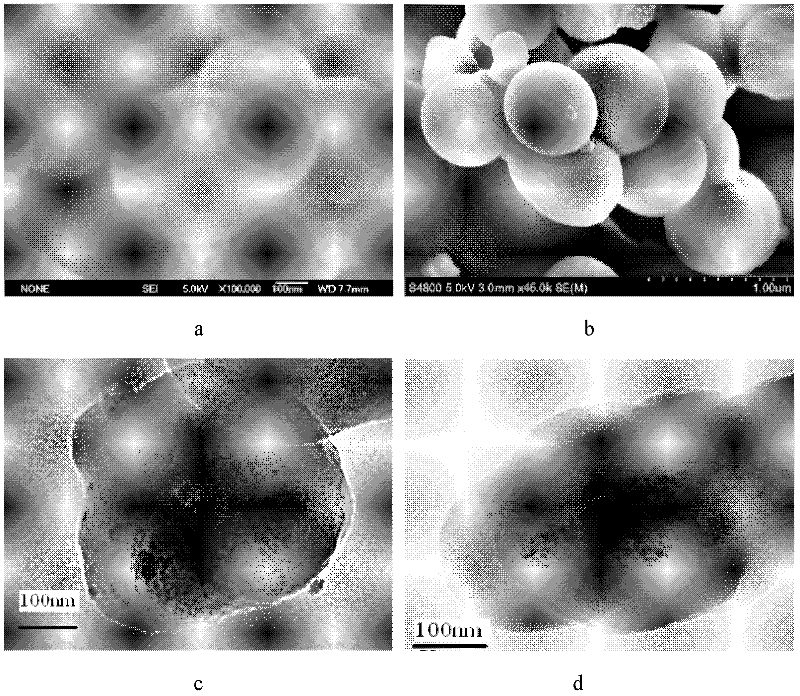

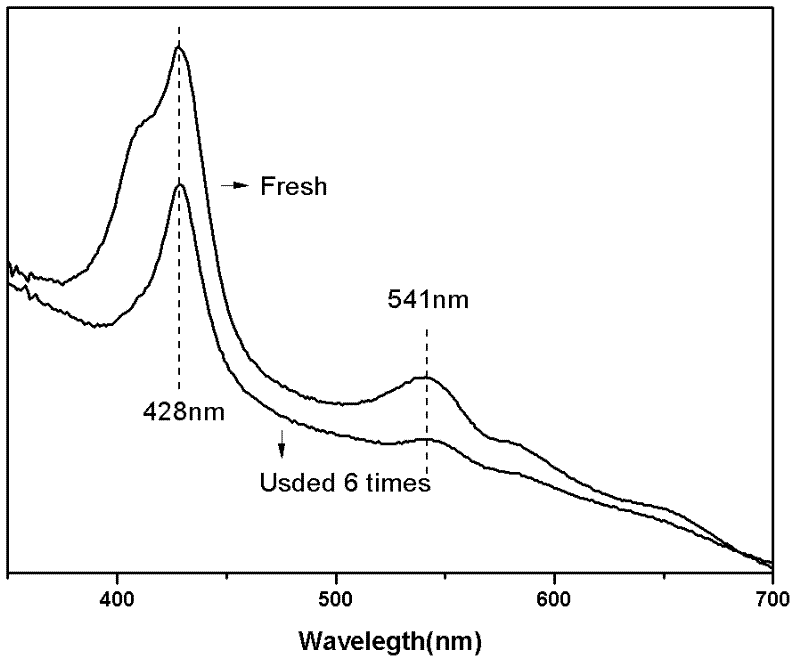

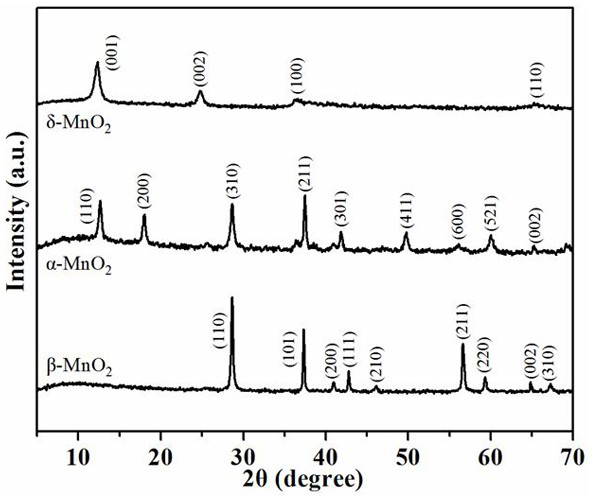

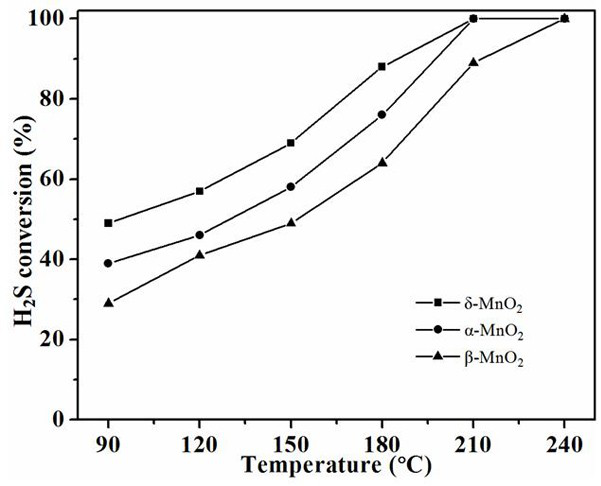

Synthesis and desulfurization application of porous manganese dioxide

ActiveCN112551590AReduce the surface energy of negative chargesImprove oxygen storage capacityManganese oxides/hydroxidesMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATEPtru catalyst

The invention discloses synthesis and desulfurization application of porous manganese dioxide, and belongs to the technical field of catalyst preparation. Manganese acetate or potassium permanganate is used as a raw material, ethanol, glucose or hydrogen peroxide is used as an additive, ammonium carbonate or ammonium bicarbonate is added as a pore-enlarging agent, and hydrothermal treatment is performed in a high-pressure reaction kettle; and washing, drying and roasting are carried out to obtain manganese dioxide with different crystal forms and a hierarchical pore structure. The synthesis method disclosed by the invention is simple in process and high in repeatability; oxygen vacancies in manganese dioxide can be regulated and controlled through crystal form control, so that the oxygen storage capacity and the oxidation-reduction capacity of the catalyst are further improved, and the catalytic activity is further improved; the hierarchical pore structure exposes rich active sites, sothat the hierarchical pore structure shows higher catalytic activity, elemental sulfur selectivity and stability in a selective catalytic oxidation H2S reaction.

Owner:中琉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com