Synthesis and desulfurization application of porous manganese dioxide

A technology of manganese dioxide and synthesis method, applied in the direction of manganese oxide/manganese hydroxide, metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, etc., can solve the problem of poor activity and poor stability of selective oxidation catalyst and other problems, to achieve the effect of increasing redox ability, improving stability and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

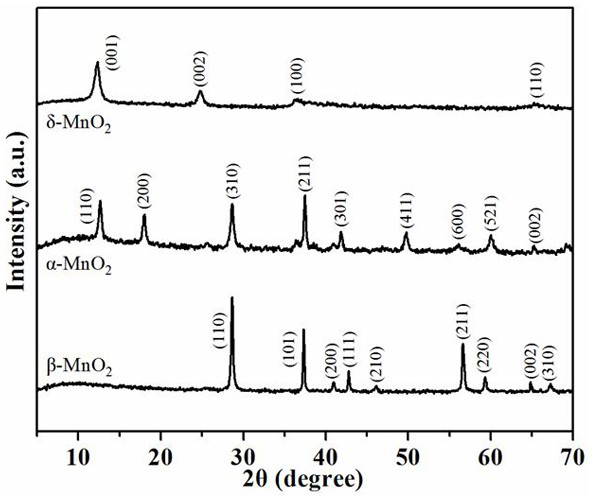

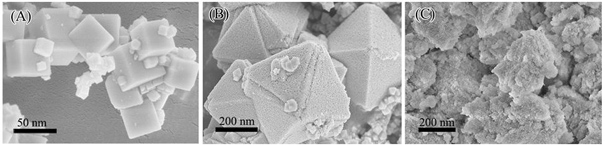

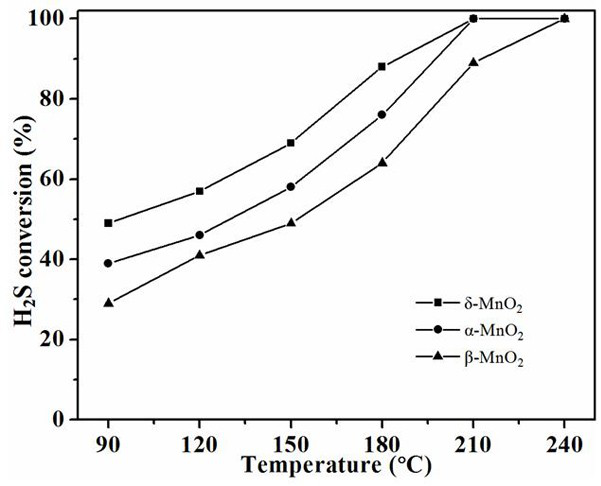

[0034] Porous δ-MnO 2 Synthetic method: Add 0.86 g of manganese acetate and 20 mL of ethanol to 60 mL of distilled water, dissolve and add 0.15 g of ammonium carbonate and stir for half an hour by a magnetic stirrer. The mixed solution was transferred to an autoclave, hydrothermally treated at 140 °C for 24 h, cooled naturally at room temperature, filtered, washed with absolute ethanol and distilled water for three times, and the obtained powder was dried at 95 °C for 12 h. Then the temperature was raised to 300 °C at a rate of 3 °C / min and kept for 2 h to obtain the final product δ-MnO 2 . δ-MnO 2 The yield of δ-MnO is about 96%, and it is found by X-ray powder diffraction (XRD) characterization comparison that δ-MnO 2 The purity is 100%.

Embodiment 2

[0036] Porous α-MnO 2 Synthetic method: 1.26 g of potassium permanganate and 2.52 g of glucose were added to 70 mL of distilled water, after dissolving, 0.2 g of ammonium bicarbonate was added and stirred by a magnetic stirrer for half an hour. The mixed solution was transferred to a 100 mL autoclave, hydrothermally treated at 160 °C for 12 h, cooled naturally at room temperature, filtered, washed with absolute ethanol and distilled water for three times each, and the obtained powder was dried at 90 °C for 12 h. h, then raised to 300 °C at a rate of 3 °C / min and kept for 2 h to obtain the final product α-MnO 2 . α-MnO 2 The yield of α-MnO is about 93%, and it is found through XRD characterization that α-MnO 2 The purity is 100%.

Embodiment 3

[0038] Porous β-MnO 2 The synthesis method of : mix 1.73 g of manganese acetate and 20 mL of 30% H 2 o 2 Added to 60 mL of distilled water, dissolved and added 0.1 g of ammonium carbonate and stirred by a magnetic stirrer for half an hour. The mixed solution was transferred to a 100 mL autoclave, hydrothermally treated at 180 °C for 12 h, cooled naturally at room temperature, filtered, washed with absolute ethanol and distilled water for three times each, and the obtained powder was dried at 90 °C for 12 h. h, then raised to 300 °C at a rate of 3 °C / min and kept for 2 h to obtain the final product β-MnO 2 . β-MnO 2 The yield of β-MnO is about 97%, and it is found through XRD characterization that β-MnO 2 The purity is 100%.

[0039] X-ray powder diffraction (XRD): The phase characterization of the sample was determined by the X' pert pro powder diffractometer of Panalytical Company, the detector was X'celerator, and the copper target (Cu Kα, λ = 0.154 nm) was used as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com