Preparation method for low-temperature V-W-TiO2 based selective reduction catalyst

A selective and catalytic technology, applied in the field of preparation of low-temperature V-W-TiO2-based selective reduction catalysts, can solve the problems of poor low-temperature activity of the catalyst, and achieve the effects of good low-temperature activity, promoting dispersibility, and improving oxygen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

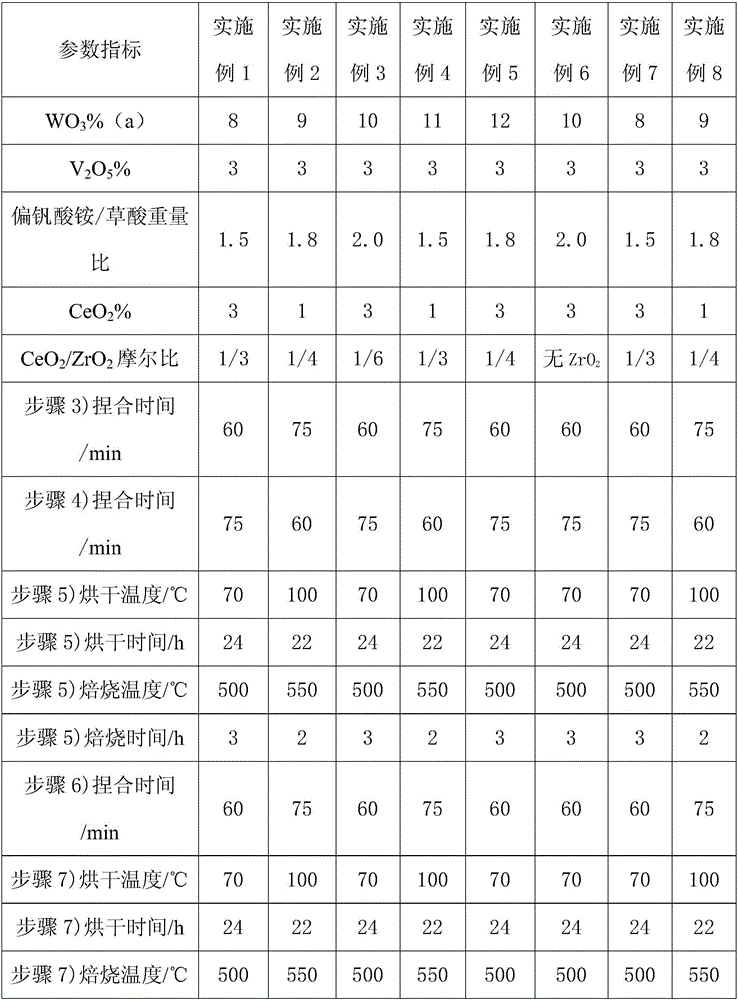

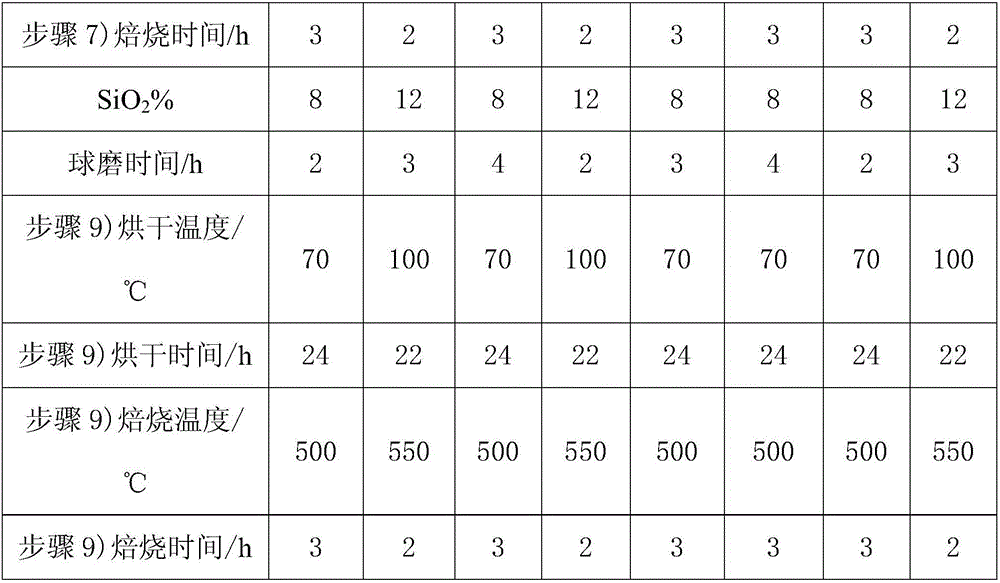

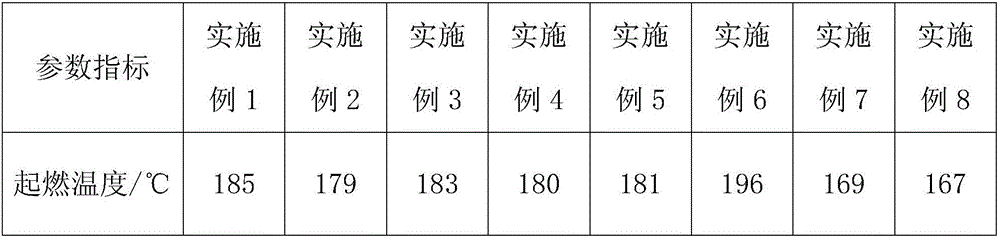

Examples

preparation example Construction

[0026] A low temperature type V-W-TiO 2 The preparation method of base selective reduction catalyst comprises the following steps:

[0027] 1) According to TiO 2 Calculate the weight of the solution required for equal-volume immersion, weigh ammonium metatungstate, cerium nitrate and zirconium acetate and add them to deionized water, and form ammonium metatungstate solution and cerium-zirconium aqueous solution after completely dissolving;

[0028] 2) According to W-TiO 2 Calculate the weight of the solution required for equal-volume immersion, weigh ammonium metavanadate and add it to deionized water, add 98% mass fraction of oxalic acid powder after heating and dissolving, and form ammonium metavanadate solution after stirring for a period of time;

[0029] In the kneader, slowly add the ammonium metatungstate aqueous solution prepared in the above step 1) to TiO 2 Knead evenly;

[0030] 4) Slowly add the cerium-zirconium aqueous solution prepared in the above-mentioned ...

Embodiment 7

[0041] The preparation method of silica sol described in embodiment 7 is:

[0042] 1. Preparation of active silicic acid: add water to industrial sodium silicate with a modulus of 2.2 to prepare an aqueous solution of sodium silicate with a silicon dioxide content of 6wt%, add it to a reaction tank, and stir at a speed of 120 rpm; Sulfuric acid is added with water to prepare a 10wt% sulfuric acid solution, which is added to the above-mentioned sodium silicate aqueous solution at a rate of 450ml / min until the pH is 9.2, and the temperature is raised to 95°C for 1 hour to obtain a silica sol bottom liquid; the industrial silicon with a modulus of 3.2 Sodium silicate is added with water to prepare a sodium silicate aqueous solution of 7wt% of silicon dioxide, and ion exchange is carried out by using a strongly acidic cation exchange resin, and the pH value after the exchange is controlled to be 2.5 to obtain silicic acid;

[0043] 2. Growth of colloidal particles: add the above-p...

Embodiment 8

[0046] The preparation method of silica sol described in embodiment 8 is:

[0047] 1. Activation of silicon powder: Weigh 50 parts of 200-mesh silicon powder and add it to 1000 parts of deionized water and soak it in hot water for 30 minutes to activate it to obtain a thin paste solution.

[0048] 2. Hydration reaction: Add the above dilute paste solution into the reaction tank containing 5 parts of 25% ammonia water and 50 parts of industrial sodium silicate aqueous solution with a modulus of 2.5 in 3 times, at a speed of 120 rpm Stir and heat, react at 90°C for 8h.

[0049] 3. Suction filtration: remove unreacted silicon powder by suction filtration to obtain silica sol;

[0050] 4. Surface modification: Add 5 parts of aminopropyltrimethoxysilane to the silica sol prepared above for surface modification, and adjust the pH value of the silica sol to 9.5 with ammonia water. The average particle size of the silica sol is 23nm, the concentration is 40%, the viscosity is 15cps,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com