Mesoporous molecular sieve-based catalyst used for ammonia removing, and preparation method and applications thereof

A mesoporous molecular sieve and catalyst technology, applied in the chemical industry to achieve high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

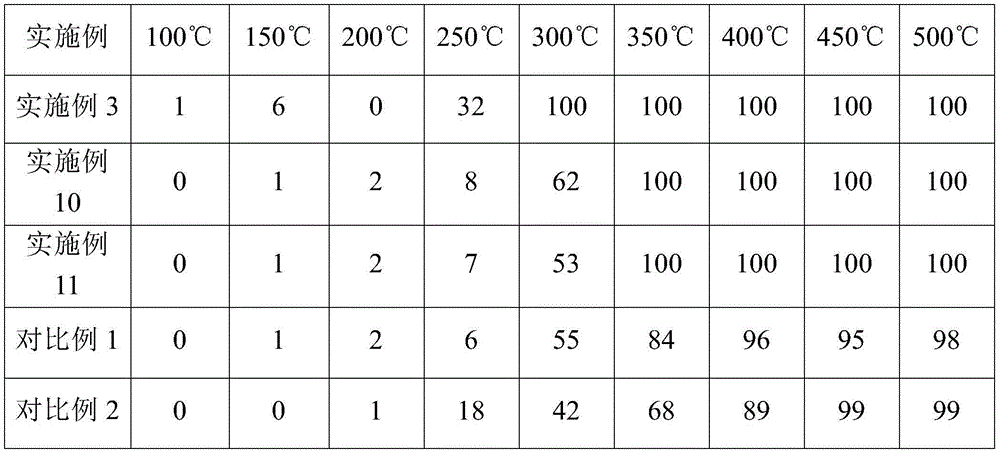

Examples

Embodiment 1

[0045] Weigh 4.0g of P123, then add 90ml of deionized water, stir for about 1 hour until completely dissolved; add 60ml, 4mol / L HCl solution to the above solution; pour it into a three-neck flask, and stir in a constant temperature water bath at 40°C for 2 hours Disperse the surfactant at a speed of 400r / min; weigh 8.5g of tetraethyl orthosilicate (TEOS), and add it dropwise to the above solution for 1 to 2 hours through a constant pressure funnel to obtain a precursor solution; continue to stir for 22 hours at a speed of 400r / min; then pour the precursor solution into the crystallization kettle, crystallize in a 100°C constant temperature drying oven for 24 hours, and separate the precipitate; then wash the precipitate to neutral; put the obtained precipitate in a 100°C constant temperature drying oven Dry it for 2-3 hours, then move it to a muffle furnace and bake it at 550°C for 6 hours (heating rate: 3°C / min) to obtain pure silicon-based mesoporous molecular sieve SBA-15. ...

Embodiment 2

[0048] Compared with Example 1, the only difference is that the loading amount of copper in this example is different, and the mass ratio of copper contained in the weighed copper nitrate to mesoporous molecular sieve is 1:25. In this example, a mesoporous molecular sieve-based catalyst with a copper loading of 4% in copper oxide was finally obtained, labeled as 4% Cu-SBA-15.

Embodiment 3

[0050] Compared with Example 1, the only difference is that the loading amount of copper in this example is different, and the mass ratio of copper contained in the weighed copper nitrate to mesoporous molecular sieve is 1:16.7. In this example, a mesoporous molecular sieve-based catalyst with a copper loading of 6% in copper oxide was finally obtained, labeled as 6% Cu-SBA-15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com