SCR (Selective Catalytic Reduction) catalytic conversion muffler

A catalytic conversion and muffler technology, applied in mufflers, machines/engines, engine components, etc., can solve the problems of low distribution uniformity, affecting NOx conversion rate, etc., and achieve the effect of improving distribution uniformity and reducing system noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

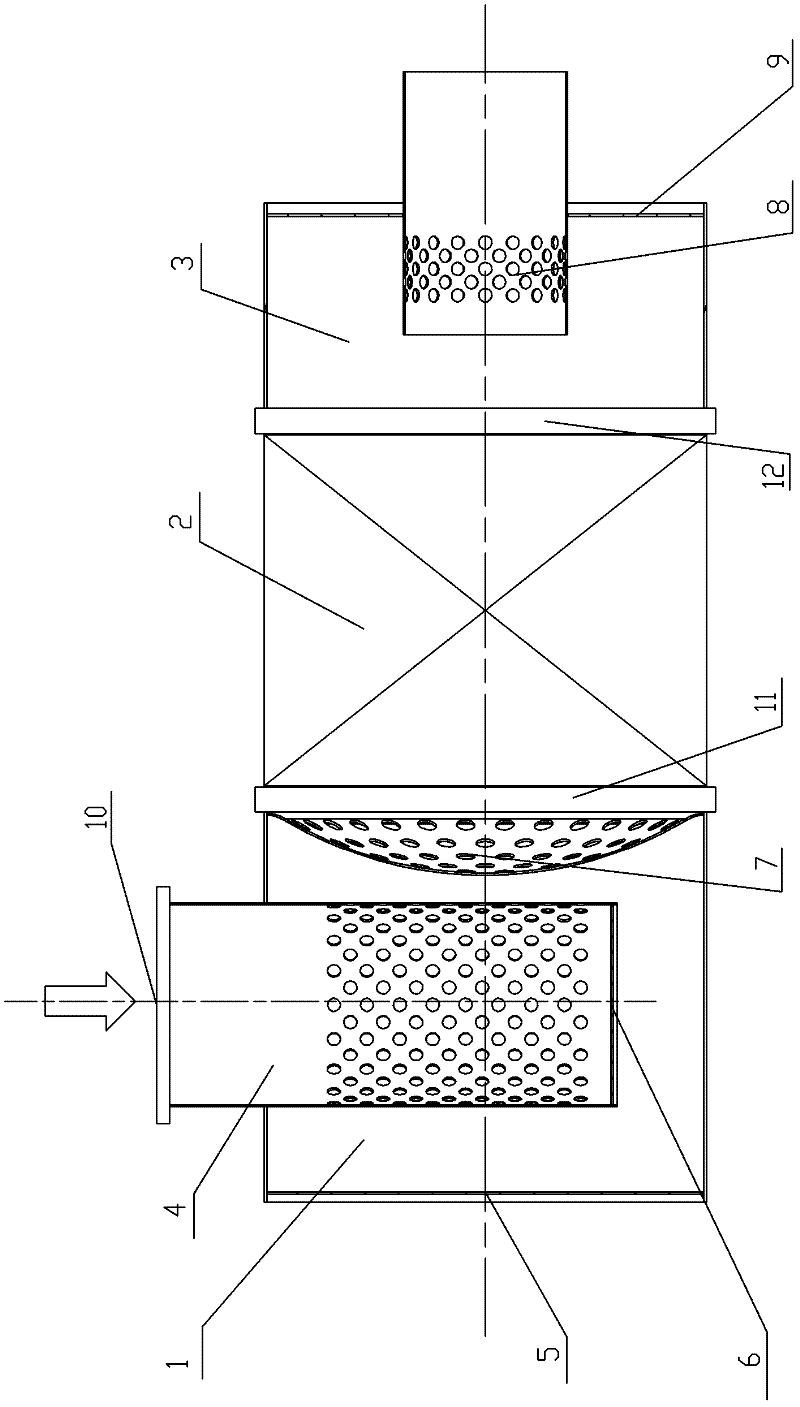

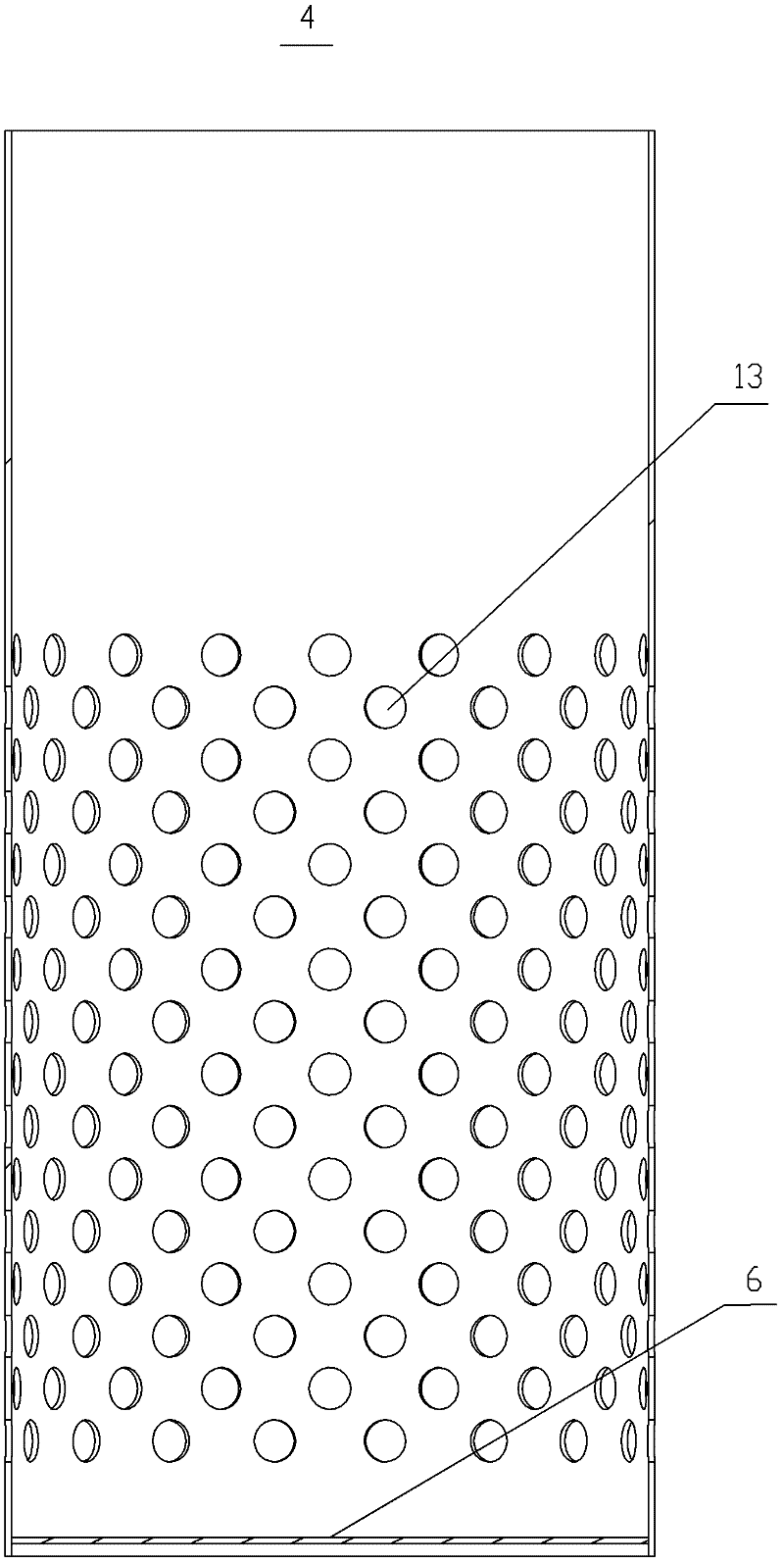

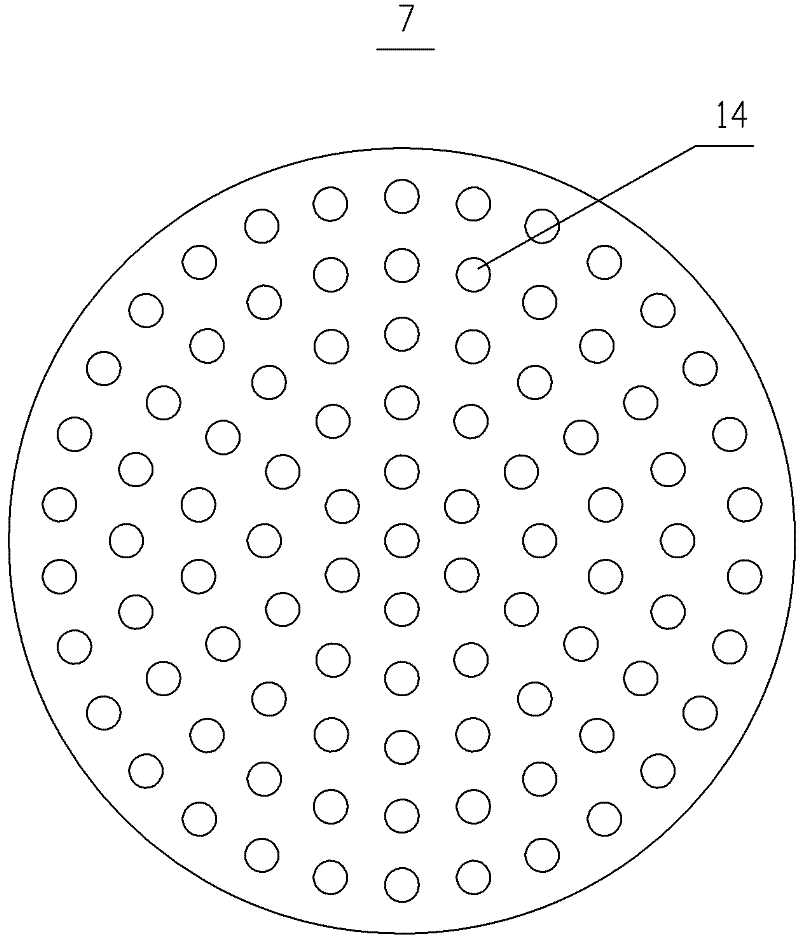

[0018] Next, with reference to the accompanying drawings, through the description of the embodiments, the specific implementation methods of this patent, such as: the shape of the structure, the structure, the mutual positional relationship and connection relationship between each part, the role and working principle of each part, etc. will be further elaborated. Detailed explanation.

[0019] The present invention is an SCR catalytic conversion muffler. By setting perforations on the air intake pipe closed at the bottom and designing a porous mixing device in front of the catalyst carrier, the airflow entering the front cavity can be distributed evenly and effectively. Prevent urea crystallization and solid particle deposition in exhaust gas from clogging catalyst carrier channels, so as to achieve the purpose of improving the catalytic conversion rate of the entire catalytic reduction aftertreatment system. In addition, this structure can also effectively reduce the noise of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com