Low-temperature micro-oxygen purification method for removing harmful gas in yellow phosphorus tail gas

A technology for harmful gases and yellow phosphorus tail gas, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as poor adaptability, effective utilization rate of less than 30%, poisoning of oxo catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

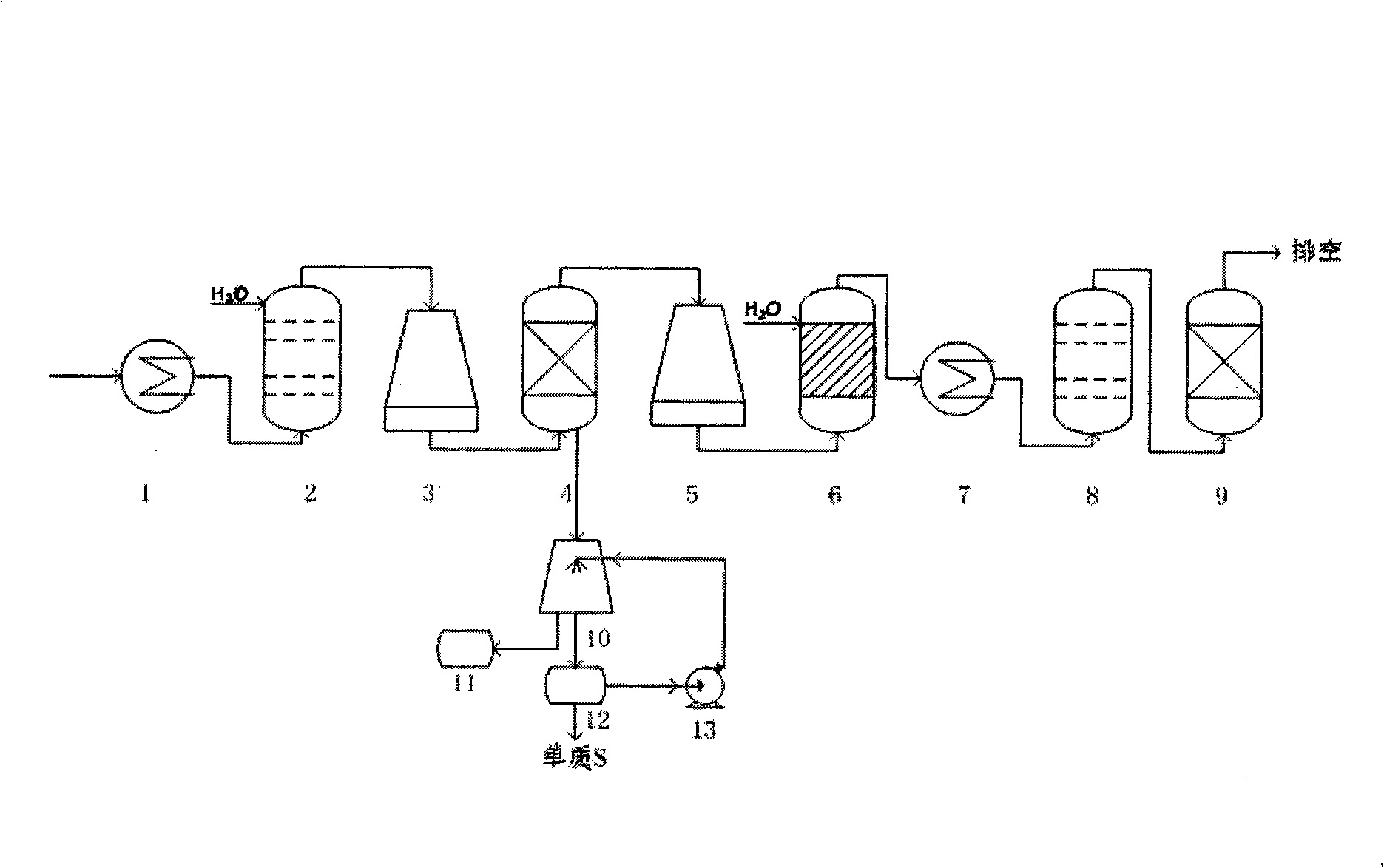

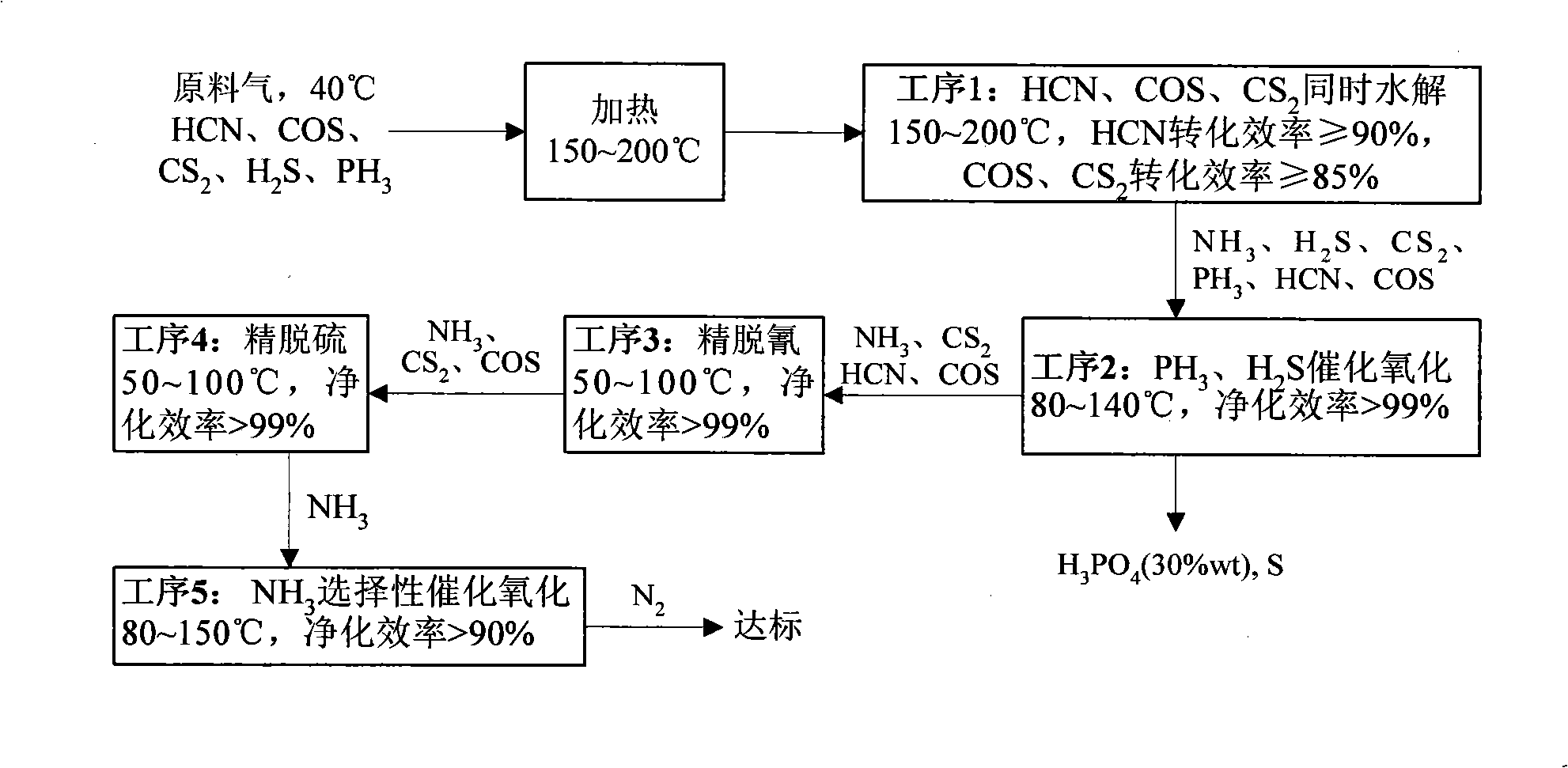

[0062] Make the flow rate 300ml / min containing HCN100mg / m 3 、COS 800mg / m 3 、PH 3 750mg / m 3 、H 2 S 800mg / m 3 、CS 2 40mg / m 3 The mixed gas enters heat exchanger 1 to heat the furnace gas to 150°C; enters HCN and COS, CS 2 Hydrolyzer 2, converts HCN to NH 3 , COS and CS 2 converted to H 2 S, the catalyst uses DJ-1 multi-functional purifier and EZX multi-functional conversion and absorption fine desulfurizer, both of which have a mass of 2.00g and are respectively filled in two layers of the packed tower with a space velocity of 4000h -1 ; Then the furnace gas enters the selective catalytic oxidation reactor 4 after being cooled to 80°C through the cooling tower 3, and the pH 3 and H 2 Catalytic oxidation of S to P 2 o 5 and S, using a dual-functional high-selectivity catalyst developed by Kunming University of Science and Technology, the catalyst component is 20g ZP-3 type activated carbon, and the supported 100ml concentration is 0.05mol / L Cu(Ac) 2 After soaking in...

Embodiment 2

[0064] Make the flow rate 400ml / min containing HCN 350mg / m 3 、COS 1000mg / m 3 、PH 3 1000mg / m 3 、H 2 S1000mg / m 3 、CS 2 80mg / m 3 The mixed gas enters the heat exchanger 1 through the intake pipe, heats the furnace gas to 200°C, and enters HCN and COS, CS 2 Hydrolyzer 2, converts HCN to NH 3 , COS and CS 2 converted to H 2 S, the catalyst adopts DJ-1 multifunctional purifying agent and the catalyst in Chinese patent CN1095963A, both of which have a mass of 2.00g and are respectively filled in two layers of the packed tower with a space velocity of 5000h -1 ; Then the furnace gas enters the selective catalytic oxidation reactor 4 after being cooled to 80°C through the cooling tower 3, and the pH 3 and H 2 Catalytic oxidation of S to P 2 o 5 and S, using a dual-functional high-selectivity catalyst developed by Kunming University of Science and Technology, the catalyst component is 20g JH-3 type activated carbon, loaded with 100ml of Cu(Ac)2 solution with a concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com