Method for preparing graphite phase carbon nitride catalyst and application of graphite phase carbon nitride catalyst in H2S oxidation

A graphitic carbon nitride, catalytic oxidation technology, applied in the preparation/purification of sulfur, catalysts for physical/chemical processes, chemical instruments and methods, etc., can solve the problems of poor selectivity and easy deactivation, and achieve good activity and selection. properties, simple preparation method, and the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

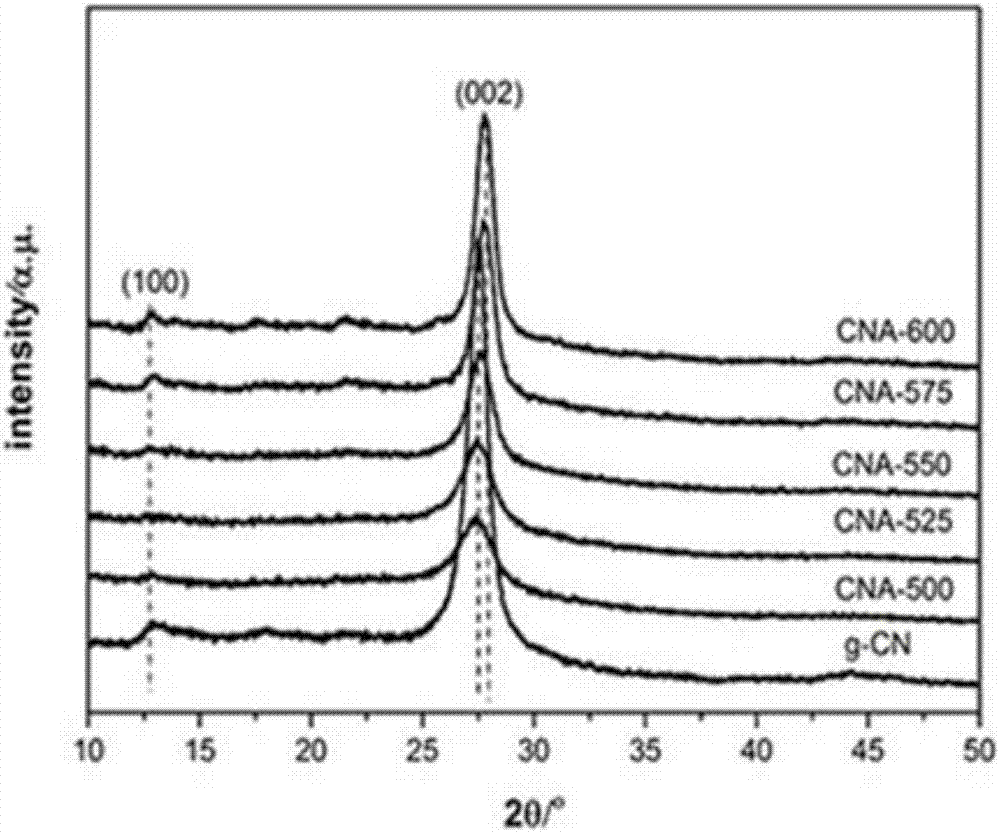

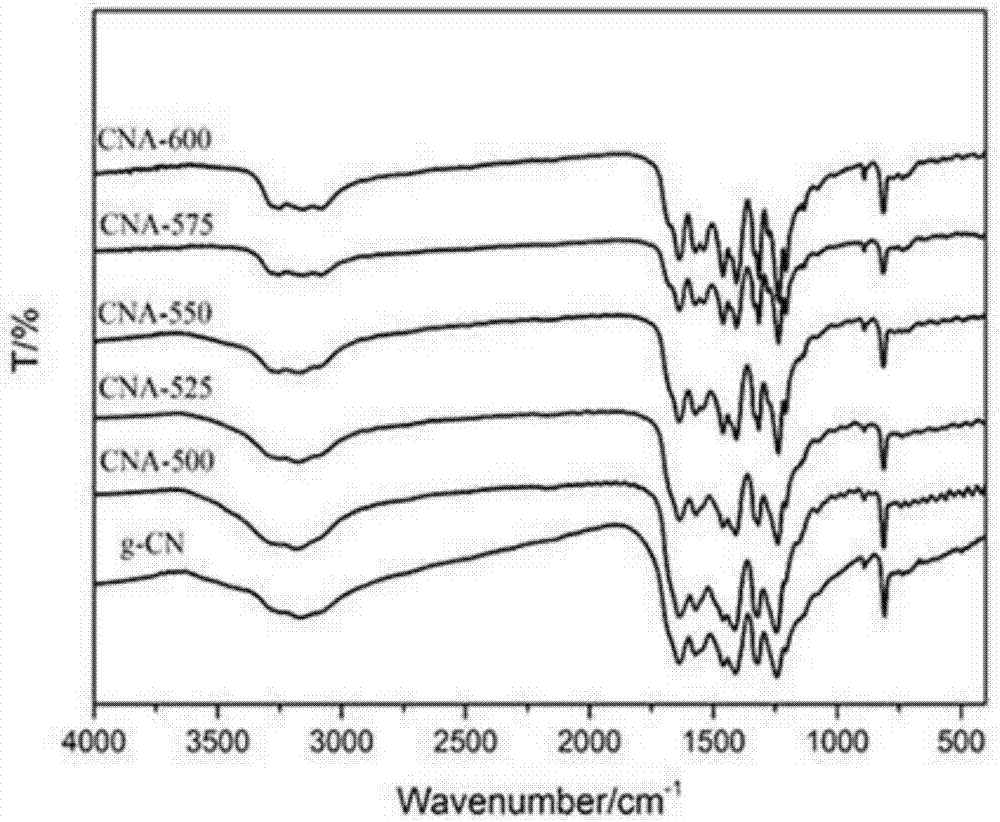

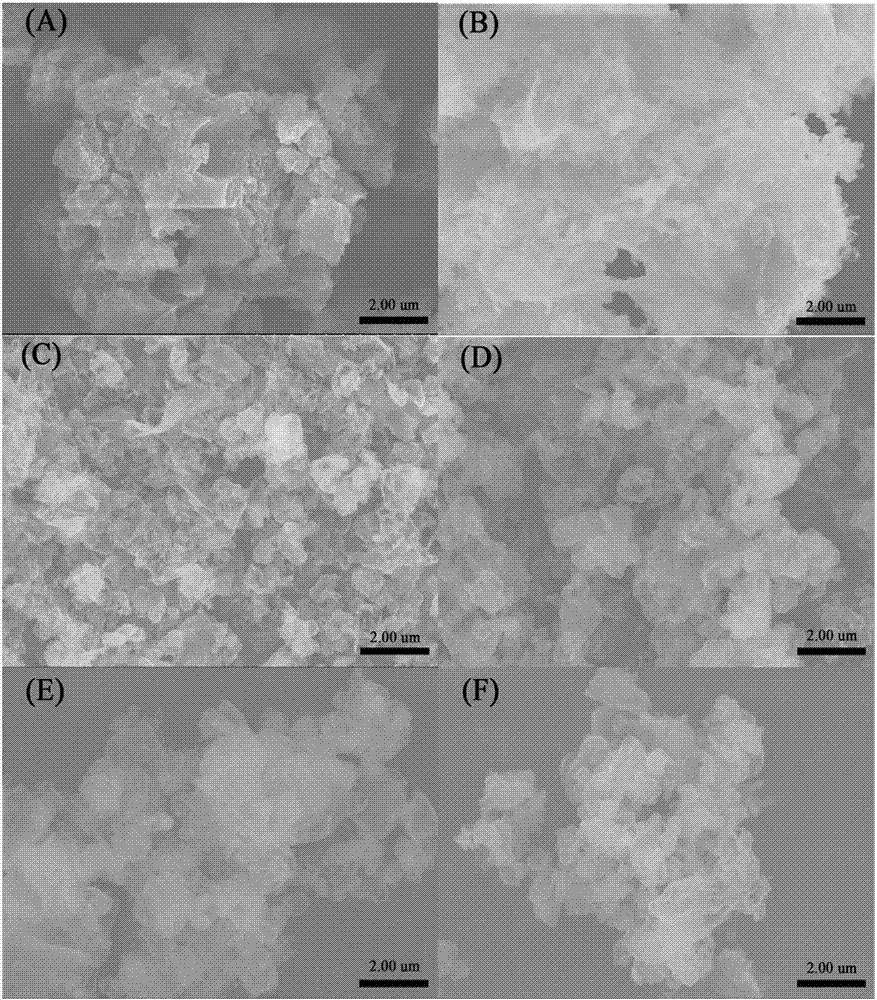

[0037] Grind 6.0g of thiocyanuric acid into a powder with a particle size of 200 mesh, place it in a heating device, and raise the temperature to 500°C at a heating rate of 5°C / min in an air atmosphere, and perform thermal polymerization for 2h. After naturally cooling to room temperature, the synthesized samples were collected to obtain a graphite-phase carbon nitride catalyst with a nano-flake structure, which was named CNA-500.

Embodiment 2

[0039] Grind 6.0g of thiocyanuric acid into a powder with a particle size of 200 mesh, place it in a heating device, and raise the temperature to 525°C at a heating rate of 5°C / min in an air atmosphere, and perform thermal polymerization for 2h. After naturally cooling to room temperature, the synthesized samples were collected to obtain a graphite-phase carbon nitride catalyst with nanoflake structure, which was named CNA-525.

Embodiment 3

[0041] Grind 6.0g of thiocyanuric acid into a powder with a particle size of 200 mesh, place it in a heating device, and raise the temperature to 550°C at a rate of 5°C / min in an air atmosphere, and perform thermal polymerization for 2 hours. After naturally cooling to room temperature, the synthesized samples were collected to obtain a graphite-phase carbon nitride catalyst with a nano-flake structure, which was named CNA-550.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diffraction angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com