Application of gold/mesoporous carbon catalyst in glucose selective oxidation reaction to prepare gluconic acid

A gluconic acid and selective oxidation technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, organic compound preparation, etc., can solve the problem of easy loss of active components and difficult recovery of precious metals in invalid catalysts and other issues to achieve high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: gold / mesoporous carbon-1 catalyst, 0.5M glucose aqueous solution, under the condition of 25 ℃, the conversion rate of glucose is 5%, the selectivity of gluconic acid is 99%, after reaction is carried out continuously for 120 hours, the catalyst's activity does not decay

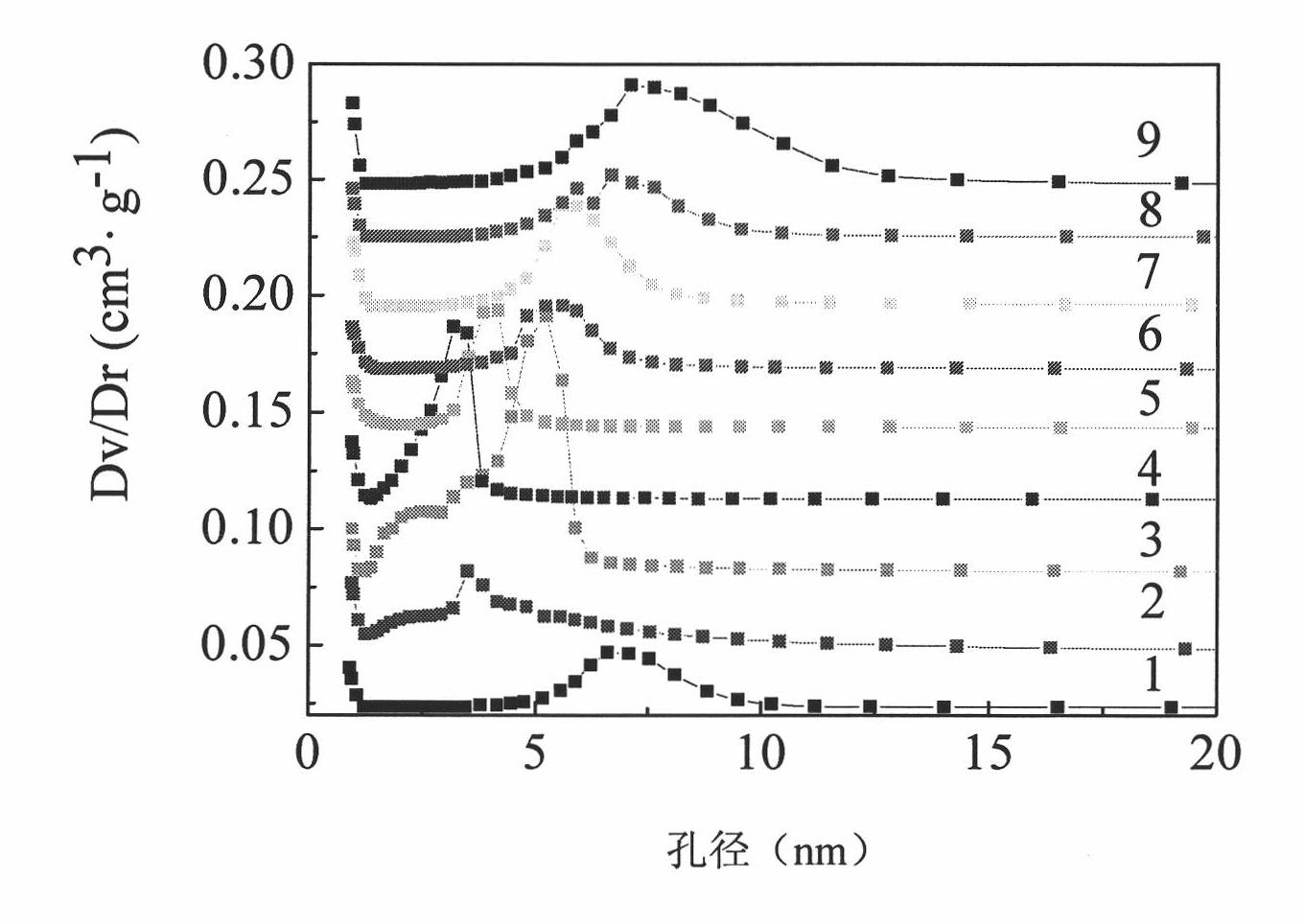

[0012] The preparation of gold / mesoporous carbon-1 catalyst: 1) the preparation of mesoporous carbon: 25g pluronic (polyoxyethylene-polyoxypropylene copolymer) and 25g phloroglucinol are stirred and dissolved in 146g ethanol at 30 ℃ In the aqueous solution, wherein the mass ratio of ethanol and water is 10:9, then add 1.6ml of 37wt% HCl solution, after stirring for 2h, add 26g of 37wt% formaldehyde solution, after 1.5h, the solution is separated, take out the bottom solution, and stir overnight After curing at 100°C, in N 2 Carry out carbonization at 850°C under atmosphere to obtain mesoporous carbon-1, wherein the most probable pore diameter of mesoporous carbon-1 is 6.8 nm, and its por...

Embodiment 2

[0015] Example 2: gold / mesoporous carbon-2 catalyst, 0.5M glucose solution, under the condition of 50 ℃, the conversion rate of glucose is 27%, the selectivity of gluconic acid is 99%, after the reaction is carried out continuously for 120 hours, the activity of the catalyst no attenuation

[0016] The preparation of gold / mesoporous carbon-2 catalyst: 1) the preparation of mesoporous carbon: after washing and drying the bagasse, sieve the bagasse of 5-10 millimeters long, add 50wt% zinc chloride solution and impregnate 24h, after filtering, in 100 °C dried overnight at N 2 Microwave radiation under the atmosphere for 15 minutes (2.45GHz, 700W), then wash with 10wt% HCl solution and deionized water, the sample after drying is mesoporous carbon-2, wherein the most probable pore diameter of mesoporous carbon-2 is 3.4 nm, the pore size distribution is detailed in figure 1 Curve 2;

[0017] 2) Loading reaction of gold: take 0.57ml of chloroauric acid solution (17.59mgAu / ml), the...

Embodiment 3

[0019] Example 3: gold / mesoporous carbon-3 catalyst, 0.5M glucose solution, under the condition of 40 ℃, the conversion rate of glucose is 22%, the selectivity of gluconic acid is 99%, after the reaction is carried out continuously for 120 hours, the activity of the catalyst no attenuation

[0020] Preparation of gold / mesoporous carbon-3 catalyst: 1) Preparation of mesoporous carbon: 1,4-isophthalonitrile (1.00g, 7.8mmol) and zinc chloride (5.32g, 39.0mmol) were added to quartz Injection, then vacuumize the injection, seal, heat at 700°C for 20h, cool to room temperature, take out the reaction mixture, stir in HCl for 15h, filter, wash with water and tetrahydrofuran, and dry under vacuum at 150°C to obtain mesoporous Carbon-3, the most probable pore diameter of mesoporous carbon-3 is 5.2 nanometers, and its pore size distribution is detailed in figure 1 Curve 3;

[0021] 2) Loading reaction of gold: take 0.57ml of chloroauric acid solution (17.59mgAu / ml), then add 283ml of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com