Method for preparing efficient oxidation catalyst through plasma-assisted sol gel method

A sol-gel method and plasma technology, applied in the field of pollutant control, can solve the problems of WFGD, such as difficult removal and insoluble in water, and achieve the effects of low cost, simple preparation process, and wide temperature adaptation window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing an efficient oxidizing catalyst by a plasma-assisted sol-gel method, comprising the steps of:

[0043] (1) Put 35.8g of 50% manganese nitrate solution into a beaker, dissolve it with deionized water, and stir at room temperature to obtain a homogeneous solution; pour 27.3g of citric acid monohydrate and 2.73g of polyethylene glycol into the previous mixture , stirring at room temperature to obtain a mixed solution;

[0044] (2) Heat the beaker containing the solution in a water bath at 80°C, and stir continuously with an electromagnetic stirrer until the solution becomes a colloid;

[0045] (3) Put the colloid in a drying oven and dry it at 110°C for 12 hours, put the dried colloid sample in a mortar, grind it into particles below 40 mesh, and wait for plasma treatment;

[0046] (4) Fill the sample between the rod-shaped electrode in the discharge quartz tube and the wall of the quartz tube, and pass through the simulated air containing 21% oxyge...

Embodiment 2

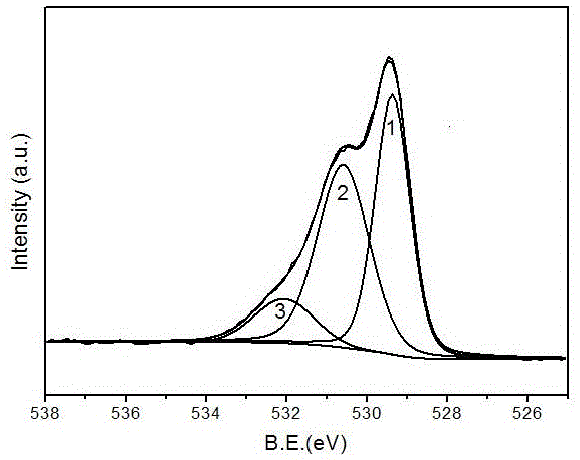

[0050]Get a certain amount of embodiment 1 catalyst powder sample, by carrying out X-ray photoelectron spectrum test to sample, analyze the energy spectrum of its O1s, its spectrogram is with reference to figure 1 shown. The test instrument is ThermoESCALAB250. analyzed by spectrum figure 1 It can be seen that peak 1 is lattice oxygen, peak 2 is surface unsaturated oxygen species, and peak 3 is adsorbed oxygen and adsorbed water species. The large areas of peaks 2 and 3 indicate that there are many active oxygen species on the surface of the catalyst, which is beneficial to the catalytic oxidation reaction.

Embodiment 3

[0052] A method for preparing an efficient oxidizing catalyst by a plasma-assisted sol-gel method, comprising the steps of:

[0053] (1) Put 26.9g of 50% manganese nitrate solution and 10.9g of cerium nitrate hexahydrate into a beaker, dissolve them in deionized water, and stir at room temperature to obtain a mixed solution; mix 27.3g of citric acid monohydrate and 2.73g of polyethylene glycol , pour the previous mixed solution, and stir at room temperature to obtain a mixed solution;

[0054] (2) Heat the beaker containing the solution in a water bath at 80°C, and stir continuously with an electromagnetic stirrer until the solution becomes a colloid;

[0055] (3) Put the colloid in a drying oven and dry it at 110°C for 12 hours, put the dried sample in a mortar, and grind it into particles below 40 mesh, and then treat it with plasma;

[0056] (4) Fill the sample between the rod-shaped electrode in the discharge quartz tube and the wall of the quartz tube, and pass through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com