Preparation method of core-shell structure CeO2@SiO2 load metalloporphyrin catalyst prepared by double wrapping method

A metal-loaded, shell-structured technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., to promote activity, improve activity and selectivity, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Synthesis of monocarboxyporphyrins. In a 500ml three-necked flask, add 200ml of propionic acid, 1.51g of benzaldehyde and 2.08g of 4-carboxybenzaldehyde, heat to reflux, and slowly drop in 1.36g of pyrrole with a constant pressure dropping funnel, control the flow rate, and complete the addition in 20 minutes. Under the condition of reflux, the reaction was continued for 30 minutes to complete. After the reaction solution was cooled, it was placed in the refrigerator overnight, filtered by suction, and separated by a silica gel column, and the monocarboxyporphyrin was synthesized.

[0018] Synthesis of monocarboxycobalt porphyrins. In a 250ml three-neck flask, add 100ml DMF, 0.5g monocarboxyporphyrin, heat to reflux, add 2.54g CoCl in batches within 1h 2 ·6H 2 O. After the addition, point the plate to monitor the reaction progress, and stop the reaction when the raw material point disappears. After the reaction solution is cooled, add 2-3 times the volume of distill...

Embodiment 2

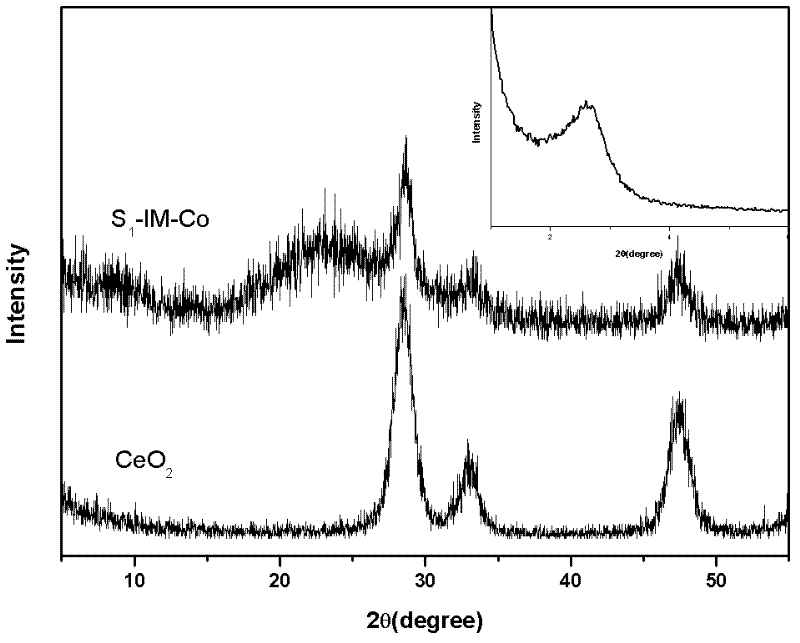

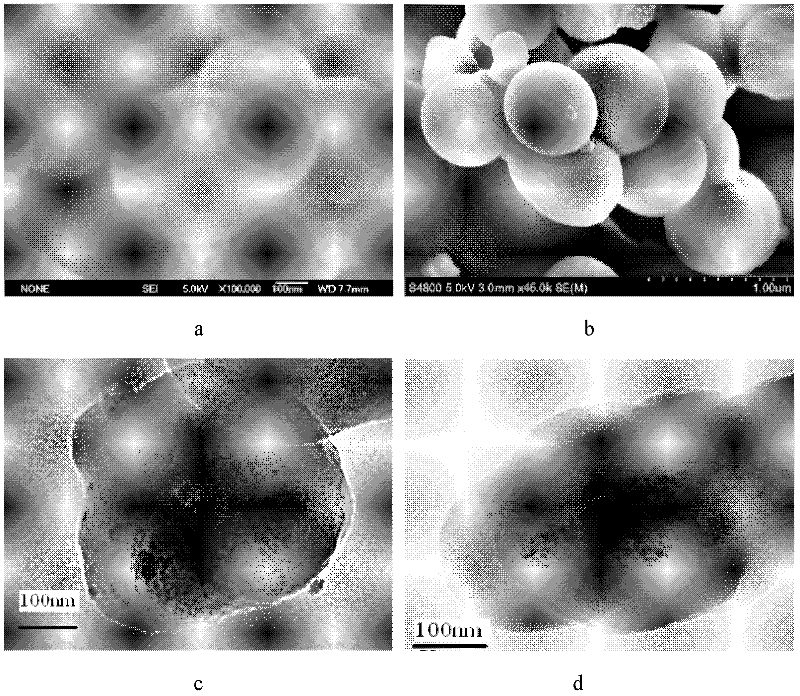

[0020] Double wrapped core-shell structure CeO 2 SiO 2 Synthesis of silica spheres. Weigh 5.996g Ce(NO 3 ) 3 ·6H 2 O, make a 250ml solution with deionized water. Under 500r / min mechanical stirring, NaOH solution was slowly added dropwise to Ce(NO 3 ) 3In the solution, adjust the pH value to 13, continue to stir for 30 minutes, filter with suction, disperse the filter cake in deionized water, and wash it twice with ultrasonic dispersion, and then disperse the filter cake in absolute ethanol, and wash it twice with ultrasonic. The resulting sample was dried under vacuum at 70 °C for 1 h. Transfer the dried cerium oxide powder into 200ml of 0.3mol / L sodium citrate solution, heat it in a water bath to 90°C for 3 hours under mechanical stirring at 500r / min, filter it with suction, and obtain the surface-modified nano Cerium oxide particles. In a 500ml three-neck flask, add 0.3g of nano-cerium oxide modified by sodium citrate on the surface, 40ml of deionized water, 160ml o...

Embodiment 3

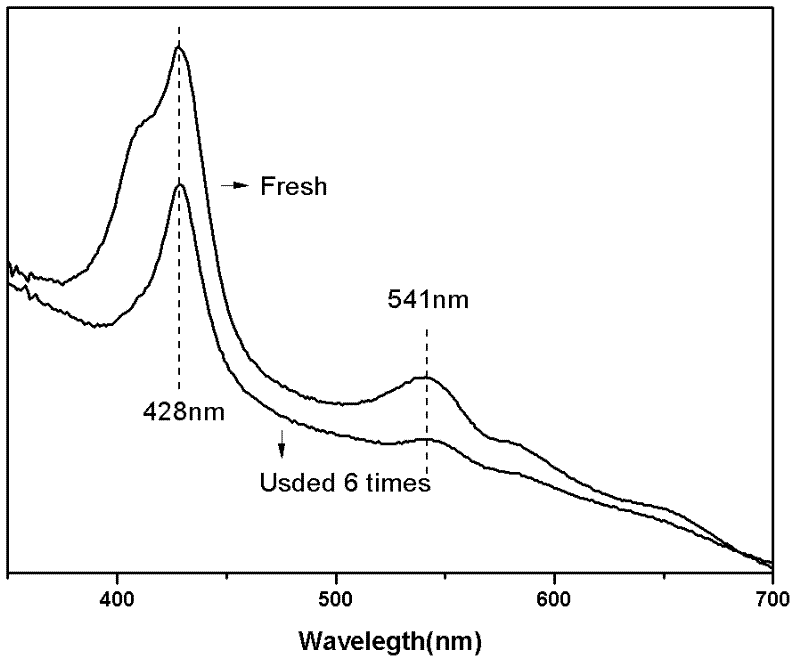

[0022] Weigh 0.050g CoTMCPP, 3.50g core-shell structure CeO prepared by double wrapping method 2 SiO 2 , added to a 250ml three-necked flask with 100ml DMF solution, refluxed for 12 hours, evaporated 70ml DMF, added 70ml deionized water after cooling, filtered, washed with deionized water until colorless, and then washed with dichloromethane until Colorless, it is directly transferred to the Soxhlet extractor after being drained, and dichloromethane is used as the extracting solution to extract until it is colorless, and then dried to obtain the core-shell structure CeO prepared by the double encapsulation method. 2 SiO 2 Supported metalloporphyrin catalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com