Process for producing methyl benzoic acid by paraxylene

A technology of p-toluic acid and p-xylene, which is applied in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of difficult separation and purification, high melting point, and achieves no three wastes and low production costs. , the effect of high production stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

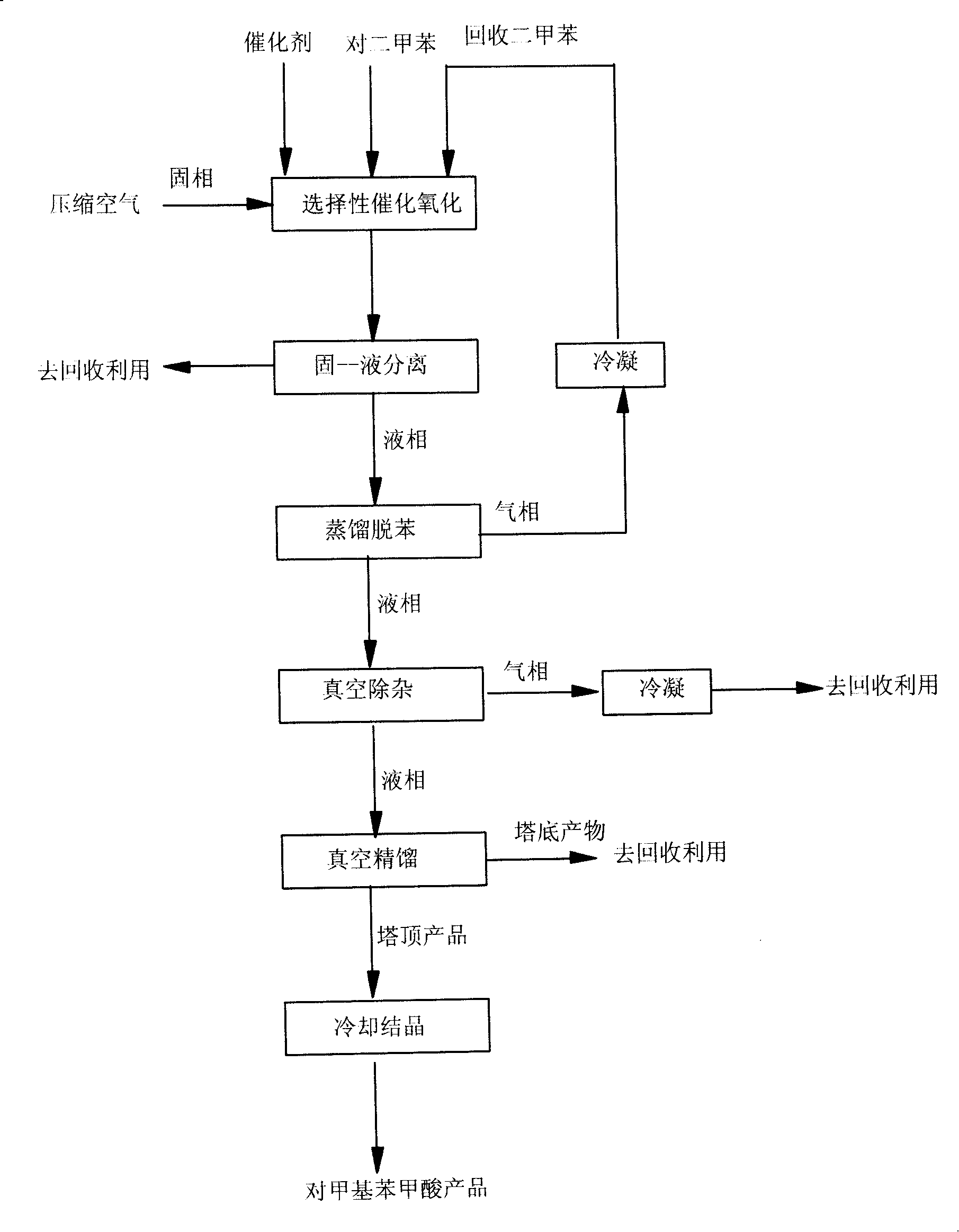

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0020] As shown in the figure, the process of producing p-toluic acid with p-xylene uses p-xylene as the raw material, and the equipment to be used is a catalytic reactor, a solid-liquid separator, a distillation and debenzene distillation device, and a scraper-type cooling crystallization device etc.

[0021] Its process steps are as follows:

[0022] (1) Use p-xylene 1500kg, catalyst cobalt isooctanoate 6kg, and compressed air at a reaction temperature of 100-130°C and an operating pressure of 0.2-0.3MPa in a tower-type bubbling reactor for oxidation reaction of p-xylene and oxygen 5-6hr, generate p-toluic acid product and by-products such as p-tolualdehyde, p-carboxybenzaldehyde, terephthalic acid and water;

[0023] (2) Solid-liquid separation, at an operating temperature of 130-140°C, use a pipeline filter for solid-liquid separation op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com