Preparation method and application of nanometer ceria-zirconia solid solution-based catalyst for selectively catalytically oxidizing ammonia

A cerium zirconium solid solution, catalytic oxidation technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of high complete conversion temperature of ammonia gas and expensive catalyst , poor stability and other problems, to achieve the effect of good thermal stability, low price and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Ce 0.8 Zr 0.2 o 2 Solid solution preparation

[0024] Weigh 6.4200g of cerium nitrate hexahydrate and 1.5868g of zirconium nitrate pentahydrate and dissolve them in 30ml and 20ml of water respectively. After completion, mix the above two metal salt solutions and stir for 10 minutes; at the same time, weigh 2.6940g CTAB and dissolve it in 100ml water, keep n(CTAB) / [n(Ce)+n(Zr)]=0.4, and keep stirring at room temperature Pour the mixture of the two metal salts into the CTAB aqueous solution and stir for 30 minutes; add a certain amount of ammonia water to the above mixture, adjust the pH value to 9 under continuous stirring, age at room temperature for 12 hours, and then put it into a polytetrafluoroethylene high-pressure reactor After 24 hours of constant temperature at 90°C, the temperature was naturally lowered and cooled, washed with deionized water and absolute ethanol, centrifuged, and dried in an oven at 100°C for 24 hours; under air conditions, placed in a ...

Embodiment 2

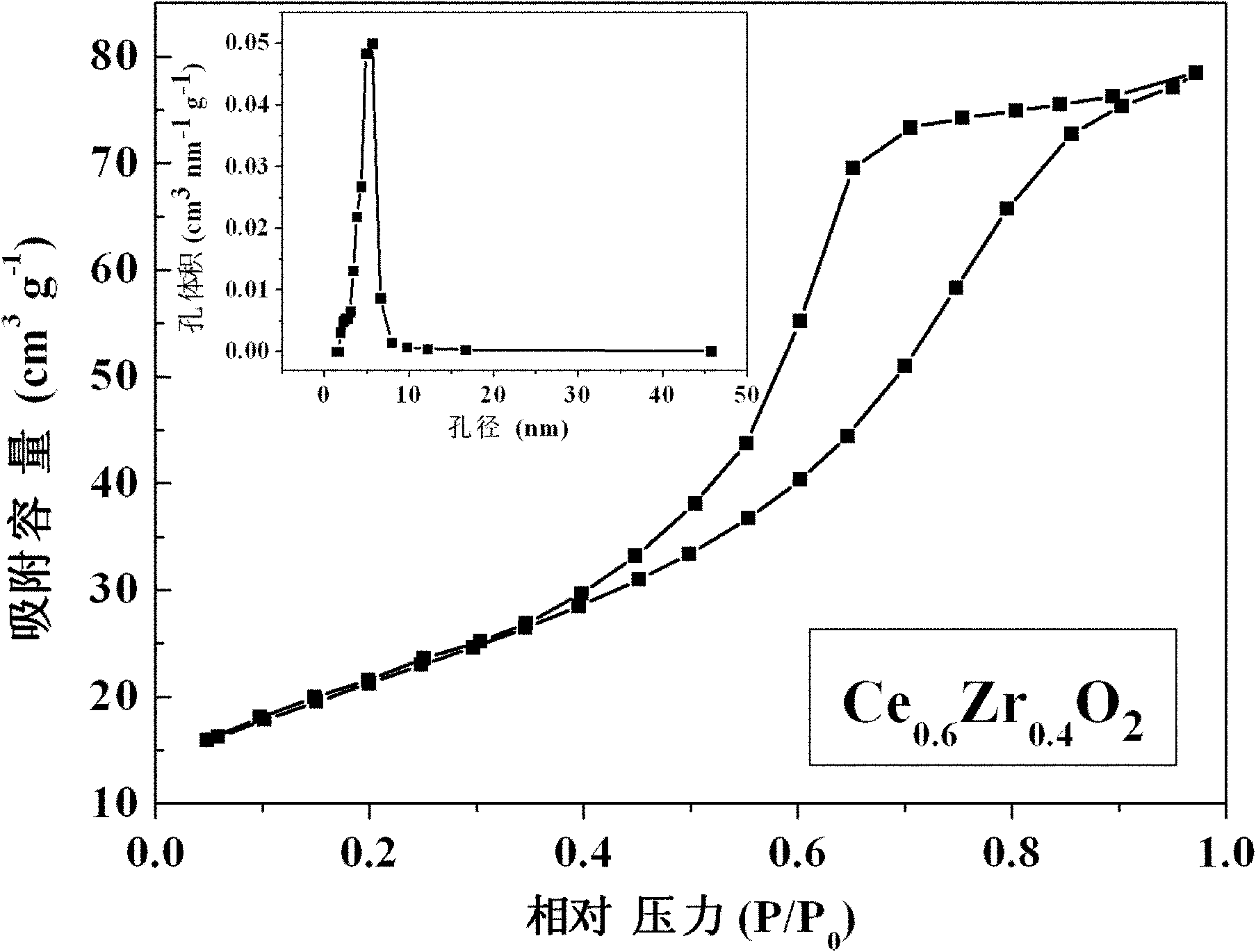

[0028] According to the preparation method of the present invention in Example 1, the molar ratio of cerium to zirconium is changed, x is taken as 0.6, the precursor of the active component Cu is changed to copper acetate, the calcination temperature is changed to 450°C, and the catalyst 6% Cu / Ce is prepared 0.6 Zr 0.4 o2 , denoted as catalyst B. where Ce 0.6 Zr 0.4 o 2 N in solid solution 2 Adsorption / desorption and pore size distribution see figure 2 .

Embodiment 3

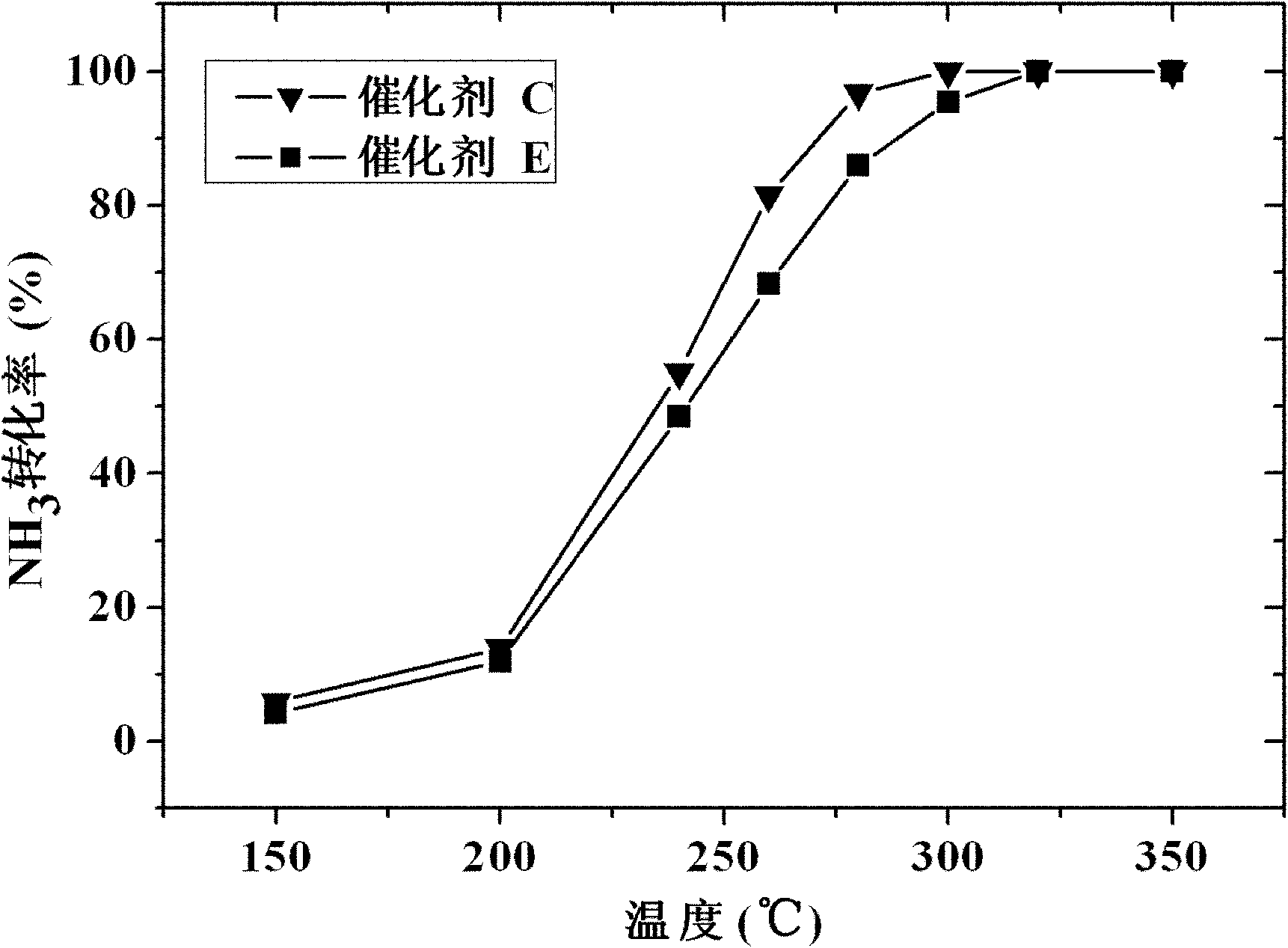

[0030] According to the preparation method of the present invention in Example 1, x is taken as 0.5, and n(CTAB) / [n(Ce)+n(Zr)]=0.6 is changed, the precipitation agent is sodium hydroxide, and the catalyst 6%Cu / Ce is prepared 0.5 Zr 0.5 o 2 , denoted as catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com