Device for automobile exhaust treatment and preparation method thereof

A technology of automobile exhaust and solid oxide, applied in the direction of exhaust device, exhaust treatment, separation method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

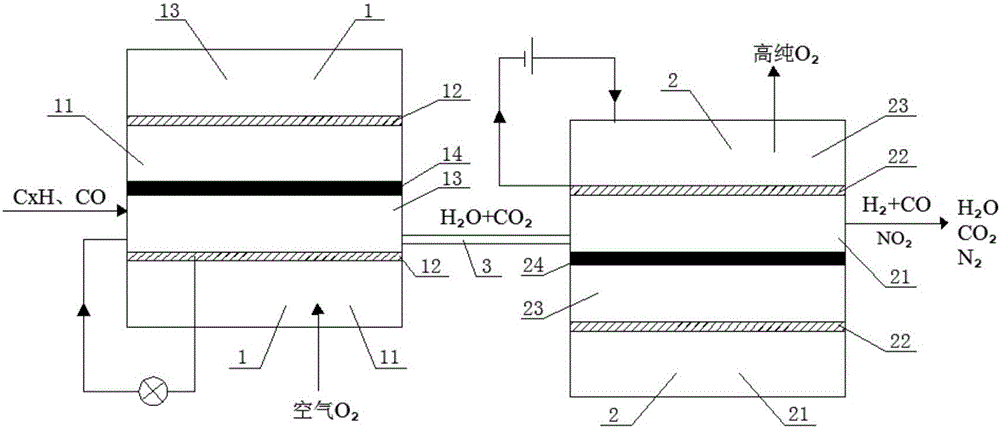

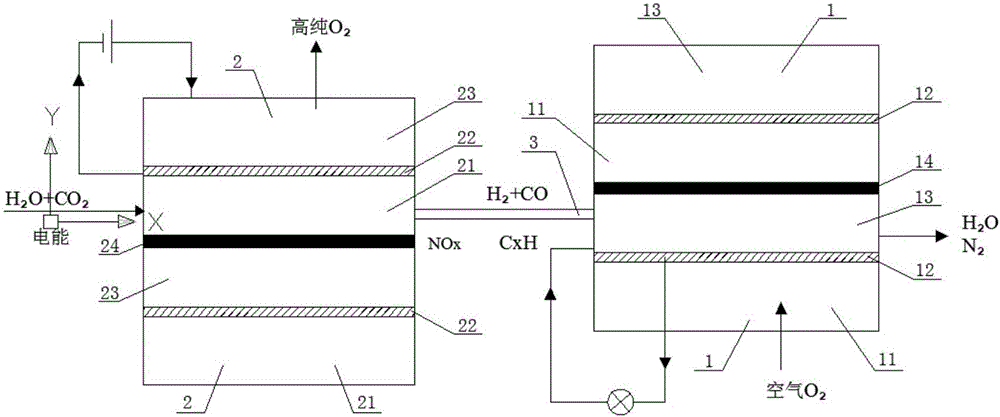

[0047] Such as figure 1 As shown, a device for automobile exhaust treatment includes a solid oxide fuel cell stack and a solid oxide electrolytic cell stack, and a function is provided between the solid oxide fuel cell stack and the solid oxide electrolytic cell stack Sealing material 3, the solid oxide fuel cell stack is composed of two solid oxide fuel cells 1 connected in series, and the solid oxide electrolytic cell stack is electrolyzed by two solid oxide fuel cells connected in series Pool 2 composition; functional sealing material 3 is Sr 0.7 Y 0.3 Ti 0.6 Fe 0.4 o 3 ;

[0048] The single solid oxide fuel cell 1 is an anode-supported oxygen ion conductor type, and the single solid oxide fuel cell 1 includes a cathode one 11, an electrolyte one 12 and an anode one 13, and the cathode one 11 is (La 0.75 Sr 0.25 ) 0.95 MnO 3 (LSM), the electrolyte one 12 is yttria-stabilized zirconia (YSZ), the anode one 13 is NiO-YSZ, and the electrolyte one 12 is arranged in the ...

Embodiment 2

[0081] This example is used for the device of automobile exhaust treatment, except that the electrolyte one 12 of the solid oxide fuel cell 1 and the electrolyte two 22 of the solid oxide cell electrolytic cell 2 all use the cation conductor Ce 0.8 SM 0.2 o 1.9 (SDC), the anode one 13 is NiO-SDC, the cathode two 21 is NiO-SDC, and other contents are the same as Example 1.

[0082] The preparation method of the device for automobile exhaust treatment in this embodiment comprises the following steps:

[0083] Step (a) Preparation of Solid Oxide Fuel Cell Stack

[0084] (1) The materials NiO, SDC and pore-forming agent used to prepare the anode-13 of the solid oxide fuel cell 1 were mixed with nodular ink in a mass ratio of 6:4:2 and dried for 24 hours to obtain the desired The anode-primary powder, the required anode-primary powder is made into an anode-support (or tube) green body by dry pressing or extrusion molding, and after sintering at 1300°C for 4 hours in an air atmos...

Embodiment 3

[0096] This example is used for the device of automobile exhaust gas treatment, except that the electrolyte one 12 of the solid oxide fuel single cell 1 and the electrolyte two 22 of the solid oxide single electrolytic cell 2 all adopt the cationic conductor BaZr 0.7 PR 0.1 Y 0.2 o 3-δ (BZPY), the anode one 13 is NiO-BZPY, the cathode two 21 is NiO-BZPY, and other contents are the same as Example 1.

[0097] The preparation method of the device for automobile exhaust treatment described in this embodiment is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com