Preparation method of Cr-Ce composite oxide catalyst

A composite oxide and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of catalyst deactivation, secondary pollution, active components problems such as loss, to achieve the effects of high selectivity, low catalyst cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

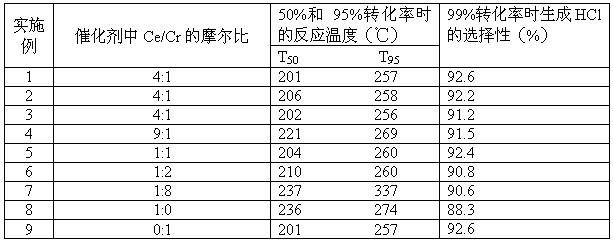

Examples

Embodiment 1

[0018] Dissolve 20.87g of cerium nitrate and 3.81g of chromium nitrate in 350ml of water, mix well, add ammonia water dropwise to pH 9.5, continue to stir for 0.5 hours, and then stand for 12 hours for aging; the filtered precipitate is filtered and washed with distilled water. After washing several times with absolute ethanol, supercritical drying treatment is adopted; after calcination in air atmosphere at 500℃ for 4 hours, a Cr-Ce composite oxide catalyst is prepared. The molar ratio of Ce / Cr in the catalyst is 4:1 .

Embodiment 2

[0020] Using the same operation as in Example 1, the difference is: the filtered precipitate was washed with distilled water for several times, then washed with absolute ethanol for several times, and then dried in an oven (110°C).

Embodiment 3

[0022] The same operation as in Example 1 was used, except that the filtered precipitate was washed with distilled water for several times, and then dried in an oven (110°C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com