Pdx/Cu monatomic catalyst for selective hydrogenation of C4 and preparation method for Pdx/Cu monatomic catalyst

A selective hydrogenation and catalyst technology, applied in physical/chemical process catalysts, hydrogenation hydrocarbon production, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of multiple and complex molecules and reactions, and achieve the cost of catalysis Effects of low, selectivity improvement, and long catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

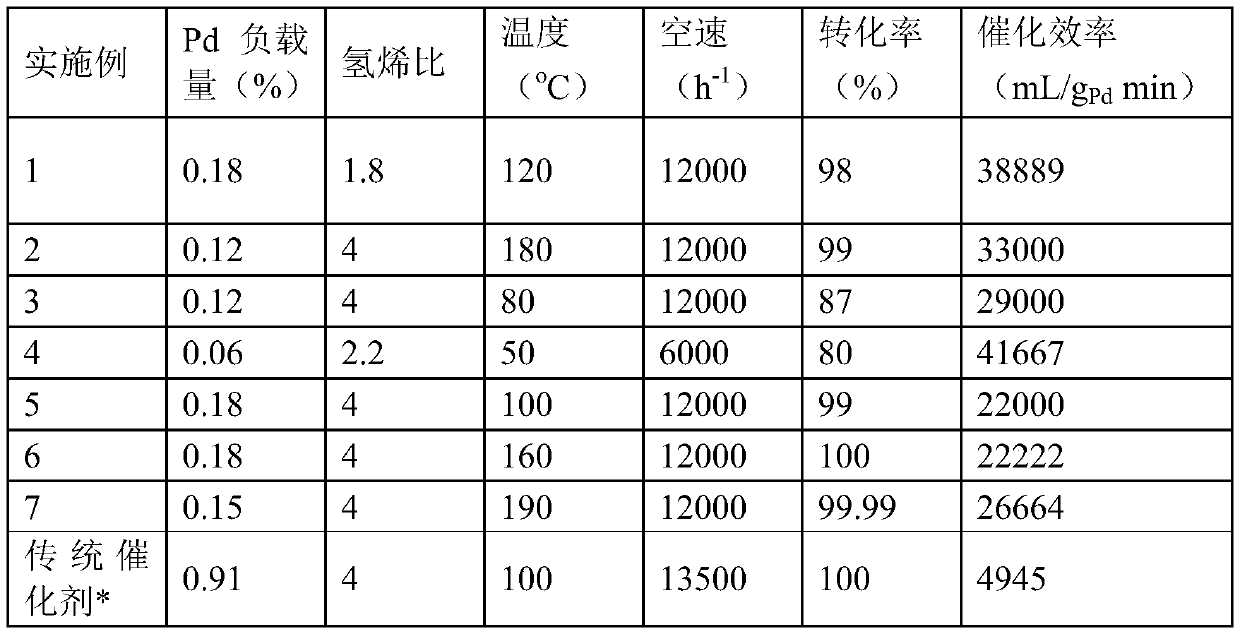

Examples

Embodiment 1

[0049] Preparation of PdCu / Al by Co-impregnation 2 o 3 Catalyst, wherein Pd content 0.18%, Cu content 15%, concrete steps are as follows:

[0050] (a) Calculate the consumption of corresponding precursor copper nitrate and palladium nitrate, and configure solution according to the volume of corresponding solution impregnated with aluminum oxide equivolume;

[0051] (b) adding the solution dropwise evenly on the alumina carrier, so that the carrier just saturates and absorbs the prepared solution;

[0052] (c) aging the impregnated carrier at room temperature for 3 hours, and drying at 100° C. for 12 hours;

[0053] (d) Calcining the catalyst obtained in (c) at 500° C. for 5 h.

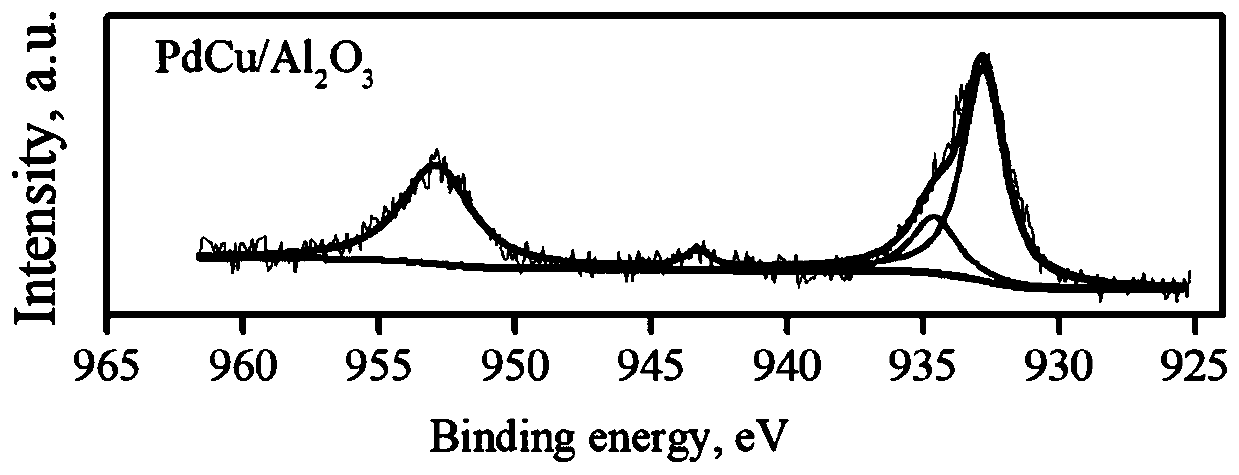

[0054] After the prepared catalyst was reduced at 450°C, it was characterized by EXAFS, and the obtained data was fitted to obtain the coordination number (CN, coordination number) of Pd. After the fitting, CN(Pd-Pd)=0 , CN(Pd-Cu)=11.2, which proves that Pd is surrounded by Cu and exists in the cat...

Embodiment 2

[0058] Preparation of PdCu / CeO by Galvanic displacement method 2 Catalyst, wherein Pd content 0.12%, Cu content 3.5%, concrete steps are as follows:

[0059] (a) calculate the consumption of precursor copper nitrate and palladium nitrate according to load data;

[0060] (b) Cu(acac) 2 The solution is evenly added dropwise on the catalyst carrier, so that the carrier is just saturated to absorb the prepared solution;

[0061] (c) Aging for 3 hours and drying at 80°C for 18 hours;

[0062] (d) calcining at 500°C for 4h;

[0063] (e) reducing the catalyst obtained in (d) at 300° C. for 2 hours;

[0064] (f) The catalyst obtained in (e) is subjected to metal replacement reaction in an ultrasonic reactor, and the replacement metal solution is Pd(acac) 2 solution;

[0065] (g) Vacuum drying at room temperature for 48 h.

[0066] After reducing the prepared catalyst at 450°C, perform EXAFS characterization, the obtained data is fitted to obtain the coordination number (CN) of ...

Embodiment 3

[0069] Preparation of PdCu / SiO by Step-wise Impregnation Method 2 Chemical agent, wherein Pd content 0.12%, Cu content 4.2%, concrete steps are as follows:

[0070] (a) Calculate the amount of precursor cupric chloride and palladium chloride according to the load data, and prepare the solution according to the volume corresponding to the equal volume impregnation of silicon oxide;

[0071] (b) the cupric chloride solution is evenly added dropwise on the catalyst carrier, so that the carrier is just saturated and adsorbed with the prepared solution;

[0072] (c) Aging for 3 hours and drying at 80°C for 18 hours;

[0073] (d) calcining at 450°C for 4h;

[0074] (e) palladium chloride solution is evenly added dropwise on the catalyst carrier, so that the carrier is just saturated and adsorbed with the prepared solution;

[0075] (f) Aging for 3 hours and drying at 80°C for 18 hours;

[0076] (g) Calcination at 550°C for 5h.

[0077] After reducing the prepared catalyst at 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com