Continuous preparation device of small molecular weight amine-terminated polyether and preparation method

A technology of amino-terminated polyether and small molecular weight, which is applied in the preparation of amino-hydroxyl compounds, the preparation of organic compounds, chemical instruments and methods, etc. It can solve the problems of low primary amine content and poor product quality, and achieve low reaction temperature and pressure , increase economic benefits and reduce usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

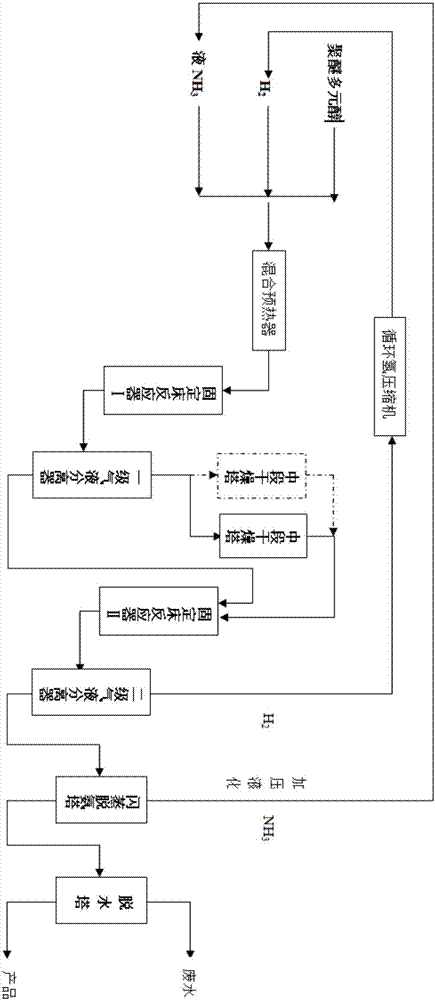

Image

Examples

Embodiment 1

[0053] 100mL supported nickel-based catalyst (containing Ni 92%, Cr 7.8%, Fe 0.2%) and 100mL Raney-type nickel-based catalyst (particle size 20 mesh, activity 1ml H 2 / min. g) Fill in fixed-bed reactors I and II of φ25×720mm (diameter 25mm, height 720mm, volume about 350ml) (catalyst volume to fixed bed volume ratio is 0.29:1), heat up and feed H 2 Activate and dry. After completion, press H into the mixing preheater at a flow rate of 12L / h 2 , the volume space velocity is 2.0h -1 NH 3 and a volumetric space velocity of 1.0h -1 , molecular weight 230, low molecular weight polyether (NH 3 The molar ratio to the hydroxyl group in the polyether polyol molecule is 8:1; H 2 The molar ratio to the hydroxyl group in the polyether polyol molecule is about 0.6:1); fully mixed and preheated at 60°C, and then enters the fixed bed reactor I from the top, and the first step of hydrogenation occurs at 180°C and 2.5MPa Ammonification reaction: the product is separated from gas and liq...

Embodiment 2

[0056] 35mL supported nickel-based catalyst (containing Ni 95%, Cr 3%, Fe 2%) and 35mL Raney-type nickel-based catalyst (particle size 40 mesh, activity 5ml H 2 / min. g) Fill in fixed bed reactors I and II of φ25×720mm (diameter 25mm, height 720mm, volume 350ml) (catalyst volume to fixed bed volume ratio is 0.2:1), heat up and feed H 2 Activate and dry. After completion, press H into the mixing preheater at a flow rate of 8L / h 2 , the volume space velocity is 4.0h -1 NH 3 and a volumetric space velocity of 2.0h -1 , molecular weight 400, low molecular weight polyether (NH 3 The molar ratio to the hydroxyl group in the polyether polyol molecule is 15:1; H 2 The molar ratio to the hydroxyl group in the polyether polyol molecule is about 1:1); fully mixed and preheated at 50°C, and then enters the fixed bed reactor I from the top, and the first step of hydrogenation occurs at 140°C and 1.5MPa Ammonification reaction: the product is separated from gas and liquid at 160°C by...

Embodiment 3

[0059] 155mL supported nickel-based catalyst (containing Ni 90%, Cr 8%, Fe 2%) and 155mL Raney-type nickel-based catalyst (particle size 30 mesh, activity 3ml H 2 / min. g) Fill in fixed bed reactors I and II of φ25×720mm (diameter 25mm, height 720mm, volume 350ml) (the ratio of catalyst volume to fixed bed volume is 0.44:1), heat up and feed H 2 Activate and dry. After completion, press H into the mixing preheater at a flow rate of 20L / h 2 , the volume space velocity is 1.0h -1 NH 3 and a volumetric space velocity of 2.0h -1 , a molecular weight of 600, a small molecular weight polyether with a functionality of 2 (NH 3 The molar ratio to the hydroxyl group in the polyether polyol molecule is 5:1; H 2 The molar ratio to the hydroxyl group in the polyether polyol molecule is about 0.9:1); fully mixed and preheated at 100°C, and then enters the fixed bed reactor I from the top, and the first step of hydrogenation occurs at 160°C and 2.0MPa Ammonification reaction: the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com