Patents

Literature

314results about How to "Reduce the maximum temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

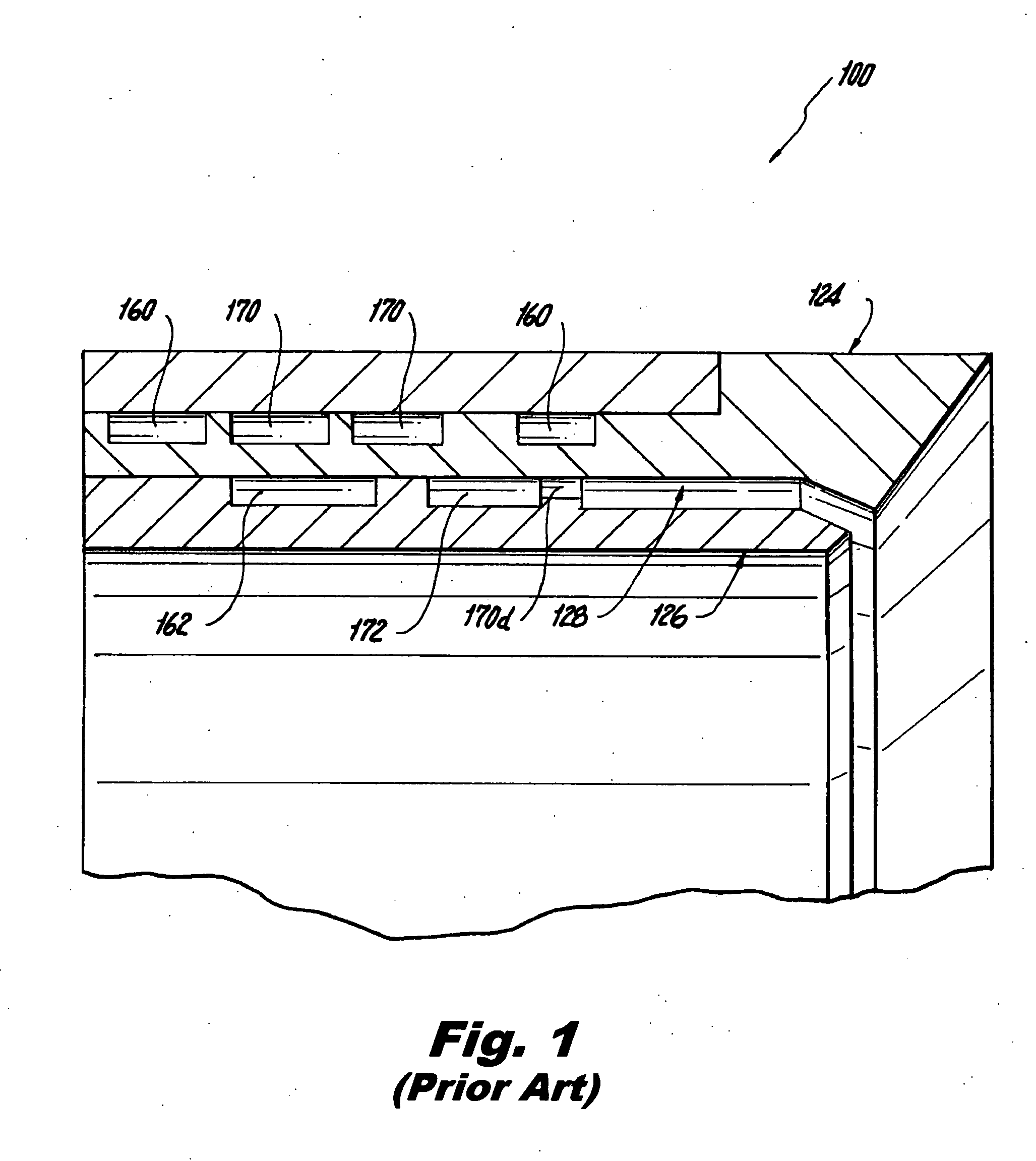

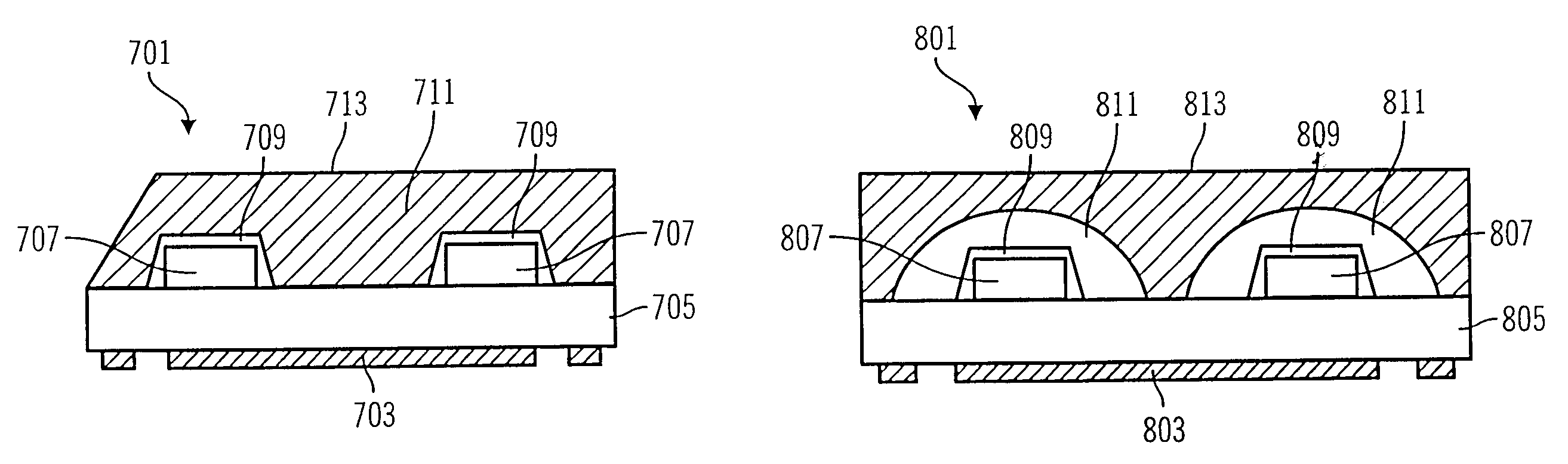

Local reduction of compliant thermally conductive material layer thickness on chips

InactiveUS20050127500A1Reduce thermal resistanceReduce the temperatureSemiconductor/solid-state device detailsSolid-state devicesThin layerConductive materials

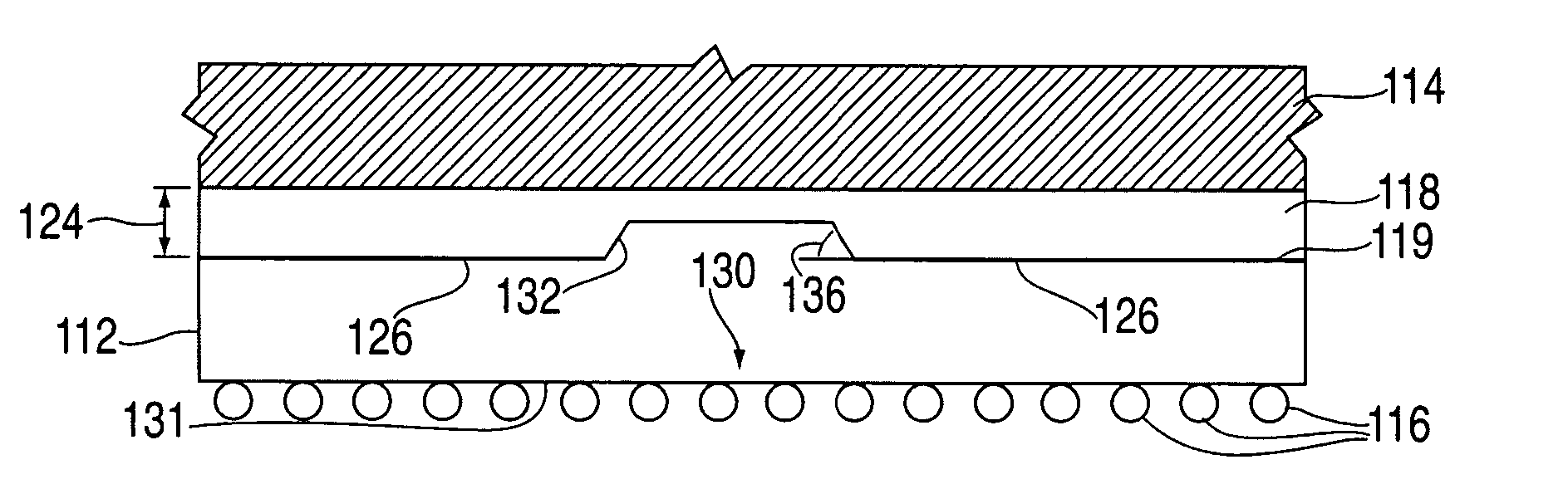

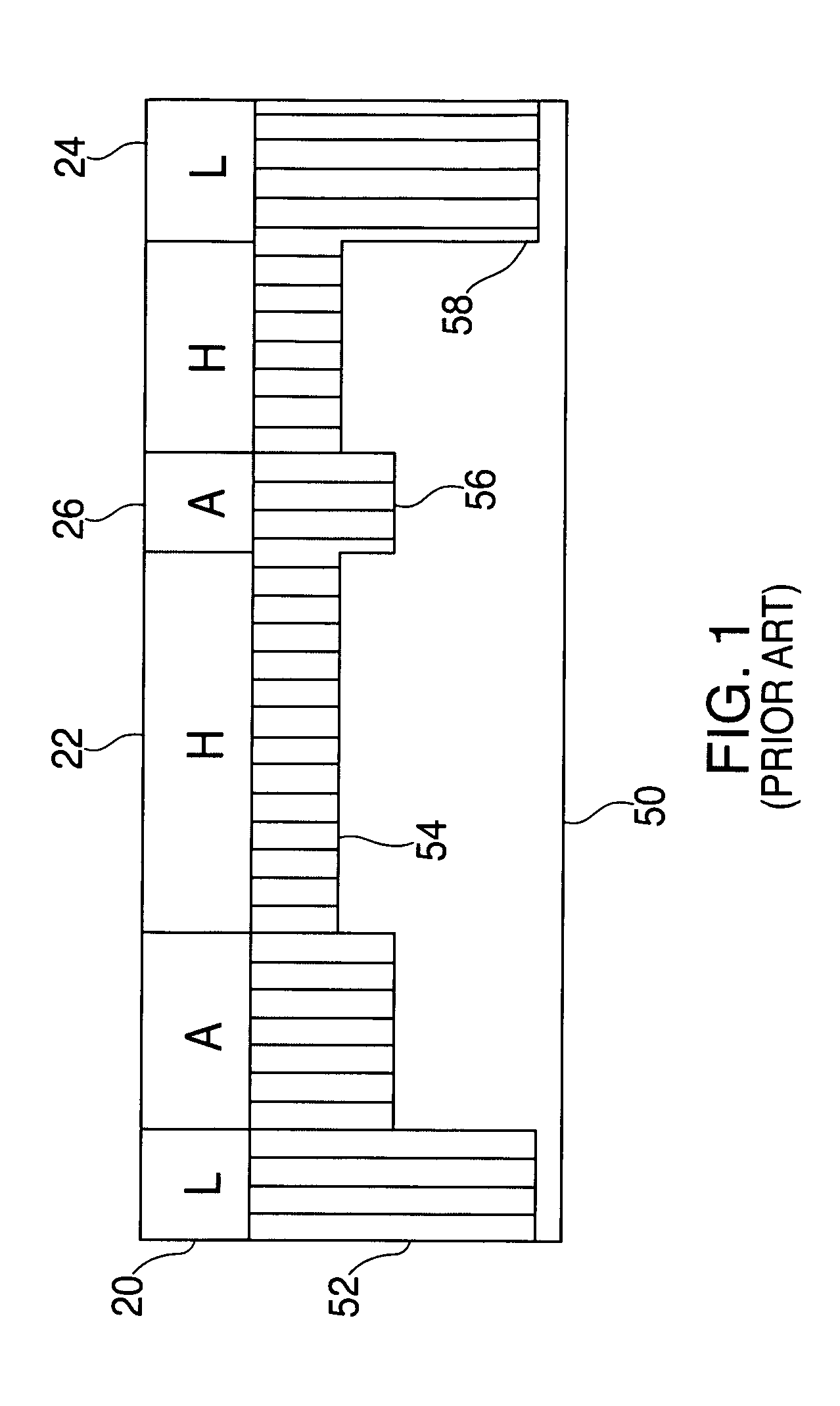

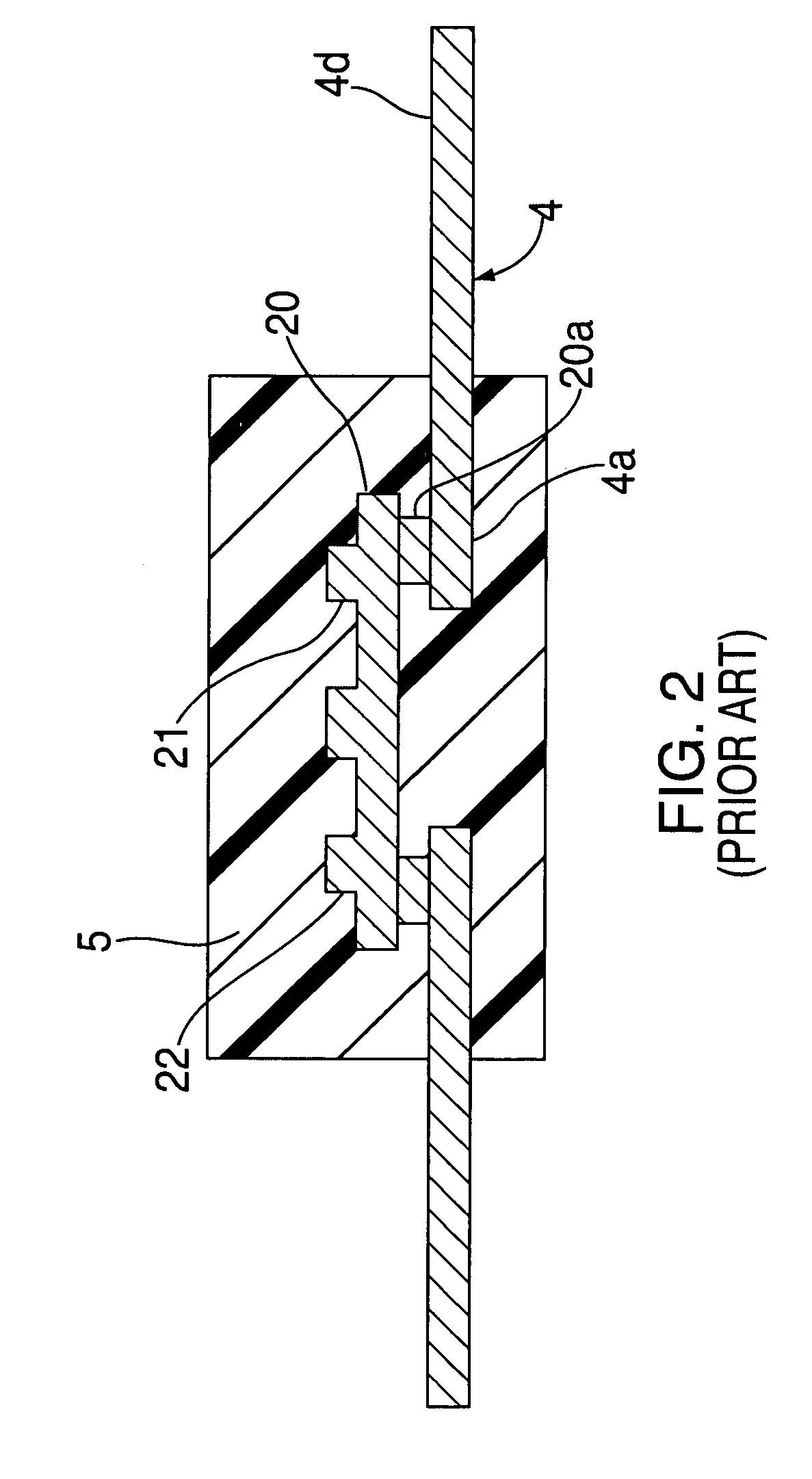

In an integrated circuit packaging structure, such as in an MCM or in a SCM, a compliant thermally conductive material is applied between a heat-generating integrated circuit chip and a substrate attached thereto. Raised regions are defined on the back side of the chip aligned to areas of a higher than average power density on the front active surface of the chip such that a thinner layer of the compliant thermally conductive material is disposed between the chip and the substrate in this area after assembly thereof resulting in a reduced “hot-spot” temperature on the chip. In an exemplary embodiment, the substrate includes one of a heat sink, cooling plate, thermal spreader, heat pipe, thermal hat, package lid, or other cooling member.

Owner:GLOBALFOUNDRIES INC

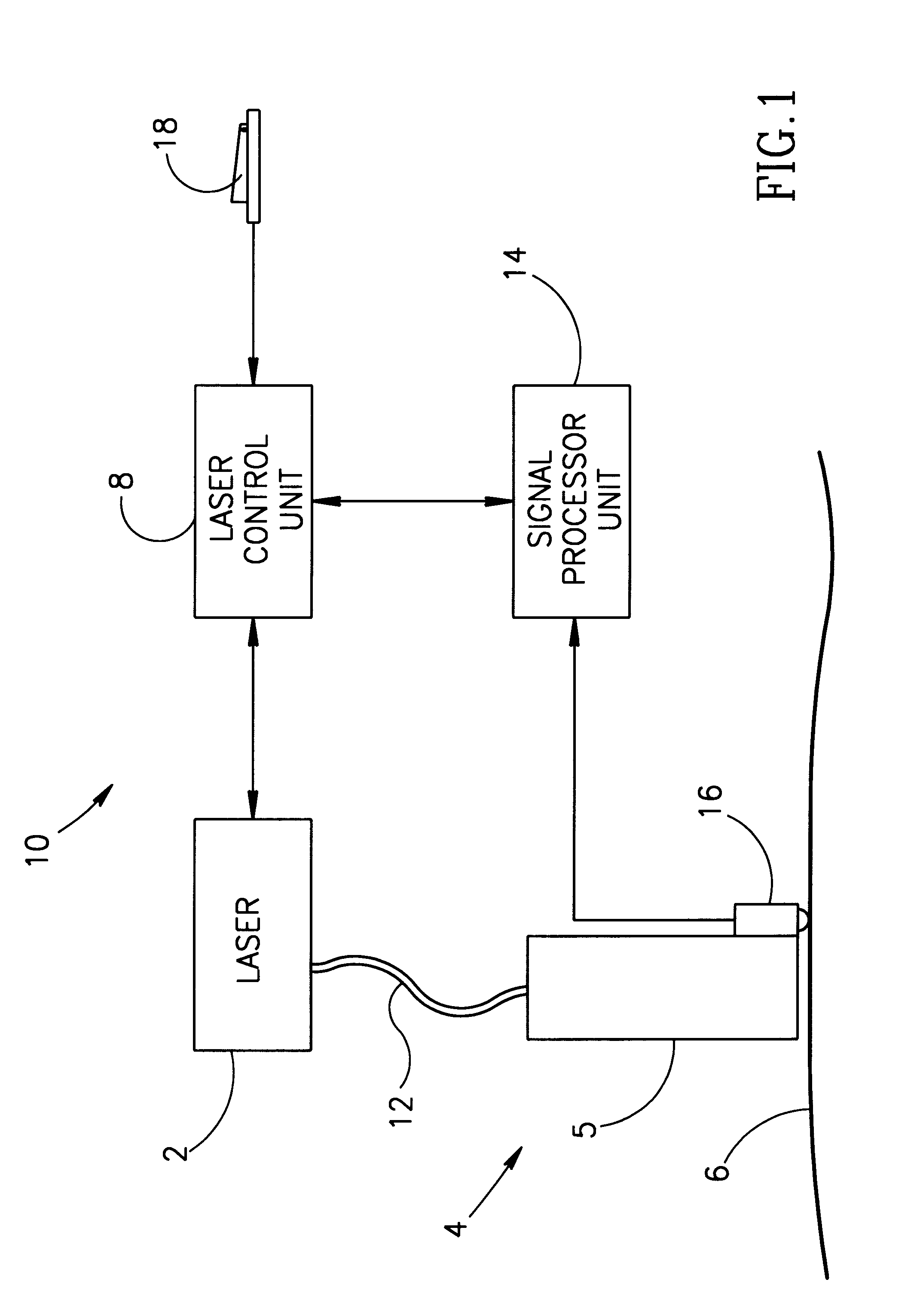

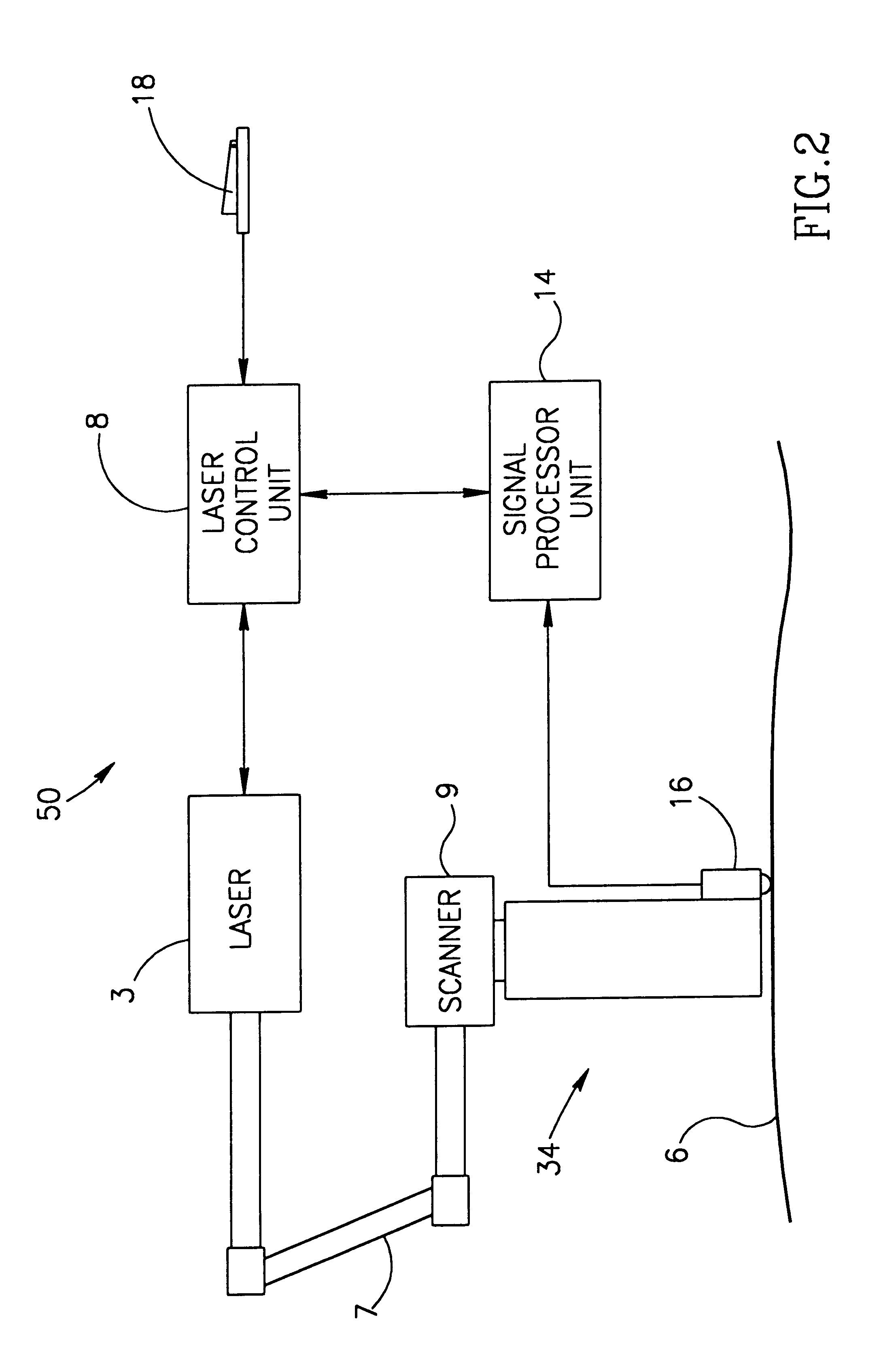

Apparatus and method including a handpiece for synchronizing the pulsing of a light source

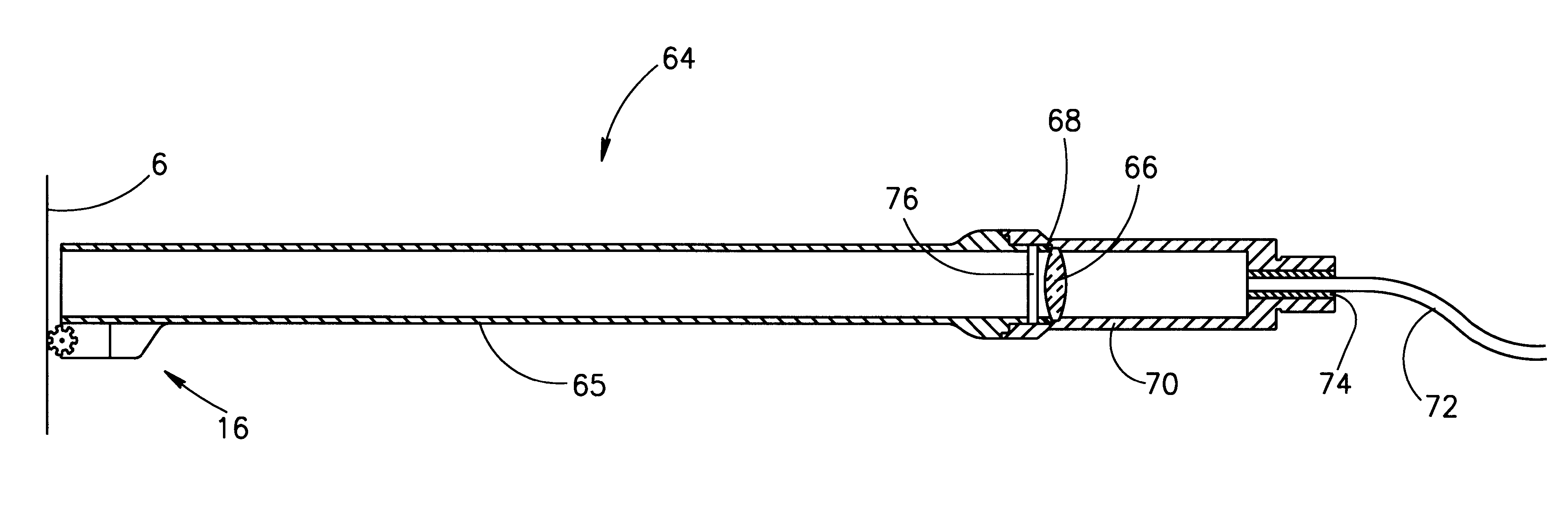

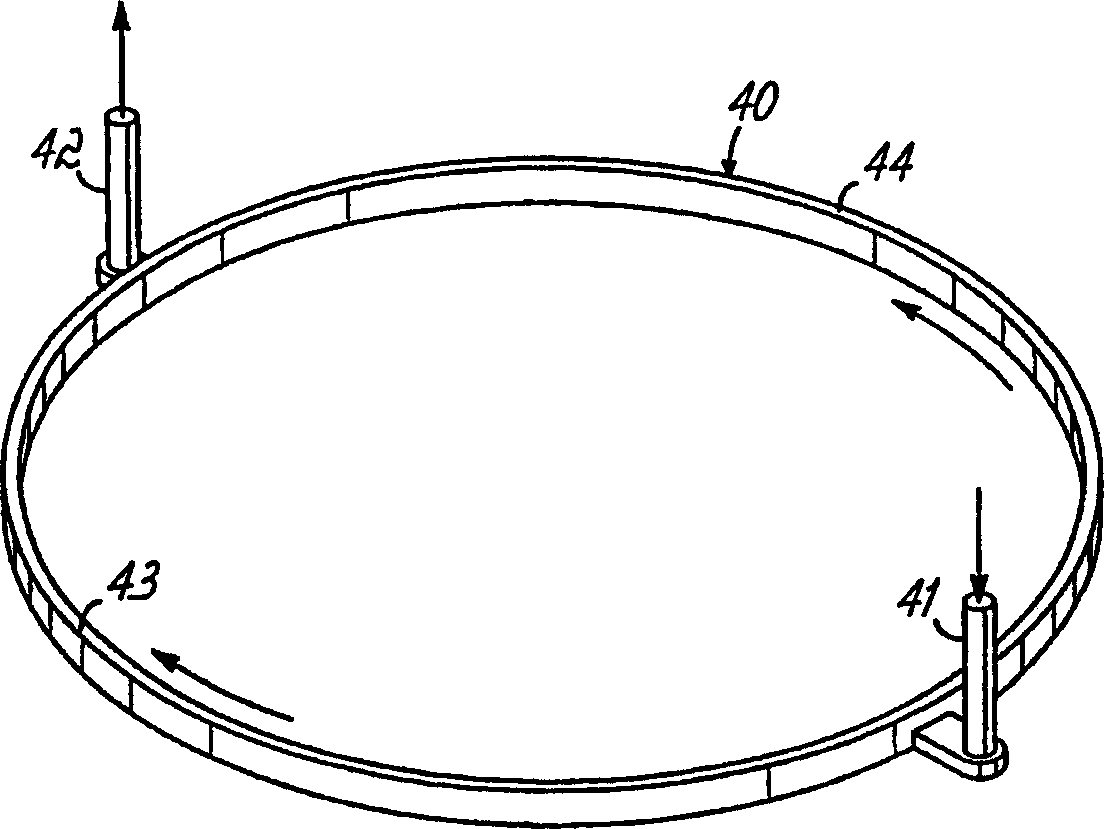

The present application discloses an apparatus and a method for synchronizing the activation of a light source with the position of a hand piece on a surface and for providing a substantially homogenous exposure of a surface to light irradiation. The apparatus includes a light source, a handpiece for delivering light pulses to the irradiated surface, and a beam delivery system for delivering light from the light source to the handpiece. The handpiece, which is moved along the surface by an operator, includes a sensor for sensing the distance traversed by the handpiece on the surface. The sensor sends signals to a signal processing unit which calculates the distance traversed by the handpiece on the surface and controls the activation of the light source either by automatically activating the light source or by providing the operator with a signal indicating that the light source should be pulsed. The handpiece can also include a device for cooling the irradiated surface and for marking the irradiated part of the surface with a visible marker. The handpiece may be constructed to be movable along a surface in a predetermined orientation relative to the handpiece. Alternatively, the handpiece may be freely movable along the surface in any desired orientation. The light source can be a pulsed laser, a continuous wave laser or a non-coherent light source.

Owner:TALPALRIU GERARD +4

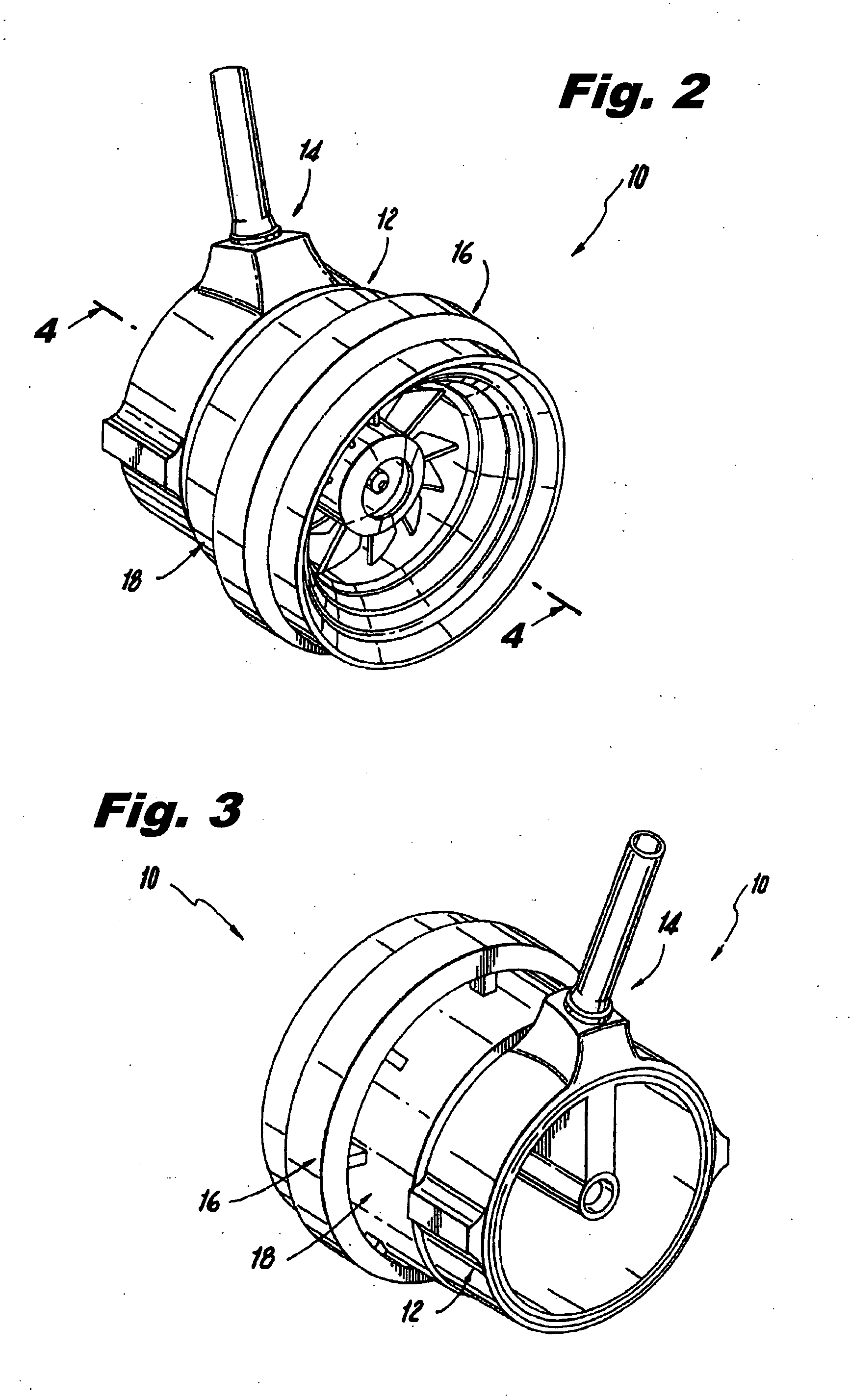

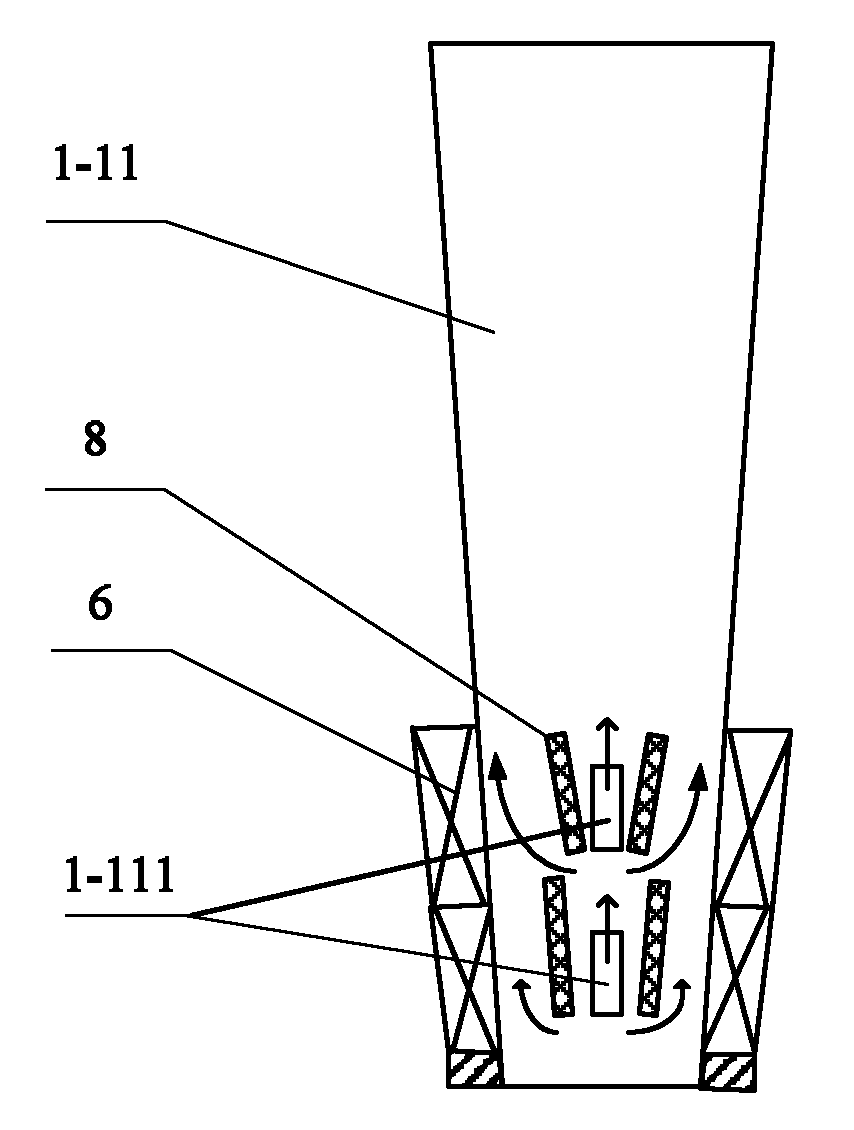

Systems and method for cooling a staged airblast fuel injector

ActiveUS20120228397A1High engine powerAvoid scorchingBurnersContinuous combustion chamberInjectorEngine power

The present invention is directed to a staged fuel injector that includes, inter alia, a main fuel circuit for delivering fuel to a main fuel atomizer and a pilot fuel circuit for delivering fuel to a pilot fuel atomizer which is located radially inward of the main fuel atomizer. The main fuel atomizer includes a radially outer prefilmer and a radially inner fuel swirler. Portions of the main fuel circuit are formed in the prefilmer and portions of the pilot fuel circuit are formed in the prefilmer and the fuel swirler and are positioned proximate to and in thermal contact with fuel exit ports associated with the main fuel circuit and formed in the prefilmer. As a result, the pilot fuel circuit cools the stagnant fuel located in main fuel circuit, including the exit ports, even when performing at engine power levels of up to 60% of the maximum take-off thrust.

Owner:ROLLS ROYCE PLC

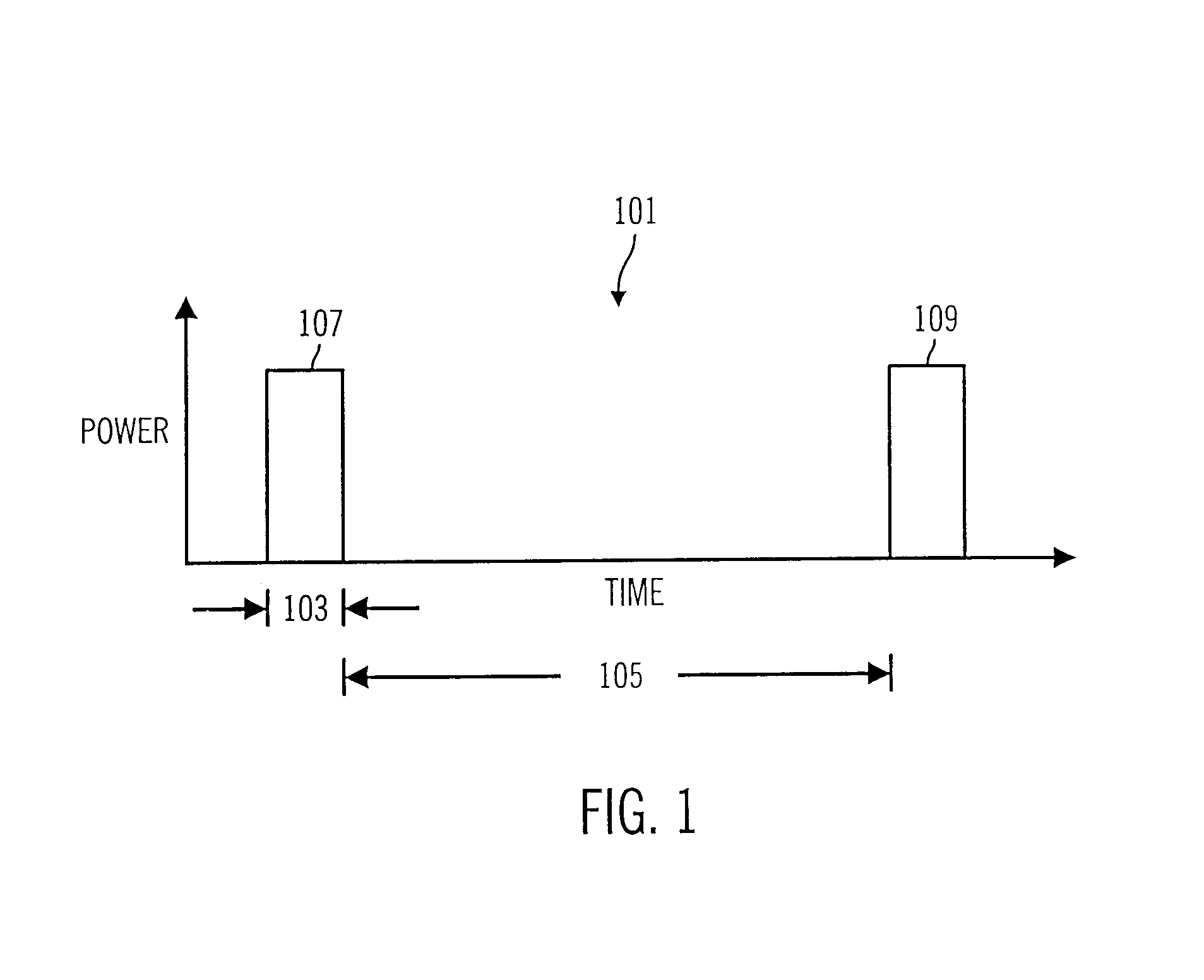

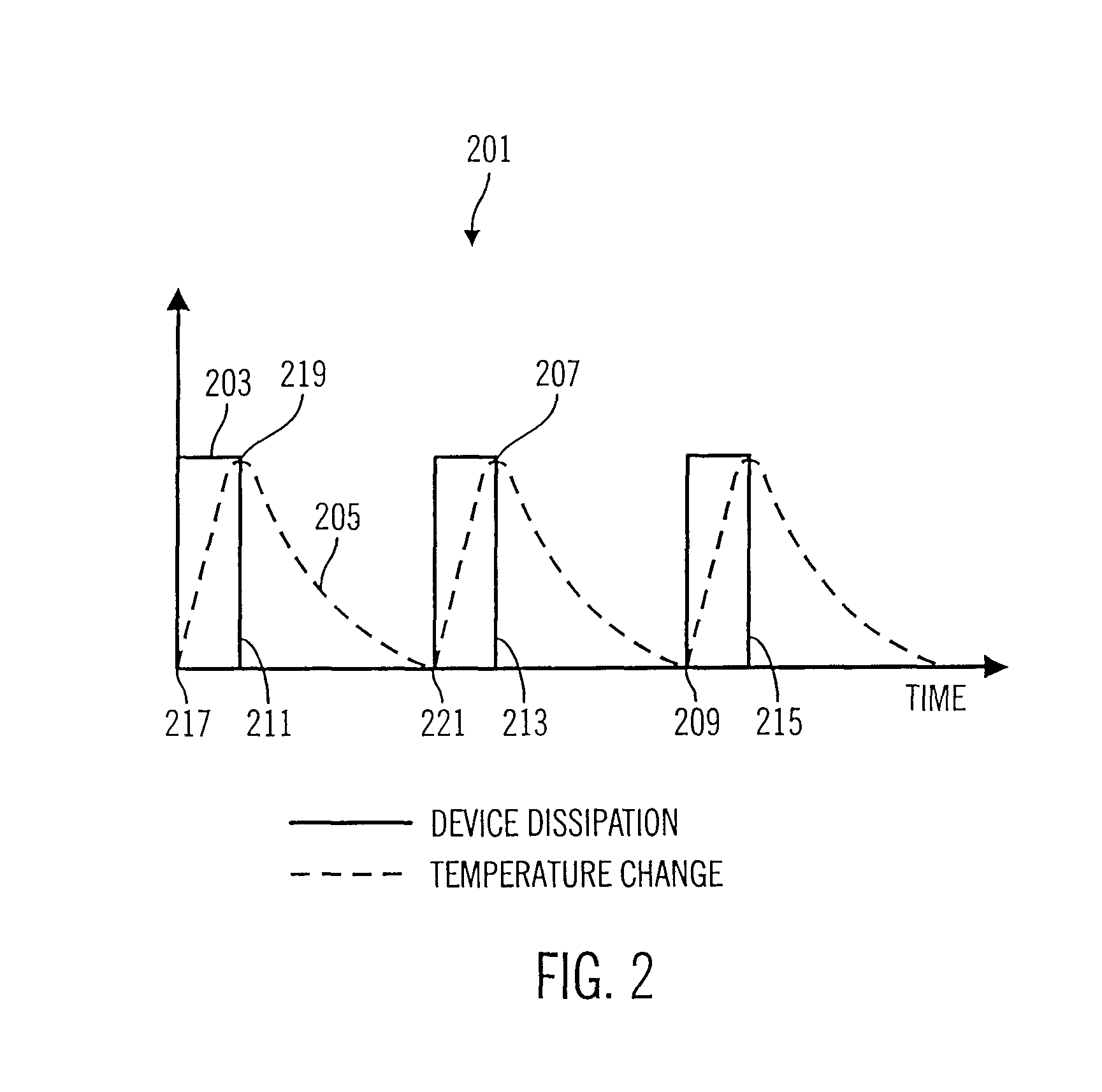

Cooling system for pulsed power electronics

InactiveUS6848500B1Reduce the maximum temperatureReduce temperature changesSemiconductor/solid-state device detailsSolid-state devicesPeak valuePhase-change material

The invention discloses an apparatus for reducing peak temperatures and thermal excursions, of semiconductor devices, particularly in pulsed power applications. The apparatus comprises thermally coupling Phase Change Material (PCM) to the dissipating semiconductor device. PCM absorbs heat and stays at a constant temperature during its phase change from solid to liquid. The PCM melting point is chosen so that it is just below the temperature the device would otherwise achieve. When the device approaches the maximum temperature, the PCM melts, drawing heat from the device and lowering the device's peak temperature. As the device stops dissipating, after its pulse period, the PCM material solidifies releasing the heat it absorbed. The apparatus lowers the peak temperature by absorbing heat when the device is dissipating. The apparatus also keeps the semiconductor device from cooling off as much as it would cool without the apparatus, as the PCM material releases heat during the part of the cycle when it is re-solidifying, i.e. when the pulse power is off. By lowering the peak temperature the device achieves, and increasing the temperature of the device when it is in the off portion of its pulsed power cycle the temperature excursions of the device during operation are reduced. By reducing the temperature swings, that the device sees during operation, the thermal stress is reduced and the reliability of the device is improved.

Owner:SKYWORKS SOLUTIONS INC

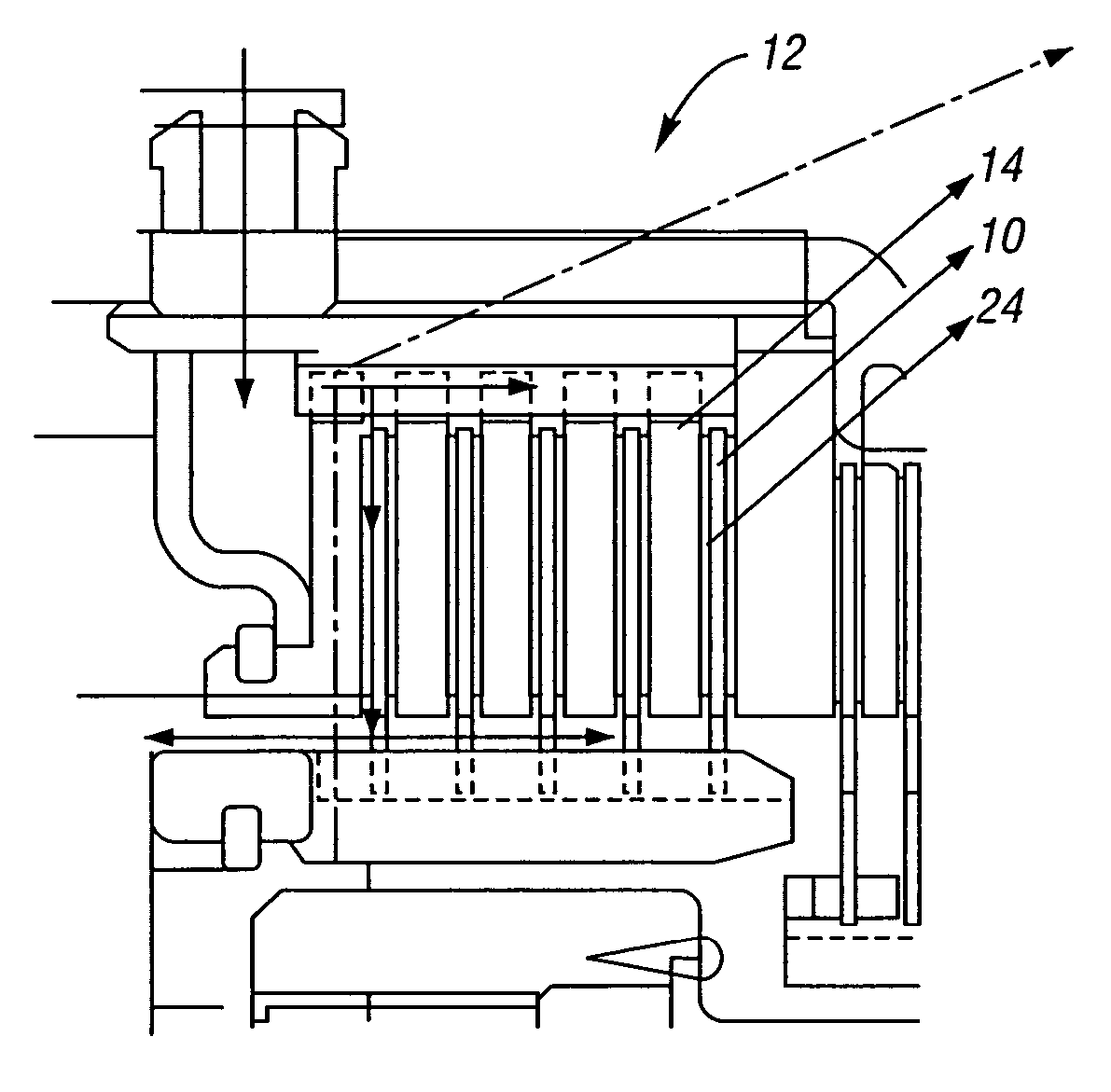

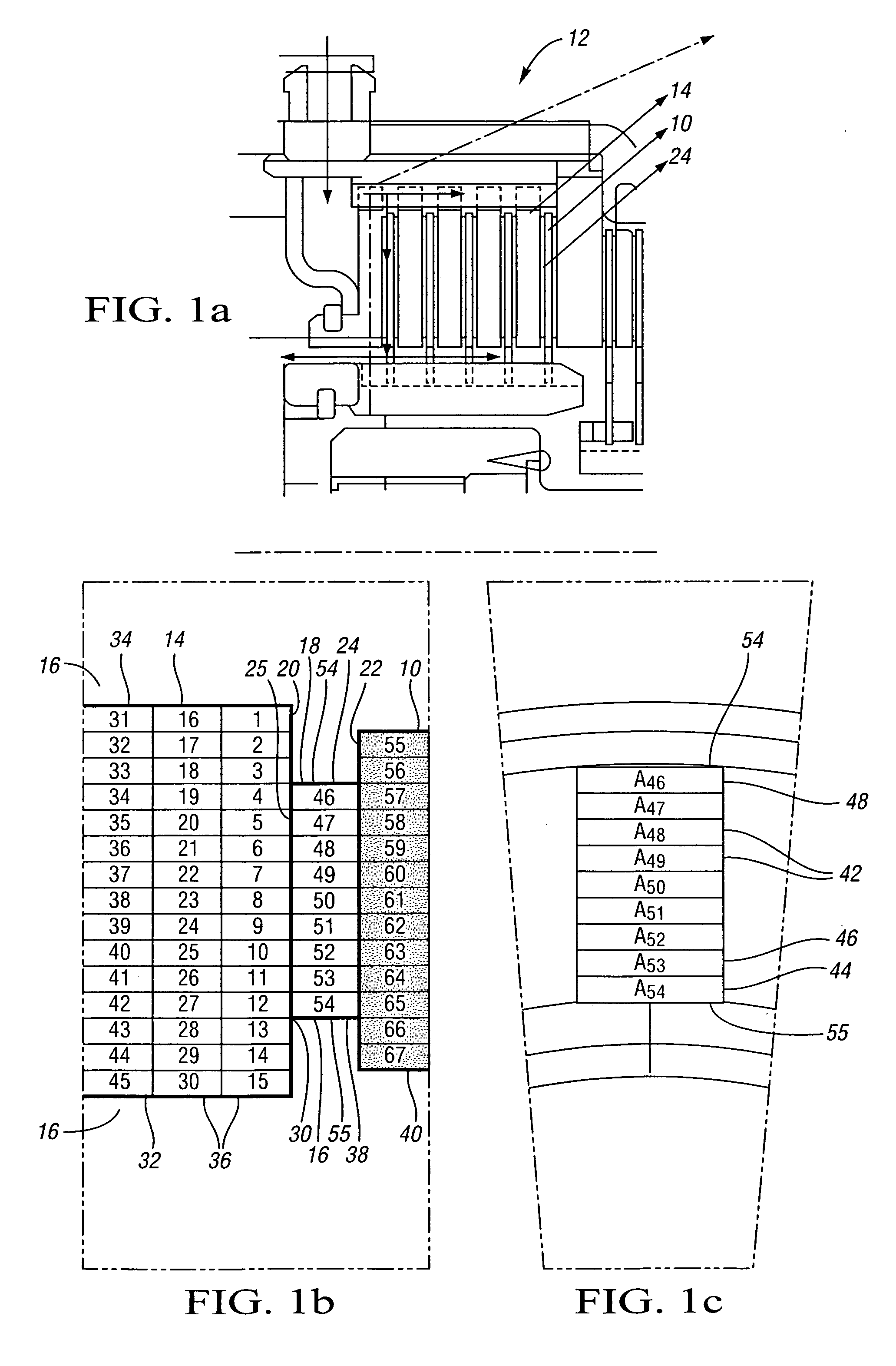

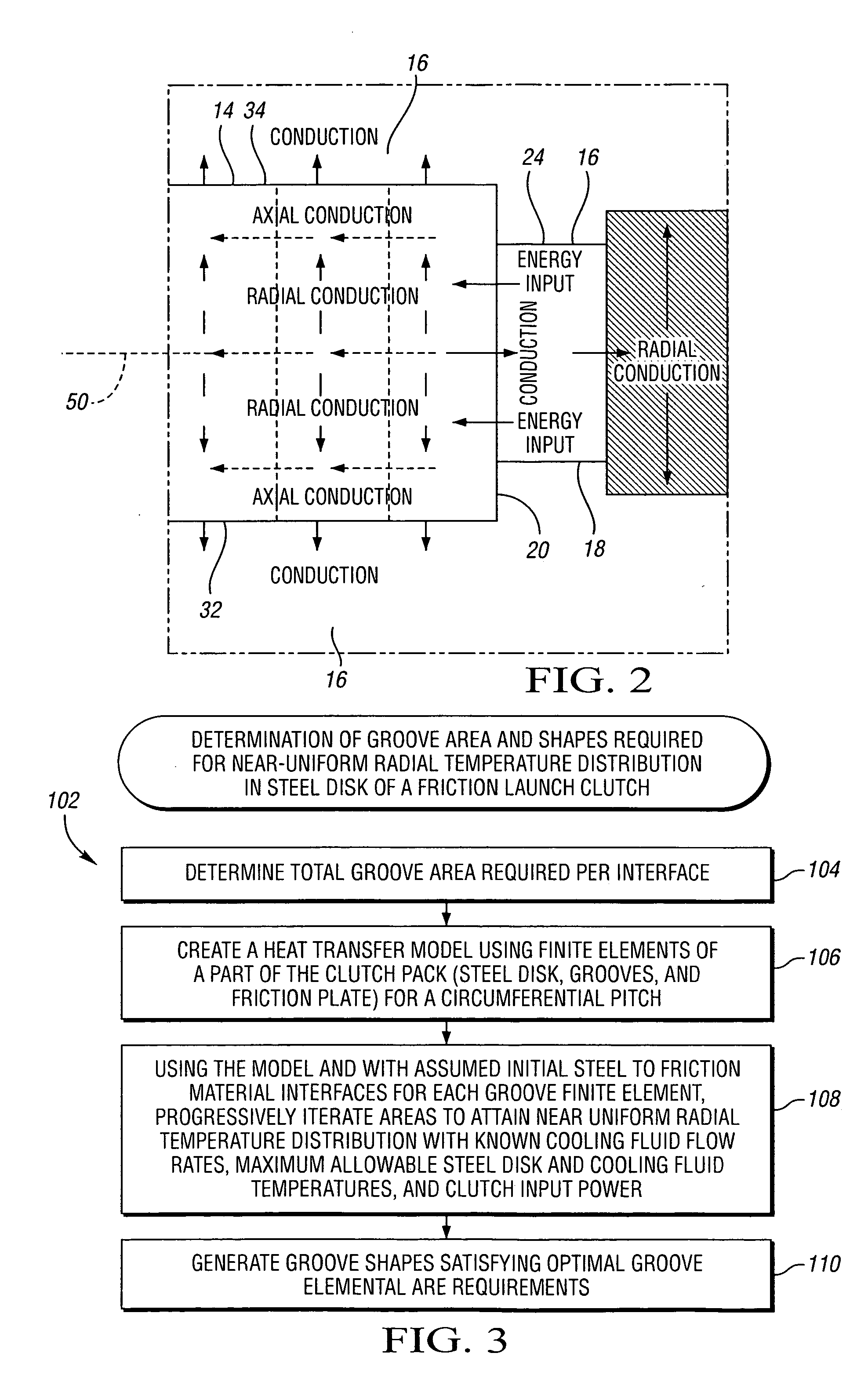

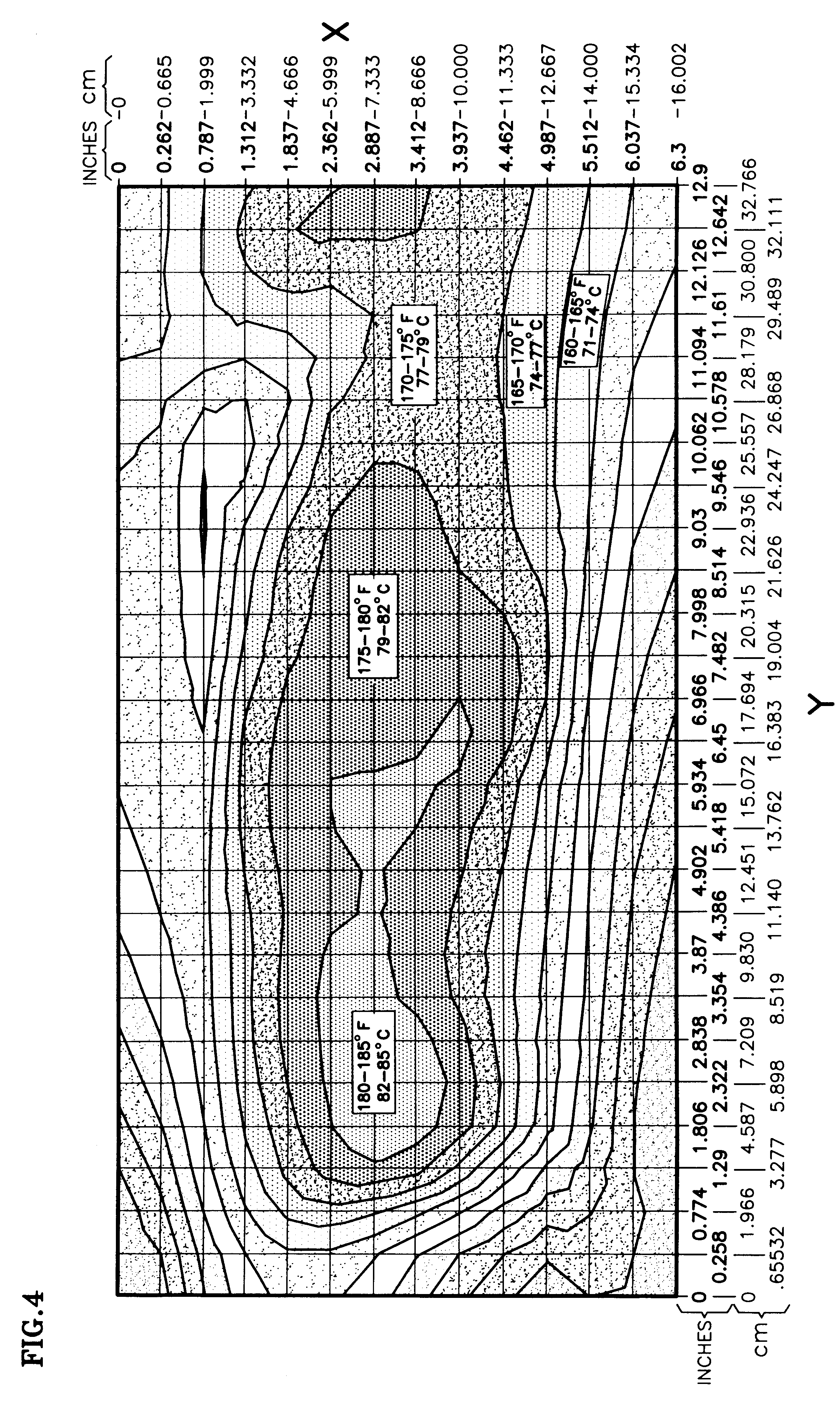

Clutch cooling grooves for uniform plate temperature in friction launch

InactiveUS20050284721A1Minimize heat distortionReduce the temperatureFluid actuated clutchesFriction clutchesEngineeringCooling fluid

Clutch cooling grooves formed on a friction plate are provided. The grooves are shaped to provide for substantially uniform steel disk temperatures in friction launch of a vehicle. The grooves are shaped such that the largest cross-sectional area is located adjacent to what would otherwise have been a hot area on the steel disk and the smallest cross-sectional area is located at the coolest location on the steel disk, at the cooling fluid inlet. Thus, the groove is shaped such that the smallest cross-sectional area is located at the cooling fluid inlet, the largest cross-sectional area is located between the cooling fluid inlet and the cooling fluid outlet, and the cooling fluid outlet has a cross-sectional area larger than the cooling fluid inlet and smaller than the cross-sectional area adjacent to the hot spot of the steel disk, between the cooling fluid inlet and the cooling fluid outlet.

Owner:GM GLOBAL TECH OPERATIONS LLC

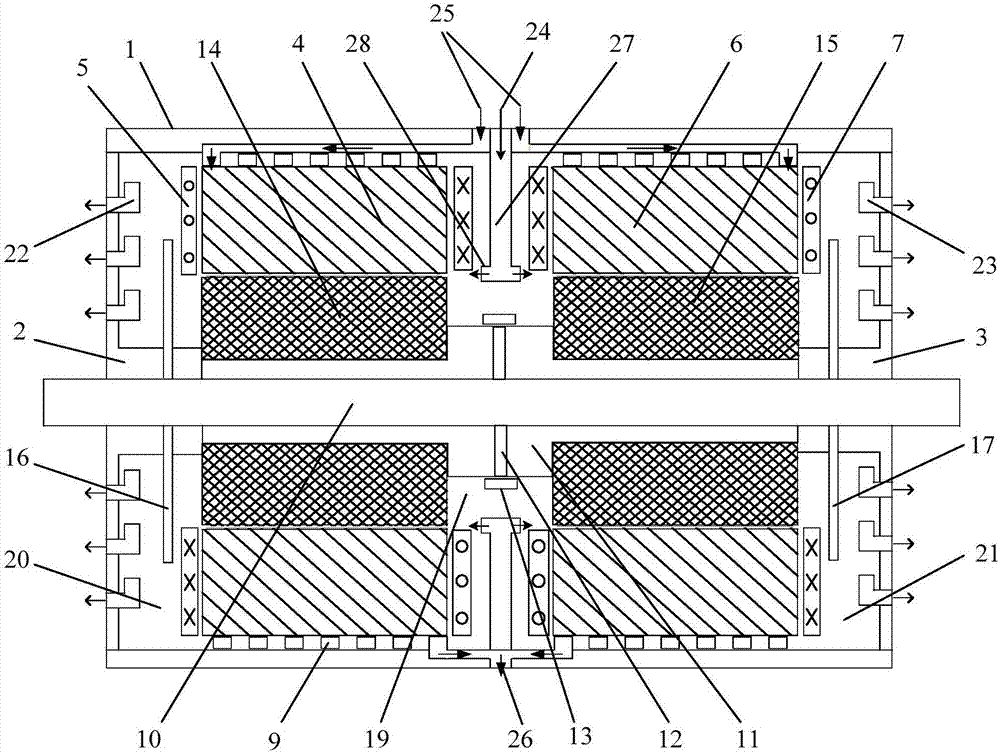

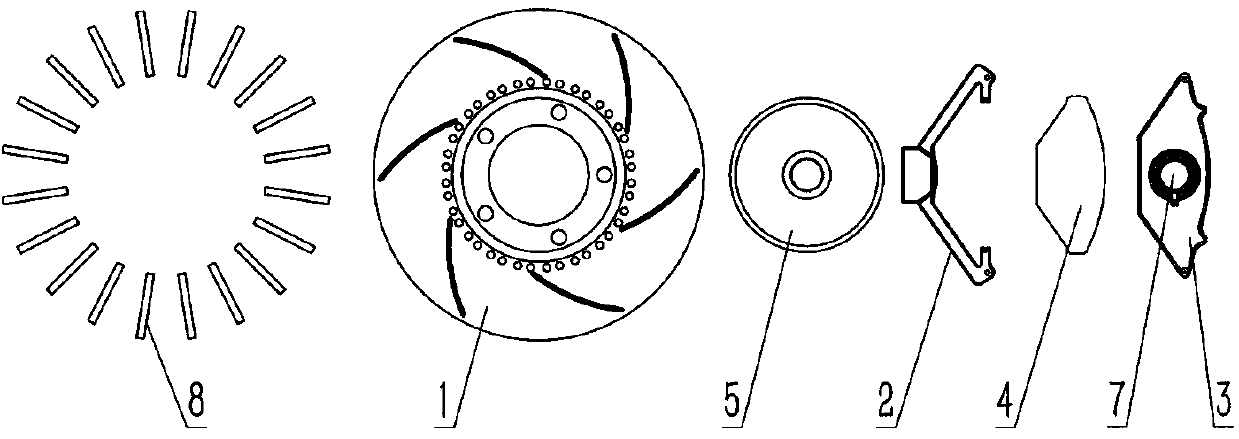

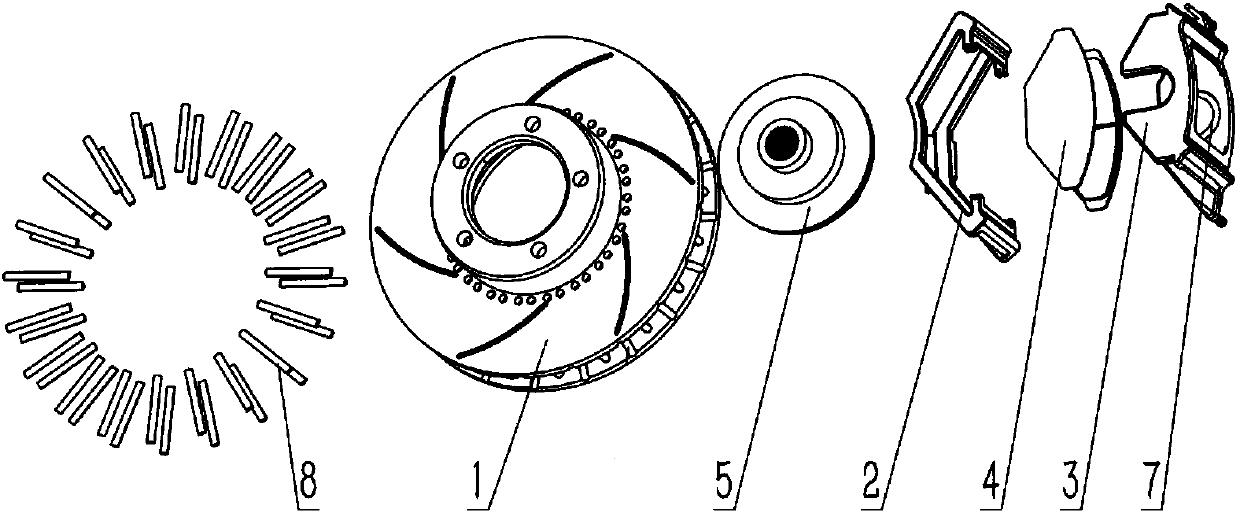

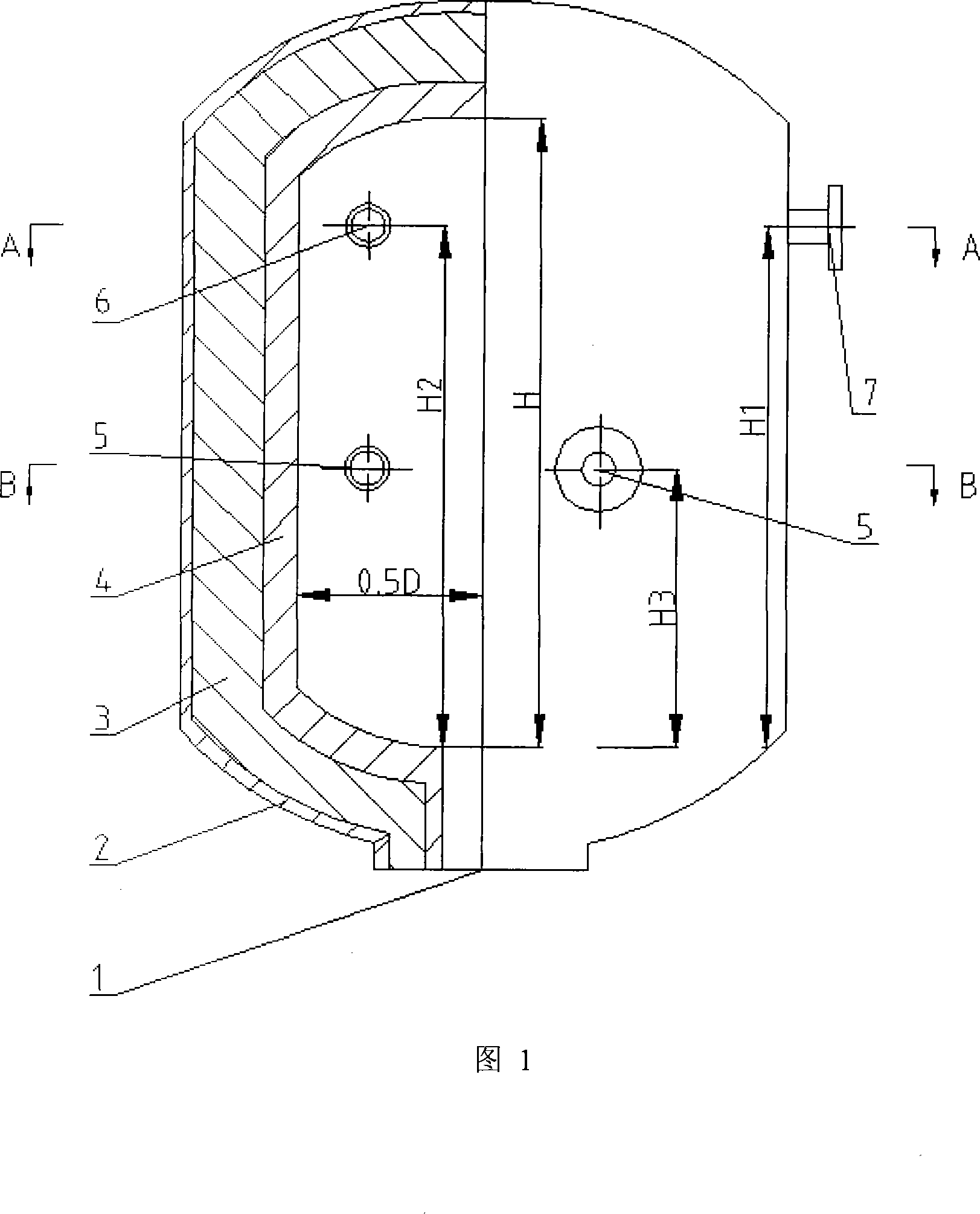

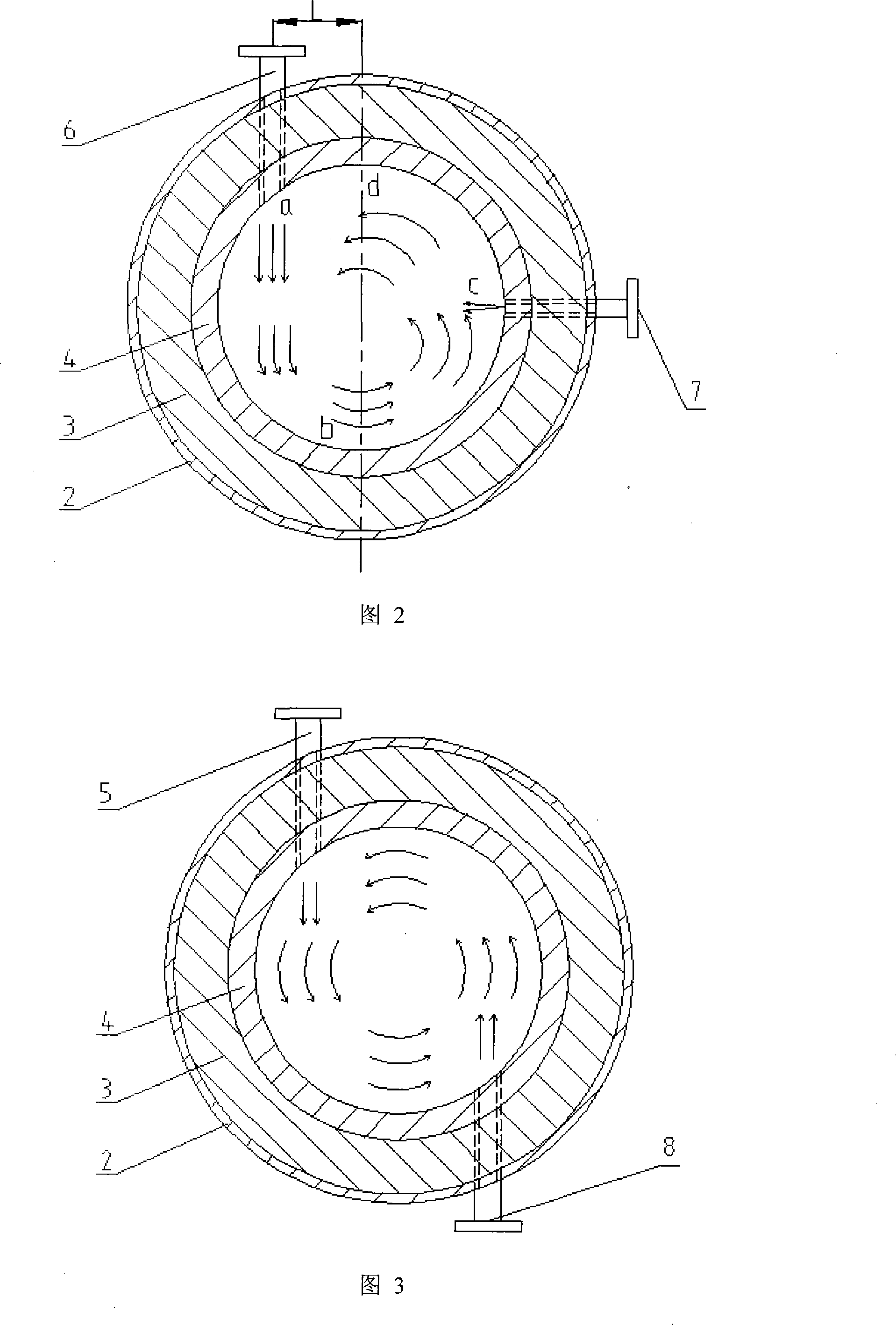

Axial permanent magnet assisted radial reluctance high-speed motor with hybrid cooling structure

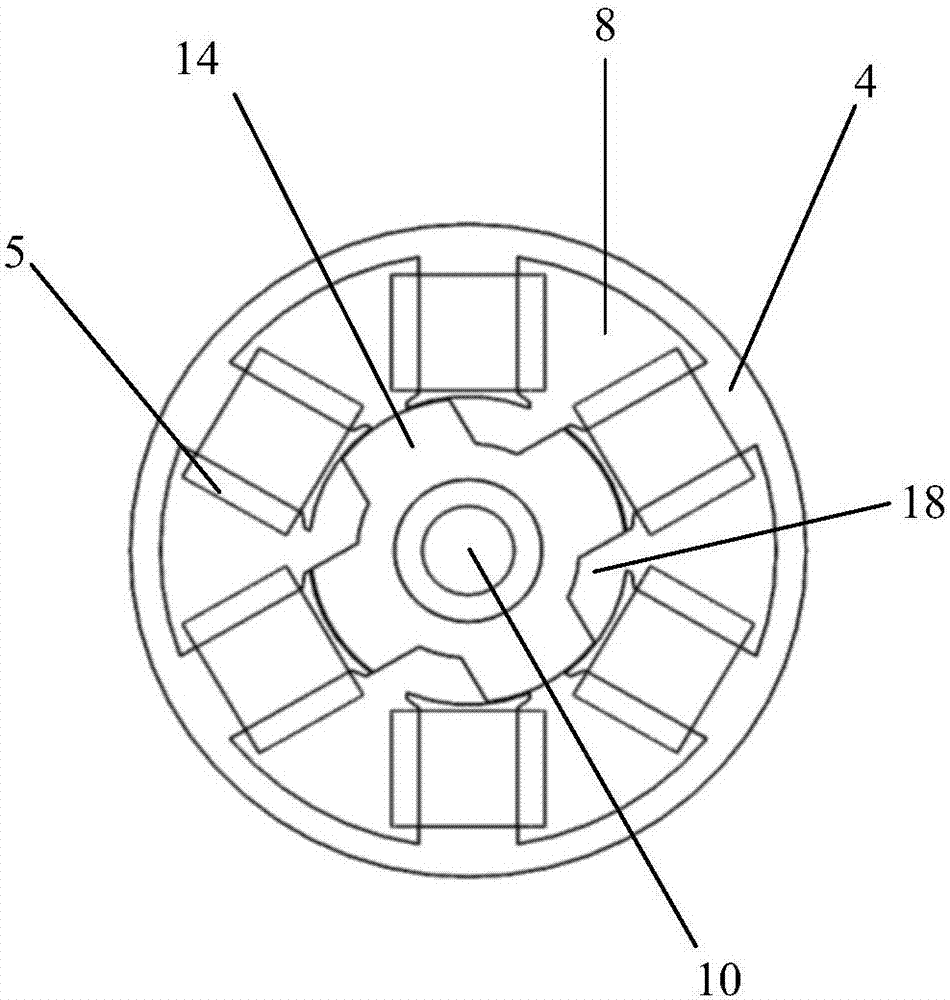

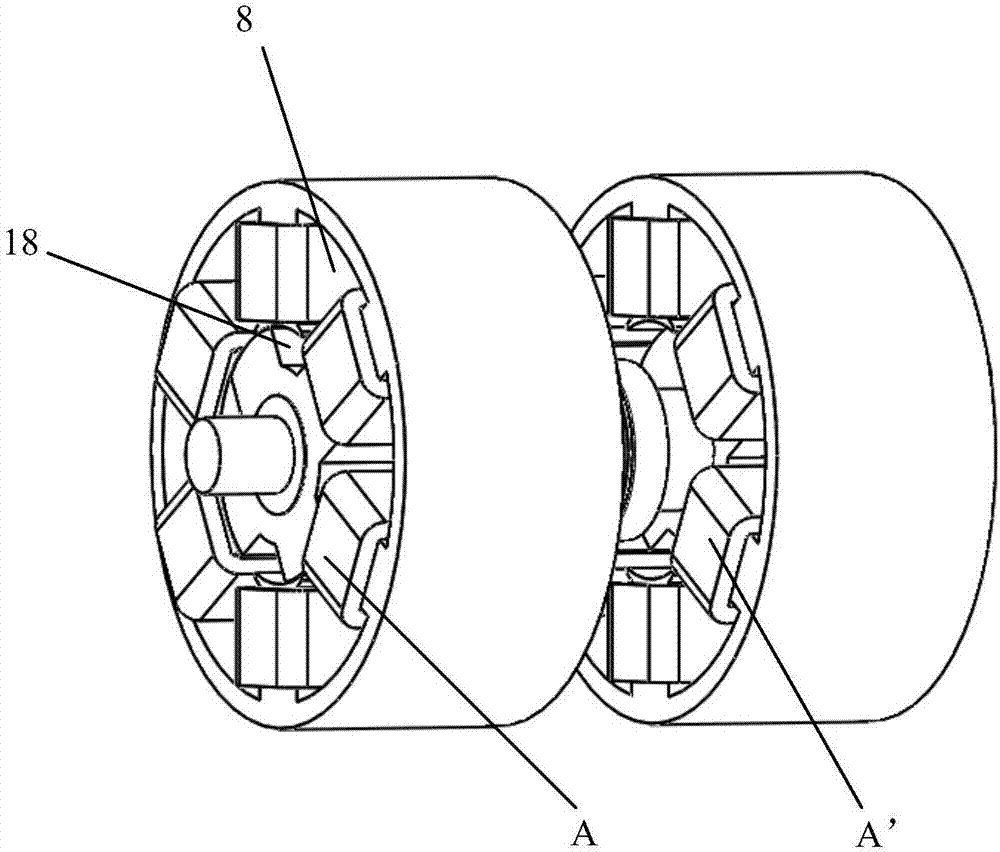

PendingCN107147260AReduce consumptionReduce copper consumptionMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic reluctance

The invention provides an axial permanent magnet assisted radial reluctance high-speed motor with a hybrid cooling structure, and relates to the technical field of motors. The motor provided by the invention is provided with an air cooling and water cooling structure on the basis of a dual group 6 / 4-pole switched reluctance motor structure. The motor comprises a casing, a front end cover, a rear end cover, a rotor and a stator, and is characterized in that an inter-tooth slot of the stator and the rotor form a cooling air channel, each end cover is provided with air discharging holes, the casing is provided with a cooling air inlet, a cooling water inlet pipe opening, a cooling water outlet pipe opening and a circumferential ring-shaped air guiding channel, the back of a ring yoke of the stator is provided with a spiral water channel pipe, and two ends of the rotor are provided with self-cooling fans respectively. According to the invention, a cooling structure combining the air cooling stator and the water cooling stator is adopted, and a water cooling function and an air cooling function are opposite in direction and complementary in cooling region, so that the stator and the rotor of the motor are effectively enabled to be reduced in temperature, a problem of difficult heat dissipation of the motor under a high-speed operating condition is avoided, thus long-term safe and stable running of the motor is ensured, and the service life of the motor is effectively prolonged.

Owner:SHENYANG POLYTECHNIC UNIV

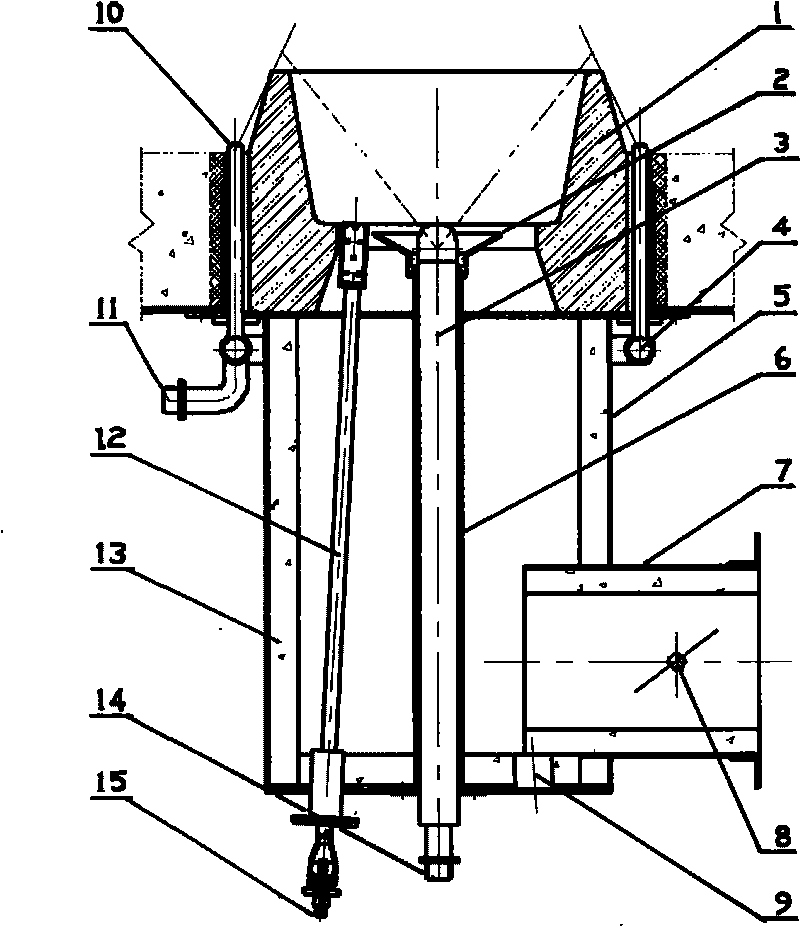

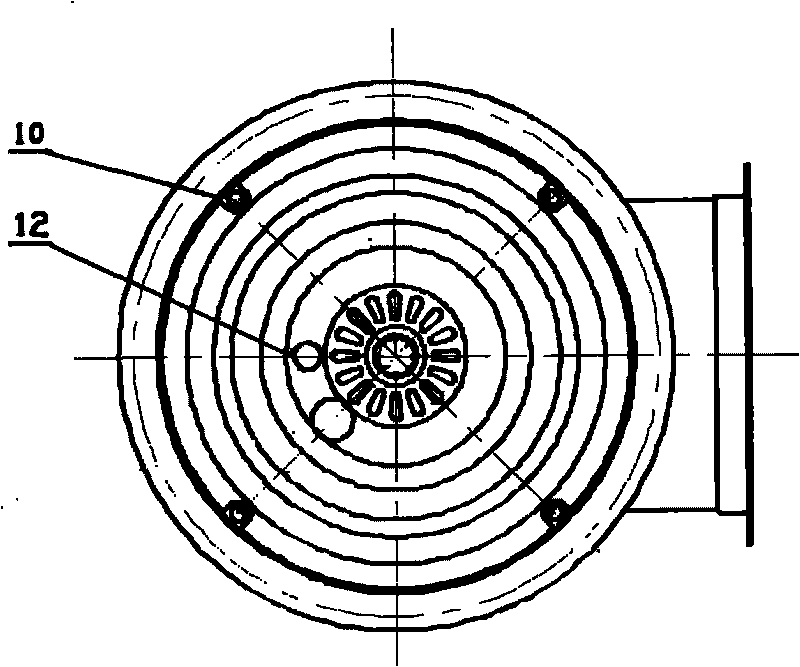

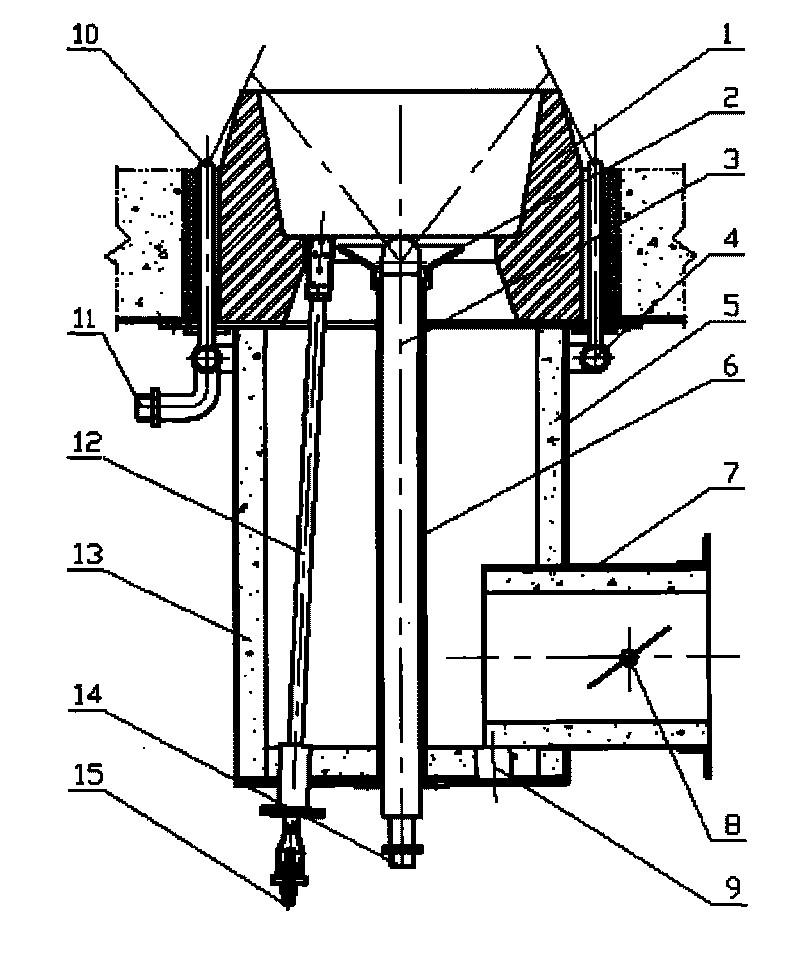

Steam turbine generator provided with axial-radial ventilating and cooling system

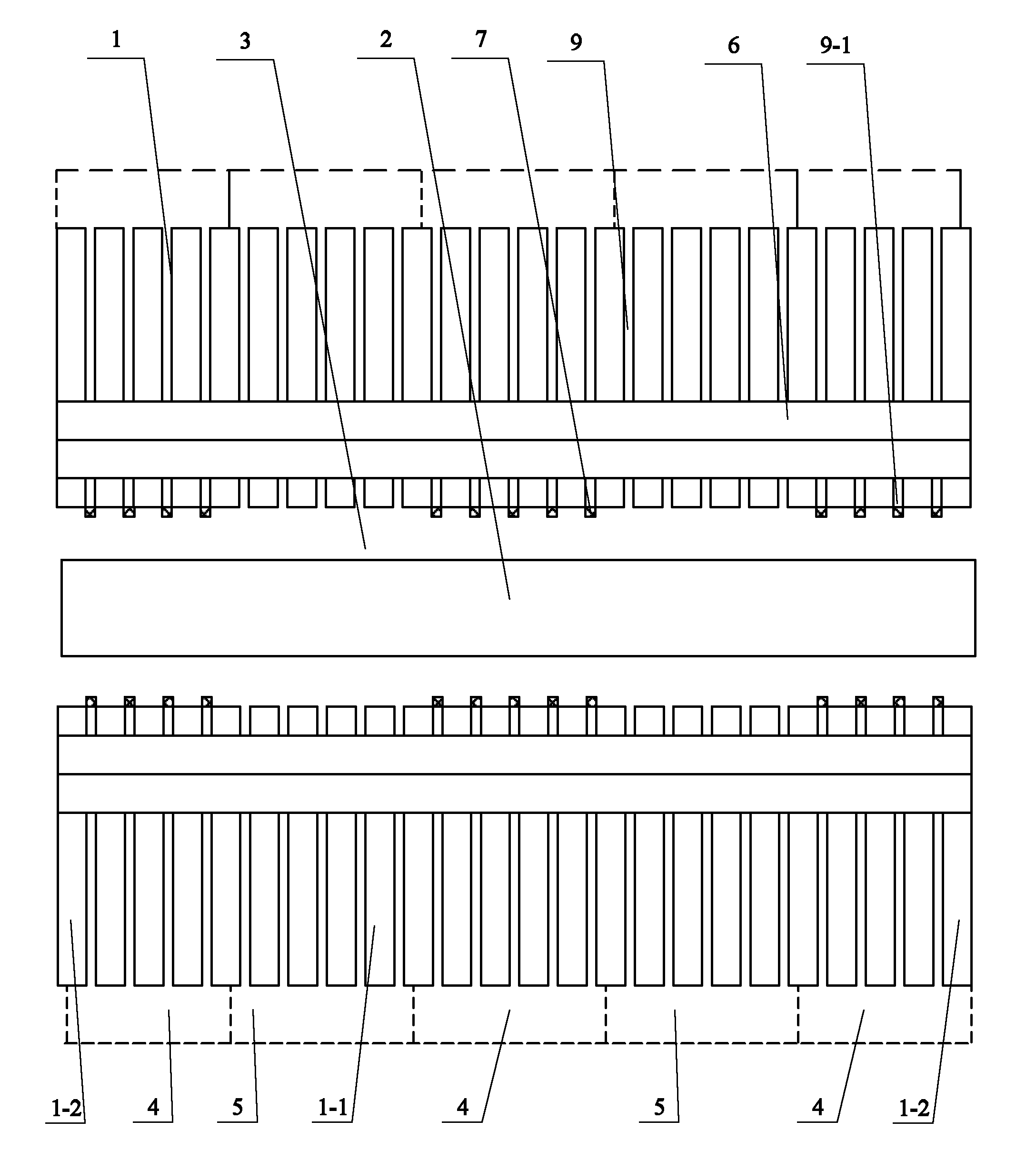

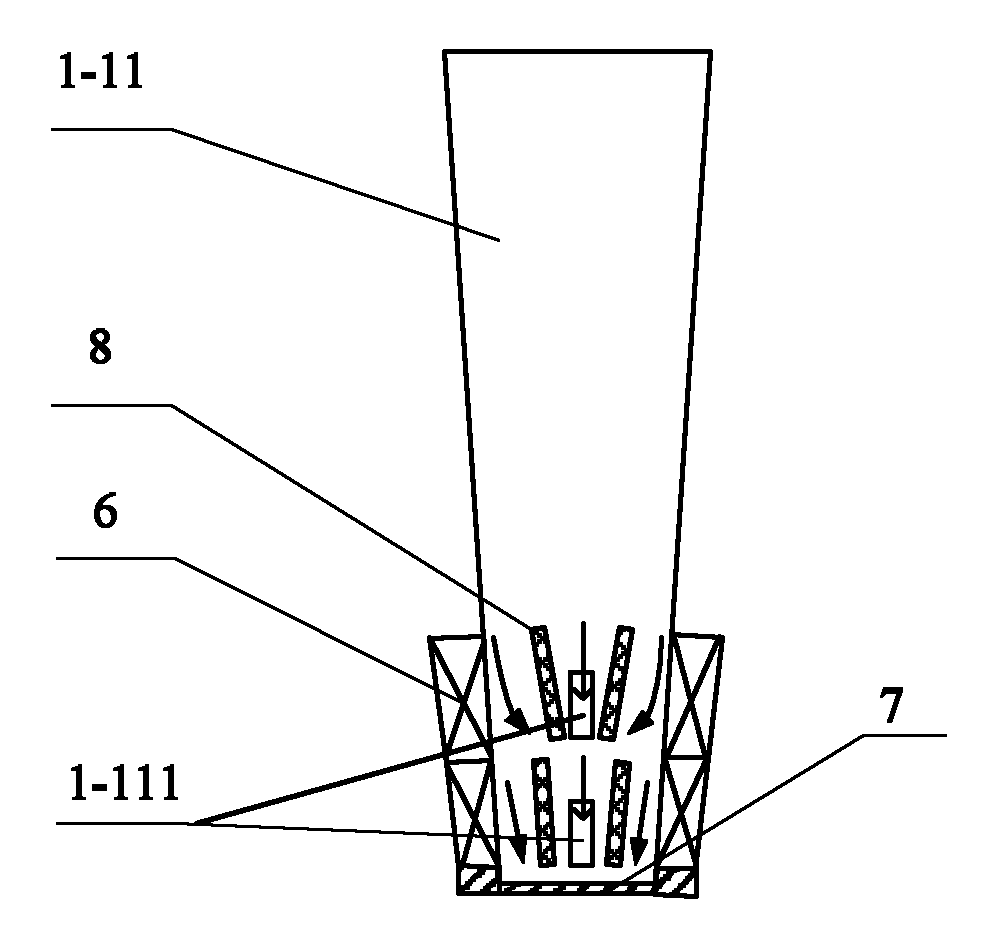

ActiveCN102064635AEnhanced convective heat transferIncrease cooling areaMagnetic circuit stationary partsCooling/ventillation arrangementCold airNon magnetic

The invention relates to a steam turbine generator provided with an axial-radial ventilating and cooling system, which belongs to the technical field of cooling of a large air-cooling steam turbine generator and aims to improve the heat dissipation capacity of a stator winding of the large air-cooling steam turbine generator. A plurality of non magnetic-conducting distance rings are additionally provided on the basis of the ventilating and cooling system of a traditional steam turbine generator, one non magnetic-conducting distance ring is arranged at a cold air outlet of each radial ventilating duct in a cold air area to realize sealing, four sectionalized baffle plates are arranged on each stator tooth on each intermediate stator core, two axial air holes are arranged on each stator tooth on the intermediate stator core, the axial air holes axially run through along the stator teeth, the two axial air holes are arranged on each stator tooth along the radial direction, the position of each axial air hole on the stator tooth corresponds to the winding position of the stator winding, and two sides of each axial air hole are provided with two sectionalized baffle plates along the peripheral direction of a stator in a mirror symmetrical way. The steam turbine generator provided with the axial-radial ventilating and cooling system is used for cooling the steam turbine generator.

Owner:HARBIN UNIV OF SCI & TECH

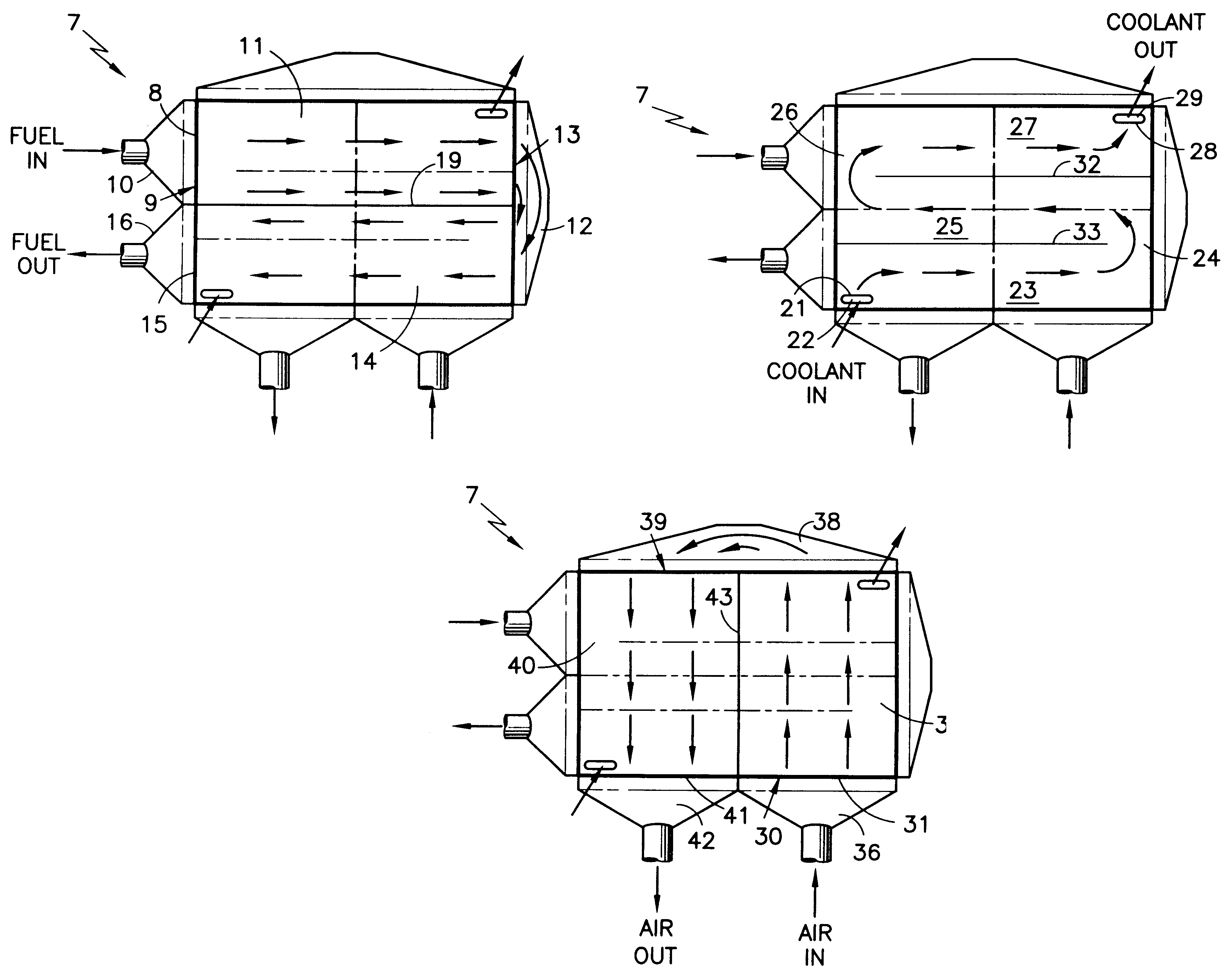

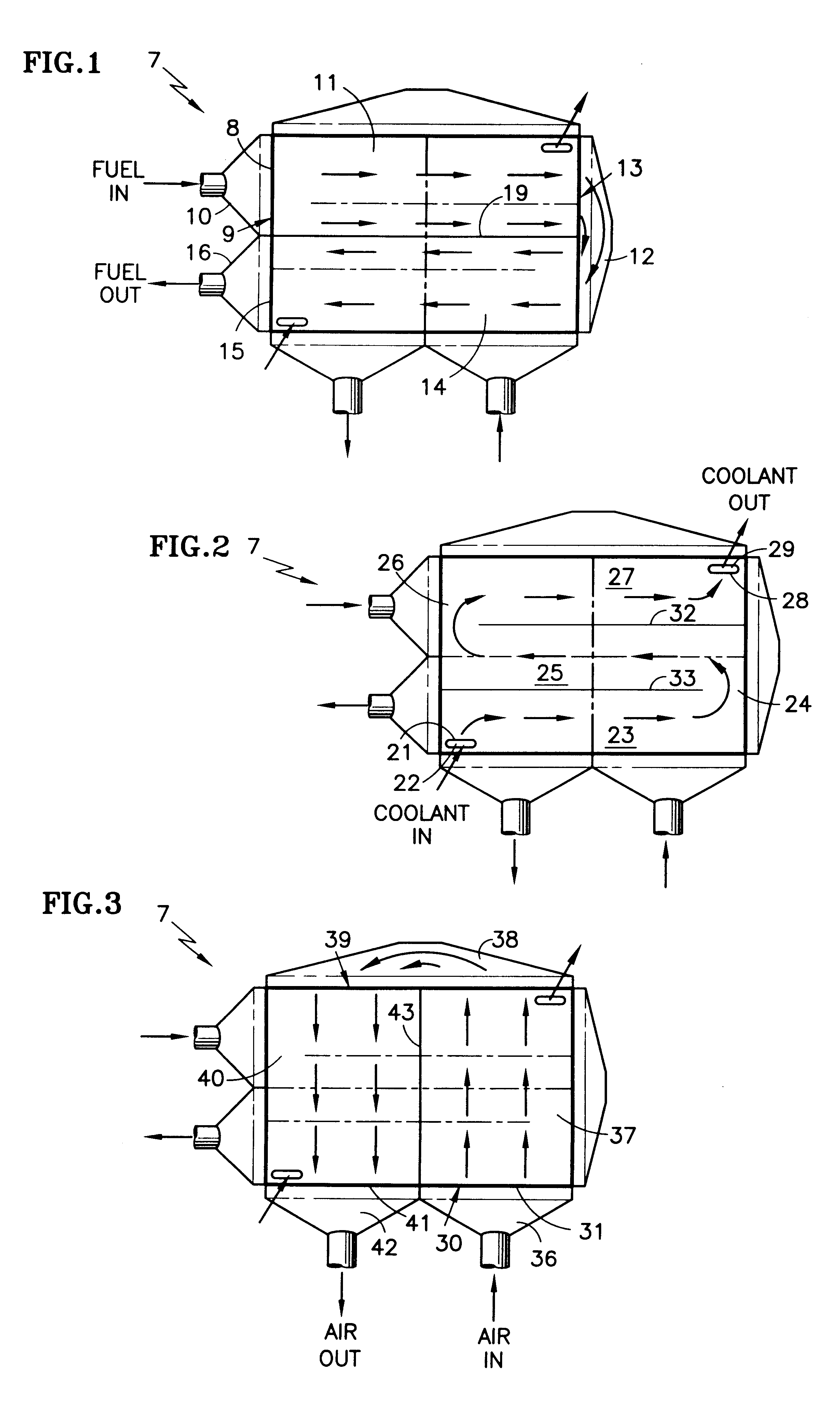

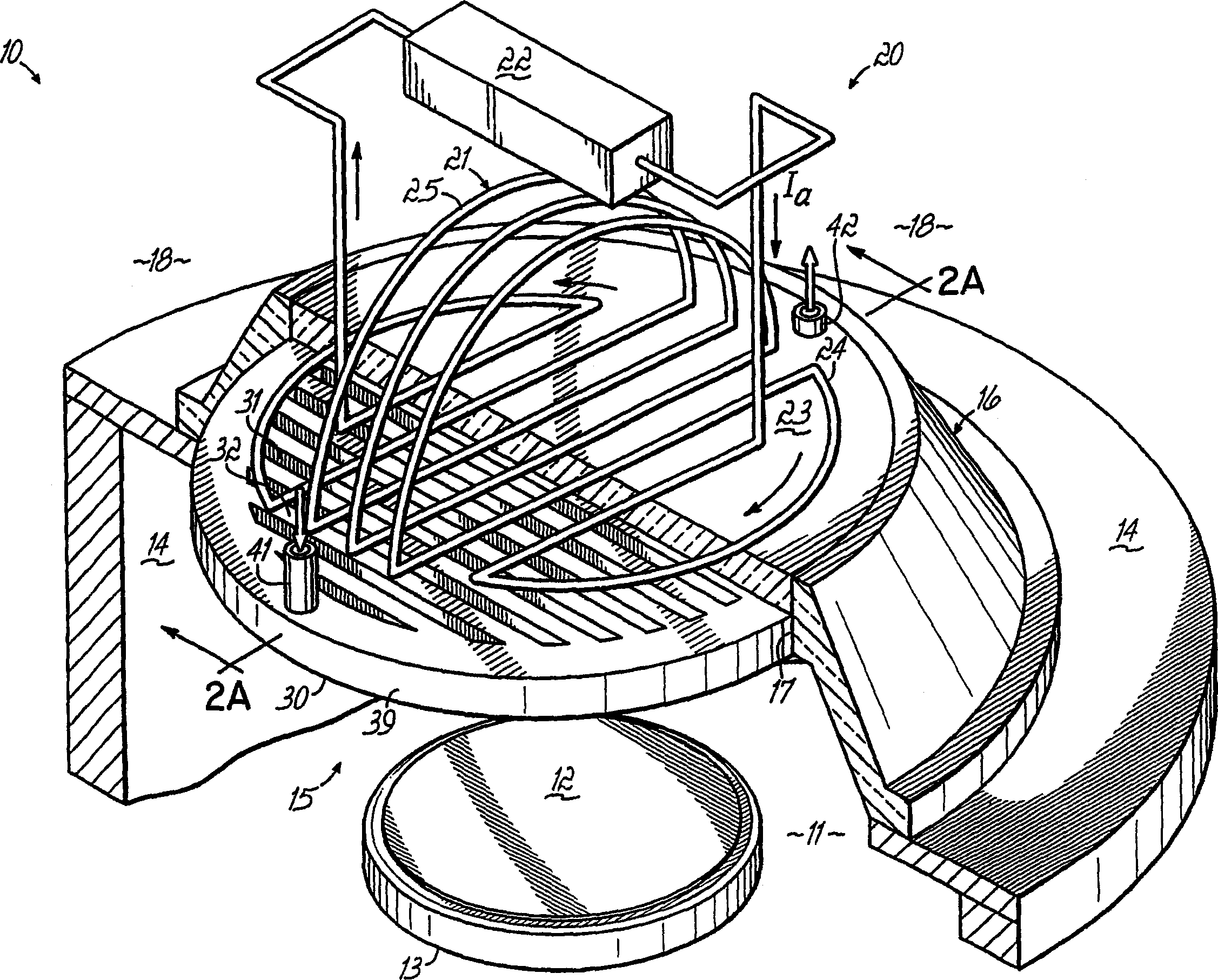

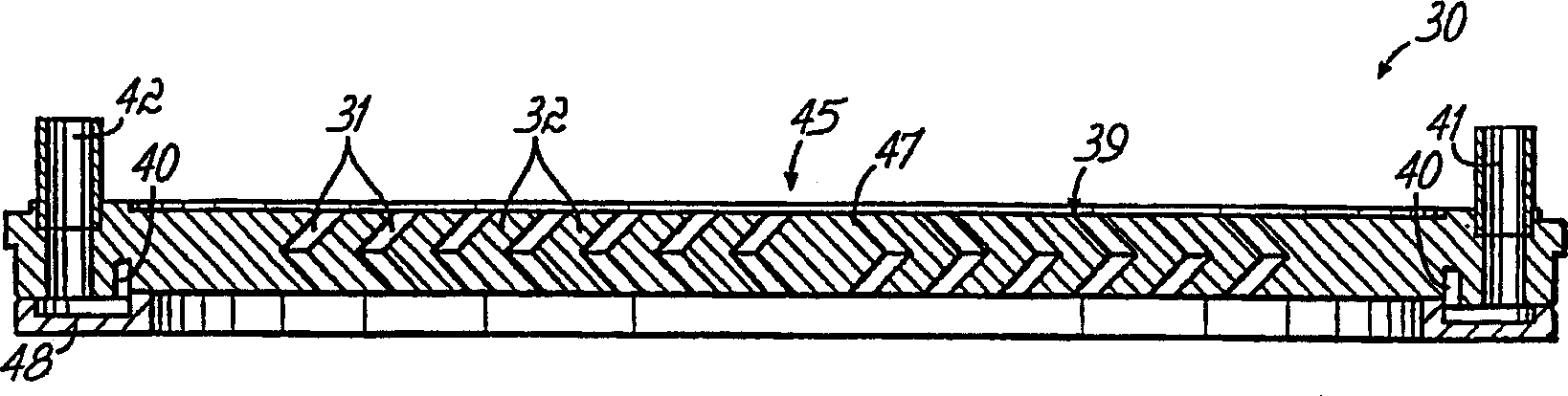

Fluid flow control for cool, efficient fuel cell operation

InactiveUS6572995B2Reduce the maximum temperatureImprove performanceFuel cell heat exchangeFuel cells groupingFuel cellsCoolant flow

A fuel cell stack (7) has a two-pass fuel flow field (11, 14) extending from a fuel inlet (8) around a fuel turnaround manifold (12) to a fuel outlet (15). The stack has two air flow fields (37, 40) extending from an air inlet (32) through an air turnaround manifold (38) to an air outlet (41), the air outlet (41) being adjacent to the fuel outlet (15). The stack includes a coolant flow field (23, 25, 27) which extends from a coolant inlet (21) to a coolant outlet (28), the coolant inlet being adjacent to both the fuel outlet and the air outlet. The fluid flow configuration provides lower temperature, a more even temperature profile, a higher coolant exit temperature, and permits operation with higher air utilization and lower coolant flow.

Owner:AUDI AG

Low-entropy mixed-fuel engine

InactiveCN101832199AImprove load responseMeet the requirements of instantaneous power outputNon-fuel substance addition to fuelMachines/enginesCombustion chamberEngineering

The invention discloses a low-entropy mixed-fuel engine which comprises an air cylinder, an air cylinder cover, a piston, a working medium storage box, an exhaust passage and a combustion chamber. A high-pressure fluid channel is arranged inside or outside of a side wall of the air cylinder and inside or outside of the air cylinder cover; the bearing capability of the high-pressure fluid channel is more than or equal to 1MPa; the low-entropy mixed-fuel engine also comprises an exhaust heat exchanger, wherein the exhaust passage is communicated with an inlet of a heating fluid of the exhaust heat exchanger; an outlet of the high-pressure fluid channel is communicated with a steam ejector through an ejection control valve; the steam ejector is communicated with the combustion chamber, and the ejection control valve is set to be a correct-time control valve; or an outlet of the high-pressure fluid channel is communicated with an inlet of a working medium of a heat engine, and the working medium of the high-temperature high-pressure fluid generated in the high-pressure fluid channel pushes the heat engine to apply work. Because the low-entropy mixed-fuel engine effectively utilizes the afterheat of the engine, the heat-power conversion efficiency of the engine is improved with energy-saving and environment protection.

Owner:靳北彪

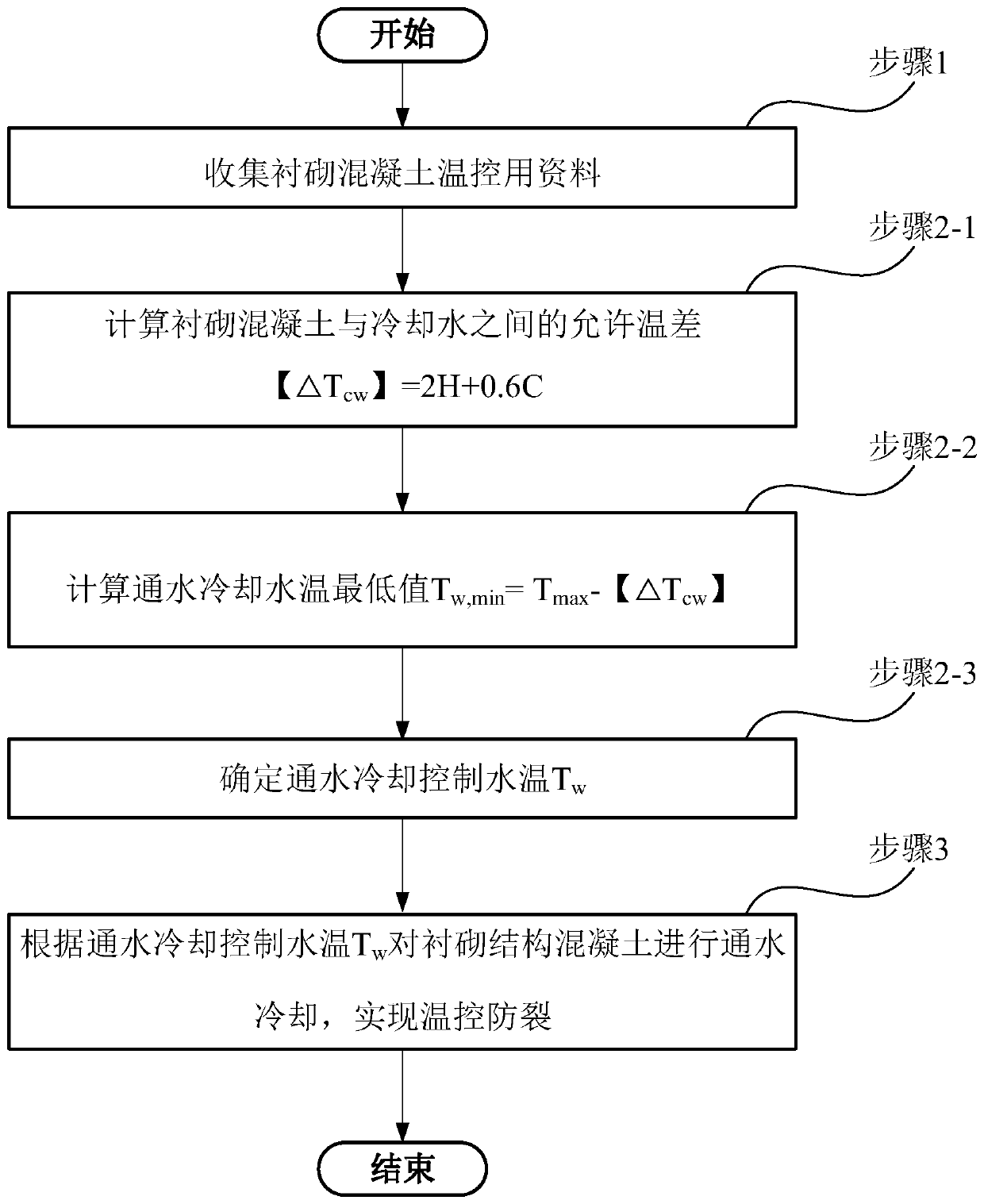

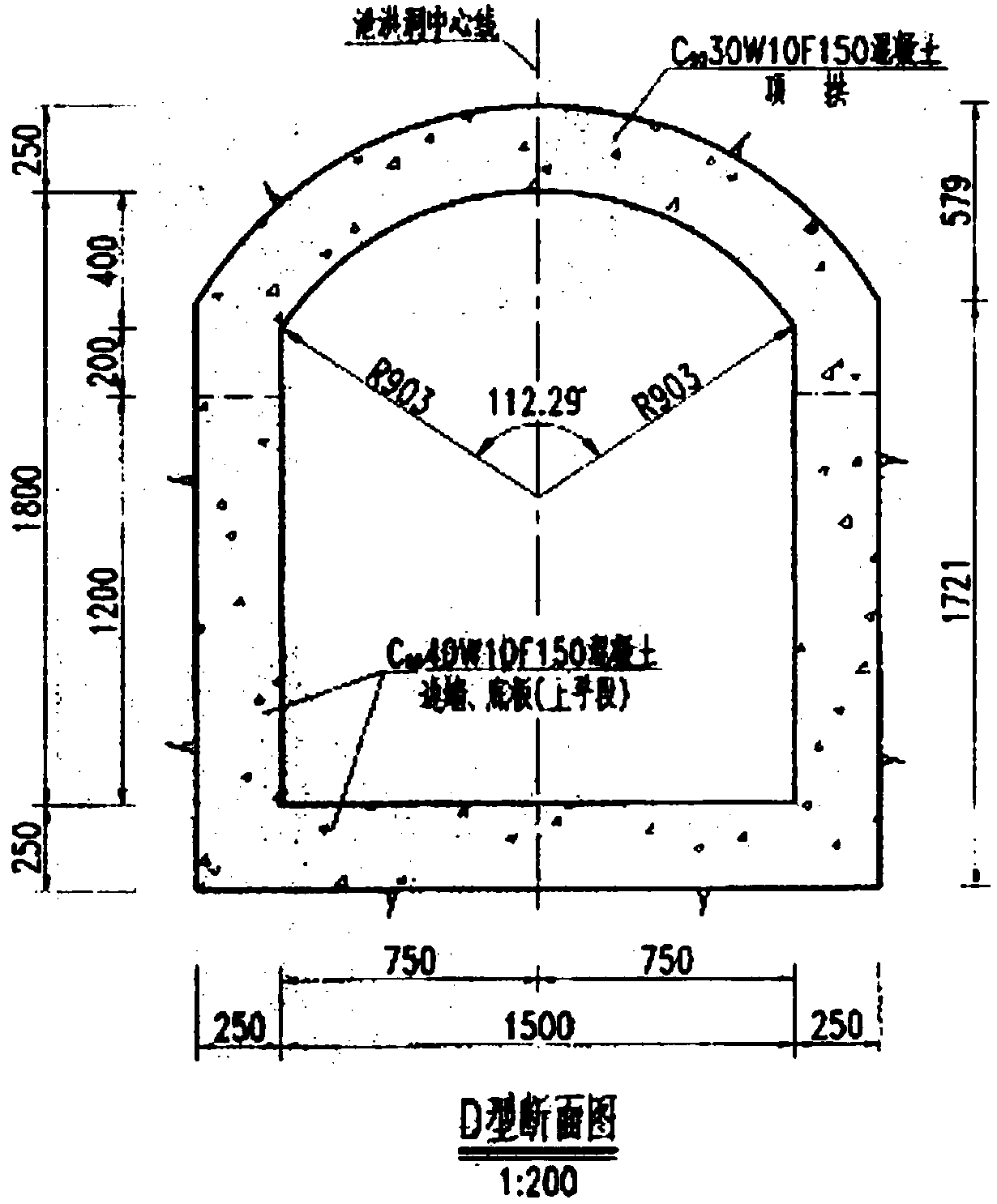

Lining structure concrete water cooling water temperature control method

ActiveCN110409387AAvoid manual control errorsReduce labor intensityWater-power plantsHydro energy generationTemperature controlEngineering

The invention provides a lining structure concrete water cooling water temperature control method. The method comprises the following steps: (1) lining concrete temperature control data is collected;(2) a water cooling control water temperature is calculated based on the collected lining concrete temperature control data, comprising: (2-1) an allowed temperature difference [delta Tcw]=2H+0.6 C between lining concrete and cooling water is calculated by a formula 1; (2-2) a water cooling water temperature lowest value Tw, min=Tmax-[delta Tcw] is calculated; and (2-3) the water cooling control water temperature Tw is determined: according to water temperature conditions in a construction site and the requirements of calculating the water cooling water temperature lowest value Tw, the water cooling control water temperature Tw is determined under the precondition of Tw not smaller than Tw, min; and (3) the water cooling is performed on lining structure concrete according to the water cooling control water temperature Tw to realize the temperature control cracking prevention to prevent cracks at the internals and pipe peripheries due to quicker temperature drop.

Owner:WUCHANG UNIV OF TECH +2

Micro porous friction material and its producing method

The present invention relates to one kind of microporous friction material and its production process. The friction material is produced with the raw materials including modified resin 10-35 wt%, butyronitrile powder 0-10 wt%, kaolin 20-40 wt%, precipitated barium sulfate 25-50 wt%, graphite 5-20 wt%, zinc oxide 1-10 wt%, corundum 0-1 wt%, chromite powder 0-5 wt%, iron oxide red 0-2 wt%, steel fiber 10-30 wt%, aramid fiber pulp 0.1-10 wt%, and carbon fiber 0- 10 wt%. The production process includes mixing the raw materials, reaction and forming at the temperature from room temperature to 140 deg.c and the pressure of 200-800 kg / sq cm for 20-800 sec, and final sintering in a sintering furnace at 150-200 deg.C for 2-16 hr. Compared with available technology, the present invention has the advantages of excellent friction performance, excellent physical and mechanical performance, no noise, etc.

Owner:SHANGHAI RENPHEN COMPOSITE MARERIALS

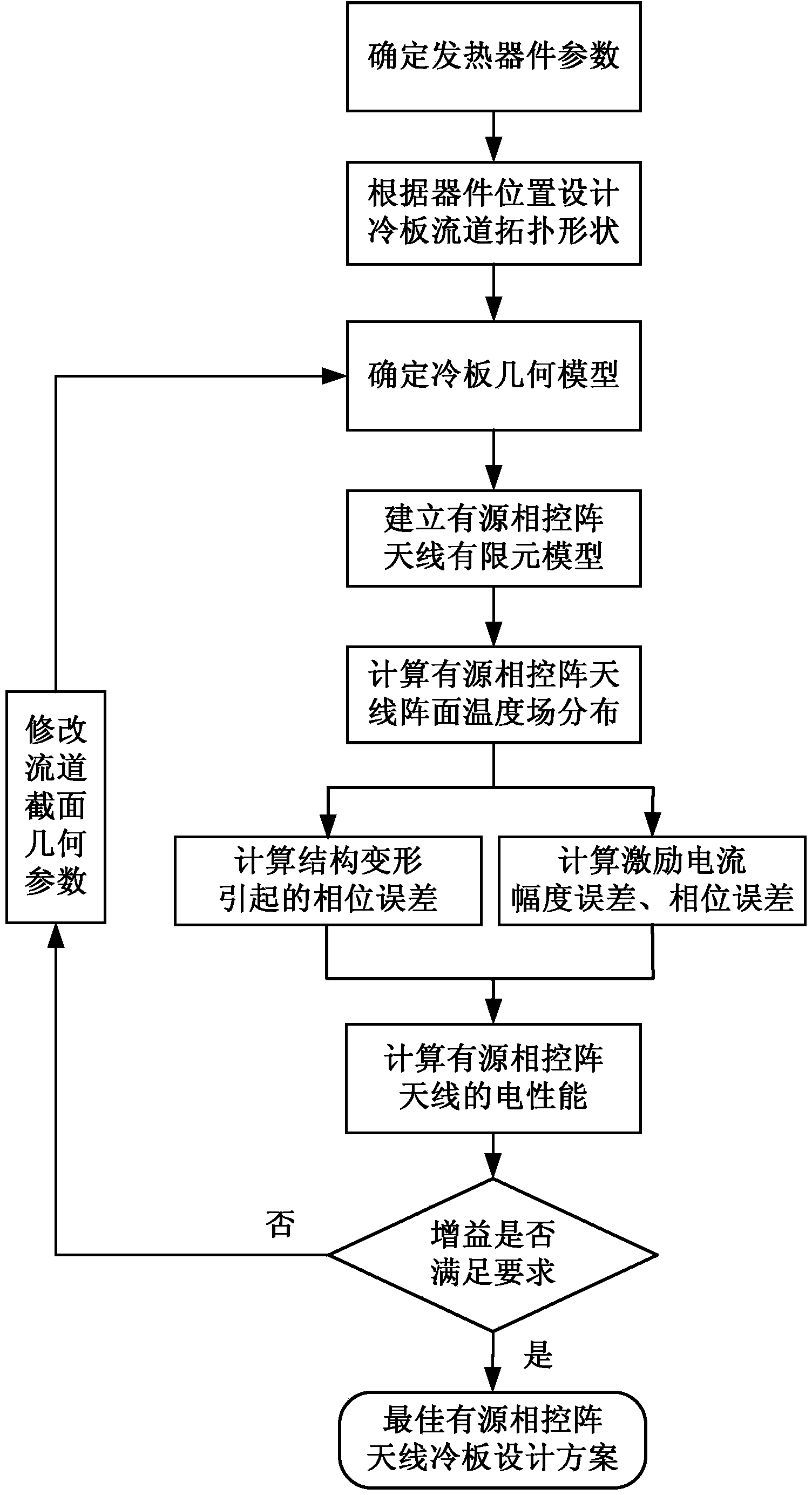

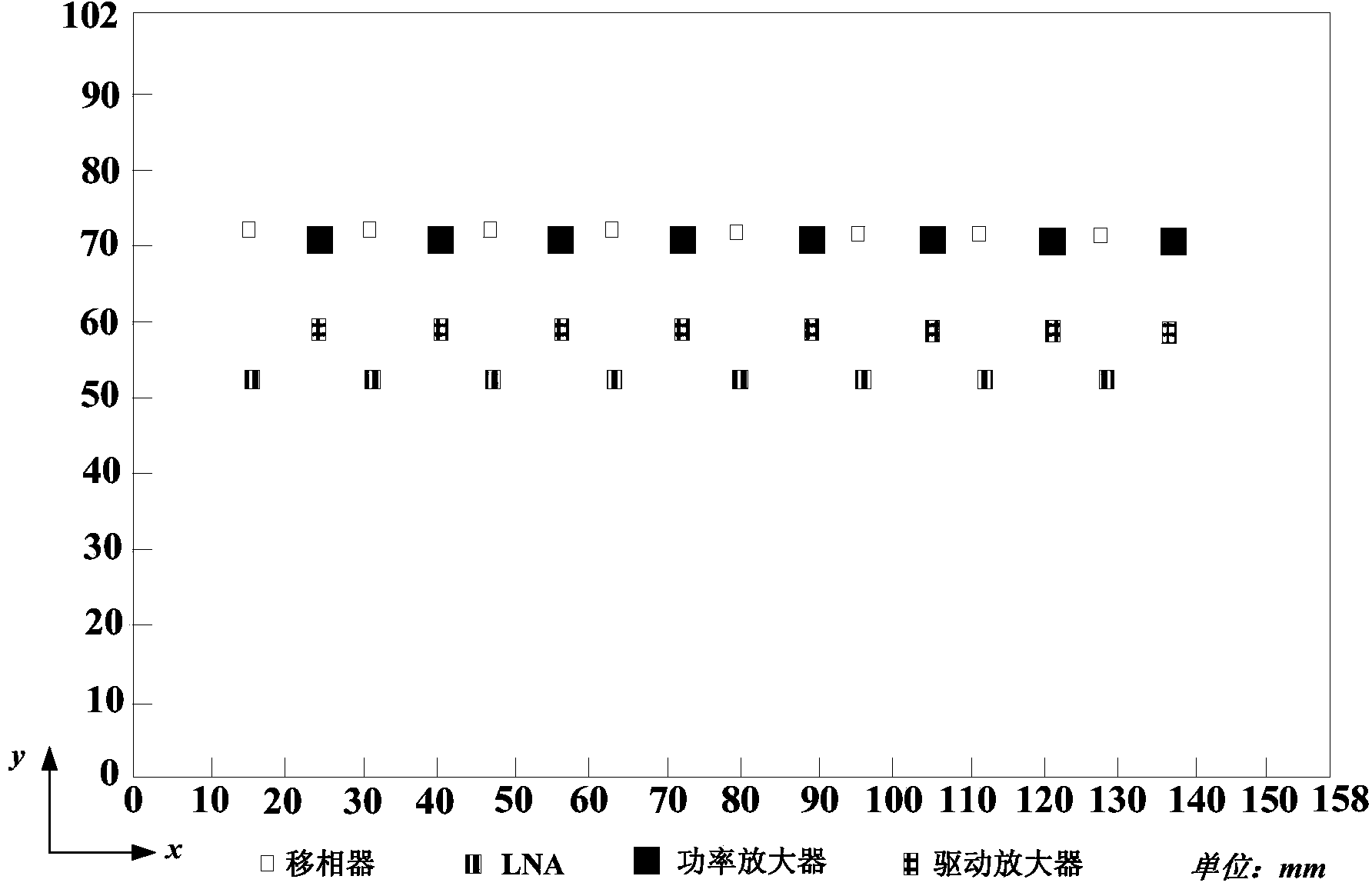

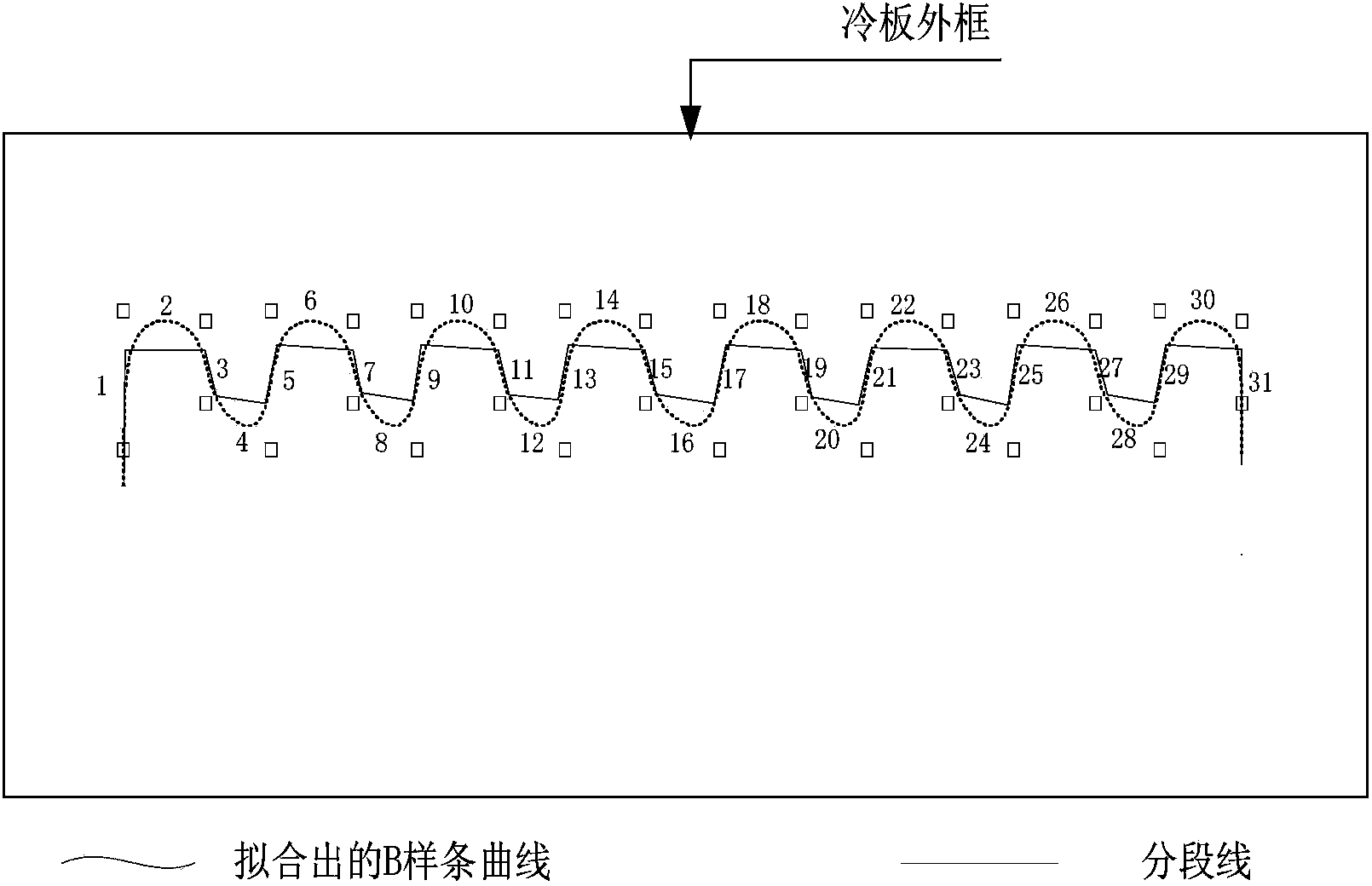

Active phase-array antenna cooling plate electromechanical heat coupling design method based on position of component

ActiveCN104166765AGuaranteed to workSolve the cooling problemSpecial data processing applicationsElectricityElement model

The invention discloses an active phase-array antenna cooling plate electromechanical heat coupling design method based on the position of a component. The method includes the steps of determining a parameter of the heating component in an active phase-array antenna T / R assembly, designing the topology shape of a cooling plate flow channel and a geometrical model of an antenna cooling plate according to the position of the heating component, building a finite element model of an antenna, calculating array temperature field distribution of the antenna, calculating a phase error caused by structure deformation of the antenna and excitation current amplitude errors and phase errors caused by temperature changes, calculating electric performance of the active phase-array antenna, and determining a design scheme of the active phase-array antenna cooling plate according to gain index requirements. By means of the method, the active phase-array antenna cooling plate scheme based on the position of the component can be designed, heat generated by the heating component can be effectively dissipated, influences of the temperature changes on structure deformation and excitation current amplitude and phase can be analyzed in a quantitative mode, and the aims of improving temperature distribution and guaranteeing effective work are achieved on the premise that requirements of the electric performance and the structure mechanical performance of the antenna are met.

Owner:XIDIAN UNIV

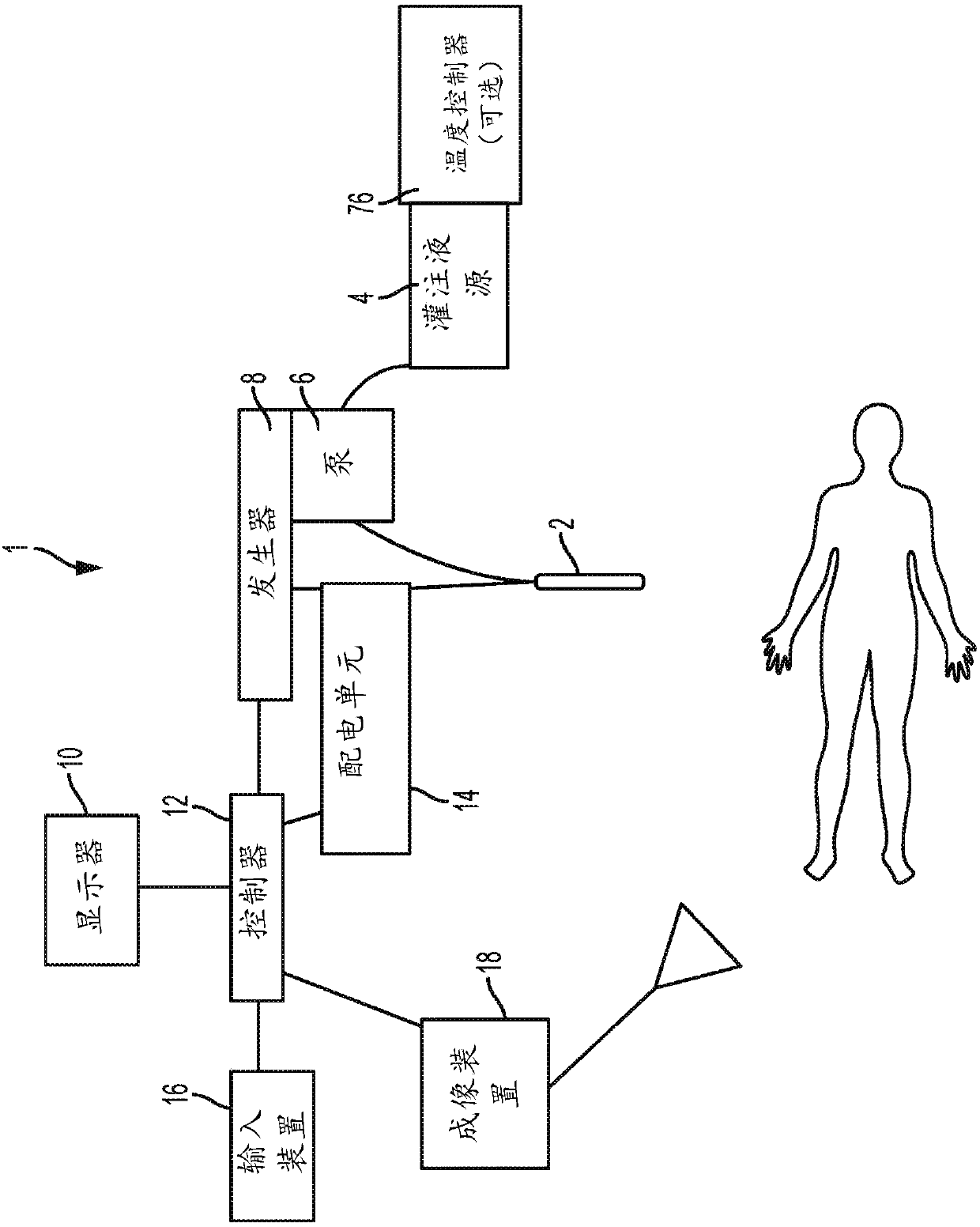

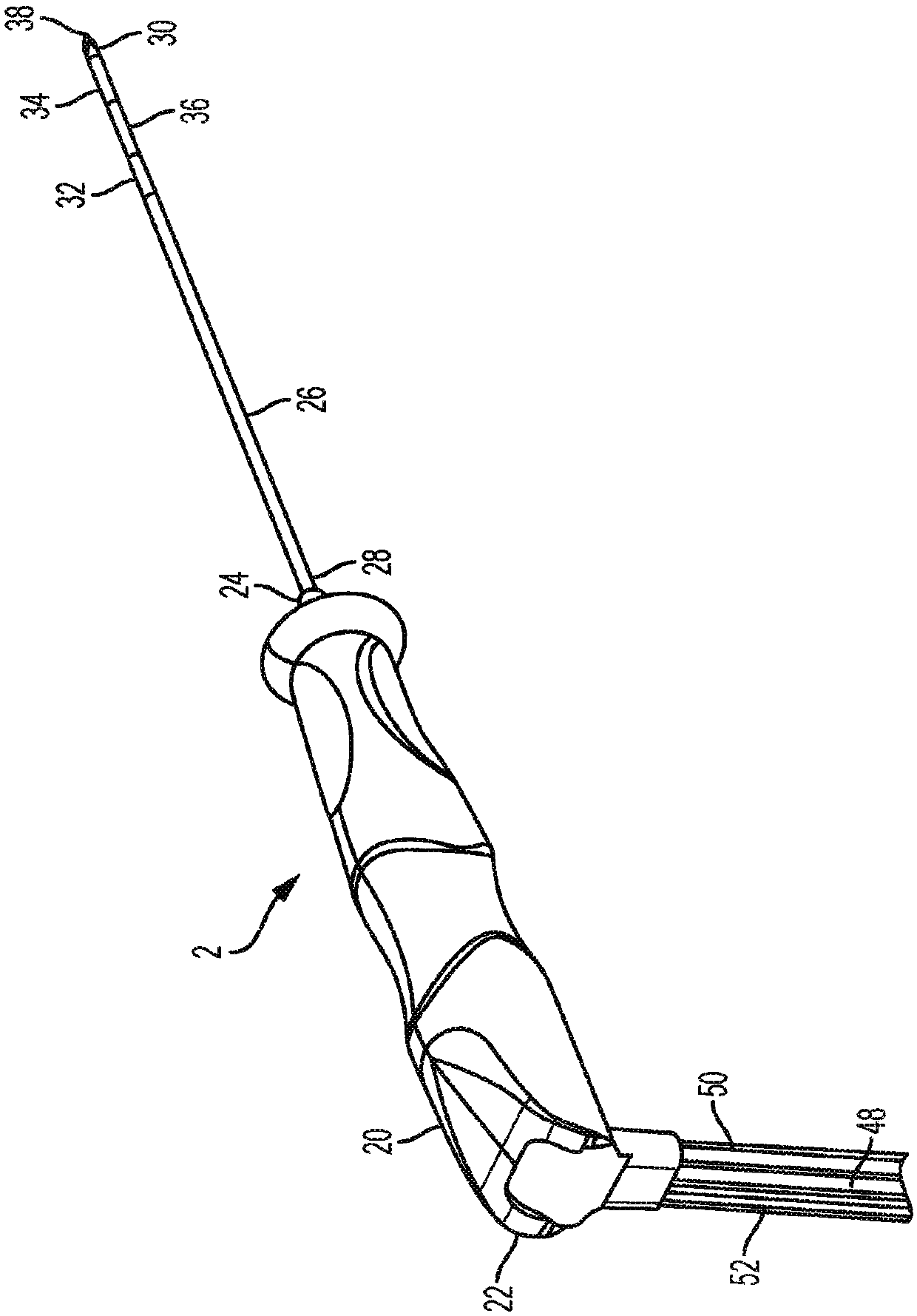

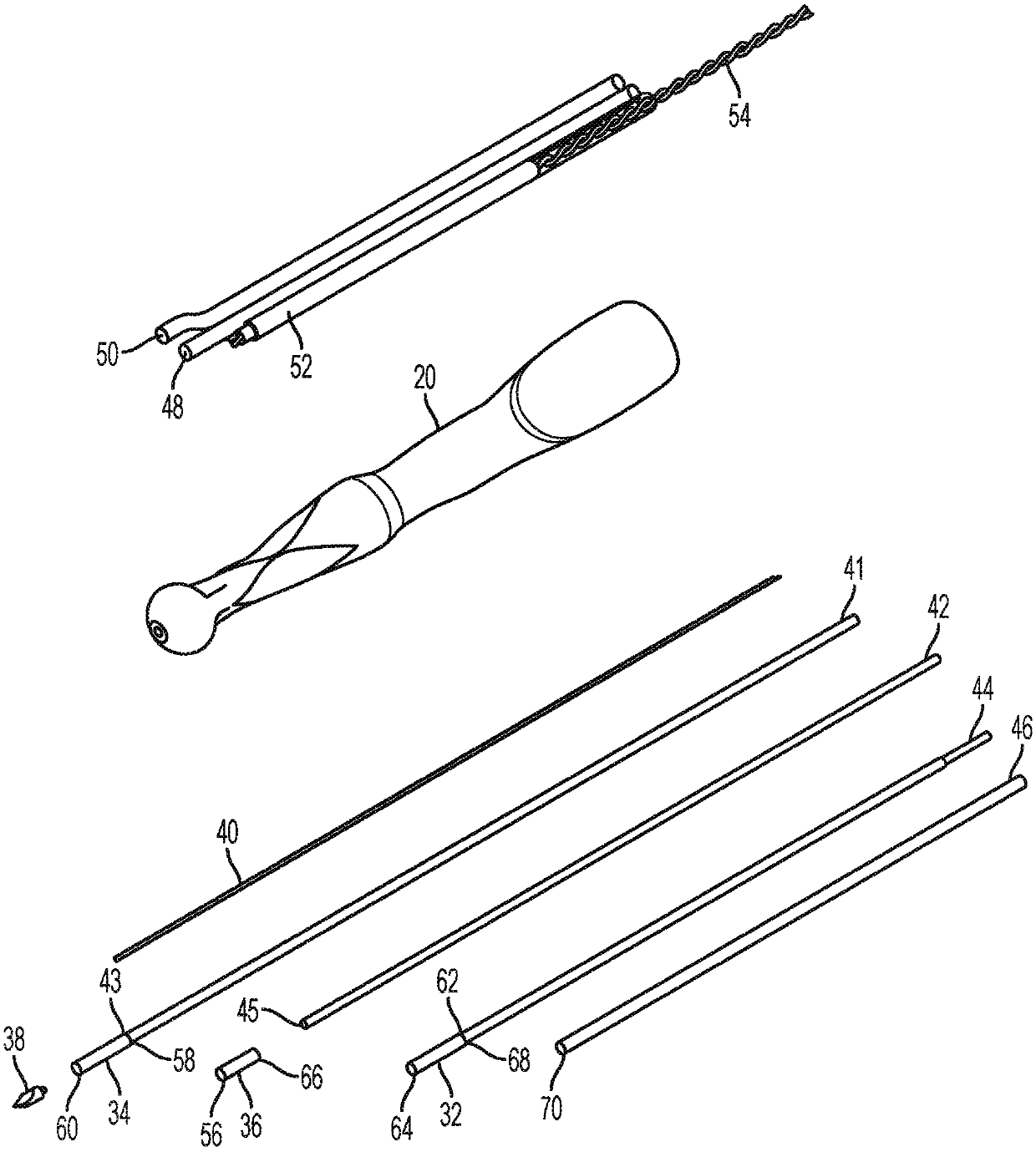

System and method for irreversible electroporation with thermally controlled electrodes

ActiveCN108024803AReduce heat damageAvoid arcingElectrotherapySurgical needlesPulse parameterElectrical impulse

A treatment device and method for delivering electrical pulses capable of creating irreversible electroporation. The system may include a bipolar probe with open or closed perfusion with the purpose of controlling the electrical conductivity rise to eliminate electrical arcing without significantly altering the electric field distribution and treatment zone. This invention may include perfusion together with the delivery of specific or customized pulse parameters to achieve clinically acceptable ablation sizes using a bipolar probe with while reducing the overall risk of arcing or system failure.

Owner:安吉戴尼克公司

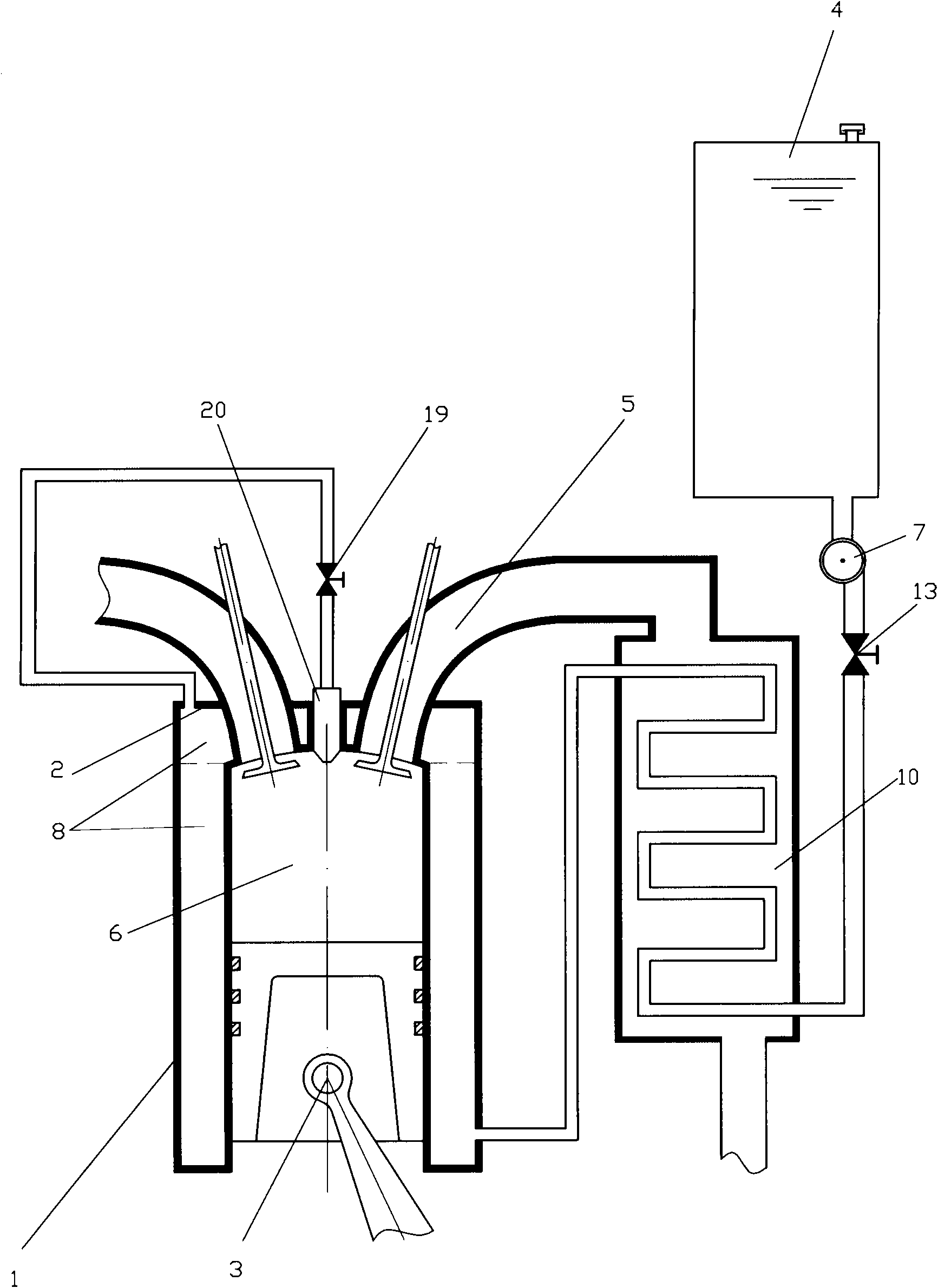

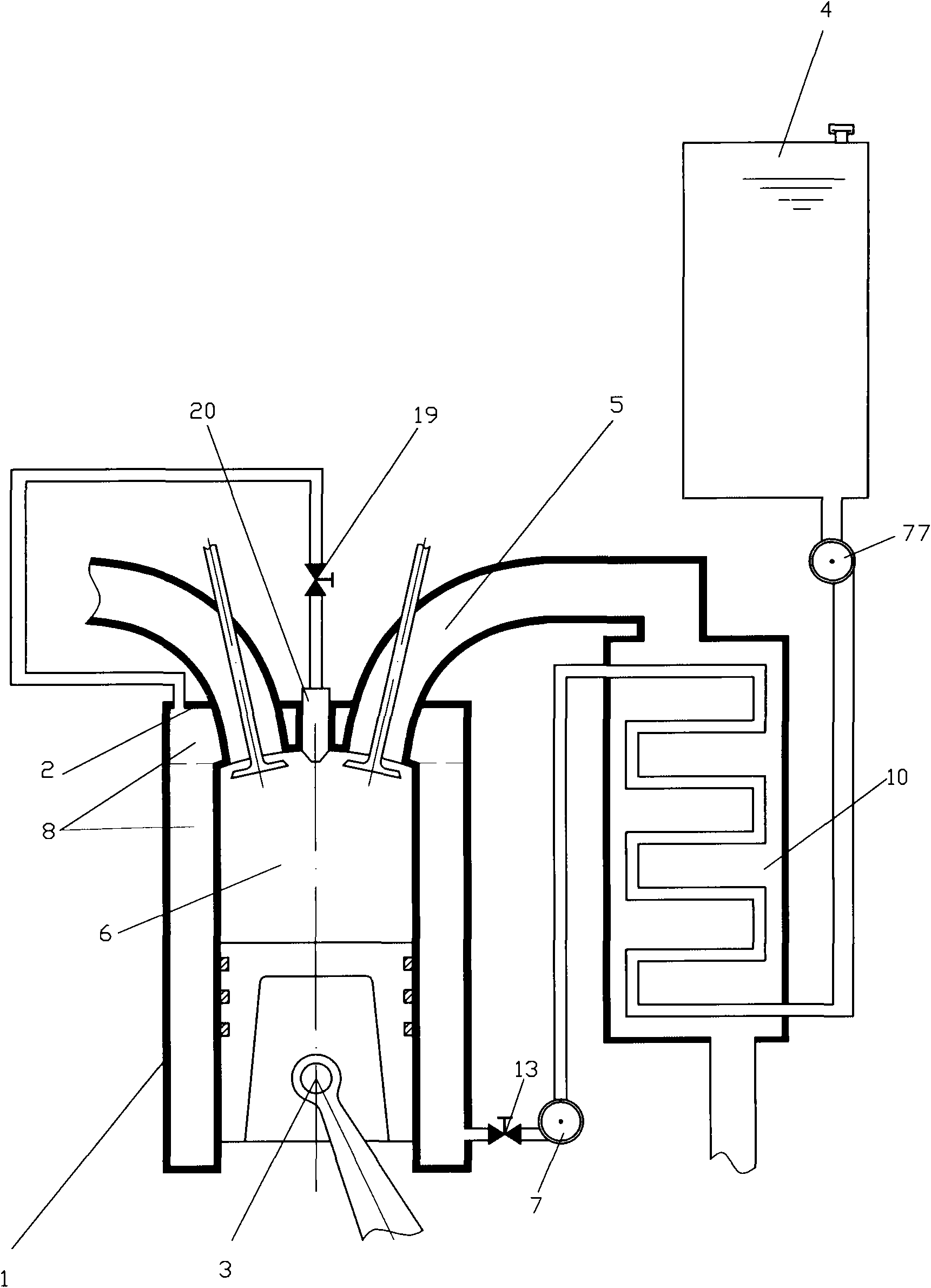

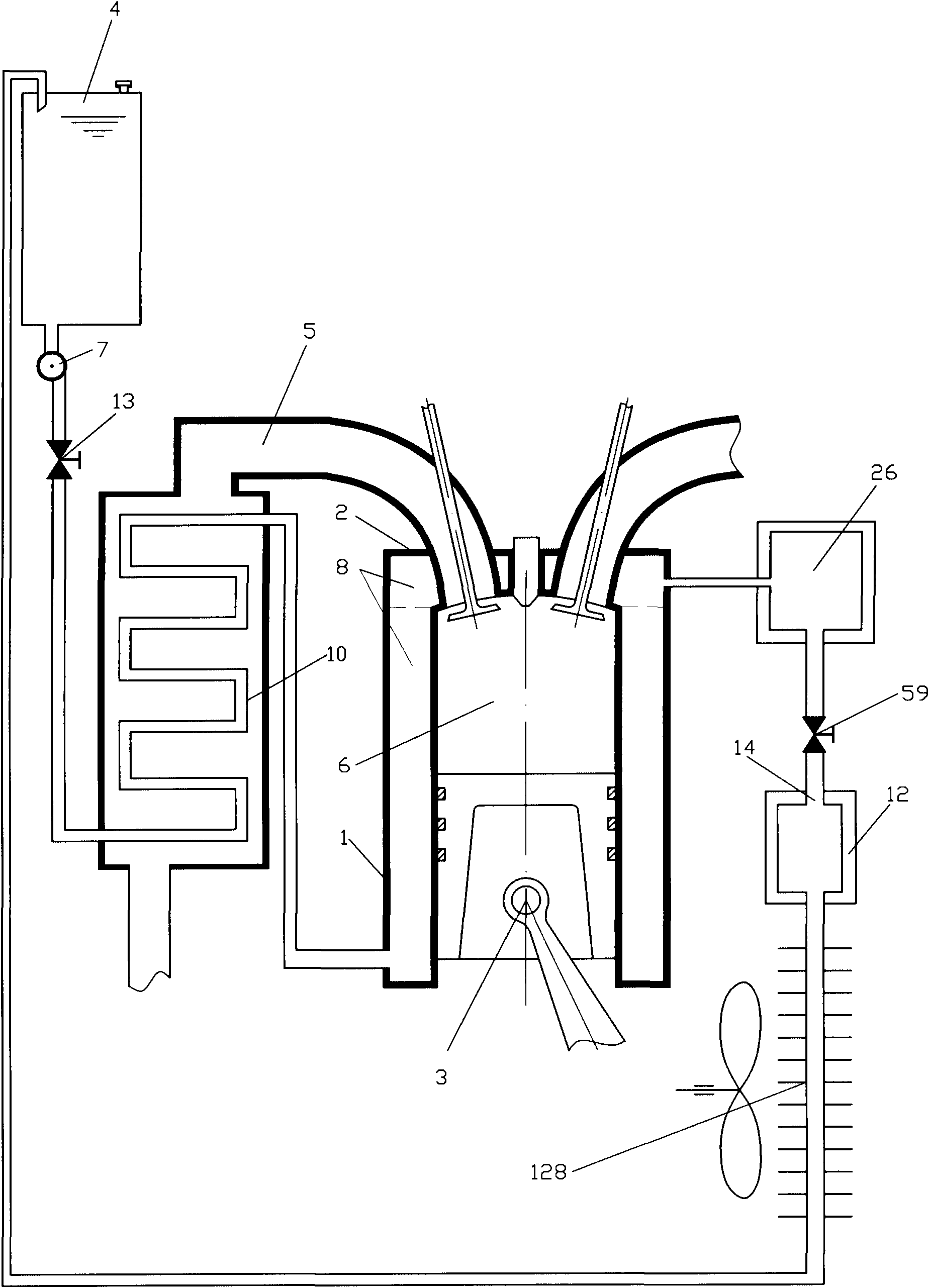

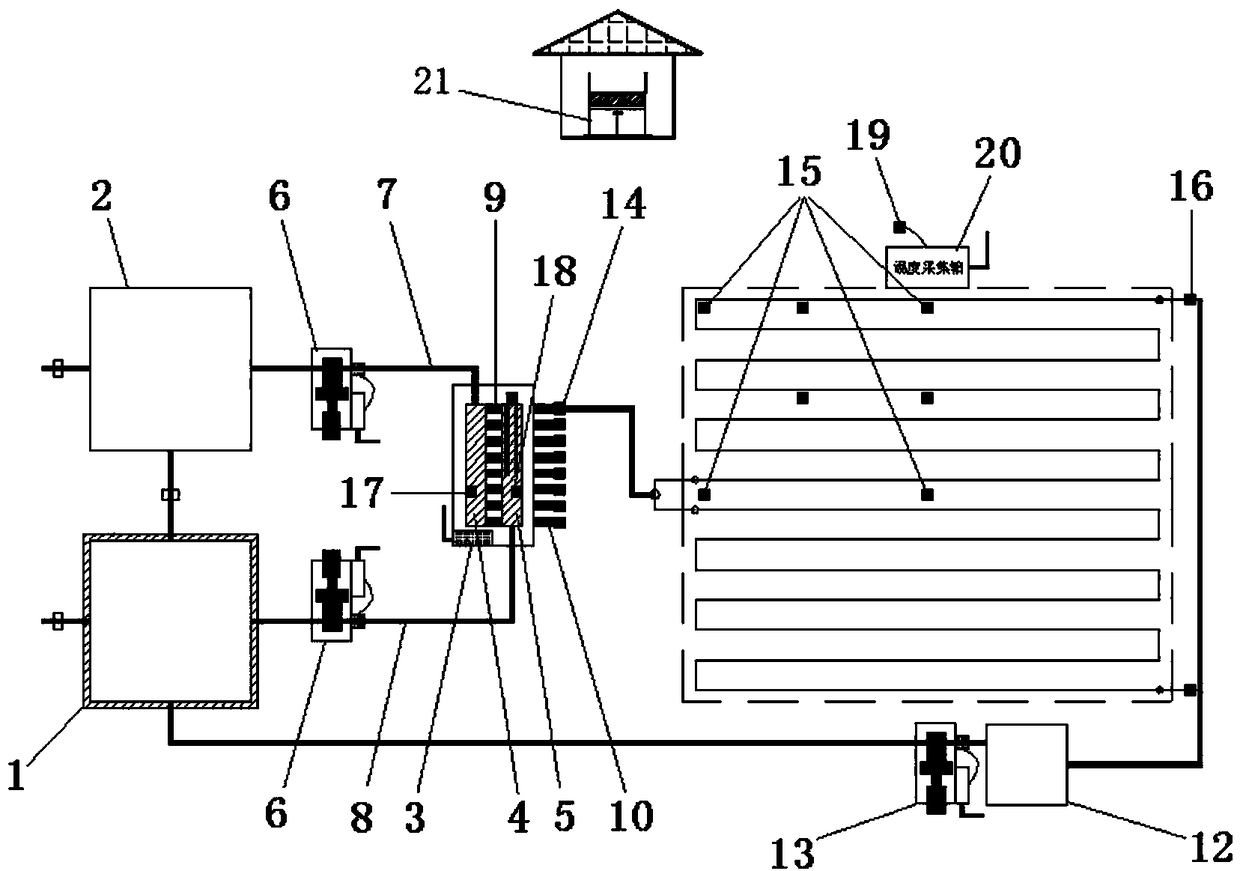

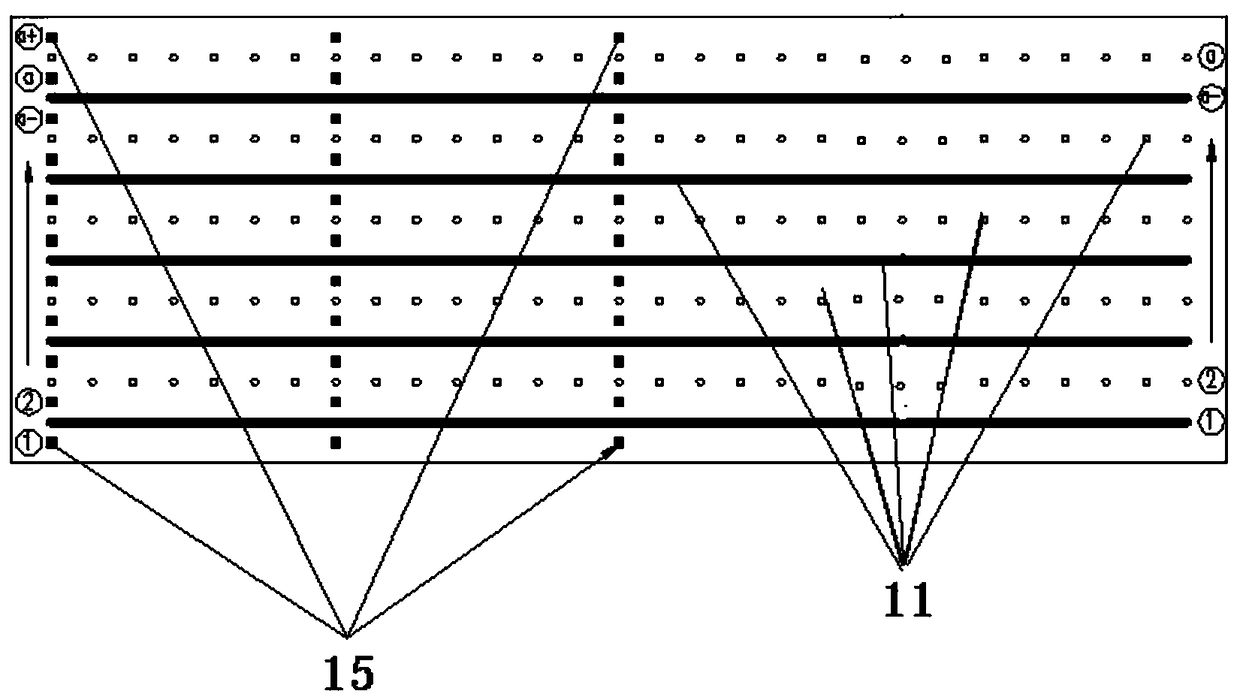

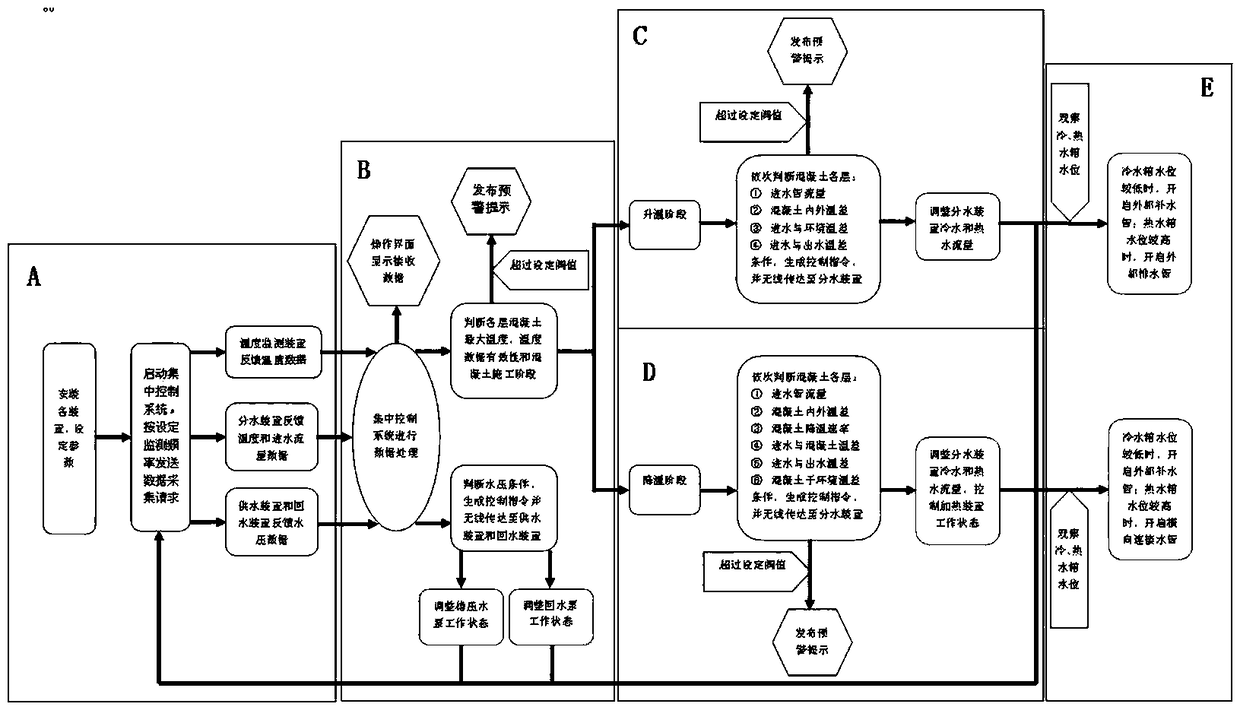

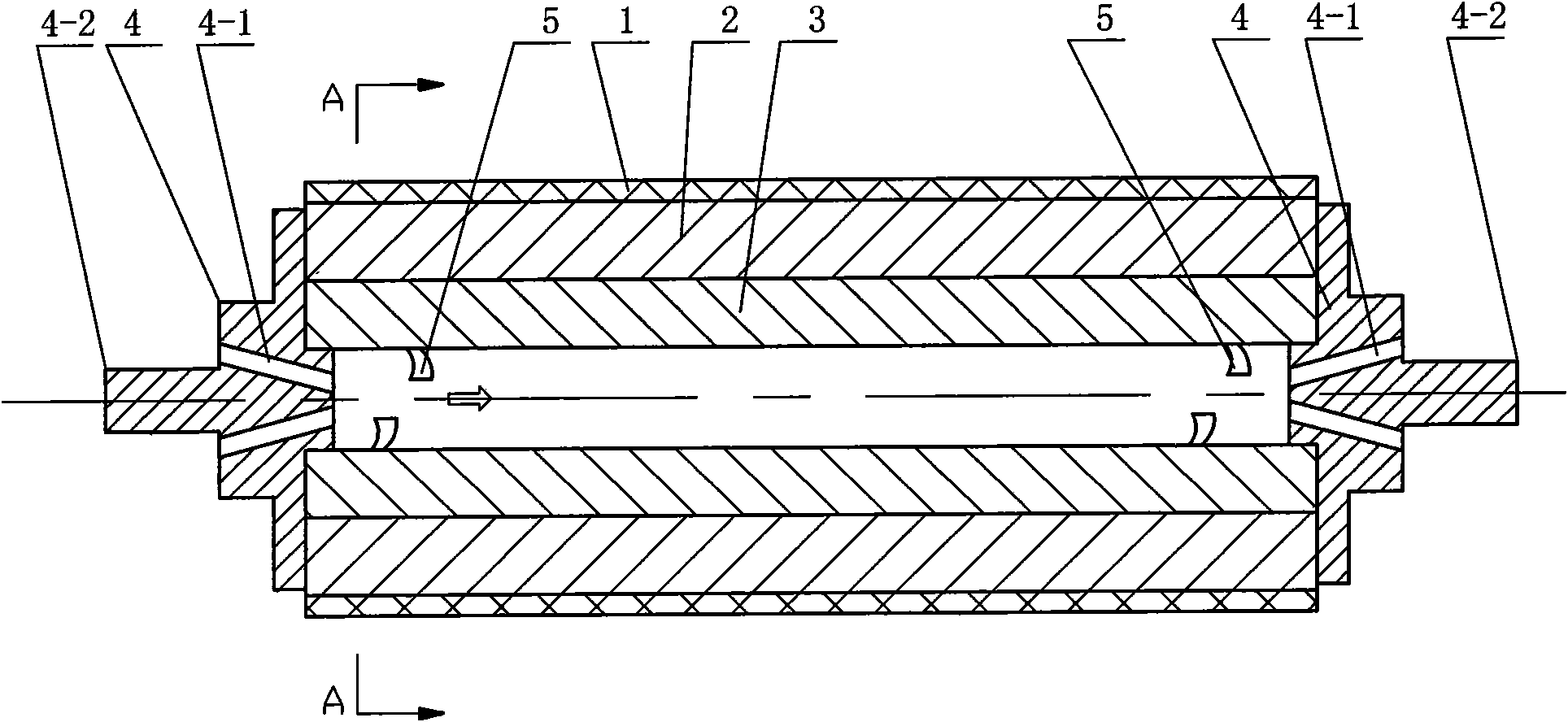

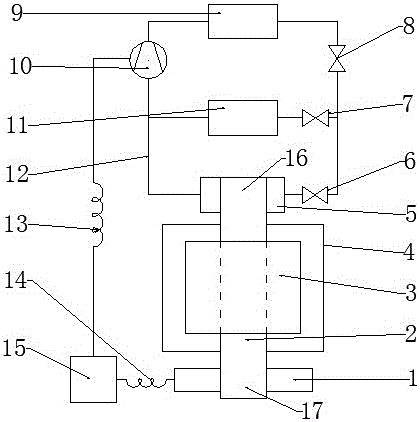

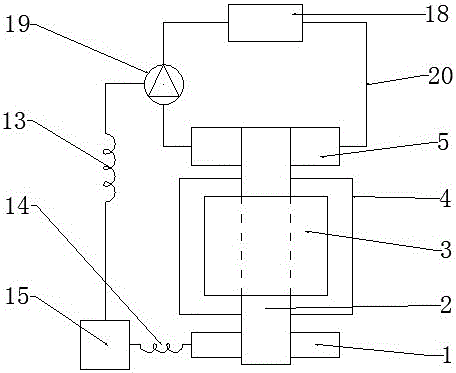

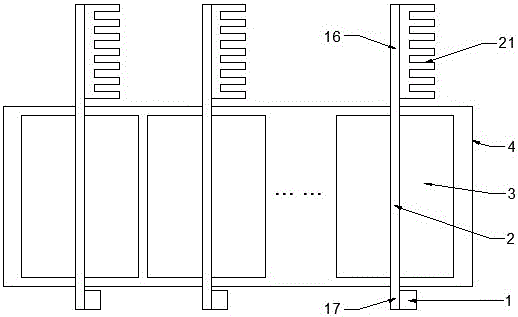

Mass concrete temperature intelligent monitoring and controlling device and method

InactiveCN109471468AControl the maximum temperatureControl cooling rateTemperatue controlPressure stabilizationData acquisition

The invention discloses a mass concrete temperature intelligent monitoring and controlling device, which comprises a circulating pipeline formed by sequentially connecting a water supply device, a water distribution device, a concrete cooling system and a water return device, wherein the concrete cooling system is internally provided with a temperature monitoring device; and a centralized controlsystem which is respectively connected with the water supply device, the water distribution device, the concrete cooling system and the water return device. The concrete cooling system comprises a cooling water pipe arranged in the concrete. Usage of the device comprises a concrete cooling system setting step, a monitoring device setting step, a water distribution device setting step, a water supply device setting step, a water return device setting step, a mass concrete construction preparation step, a data acquisition step, a water supply pressure stabilization step, an alarm step, a hot water tank drainage step and a cold water tank water replenishing step. By the adoption of the mass concrete temperature intelligent monitoring and controlling device, water supply pressure can be stabilized, different water inlet temperatures and flow rates of each layer can be dynamically adjusted, temperature field change in the mass concrete can be developed according to a target of temperature control, and an alarm function is equipped, so that the problems that a temperature difference of each region of the mass concrete is too large and cracks are easy to generate are solved.

Owner:GUIZHOU BRIDGE CONSTR GROUP +1

Fan-cooled rotor in shaft of high-speed permanent magnet motor

InactiveCN101604876AImprove stabilityImprove reliabilityMagnetic circuit rotating partsFiberInterference fit

The invention provides a fan-cooled rotor in a shaft of a high-speed permanent magnet motor, which relates to a cooled rotor of the high-speed permanent magnet motor. The invention aims to solve the problems that when the outer surface of a rotor permanent magnet of the prior high-speed permanent magnet motor is provided with a high-strength non-magnetic metallic sheath or is bond with carbon fibers, the eddy current loss is large so that the temperature rise of the rotor is over-high and the rotor permanent magnet generates irreversible high-temperature magnetism loss. The fan-cooled rotor comprises a sheath or carbon fibers, a permanent magnet and a rotor core, wherein the surface of the outer circle of the rotor core is annularly sleeved with the permanent magnet and the surface of the outer circle of the permanent magnet is provided with the sheath or the carbon fibers. The fan-cooled rotor also comprises two end supporting parts and a fan blade group, wherein shoulders of the two end supporting parts are in interference fit with two ends of the inner cavity of the rotor core, the end supporting parts are coaxial with the rotor core and are provided with a plurality of air vents communicated with the inner cavity of the rotor core along the axial direction, and the wall of the inner cavity of the rotor core is provided with the fan blade group. The fan-cooled rotor is used as the rotor of the high-speed permanent magnet motor.

Owner:HARBIN UNIV OF SCI & TECH

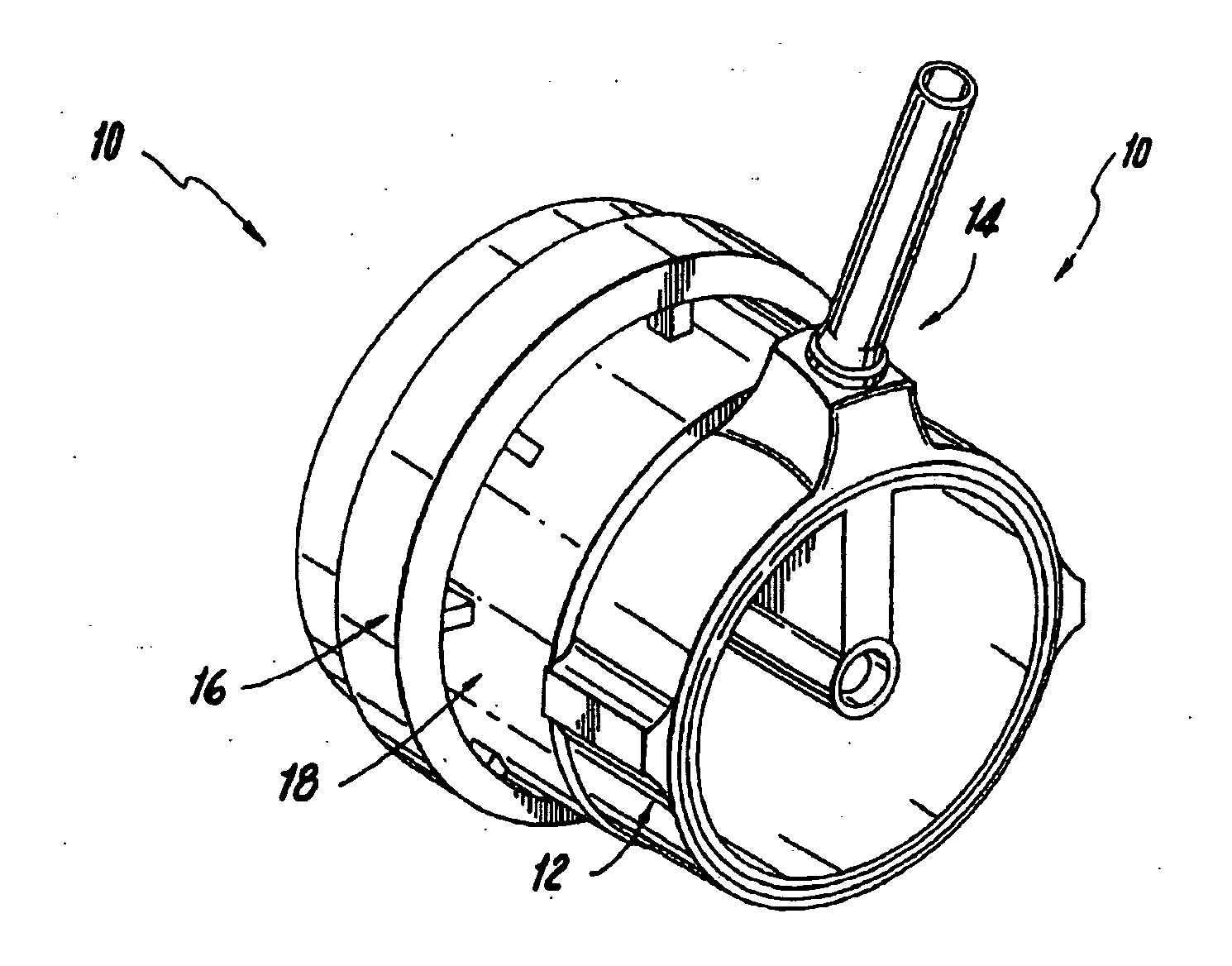

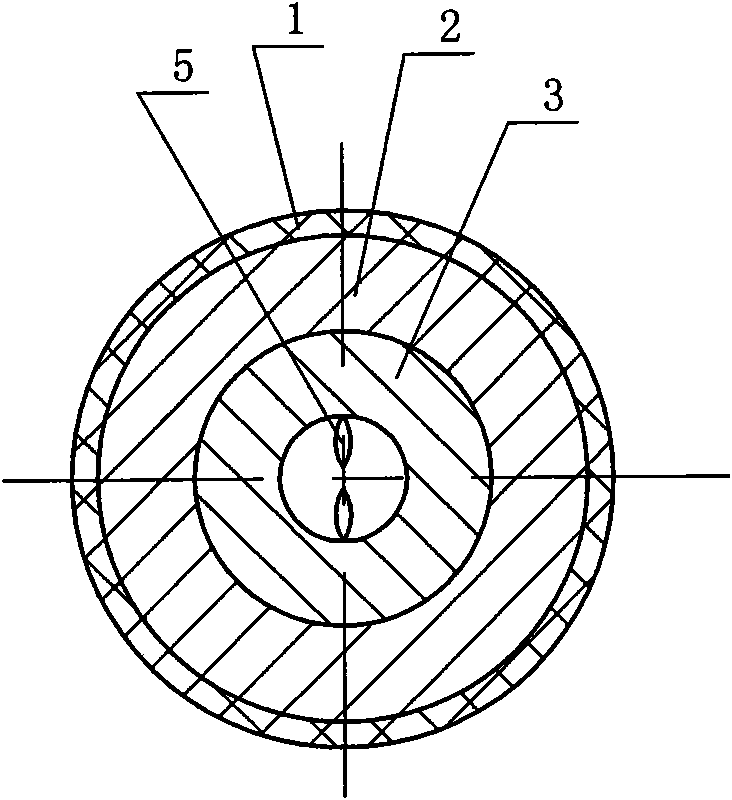

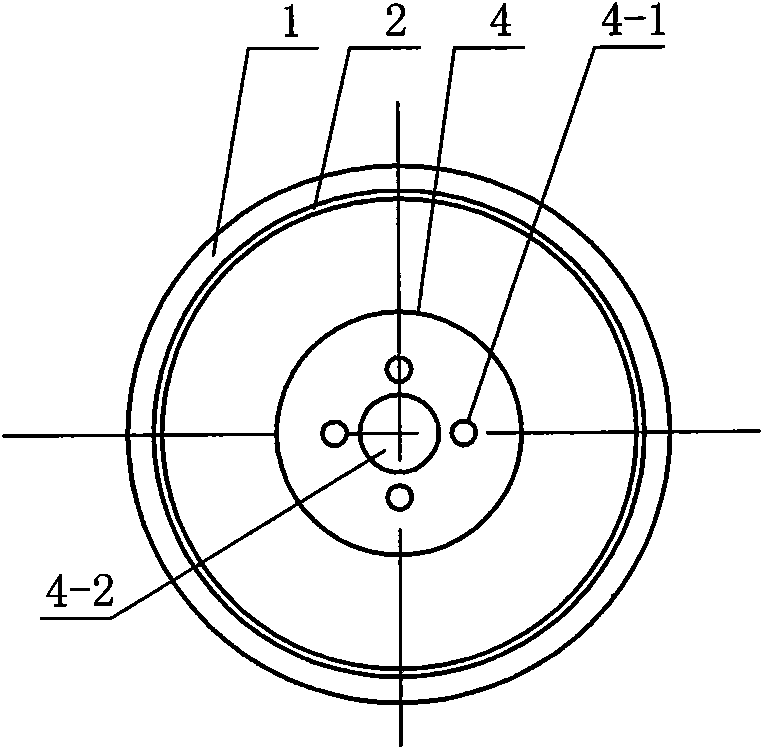

Cooled deposition baffle in high density plasma semiconductor processing

InactiveCN1723530AReduce the maximum temperatureUniform heat fluxElectric discharge tubesVacuum evaporation coatingHigh densityEngineering

An improved deposition baffle, that is provided to protect a dielectric window from conductive deposits, is provided in high-density-plasma apparatus. The baffle has a central circular part having slots cut therein that are interrupted by electrically conductive bridges. Ribs in the body between the slots have cooling fluid channel sections bored therein, which are joined in series by interconnecting channel portions in a peripheral annular part of the baffle to form a continuous serpentine cooling fluid flow path from an inlet to an outlet in the annular peripheral part of the baffle.

Owner:TOKYO ELECTRON LTD

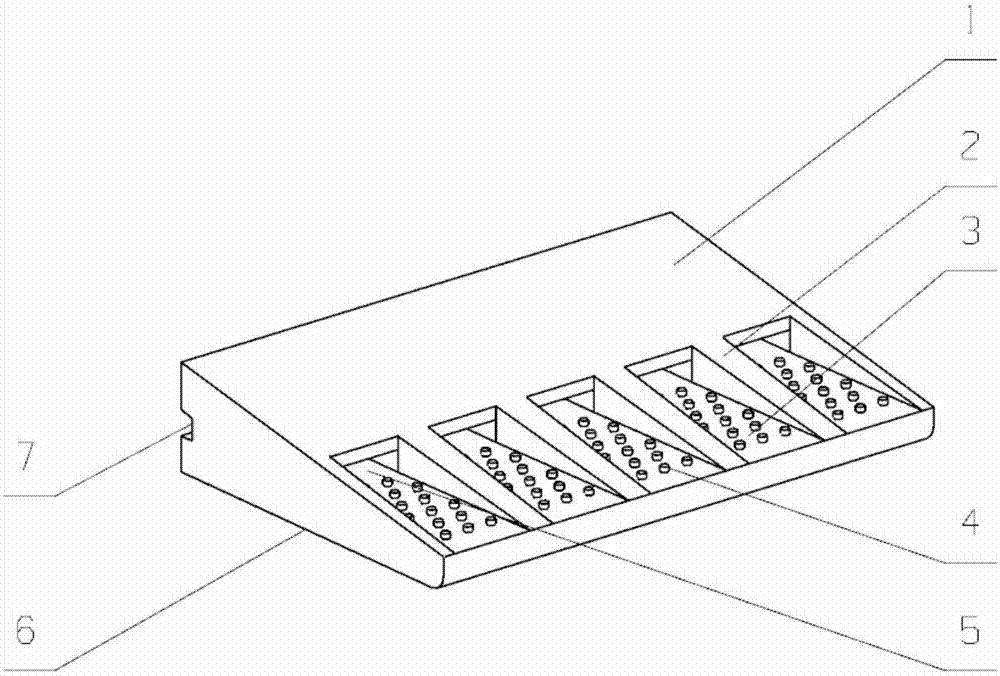

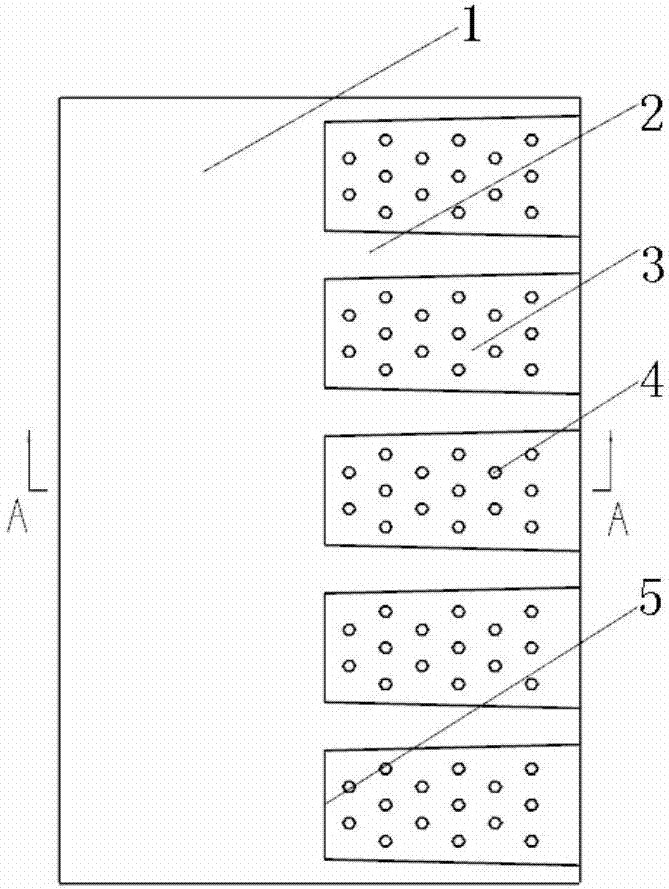

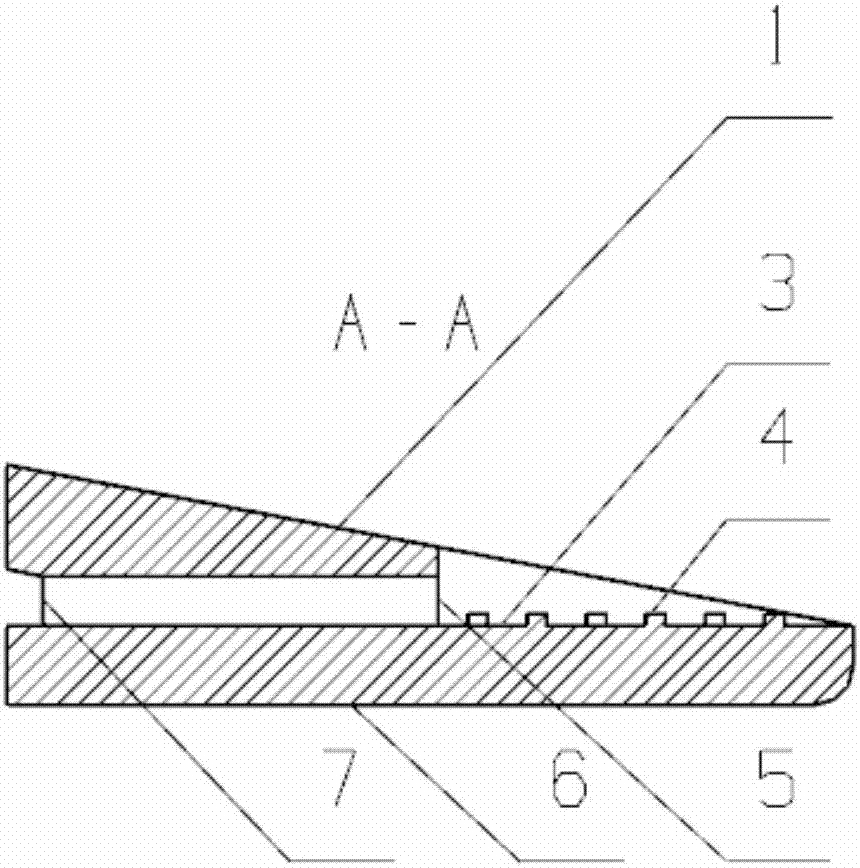

Turbine blade trailing edge turbulent flow half-wedge type seam cooling structure with array pin fins

InactiveCN107035421AImprove cooling effectImprove heat transfer effectBlade accessoriesMachines/enginesTurbine bladeCooling effect

The invention discloses a turbine blade trailing edge turbulence half-slit cooling structure with an array of pin ribs. The array of pin ribs is applied to the half-slit wall surface, and the flow turbulence structure is passed without increasing the outflow of the gas film. Improve the convective heat transfer coefficient and heat transfer area of the air film, and enhance the convective heat transfer intensity of the half-slit air film cooling, thereby improving the comprehensive cooling effect of the trailing edge of the blade. Turbine blade trailing edge turbulent half-split cooling structure with continuous array of needle ribs cuts off part of the wall on the pressure surface of the blade trailing edge, retains the wall on the suction side of the blade trailing edge and separates the partition ribs to form multiple half-splits Slit structure, the cooling air flow is ejected from the cold flow outlet and covers the split wall of the trailing edge to form a cooling air film. The structure is simple; the maximum temperature and average temperature of the suction surface can be effectively reduced, and high-temperature ablation of the suction surface of the turbine blade can be avoided. The straight rib structure is arranged on the half-slit wall surface, which has good heat transfer characteristics and good processing feasibility.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

High-content environmental alcohol ether fuel used for compression ignition engine

InactiveCN105505484AEmission reductionLarge latent heat of evaporationLiquid carbonaceous fuelsFuel additivesAlkaneAlcohol fuel

The invention discloses a high-content environmental alcohol ether fuel used for a compression ignition engine, which belongs to the technical field of alcohol ether fuel clean energy. The alcohol ether fuel comprises the following raw materials: methanol or ethanol or a mixture of methanol and ethanol, toluene, stearic acid, hexamethylphosphoric triamide, a nitryl solvent, acetone, fatty acid methyl ester, n-alkane, N-toluidine, plant oil, an alcohol fuel ether stabilizing agent, a catalysis combustion-supporting agent, an anti-knock reinforcing agent, a cetane number regulator, an eduction agent, an alcohol fuel recognition agent, an alcohol fuel rubber / plastic part corrosion and swelling inhibitor, an alcohol fuel metal corrosion inhibitor, an antioxidant anti-gum inhibitor, a metal deactivator, a corrosion inhibitor, an antistatic agent, a purification dispersant, an anti-wear repair agent, and an alcohol fuel sterilizing agent. The high-content environmental alcohol ether fuel has the advantages of stable performance, strong power, full combustion, good anti-knock property, good acceleration speed, easy starting, no air resistance, and low fuel consumption, and is especially suitable for the compression ignition engine.

Owner:SICHUAN ZHENGJIA NEW ENERGY TECH CO LTD

Battery heat management system for electric vehicle with plate type heat pipe

PendingCN106785213AQuick and efficient exportReduce the maximum temperatureSecondary cellsElectrical batteryElectric vehicle

Owner:江乐新

Reinforced magnesium-lithium alloy of long-period structure and preparation method of reinforced magnesium-lithium alloy

The invention provides a reinforced magnesium-lithium alloy of a long-period structure and a preparation method of the reinforced magnesium-lithium alloy. The magnesium-lithium alloy is composed of, by weight percentage, 11-16% of Li, 1-5% of Y, 0.2-2% of Zn, 0-0.6% of Zr and the balance Mg and inevitable impurities, wherein the total amount of Si, Fe, Cu and Ni is less than 0.02%. The preparation method of the magnesium-lithium alloy comprises the steps of smelting under the atmospheric environment and thermal treatment in a common furnace, wherein the smelting process comprises the steps of drying materials, smelting magnesium, adding Y, adding Zn, adding Zr, adding Li, performing refining and performing casting. Double-stage solution treatment is mainly adopted in the thermal treatment process, that is, 300-400 DEG C solution treatment is conducted for 2-10 h, then 200-300 DEG C solution treatment is conducted for 2-6 h, and the cast alloy with the LPSO structural phase is obtained through phase transformation. According to the reinforced magnesium-lithium alloy and the preparation method, the Y element and the Zn element are added to the magnesium-lithium alloy, the LPSO structure phase is introduced into a magnesium-lithium alloy substrate, and the cast magnesium-lithium alloy material with the low density, high strength and good thermal resistance is prepared.

Owner:苏州轻金三维科技有限公司

Welding method for semiconductor ceramic shell sealing cap

ActiveCN103056500AReduce the maximum temperatureAvoid the problem of excessive local heating temperatureSemiconductor/solid-state device manufacturingWelding/cutting media/materialsMetal coatingCopper electrode

The invention relates to a welding method for a semiconductor ceramic shell sealing cap and belongs to the technical field of semiconductor ceramic packaging. The welding method comprises the steps of pre-arranging a metal coating layer on the surface of a metal cover plate, and pre-arranging a coated metal seal frame in a ceramic shell welding area; enabling a solder ring to undergo spot welding on the metal coating layer of the metal cover plate; enabling the metal cover plate to be aligned with the metal seal frame of a ceramic shell under the atmosphere of nitrogen, utilizing a parallel seam welding device and a small-angle (5-degree) copper electrode to perform low-power welding, and enabling the solder ring to be fully molten and respectively welded to the metal coating layer of the metal cover plate and the metal seal frame of the ceramic shell to finish melting seal of a circuit. According to the welding method, the problems that pulse is too large and the local central heating temperature is too high in the parallel seam welding process are solved, the problem that chips inside the circuit and bonding positions are in a high-temperature state in a melting seal process is solved, and the maximum temperature of parallel seam welding is reduced.

Owner:BEIJING MXTRONICS CORP +1

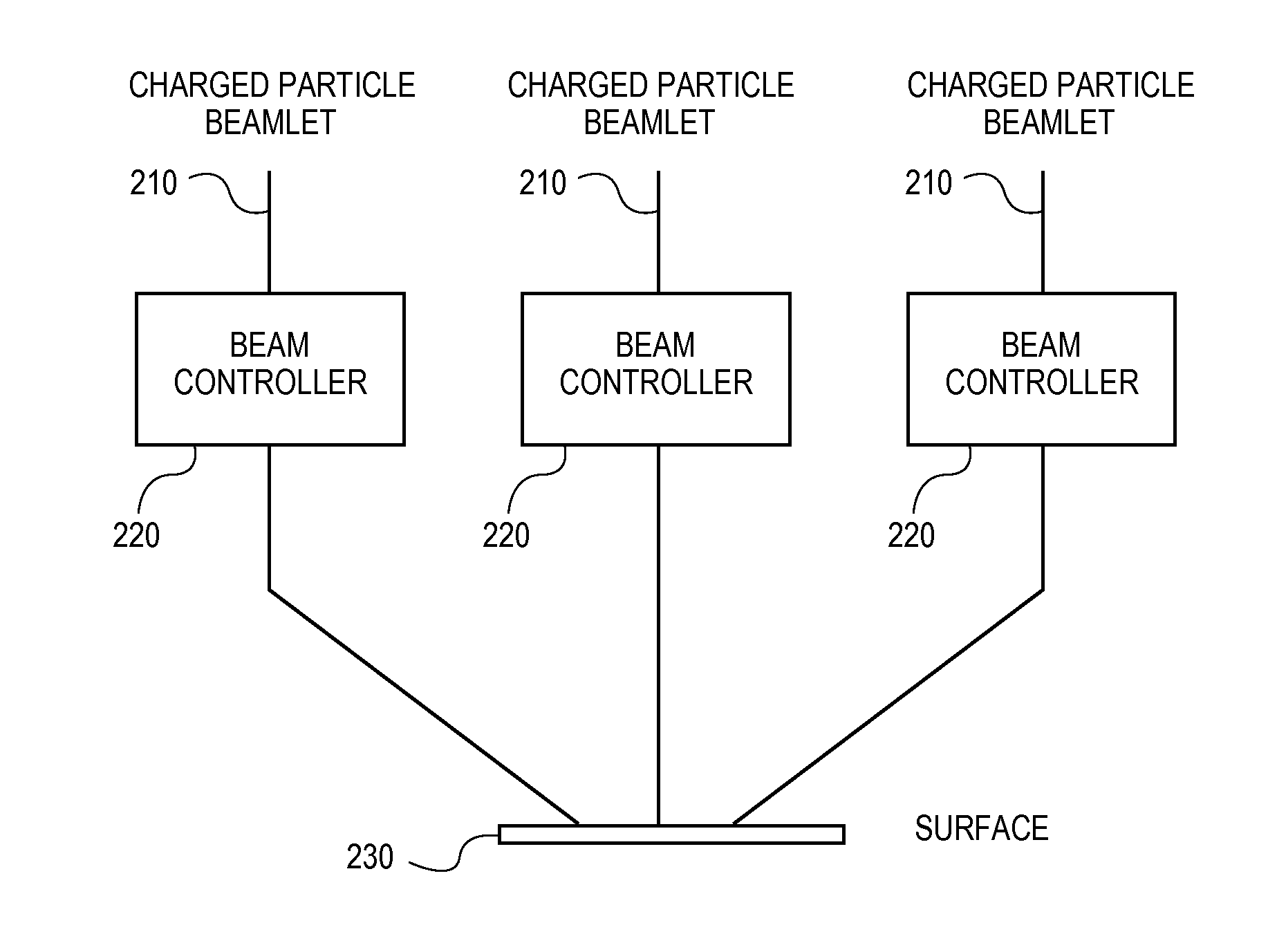

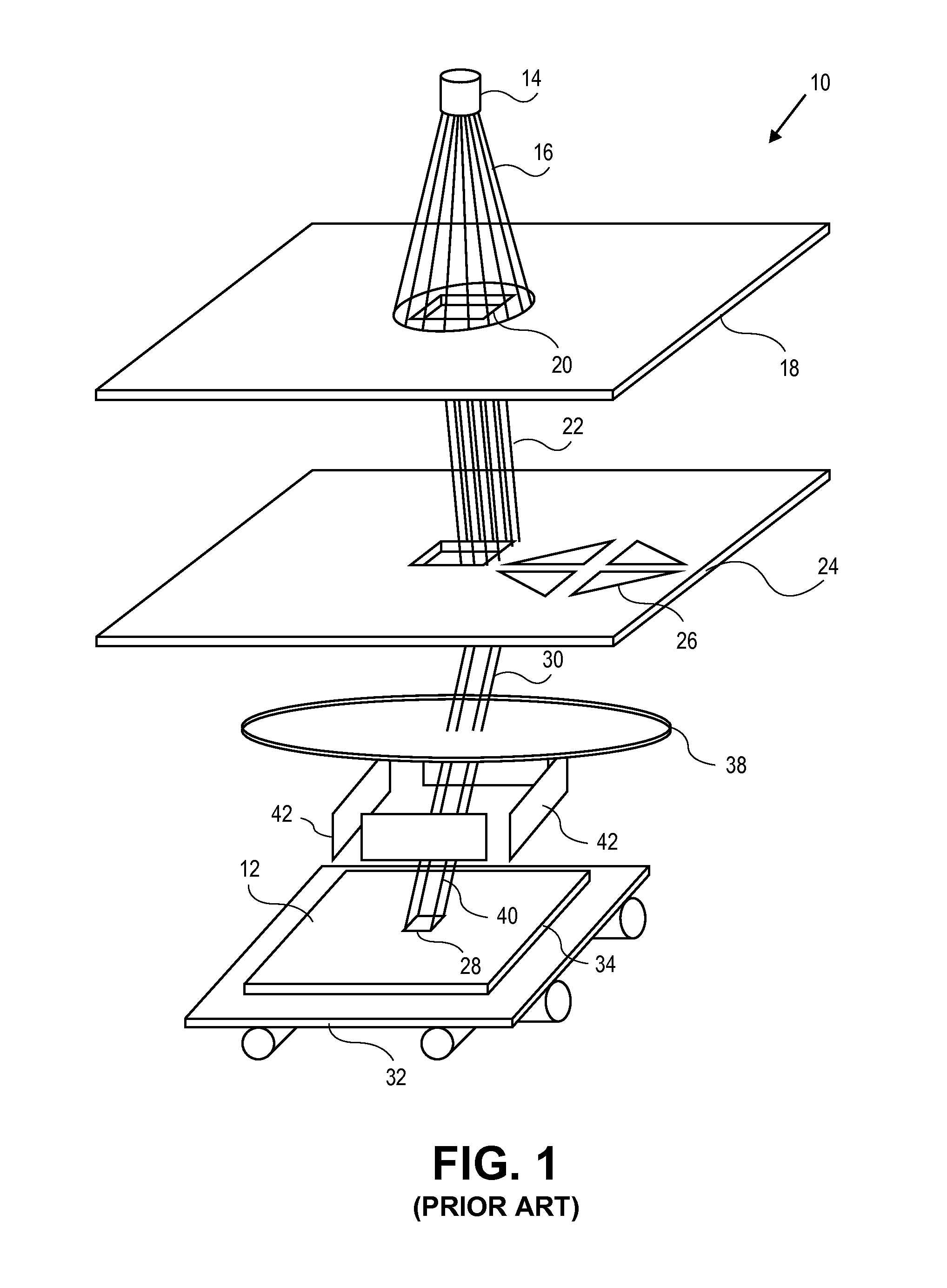

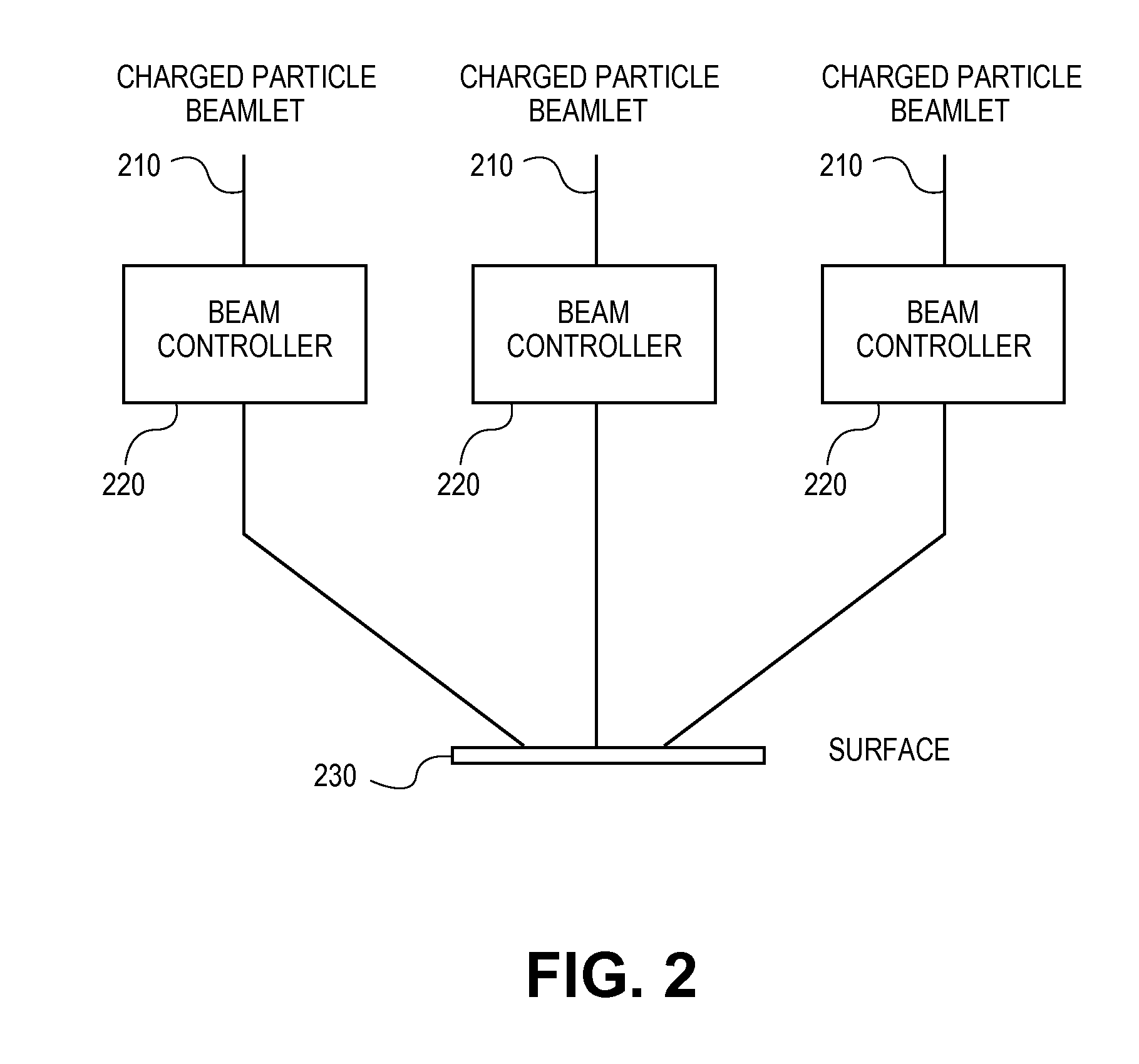

Method and system for improving critical dimension uniformity using shaped beam lithography

ActiveUS20140127628A1Reduce the maximum temperatureReduce the temperatureElectric discharge tubesNanoinformaticsShaped beamLithographic artist

A method for forming a pattern on a surface using charged particle beam lithography is disclosed, where the shots in an ordered set of input shots are modified within a subfield to reduce either a thermal variation or a maximum temperature of the surface during exposure by the charged particle beam writer. A method for fracturing or mask data processing is also disclosed, where an ordered set of shots is generated which will expose at least one subfield of a surface using a shaped beam charged particle beam writer, and where a temperature or a thermal variation generated on the surface during the exposure of one subfield is calculated. Additionally, a method for forming a pattern on a surface with an ordered set of shots using charged particle beam lithography is disclosed, in which a blanking period following a shot is lengthened to reduce the maximum temperature of the surface.

Owner:D2S

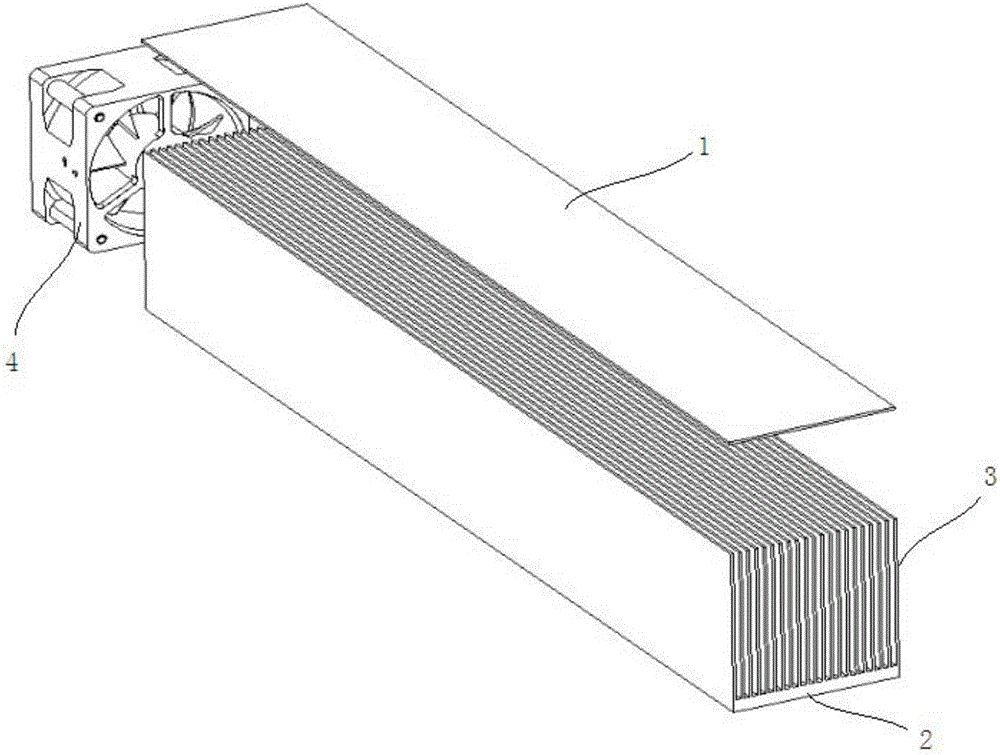

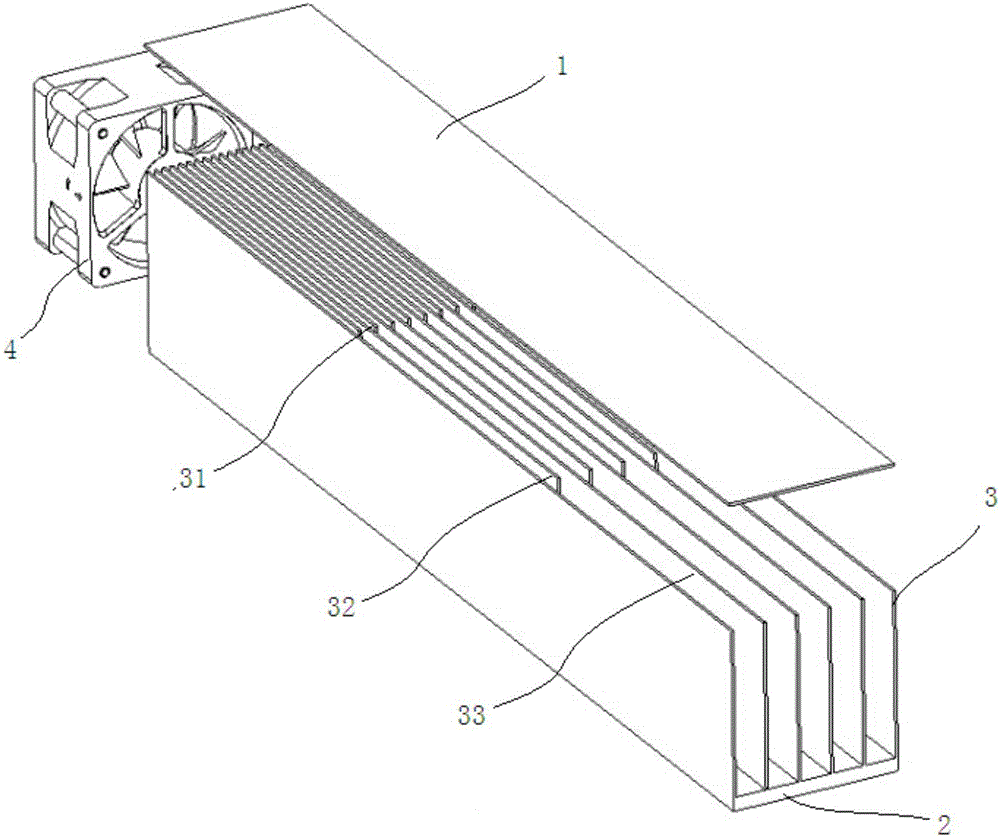

Novel cooling fin runner structure

InactiveCN106028766ASmall flow resistanceIncrease air volumeCooling/ventilation/heating modificationsThermodynamicsAir velocity

The invention relates to cooling devices, in particular to a novel cooling fin runner structure. The runner structure is divided into at least two runner parts in the length direction, intervals between fins in the runner part close to an air inlet are larger, and therefore the flow resistance of the runner part at the air inlet is reduced, and under the situation that the fan power is not changed, the supply air rate and the air speed in the whole fin runner can be effectively increased relative to an original runner structure; meanwhile, due to the fact that the closer the fins in the runner part are to the air outlet of the runner structure, the smaller the intervals of the fins are, the number of the fins is relatively large, and relative to the runner part at the air inlet, the contact surface of the runner fins with cooling air is increased, and the cooling effect is further enhanced. By means of the structure, under the situation that the fan power is not changed, the highest temperature (generally, a heating device close to the air outlet of the fin runner will have the highest temperature) of the heating device can be effectively reduced.

Owner:成都雷电微力科技股份有限公司

Forced-draft burner and method for regularizing side-combustion high-temperature preheated air of square-box furnace

InactiveCN101694297AReduce the maximum temperatureReduce generationThermal naphtha reformingIndirect carbon-dioxide mitigationCombustorBrick

The invention discloses forced-draft burner and method for regularizing side-combustion high-temperature preheated air of a square-box furnace. The burner is provided with two independent grades of gas wheels; a main gas gun 3 is arranged in the center of the burner and the gas blower of the gas gun is communicated with a combustion channel consisting of flam path bricks 1, that is to say, the gas blower of the gas gun is communicated with a primary combustion area; a combustion air channel is communicated with the center of the burner; and an air adjustment butterfly vale 8 is arranged for controlling the quantity of combustion air; all combustion air enters the burner via the combustion air channel and is mixed with the gas blown out of the main gas gun 3 for combustion together in the combustion channel consisting of the flame path bricks 1; a second-level gas distribution ring 4 is arranged and communicated with a second-level gas source; and a plurality of second-level gas guns 10 are arranged on the second-level gas distribution ring 4 and around the outer wall of the flame bricks of the burner. By adopting graded combustion and flue backflow technologies, the invention can reduce the generation of nitric oxides and has the advantages of full combustion, energy saving, environmental protection and high efficiency.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

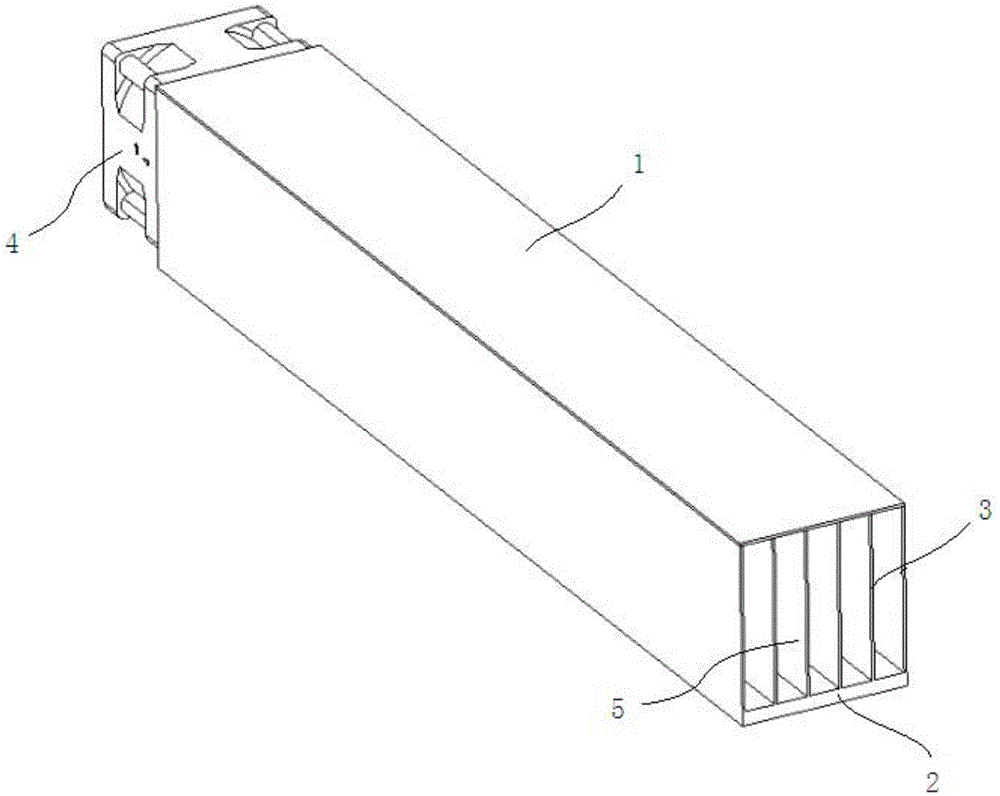

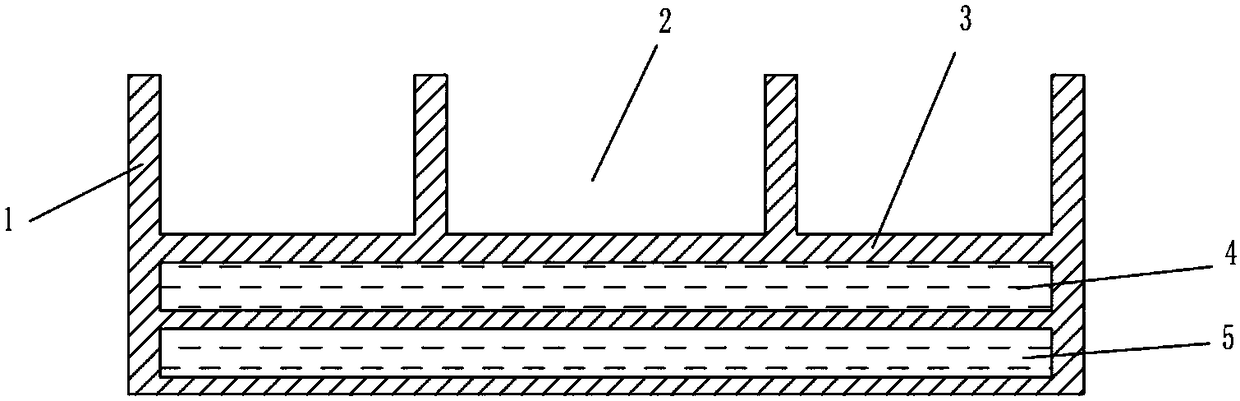

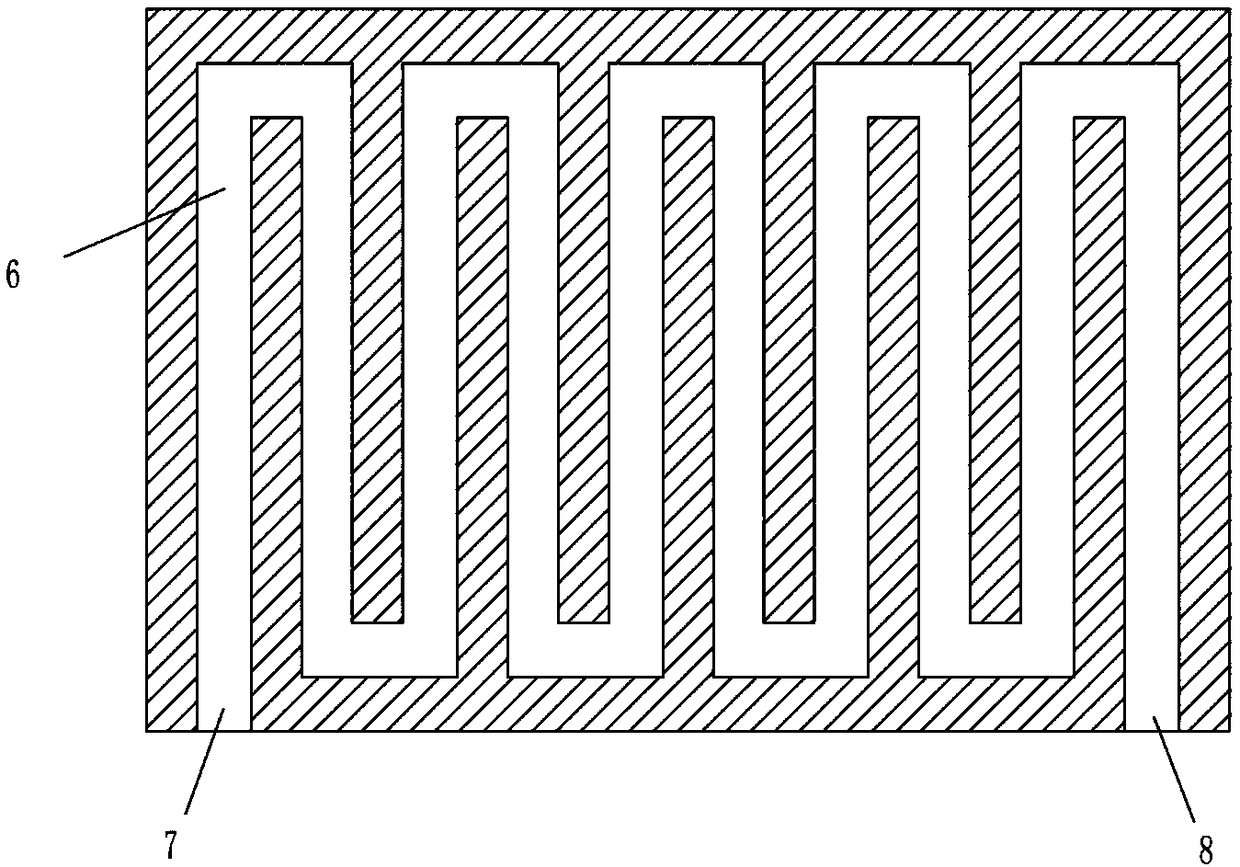

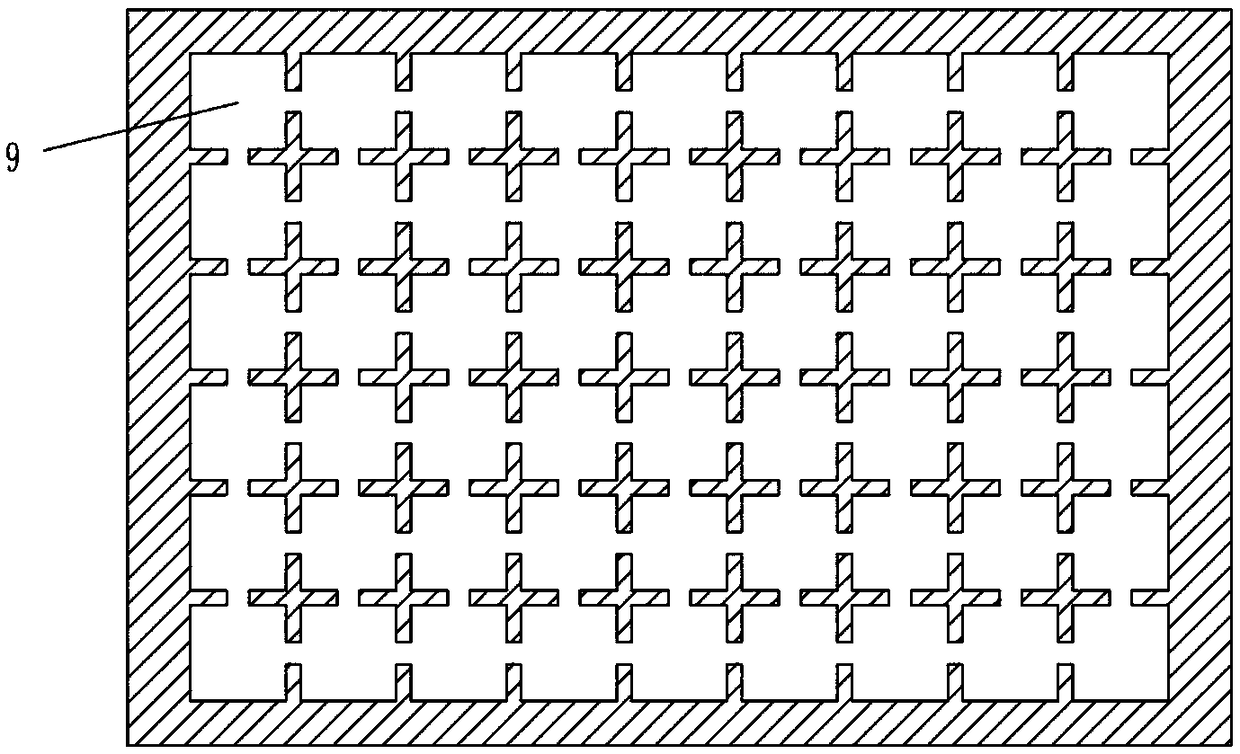

Airborne phased array antenna phase change heat storage liquid cooling heat dissipation box

InactiveCN109037882AMeet cooling needsHeat dissipation fastDe-icing/drying-out arrangementsHoneycombEngineering

The invention discloses an airborne phased array antenna phase change heat storage liquid cooling heat dissipation box, which aims to provide a phased array antenna box body with fast heat dissipation, good effect and high heat dissipation efficiency and combining liquid cooling heat dissipation and phase change heat storage. The heat dissipation box is realized through the following technical scheme: the bottom of a box body (1) is a heat dissipation base (3), the upper layer of the heat dissipation base (3) is a liquid cooling layer (4), and the lower layer is a phase change material layer (5); the liquid cooling layer is provided with an S-shaped liquid cooling flow channel, a liquid cooling inlet and a liquid cooling outlet; the phase change material layer is provided with a pluralityof honeycomb-shaped partition frame cavities enclosed between a liquid cooling layer partition plate and a box body bottom plate; the liquid cooling flow channel transfers heat out by theflow of the liquid cooling coolant; and the phase change material layer transfers heat generated by the phased array antenna to the phase change material stored in the phase change material layer by utilizing a metal partition frame connected between the partition frame cavities. The invention solves the problem that the antenna heat of the phased array antenna cannot be exported in time due to the interruption of the liquid supply under a short-time emergency condition.

Owner:10TH RES INST OF CETC

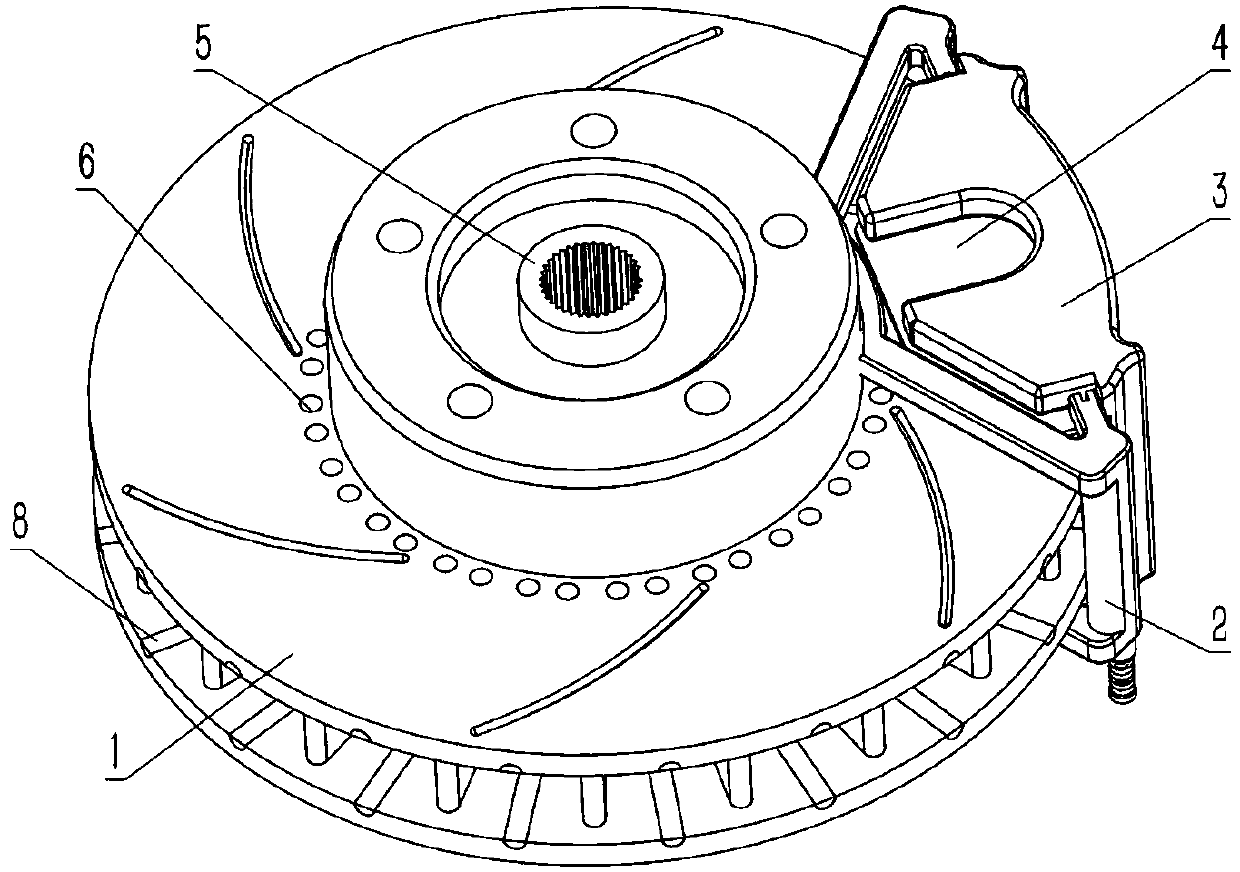

Heat pipe even-temperature heat dissipation device used for vehicle disc brake

The invention discloses a heat pipe even-temperature heat dissipation device used for a vehicle disc brake. The device comprises a brake disc composed of brake flanges arranged oppositely. Heat pipe arrays are arrayed on the opposite faces of the two brake flanges respectively in an annular shape, and the heat pipe arrays are fixed to the brake flanges in a surface contact mode through heat pipe grooves formed in the brake flanges. According to the device, it is unnecessary that an extra auxiliary power source is used for maintaining operation of heat pipes, extra motion components do not need to be arranged inside the brake disc, in this way, reliability is high, and it is avoided that the motion components fail because of abrasion, collision and others. The structure of an existing brake disc is sufficiently used, the heat pipe grooves are formed in air ducts between the opposite surfaces of the brake flanges, people do not need to change the overall structure of the brake disc, adaptability is high, the technology is simple, and the cost is low. According to the device, the technology means is simple and easy and convenient to implement, the even-temperature performance of the brake disc is good, the surface average temperature and the transient temperature are low, the structure is simple, the reliability is high, and installing is convenient.

Owner:SOUTH CHINA UNIV OF TECH

High ash melting point coal seed gasification method and device thereof

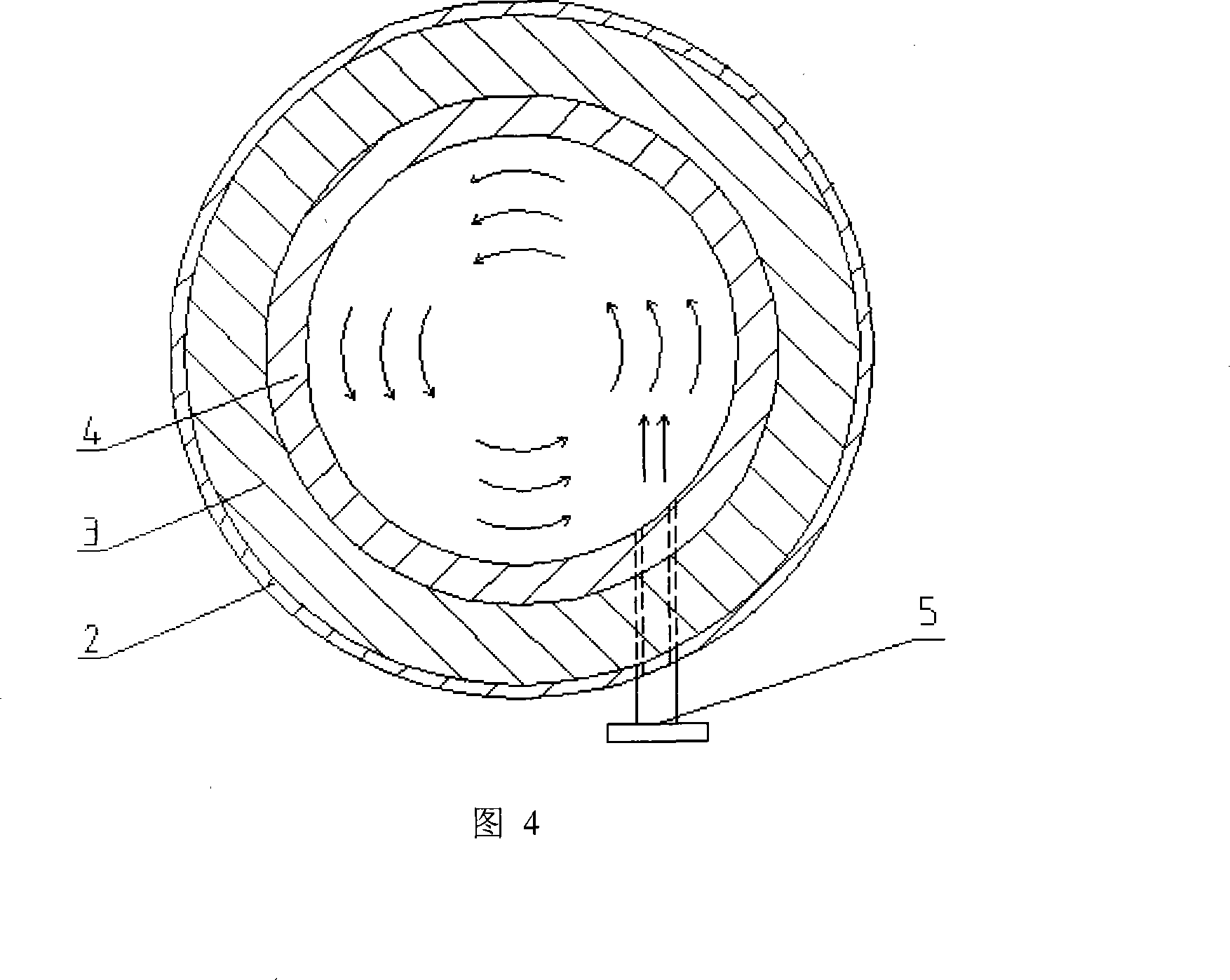

InactiveCN101235320AReduce the maximum temperatureRaise the temperature levelGranular/pulverulent flues gasificationWater vaporSlag

The invention discloses a vertical pressurization entrained flow gasification method and a device which is suitable for dust coal with high ash fusion point, slag tapping, synthesis gas and liquid slag and flows to a slag hole of down stream, the device comprises a metal casing 2 of a gasification stove, a thermal-insulating heat-insulating layer 3, a flame-proof inner container 4, a oxidize nozzle 6, a dust coal nozzle 7, a water vapor nozzle 5 and a water vapor nozzle 8. The invention is characterized in that dust coals and gasifying agents are sprayed into a gasification stove through nozzles on different heights on stove walls in different stove inlet mode, dust coal is radially sprayed through a nozzle on the upper portion of a stove body under the conveying of carrier gas, oxidizing agent is injected with high speed through a nozzle 6 on another different on the upper portion of the stove body along the direction which is parallel to the circular cross section tangent of the stove body, water vapor is injected with high speed through nozzles 7 and 8 on the lower part of the stove body along the direction which is parallel to the circular cross section tangent of the stove body, and the rotating directions of the gasifying agents on the upper portion and the lower portion are the same. Contact and reaction time of dust coal and gasifying agents in the stove is increased, gasification reaction is led to be more complete, which is beneficial further improving gasification efficiency. And the method adopts a downwards parallel current model of synthesis gas and liquid slag, which smoothly achieve slag tapping of dust coal with high ash fusion point.

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing carbon-fixation filling paste from waste concrete

InactiveCN109650805AAffect qualityIncrease carbon sequestrationGas treatmentDispersed particle separationCarbonizationToxic industrial waste

The invention discloses a method for preparing a carbon-fixation filling paste from waste concrete. The method comprises the following steps: industrial waste gas is dedusted, and then is mixed with normal temperature air, a waste concrete and a gangue mixture is crushed in the obtained industrial exhaust gas atmosphere, and coarse aggregates, fine aggregates and fine powder obtained after screening and carbon dioxide in the industrial exhaust gas undergo a carbonization reaction in a carbon fixation chamber; and the carbon-fixation coarse aggregates, the carbon-fixation fine aggregates, a filling paste additive, cement, phase change material microcapsules and water are stirred and mixed to form a filling body mixture, and the industrial exhaust gas is continuously injected in the stirring, mixing and conveying process of the filling paste to make the filling paste and the carbon dioxide in the industrial exhaust gas undergo the carbonization reaction in order to obtain the carbon-fixation filling paste. The carbonization reaction of the waste concrete and carbon dioxide is fully used, so the damages of the waste concrete to the environment are reduced, and the emission of greenhouse gases is reduced; and hydration heat is fully used in the carbonization reaction, so the filling effect of the carbon-fixation filling paste is good.

Owner:XUZHOU UNIV OF TECH

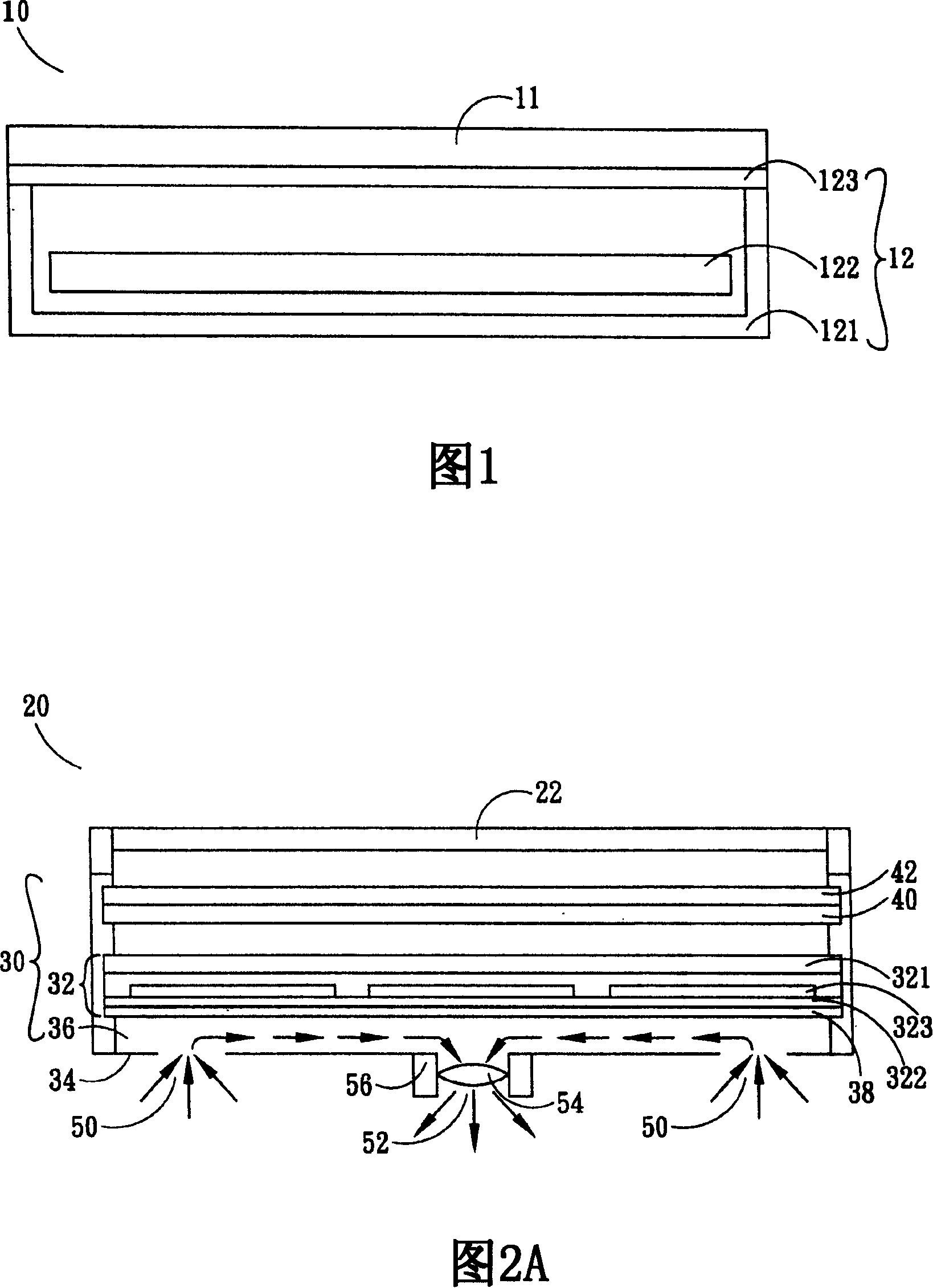

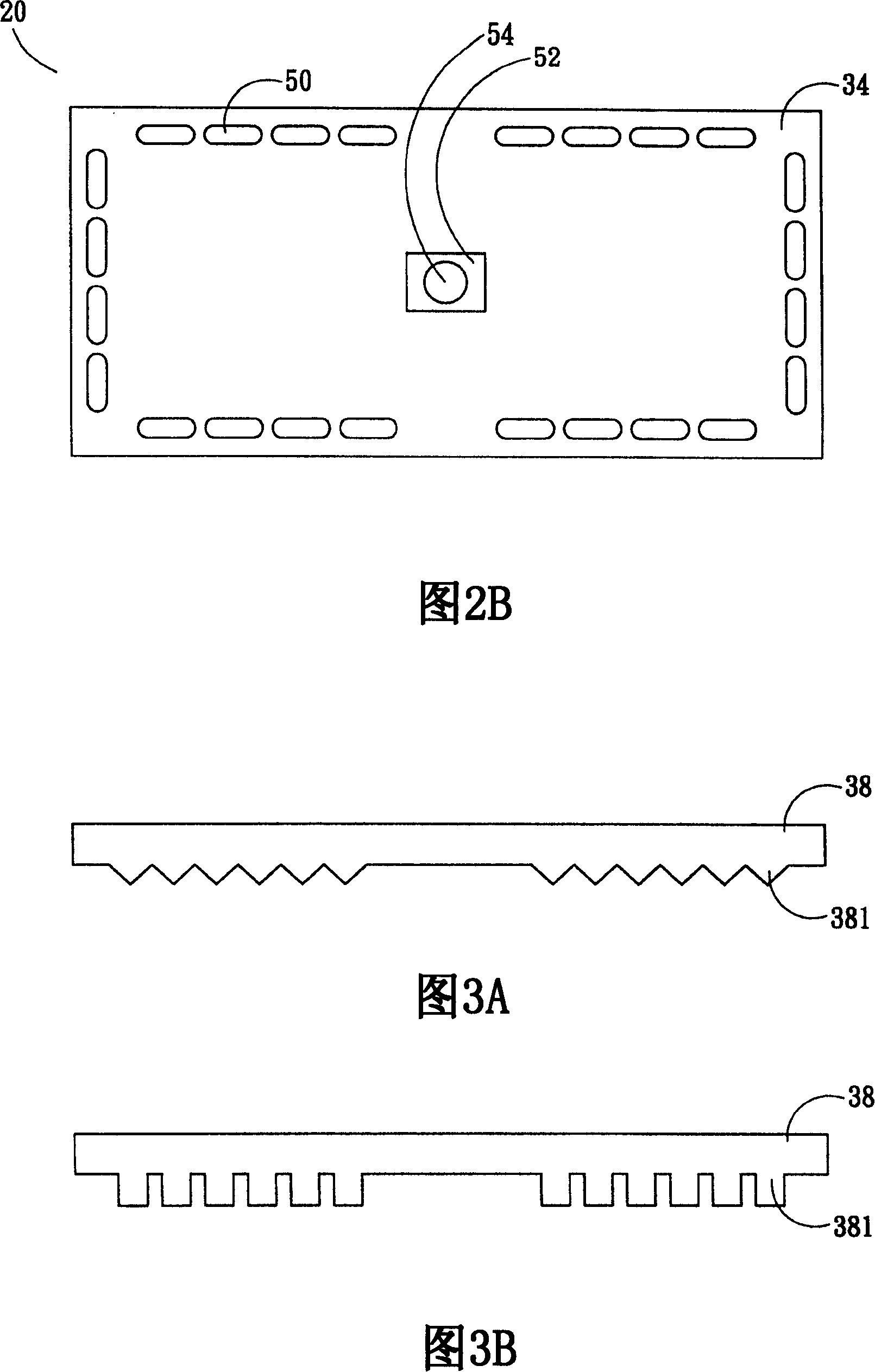

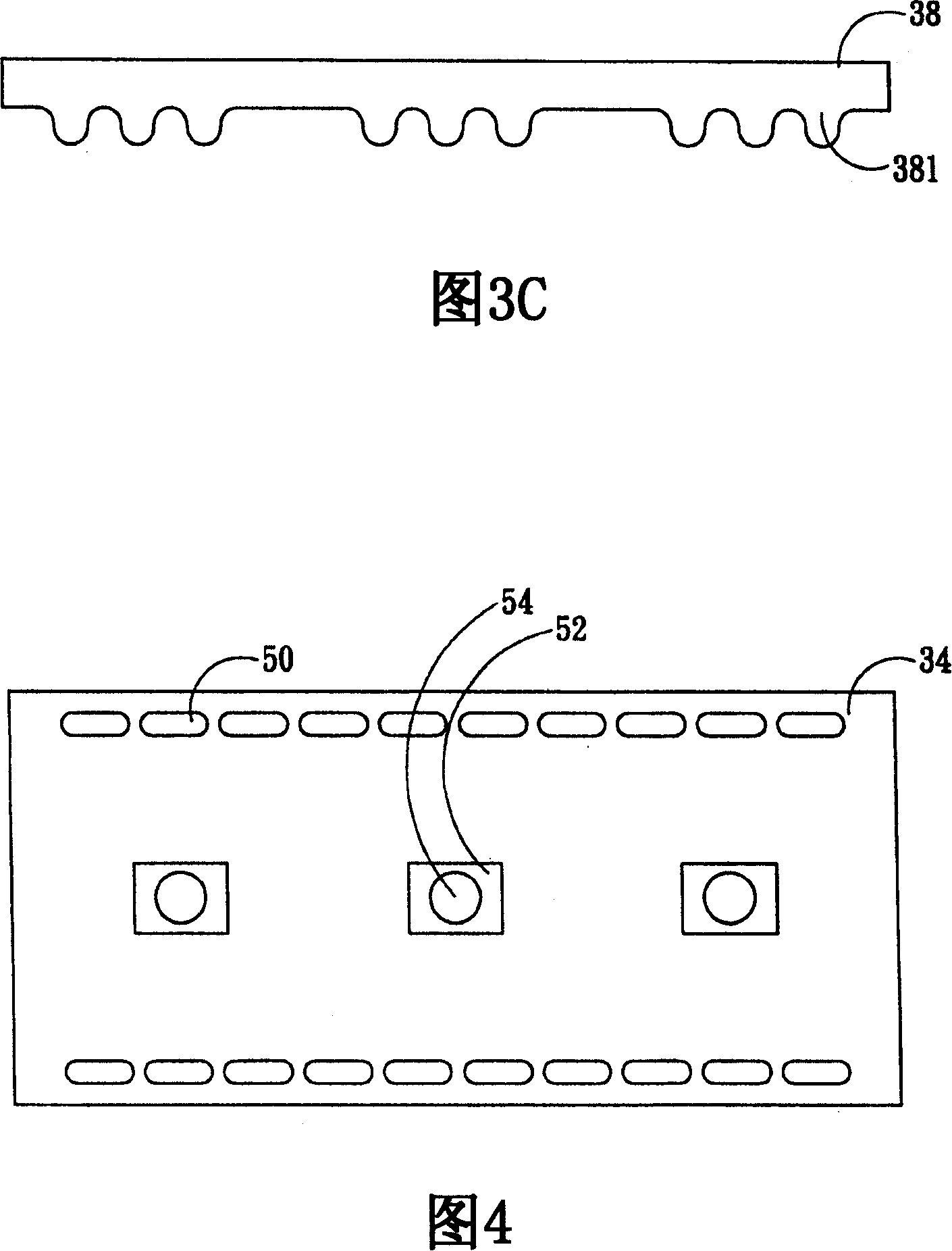

Backlight module

InactiveCN101131503AUniform temperature distributionReduce the temperatureNon-linear opticsEngineering

This invention provides a kind of negative phototropism module, it includes a plane lamp board, a flat, and a passage between the plane lamp board and the flat. The flat has complex number hole and at least one hatch, the said hole are set in the circum of the flat, the hatch is in the middle of the flat, and it sets a fan in the hatch, the distance between the hole and the hatch are almost the same. This invention can reduce the temperature of the lamp board, to make the lamp board temperature distribute equally, so it can increase the stability of the lamp board, enhance the display effect, prolong the use life of the lamp board.

Owner:CHUNGHWA PICTURE TUBES LTD

Lining concrete water cooling age control method

ActiveCN110516285ANo wasteAvoid manual control errorsHydro energy generationSpecial data processing applicationsTemperature controlEngineering

The invention provides a lining concrete water cooling age control method. The lining concrete water cooling age control method comprises the steps of collecting lining concrete temperature control data; calculating the water cooling control age Tj = 2H + 5 (formula 1) based on the collected lining concrete temperature control data, wherein H is the thickness of the lining concrete structure; andcontrolling the water cooling time of the low-heat cement concrete of the lining structure according to the water cooling control age Tj. The water cooling control age calculation formula 1 provided by the invention directly reflects the influence of the lining thickness; influences of different lining structures, section sizes of the lining structures, concrete varieties, strength grades, pouringseasons, pouring temperatures, water cooling, water temperatures of the water cooling and heat preservation measures are indirectly included. The water cooling age is controlled in the optimal time period, manual control errors are avoided. The labor intensity is reduced. The waste caused by long-time water cooling is avoided. The water cooling temperature control quality is guaranteed, and the lining concrete water cooling age control can be scientifically achieved.

Owner:WUCHANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com