Novel cooling fin runner structure

A heat dissipation fin and flow channel technology, which is applied in the field of new heat dissipation fin flow channel structure, can solve the problems of cooling air velocity and air volume reduction, poor temperature uniformity of the fin flow channel, and large flow resistance, etc., to achieve increased air intake, The effect of reducing flow resistance and increasing wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

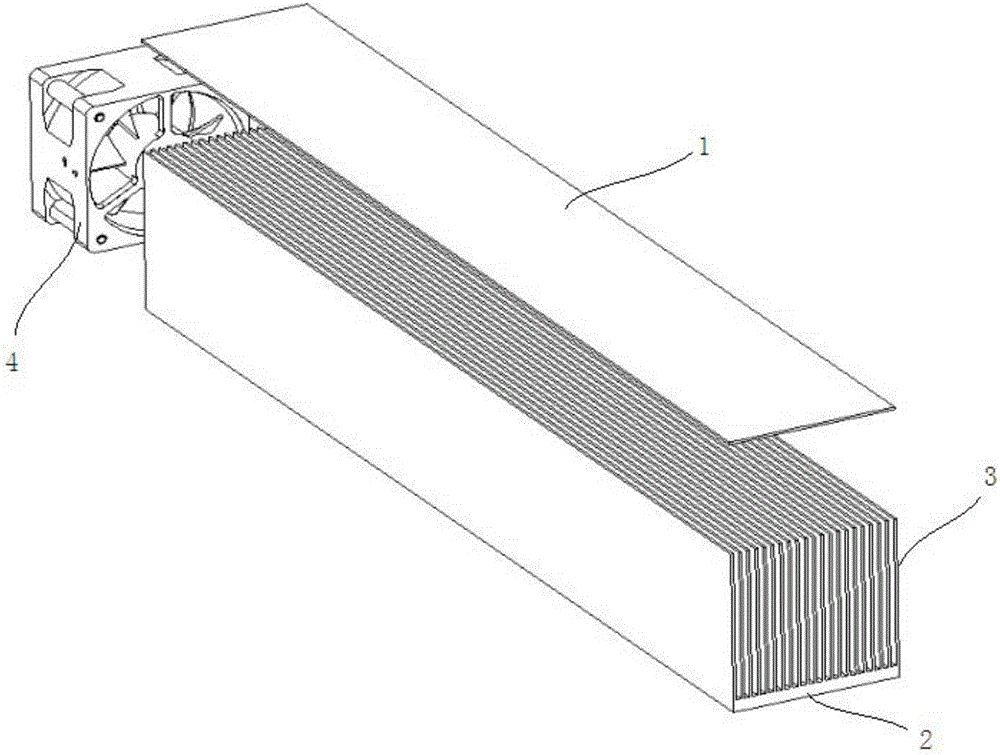

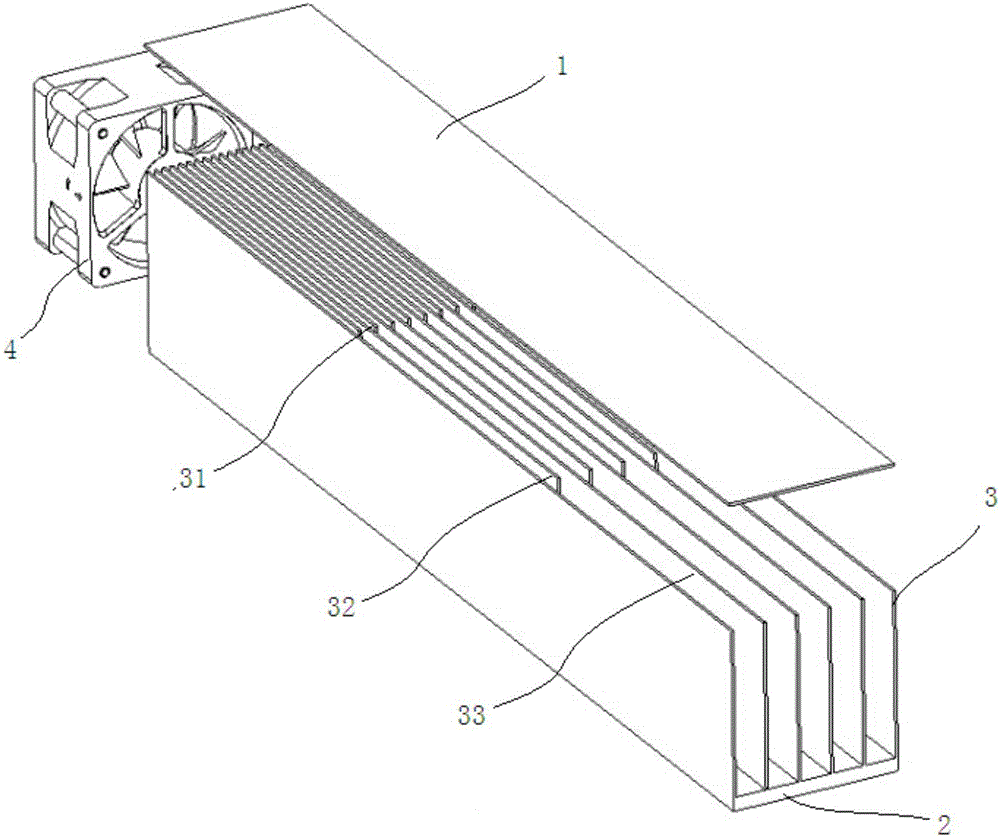

[0021] Embodiment 1: as figure 2 , image 3 As shown, this embodiment provides a novel cooling fin flow channel structure, the flow channel structure includes a flow channel cover plate 1, a flow channel bottom plate 2, and a plurality of mutually parallel channels located between the flow channel cover plate and the flow channel bottom plate The fins 3 are perpendicular to the flow channel cover plate 1 and the flow channel bottom plate 2; the two ends of the flow channel structure are the air inlet 5 and the air outlet; in this embodiment, the air outlet A fan 4 is provided on the end face for sucking cooling air into the flow channel (flow channel structure);

[0022] In this embodiment, the flow channel structure is evenly divided into three flow channel parts along the length direction, wherein the flow channel part near the air inlet is a low-temperature section, and the flow channel part near the air outlet is a high-temperature section. The flow channel part between...

Embodiment 2

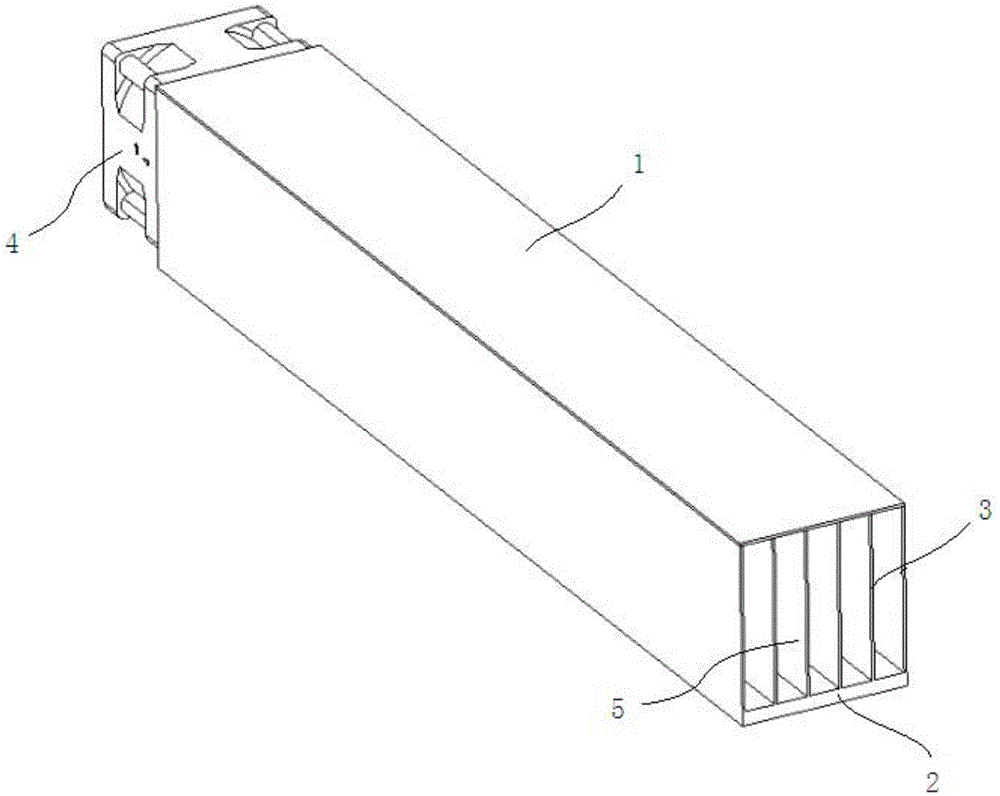

[0025] Embodiment 2: The difference from Embodiment 2 is that the novel cooling fin channel structure provided by this embodiment is divided into two channel parts along the length direction, among which the channel part near the air inlet 5 is a low-temperature section, and the channel part near the outlet The flow channel part of the tuyere is a high-temperature section, and the fin spacing in the low-temperature section is larger than the fin spacing in the high-temperature section.

[0026] In this embodiment, both the flow channel bottom plate 2 and the flow channel cover plate 1 are heat-conducting contact surfaces in contact with the heat-generating device, and simultaneously transfer heat to each fin 3 arranged in parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com