Novel low-cost stack-up array liquid refrigeration semiconductor laser and manufacturing method thereof

A low-cost, laser technology, applied in semiconductor lasers, semiconductor laser devices, structural details of semiconductor lasers, etc., to achieve the effects of increasing circulation space, reducing voltage drop, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is described in further detail below in conjunction with accompanying drawing:

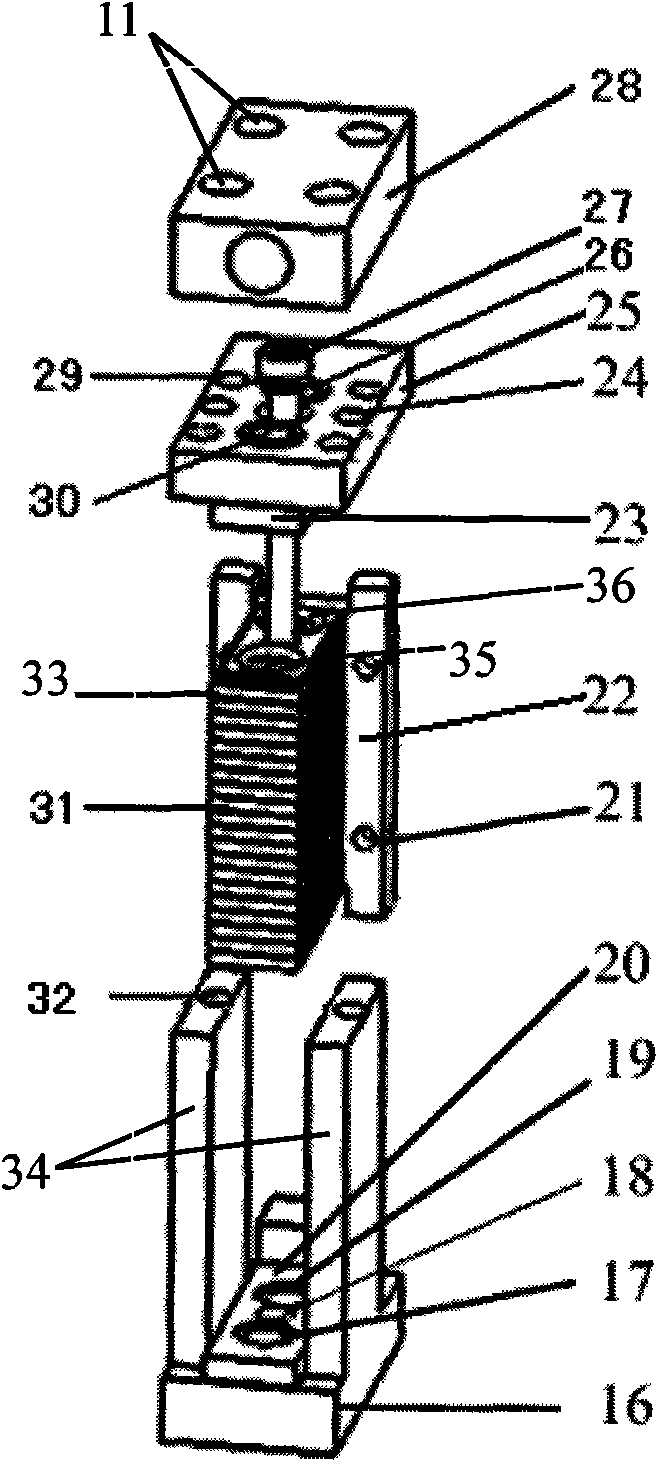

[0048] figure 1 It is a dismantling schematic diagram of various components of the new low-cost stacked array liquid-cooled semiconductor laser of the present invention. This stacked array liquid-cooled semiconductor laser includes a lower base plate 16, a positive electrode block 20, multiple Bar series module group 31, negative electrode block 23, upper pressure block 25 and liquid refrigeration block 28, wherein multi-bar series module group 31 includes two or more micro-refrigeration modules 33 with chips. The liquid inlet channel 35 and the liquid outlet channel 36 are arranged on the multibar series module group 31 , and the liquid inlet channel 35 and the liquid outlet channel 36 are perpendicular to the horizontal plane of the chip microrefrigeration module 33 .

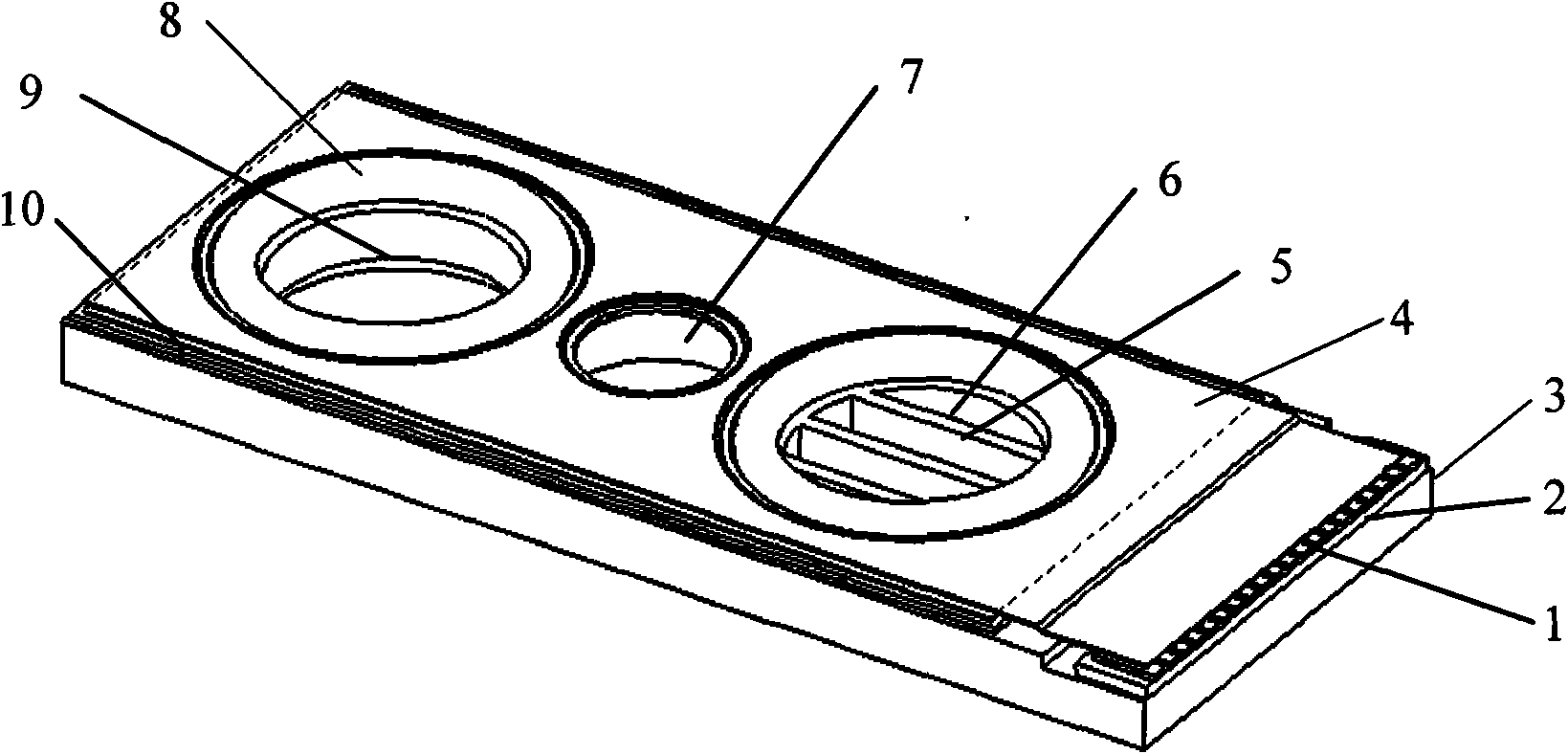

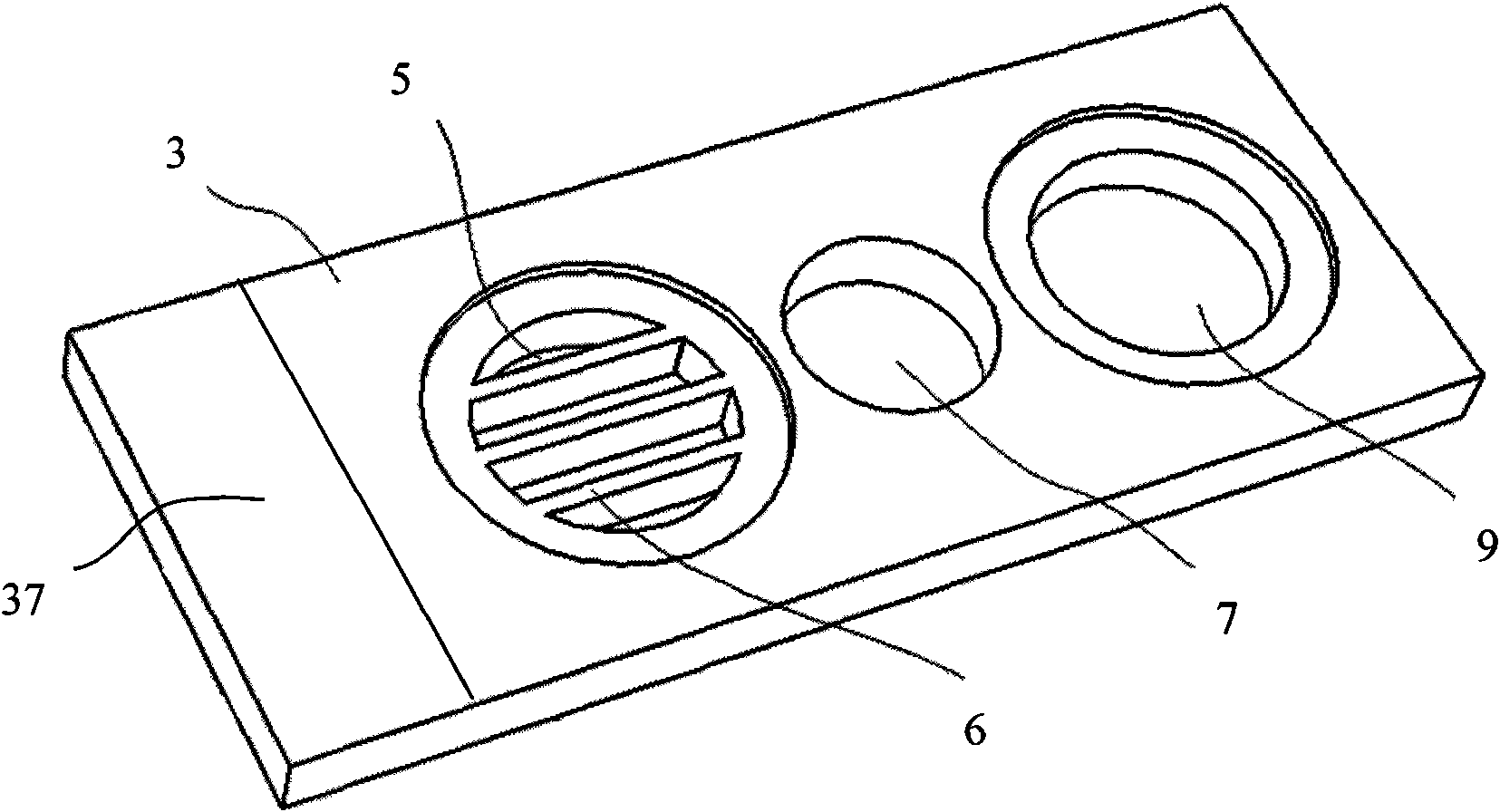

[0049] Such as figure 2 , the micro-refrigeration module 33 with a chip comprises a copper con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com