Tubulation and/or sepcial-section tubulation reforced heat exchange tube

A technology for heat exchange tubes and tube sections, which is applied in the field of enhanced heat exchange tubes with special-shaped/shaped cross-sections of tube sections and/or tube sections, which can solve the requirements of increased cleaning and maintenance workload, increased flow resistance or power consumption, and fluid cleanliness Very strict and other problems, to achieve the effect of heat transfer enhancement, reduce vibration, and easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

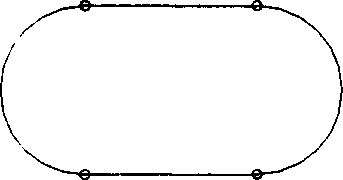

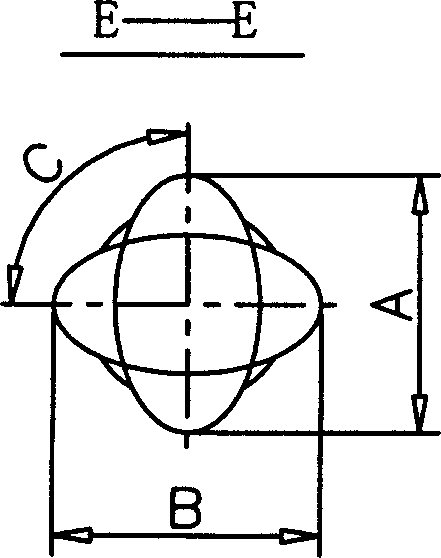

[0046] Figure 9 It is a schematic structural view of the regular shaped tube in embodiment 1. The entire normal-shaped pipe consists of a deformed pipe section 1, an oval pipe section 2, a transition pipe section 3 and a round pipe section 4; Figure 9 From left to right, the four basic pipe sections follow the rules of "circular pipe section - transitional pipe section - elliptical pipe section - positive deformation pipe section - elliptical pipe section - positive deformation pipe section - elliptical pipe section - transitional pipe section - circular pipe section—…" The sequence is arranged periodically, and the deformed pipe section and the elliptical pipe section are the main body of heat exchange. During implementation, the number of circular pipe sections can be increased or decreased according to the requirements of the compressive strength of the pipe, and the circular pipe sections can be arranged in other appropriate positions according to the needs of installin...

Embodiment 2

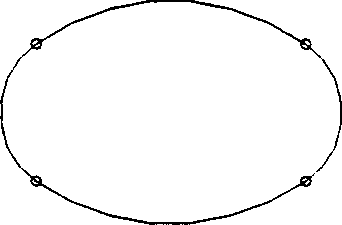

[0049] Figure 11 It is a structural schematic diagram of the deviation-shaped tube of Example 2. The whole deformed pipe consists of a deformed pipe section 1, an oval pipe section 2, a transition pipe section 3 and a round pipe section 4. The four basic pipe sections are periodically arranged in the order of "round pipe section—transition pipe section—elliptical pipe section—deformed pipe section—elliptical pipe section—deformed pipe section—elliptical pipe section—transition pipe section—circular pipe section—…". The entire deviation-shaped pipe is made of a base pipe with an inner diameter d after rolling or molding, and can also be formed at one time when rolling a seamless pipe. The length Lo of the circular pipe section, the length Lt of the transition pipe section, the length Lr of the deflected pipe section, and the length Le of the elliptical pipe section are the same as those of the normal shaped pipe. The cross-sectional shape of the elliptical pipe segment is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com