Axial round tube type silk net heat-tube using cupric oxide nano particle suspending liquid as working medium

A technology of nanoparticles and copper oxide, which is applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of heat transfer performance of heat pipes that no one has raised, and achieve improved heat transfer coefficient, improved heat dissipation power, and reduced total thermal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. The parameters in the following examples do not limit the present invention.

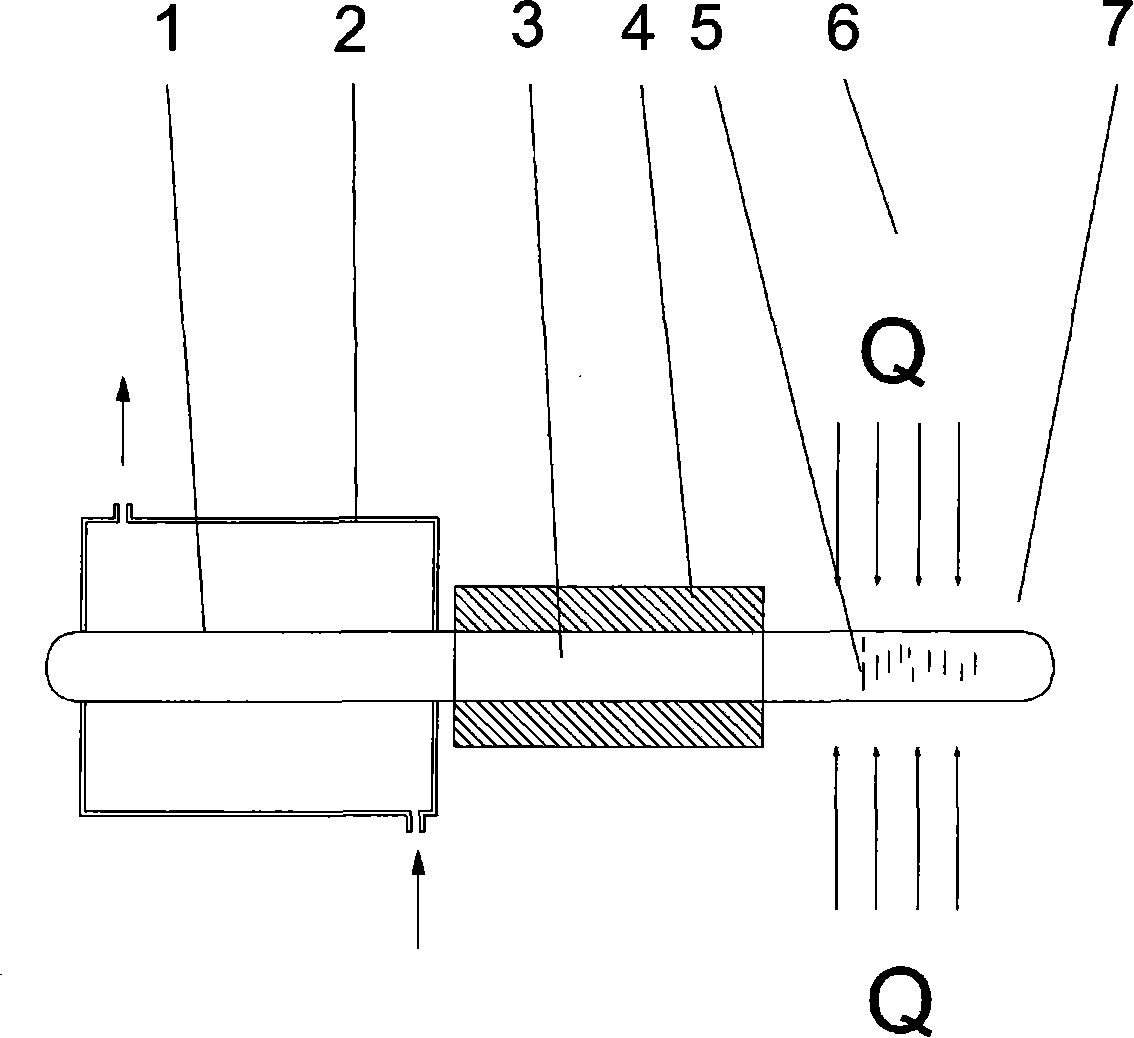

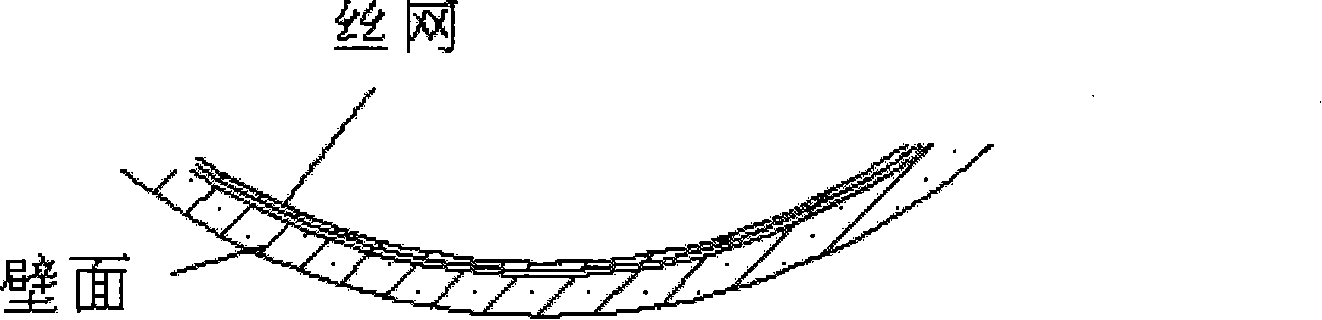

[0017] The structure of the axial circular tube type wire mesh heat pipe of the present invention is as follows: figure 1 As shown, the entire heat pipe is made of copper tube, the outer diameter of the copper tube is 10mm, the wall thickness is 0.6mm, the total length is 350mm, the length of the heating section is 100mm, the length of the adiabatic section is 100mm, and the length of the condensation section is 150mm. The size of the heat pipe can be designed arbitrarily. The insulation section 3 is covered with Teflon rods 4 for heat preservation. The evaporation section 7 is heated by an electric heater. The inner wall of the evaporation section 7 is equipped with a wire mesh liquid-absorbing core structure. Water enters from the lower part of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com