Patents

Literature

46results about How to "Good flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

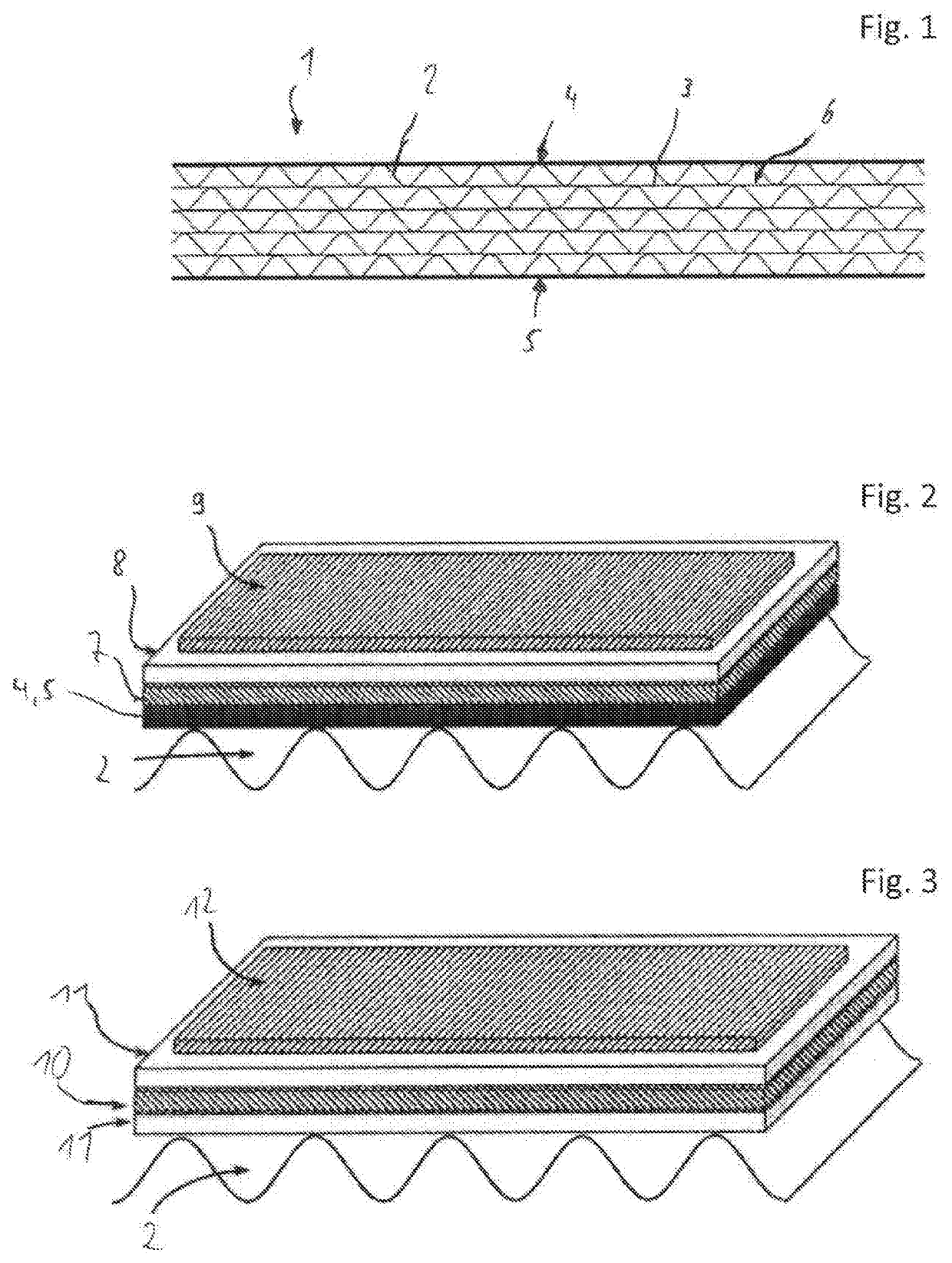

Filter medium for leukocyte removal, method of making, and method of using thereof

InactiveUS6048464AGood flowHigh in leukocyte-removing performanceHaemofiltrationEnzymologyFiber structureWhite blood cell

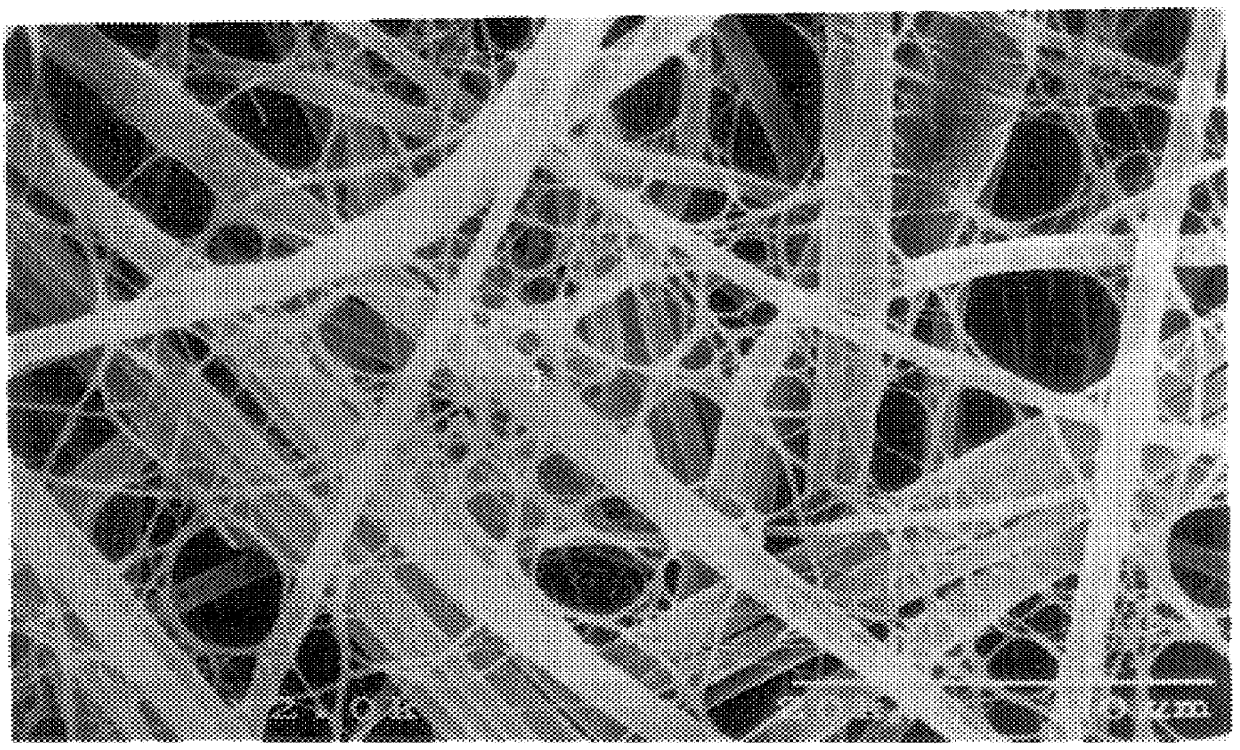

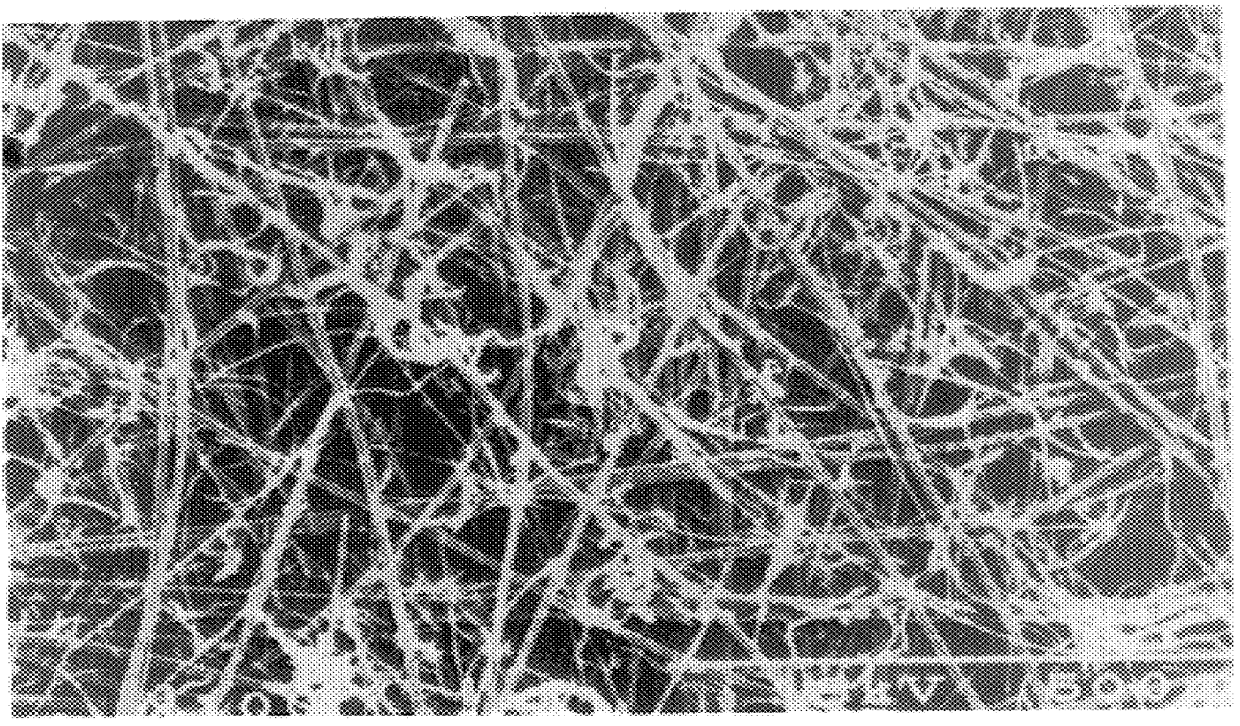

PCT No. PCT / JP96 / 03814 Sec. 371 Date Aug. 14, 1997 Sec. 102(e) Date Aug. 14, 1997 PCT Filed Dec. 26, 1996 PCT Pub. No. WO97 / 23266 PCT Pub. Date Jul. 3, 1997A leukocyte-removing filter material is described, which includes a porous element having fine pores of an average pore diameter of not less than 1.0 mu m but less than 100 mu m and a fiber structure composed of a plurality of fibers having an average fiber diameter of not less than 0.01 mu m but less than 1.0 mu m kept on the porous element. The porosity of the filter material is not less than 50% but less than 95%, and the proportion of the fiber structure to the filter material is not less than 0.01% by weight but less than 30% by weight. The ratio between the average pore diameter of the porous element and the average fiber diameter of the fiber structure is not less than 2 but less than 2,000 and the above fiber structure forms a reticulate structure. A process for producing the leukocyte-removing fiber material and an apparatus for removing leukocyte using the above fiber material are also described.

Owner:ASAHI KASEI MEDICAL CO LTD

Heat-resistant stable non-soluble sulfur and production method thereof

InactiveCN107337184APrevent depolymerizationThe preparation yield effect is obviousSulfur preparation/purificationHeat resistanceSulfur

The invention relates to the field of non-soluble sulfur, in particular to heat-resistant stable non-soluble sulfur and a production method thereof. The production method comprises the steps of (1) premelting; (2) reaction; (3) quenching; (4) extraction; (5) smashing. The heat-resistant stable non-soluble sulfur provided by the invention can compensate the shortcomings of low heat resistance stability and low yield of non-soluble sulfur in the prior art to a certain extent.

Owner:SHANGHAI JINGHAI ANHUI CHEM

Method for preparing chitosan in situ gel agent

InactiveCN101327183AGood flowExpand the delivery methodPharmaceutical delivery mechanismPharmaceutical non-active ingredientsGel preparationOrganic solvent

The invention discloses a preparation method of chitosan in situ gel preparation, which belongs to the medicine technical field. The invention comprises the steps as follows: first, dissolving chitosan into water solution and / or water solution with cosolvent; second, adding medicine into the chitosan solution and stirring sufficiently; third, adding strong base-weak acid salt into the chitosan solution slowly in CO2 atmosphere and under the stirring condition, and keeping stirring; fourth, distributing the evenly mixed chitosan collosol into sterile bottles with stoppers for sealing or filling chitosan collosol into an atomizing device under the protection by CO2 and then obtaining the chitosan in situ gel preparation. The invention not only avoids using organic solvent in the cause of preparation production but also simplifies the preparation production flow and widens the preparation application ways.

Owner:SHANGHAI JIAO TONG UNIV

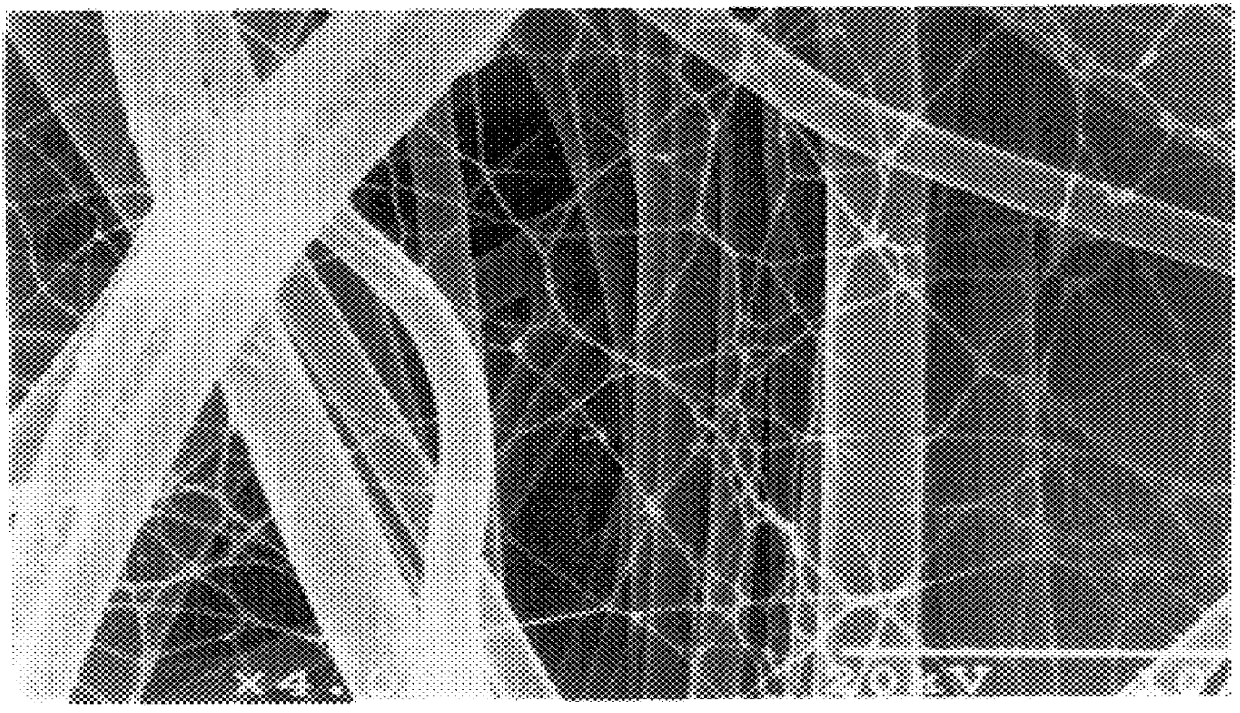

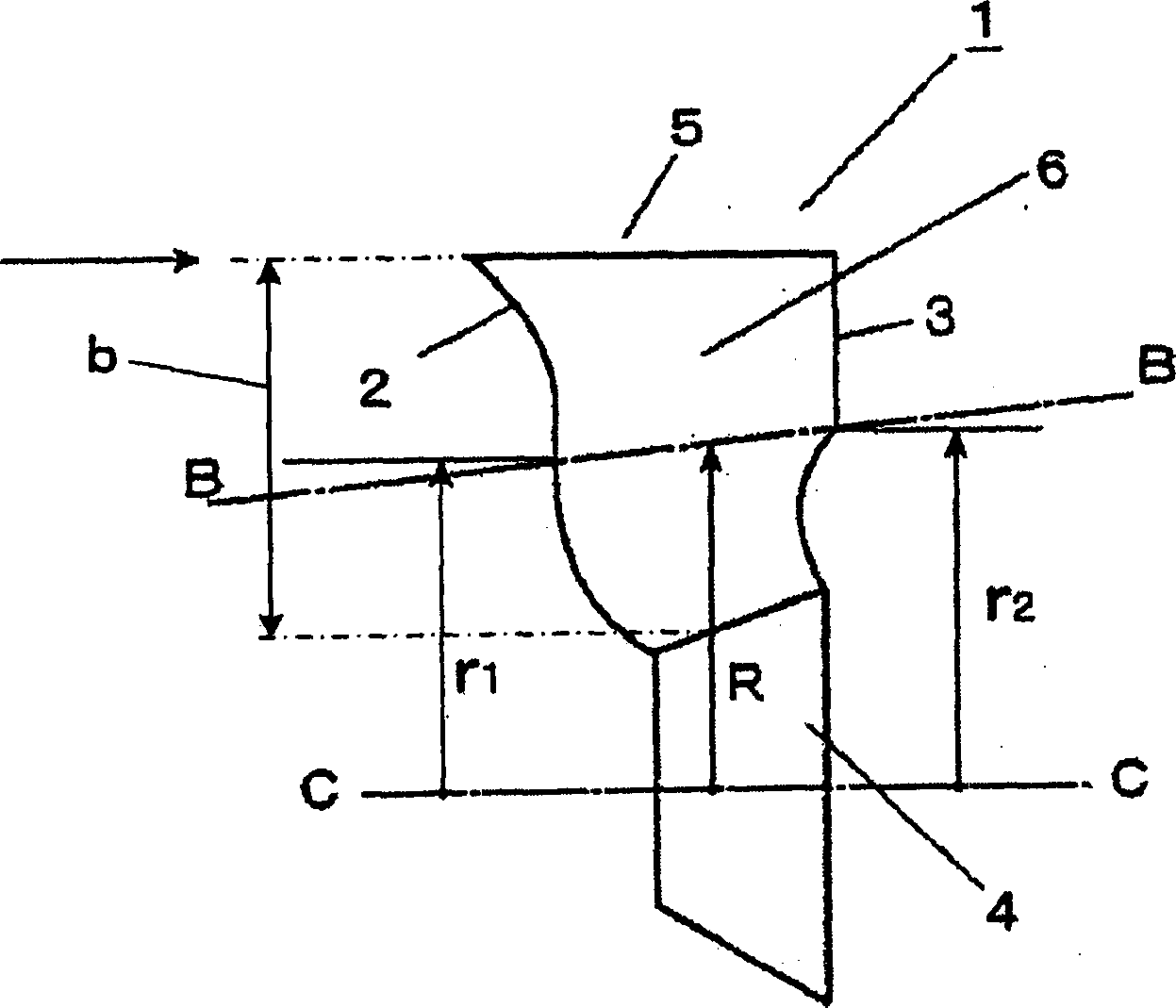

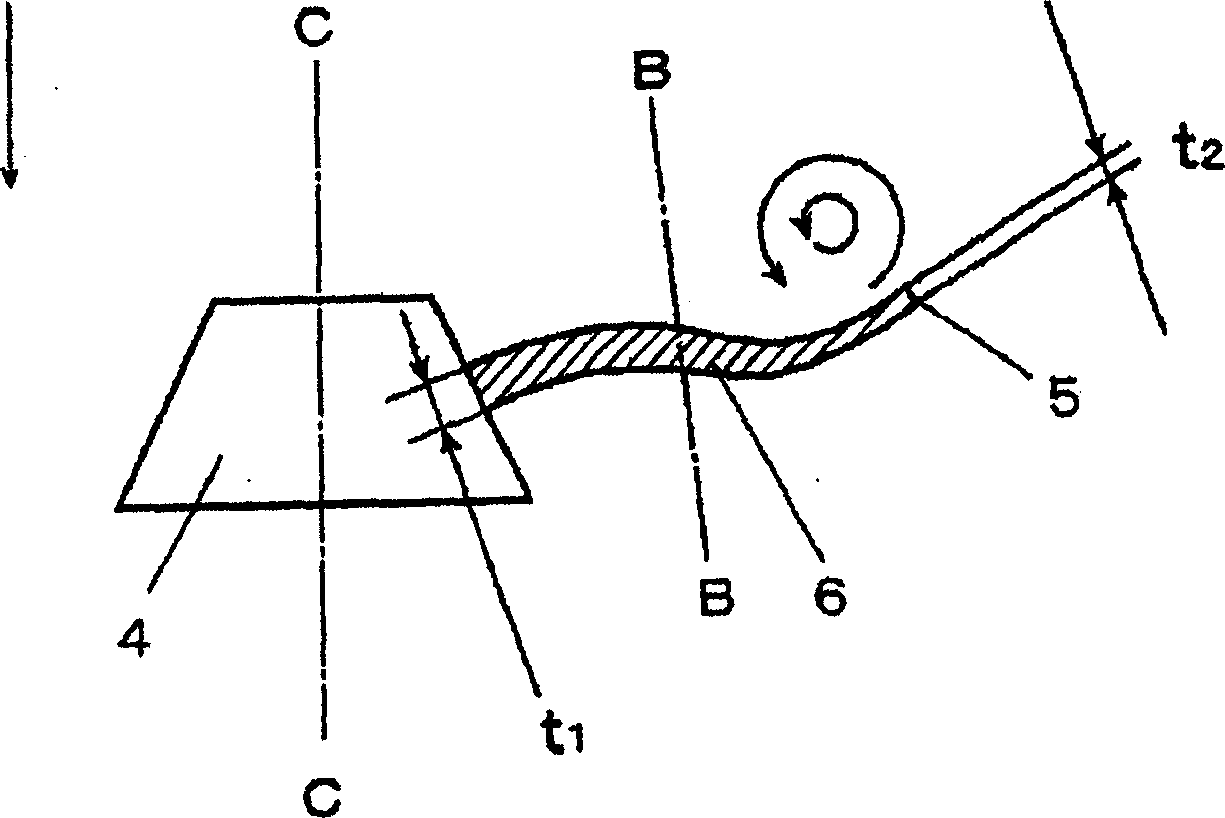

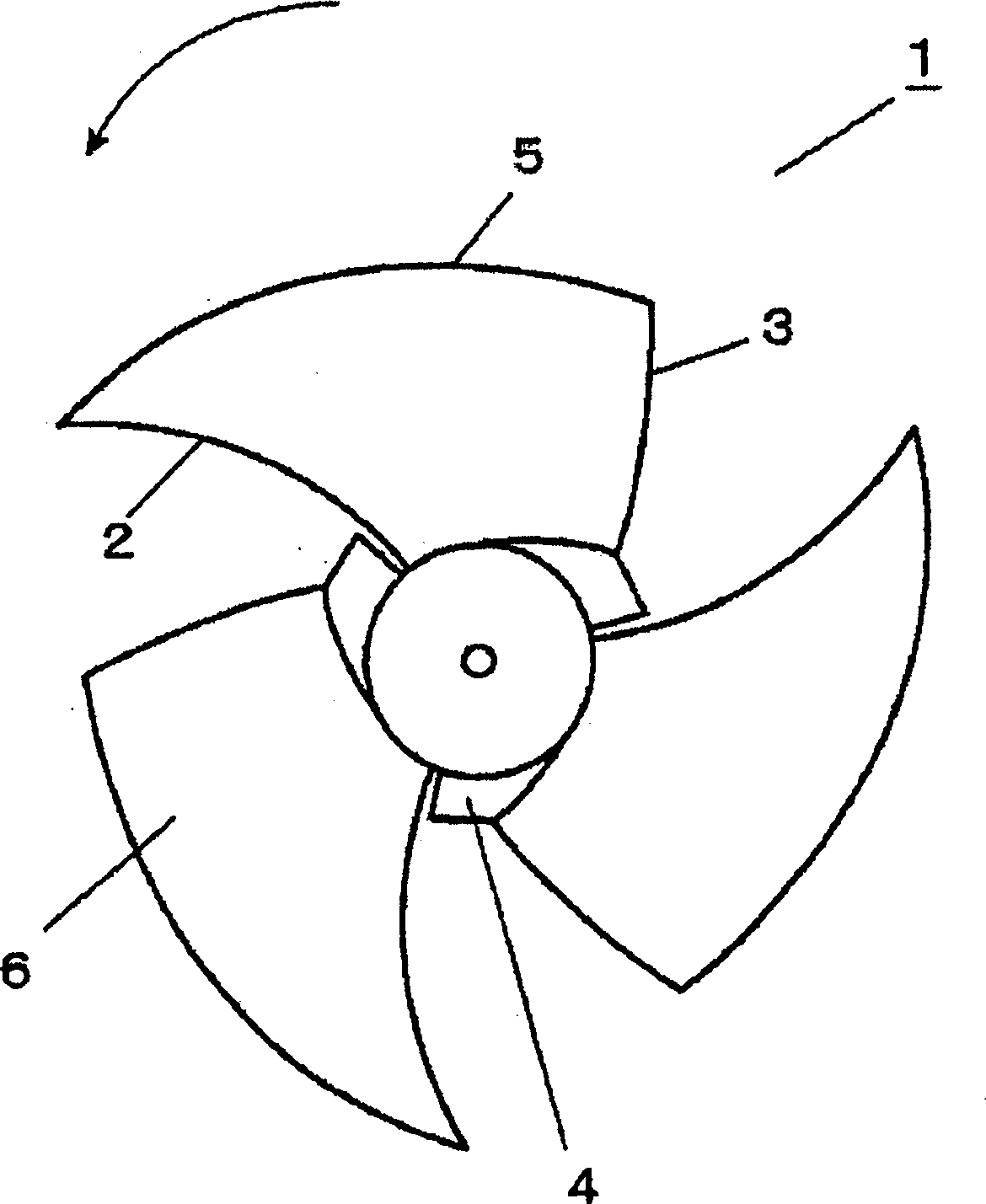

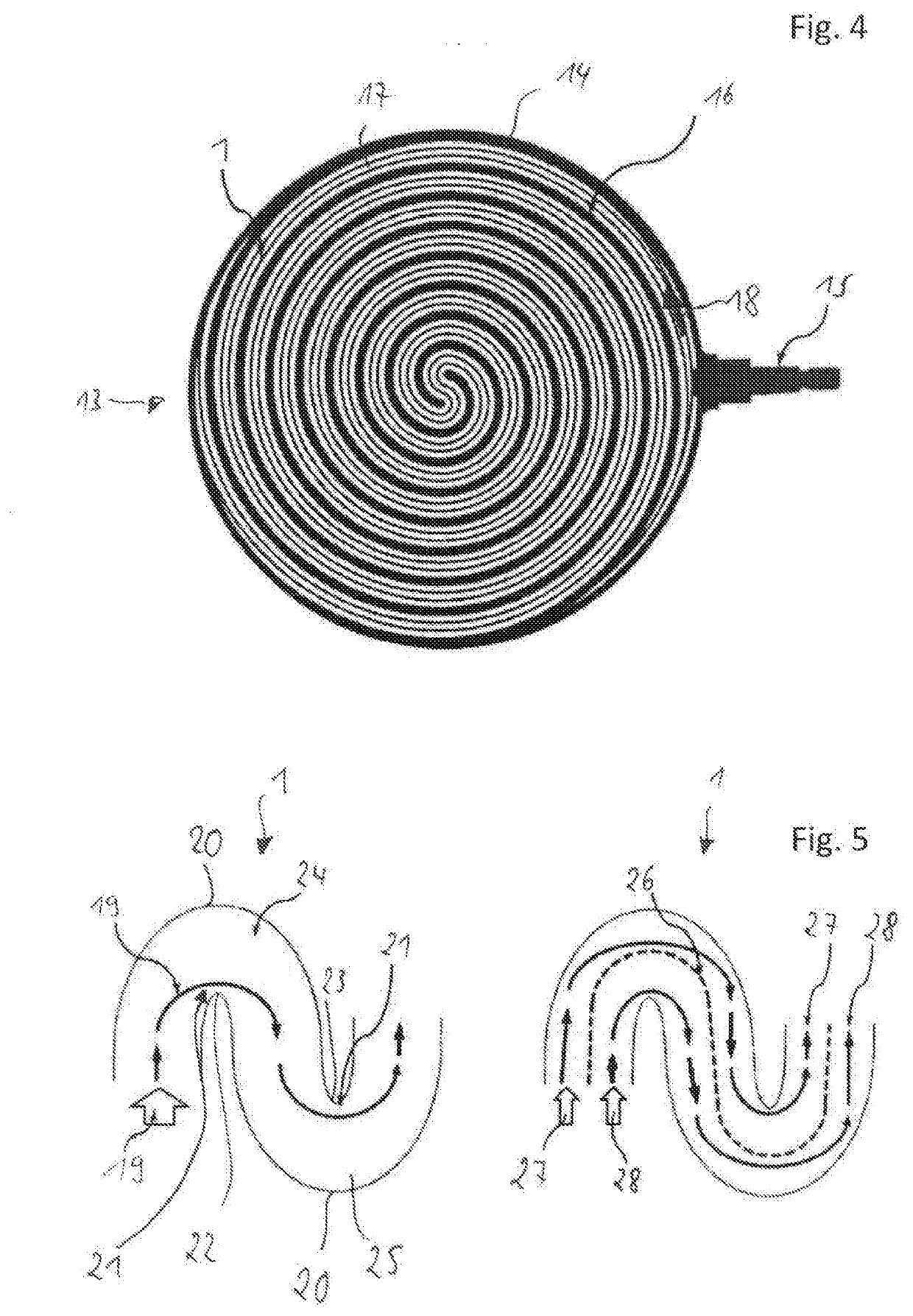

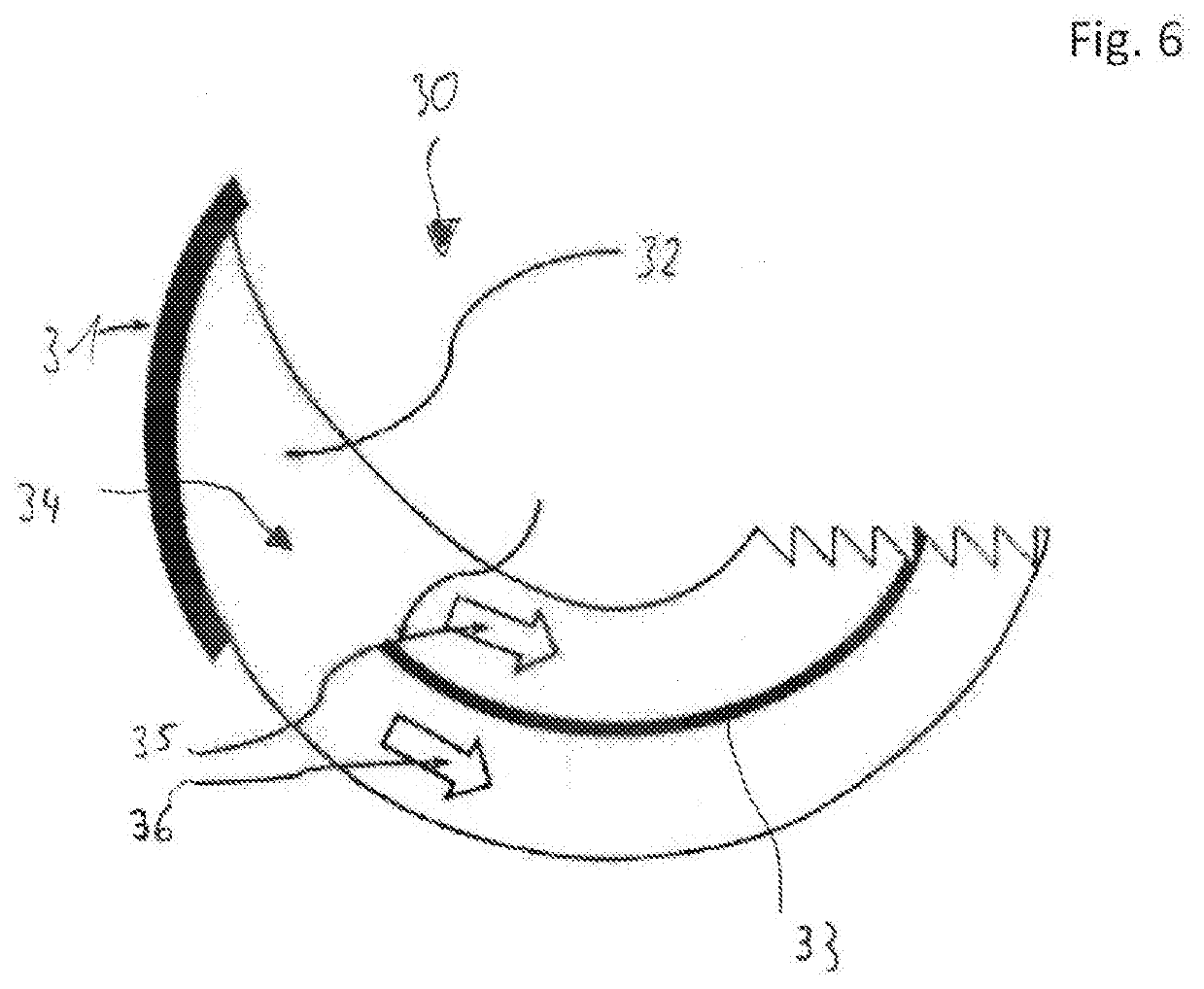

Air feeder vane wheel

The oblique flow blower impeller of the present invention focuses on improving fan efficiency and reducing noise, and improves these performances by improving the structure of the fan. An impeller (1) of a diagonal flow blower is formed by arranging a plurality of thin blades (6) on a roughly truncated cone-shaped hub (4), and the front edge (2) of the blades (6) is formed in the following shape: On the meridian surface of the blade (6), a concave curve is formed on the upper side of the outer peripheral side near the midpoint (BB) of the blade tip (5) of the hub (4) and the blade (6) relative to the wind. The more hub side near the point is formed as a convex curve relative to the upper side of the wind, and the radial cross-sectional shape of the blade (6) is formed as follows: the more blade tip (5) side near the midpoint is formed as a concave curve relative to the upper side of the wind , the more hub (4) side near the midpoint is formed as a convex curve relative to the upper side of the wind. And, the leading edge (2) is formed by a helical curve.

Owner:PANASONIC CORP

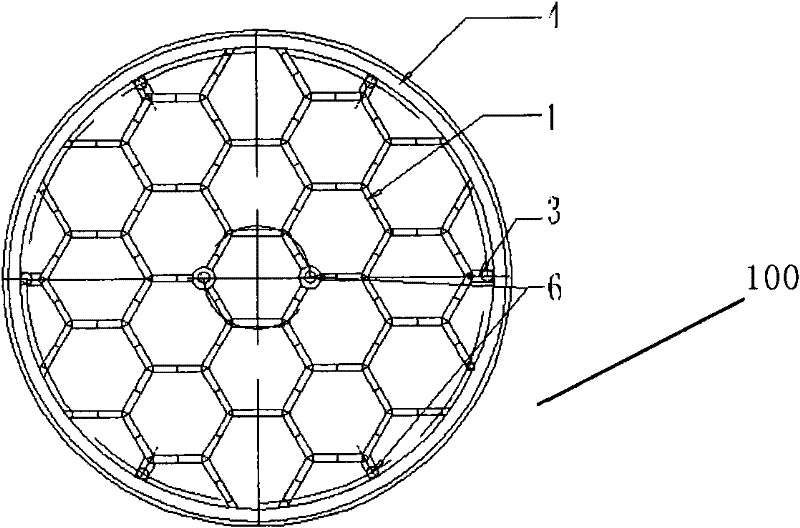

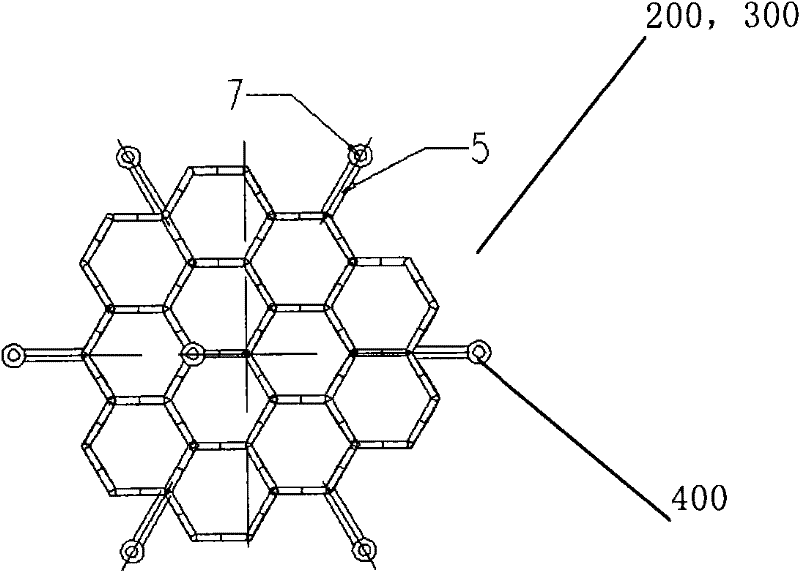

Catalyst stuffing and stuffing bed for seawater desulfurization process

InactiveCN102211045AReduce oxidationSmooth releasePhysical/chemical process catalystsDispersed particle separationCatalytic oxidationSULFATE ION

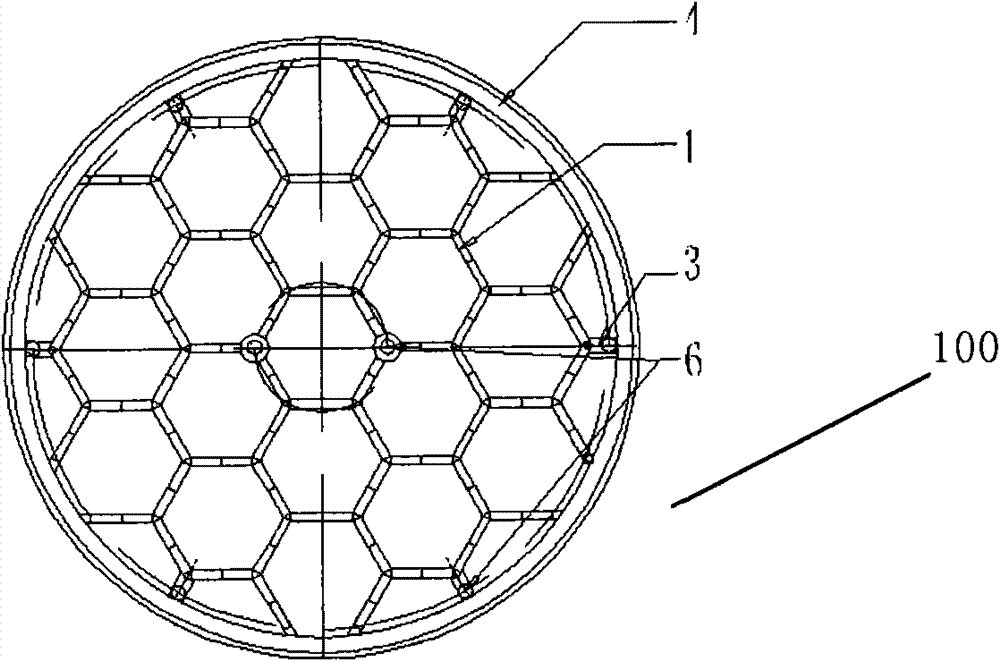

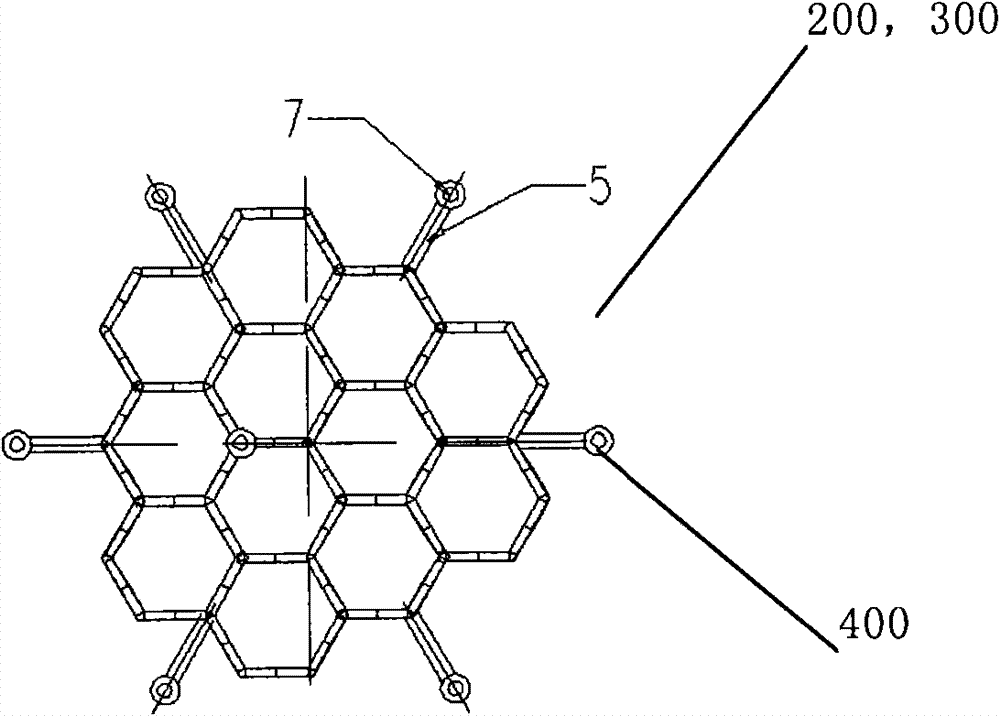

The invention provides a catalyst stuffing and stuffing bed for a seawater desulfurization process. The surface of the catalyst stuffing is coated with a catalyst, and the catalyst stuffing is composed of a three-layered cellular ring structure which comprises (a) a middle cellular ring (100), (b) an upper cellular ring (200) and a lower cellular ring (300) as well as (c) a supporting structure (400) connected with the upper cellular ring (200), the middle cellular ring (100) and the lower cellular ring (300). The catalyst stuffing has a good contacting surface, a relatively low pressure dropand an effect of catalytic oxidation, and can catalytically oxidize the SO2 absorbed in seawater into stable sulfate ions. Sulfite ions are further stabilized into the sulfate ions on the basis of improving the desulfurization efficiency; the oxidation quantity in the later stage of the seawater desulfurization process is reduced, so that an aeration basin and the aeration quantity can be reduced.

Owner:SHANGHAI HUOLIN ENG PLASTICS

Soundproof-cotton gluing machine application method

ActiveCN104722450AImprove uniformityQuality improvementLiquid surface applicatorsCoatingsAdhesive glueLeather belt

The invention discloses a soundproof-cotton gluing machine application method and belongs to the technical field of gluing machines. The soundproof-cotton gluing machine application method includes the steps of 1), equipment starting, namely respectively starting a gluing mechanism, a glue discharging mechanism, a recycling mechanism and a belt conveying mechanism on a soundproof-cotton gluing machine; 2), gluing, namely allowing glue flowing out from a glue discharging device to flow down along a gap between a gluing roller and a glue mixing roller and a to-be-glued rubber skin to be driven by the gluing roller to move sequentially in gaps of between a glue applying roller and the glue roller as well as between the glue applying roller and the glue mixing roller for gluing; 3), gluing completion, namely allowing the rubber skin coated with the glue to be conveyed to the tail portion of a conveying platform through a conveying belt, wherein the lower surface of the rubber skin is in friction contact with the upper surface of a cushion block, movement speed of the rubber skin is reduced, the rubber skin is taken away by workers, and gluing is completed. With the method, problems that gluing is uneven, waste glue cannot be effectively recycled and the like are solved.

Owner:河北蓝格隔音材料有限公司

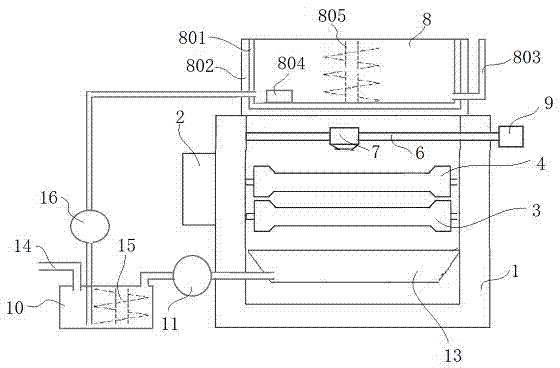

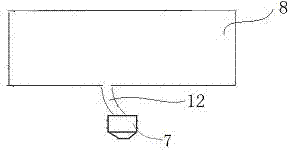

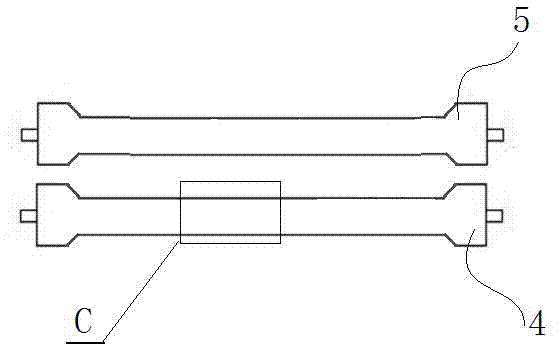

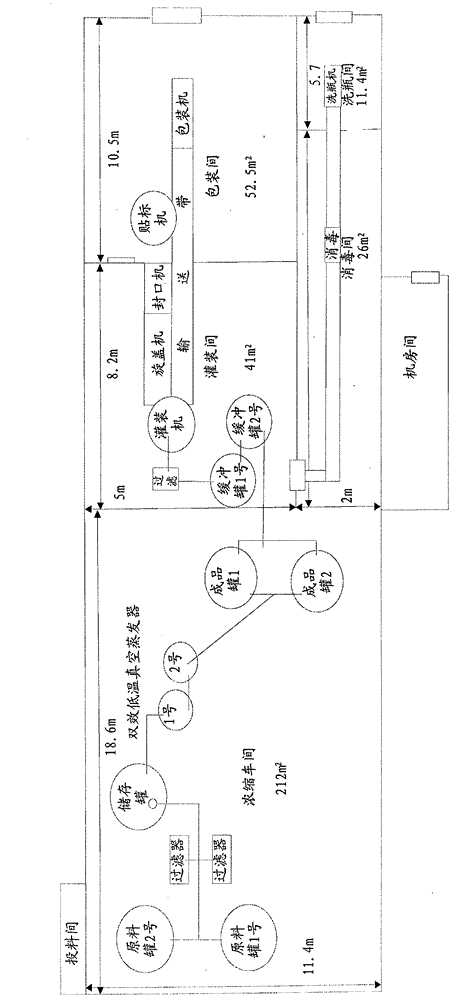

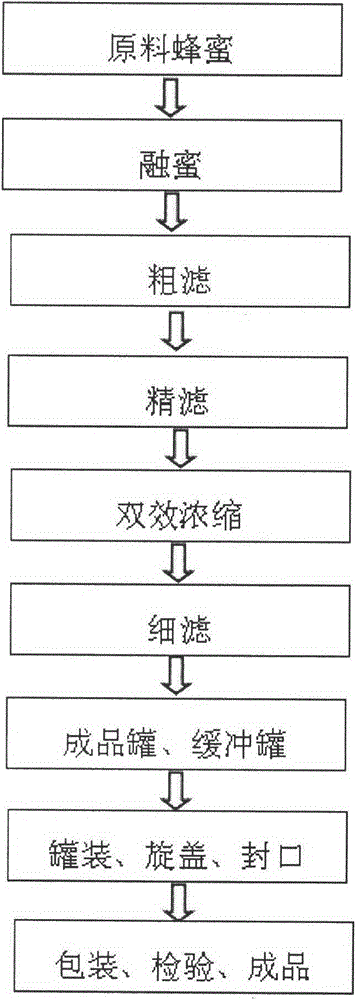

Refined honey processing process

The present invention discloses a refined honey processing process, which comprises a honey processing stage and a honey canning stage, wherein the honey processing stage comprises honey melting, coarse filtration, vacuum compression, fine filtration, buffering, fine filtration, canning and other steps, the honey canning stage comprises washing of bottles, disinfection, capping, sealing, labeling, packaging and other steps, the processing temperature is within 55 DEG C, the vacuum compression adopts double-effect concentration equipment and the vacuum degree is 0.09 Mpa at the honey processing stage, and the honey canning stage adopts the full-automatic production line to produce. According to the present invention, the scientific and reasonable double-effect concentration manner, the triple filtration, the application of the buffer tank before the canning, and other optimized processes and conditions are utilized, such that the quality of the produced honey is not affected, and the process has characteristics of simple process, low cost, and no color change, no taste change and stable character of the produced honey after long timer placing, is a scientific and simple processing method, and can be widely promoted and used.

Owner:SUZHOU SHANDING BEE PROD CO LTD

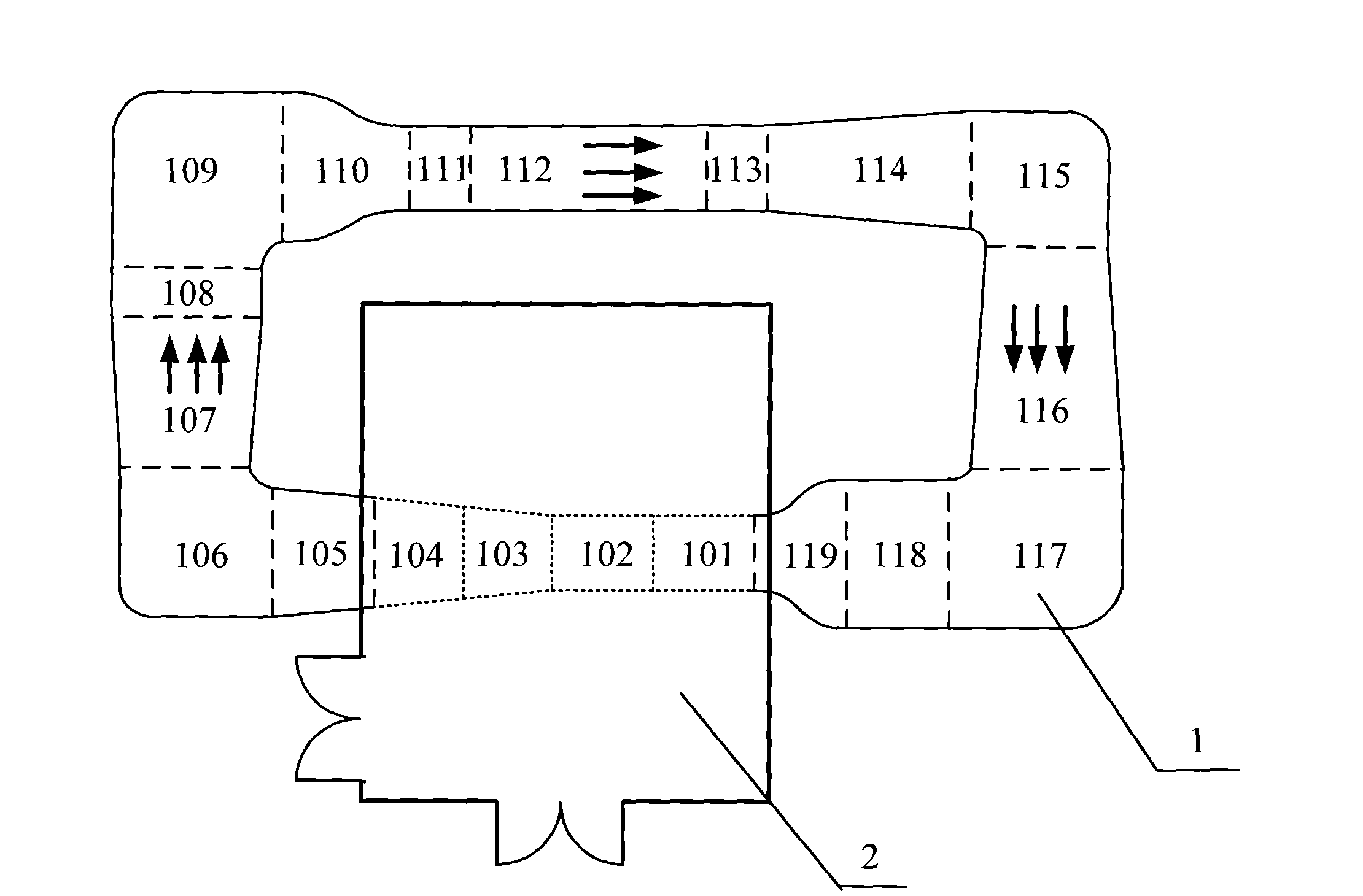

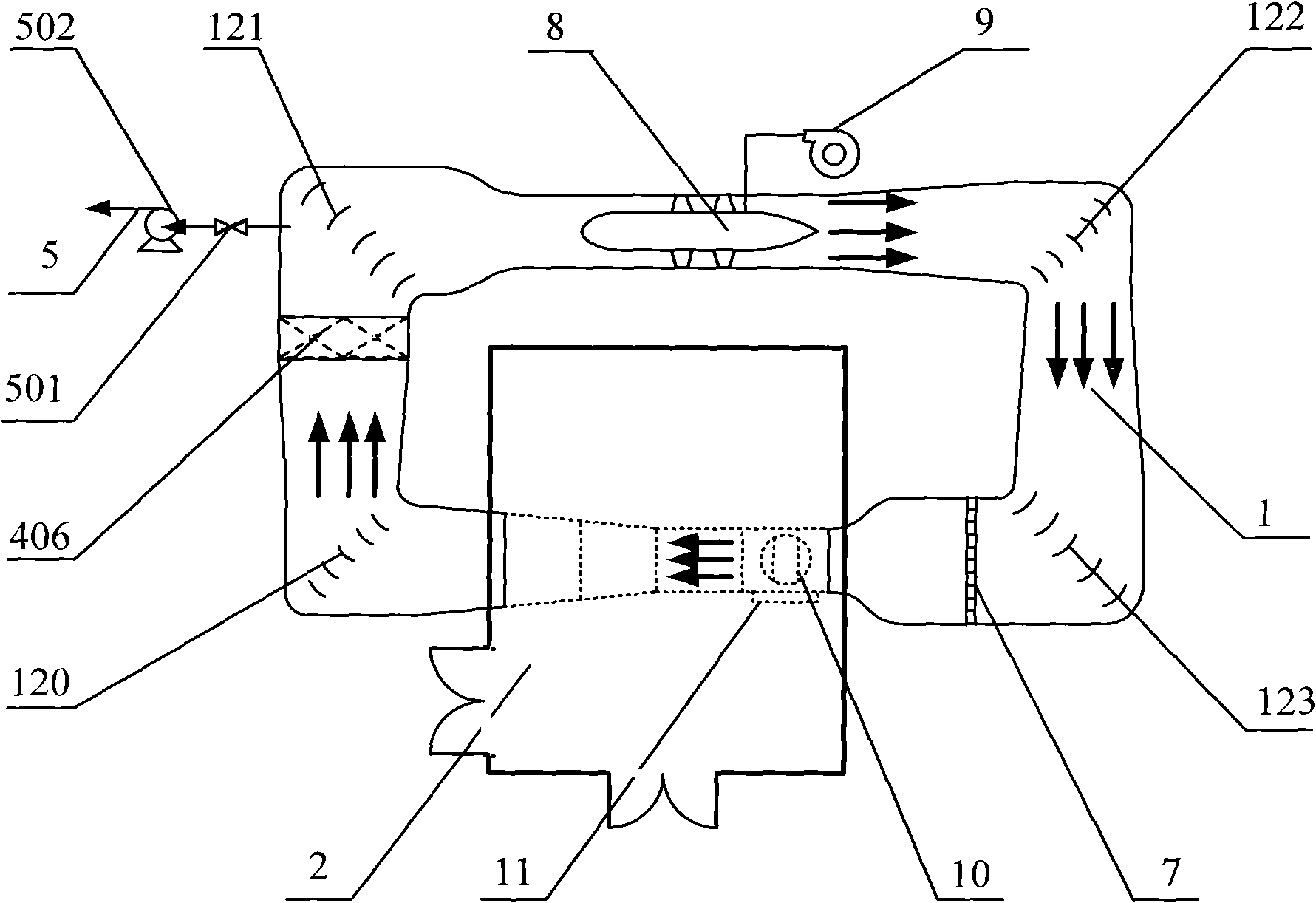

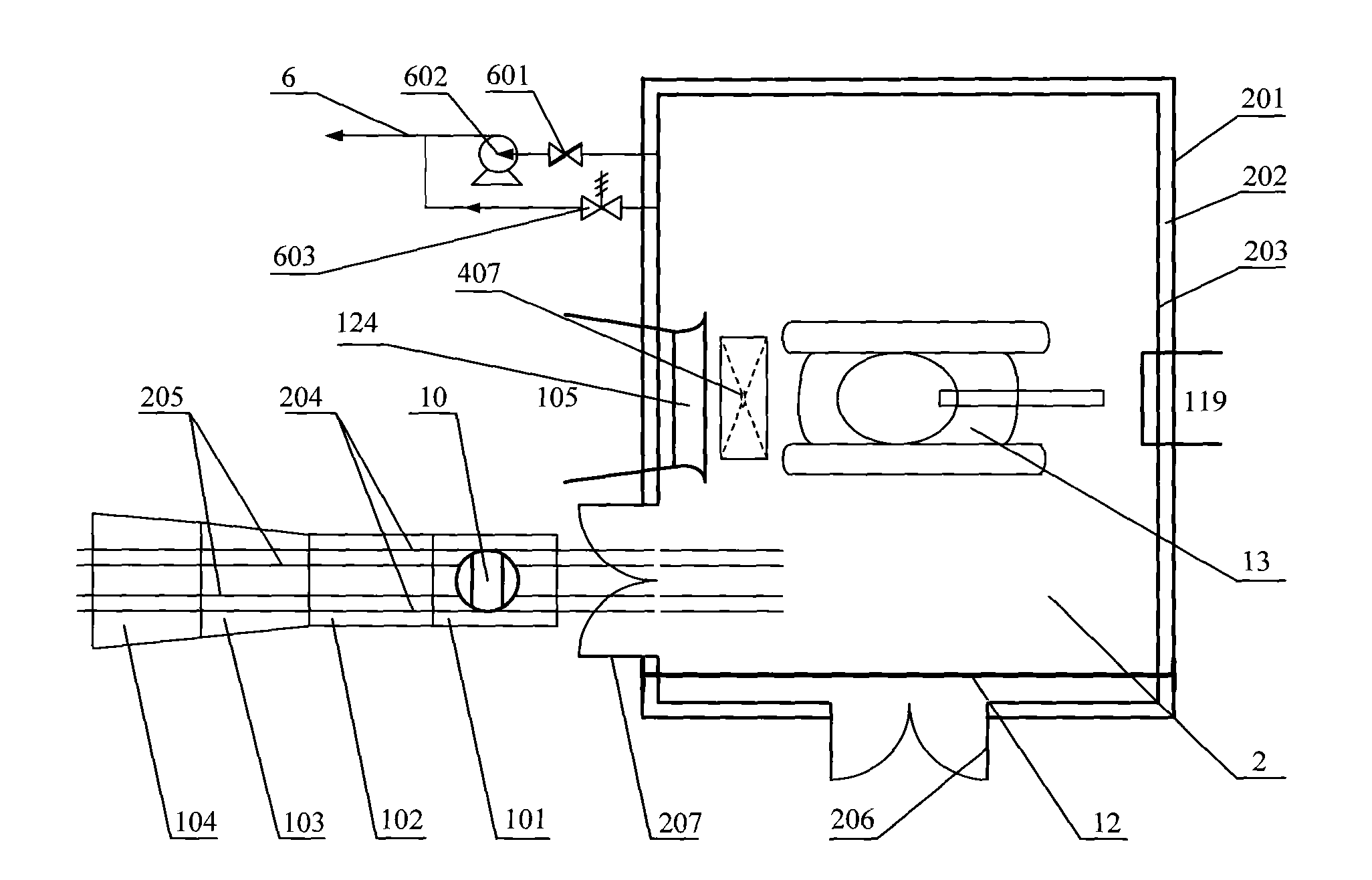

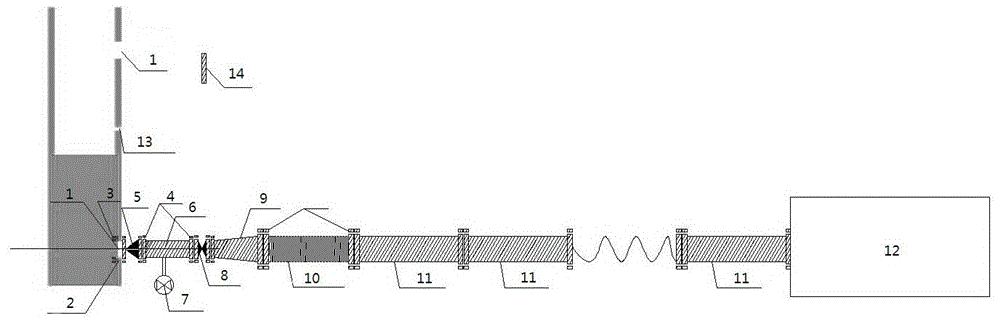

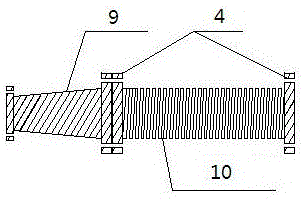

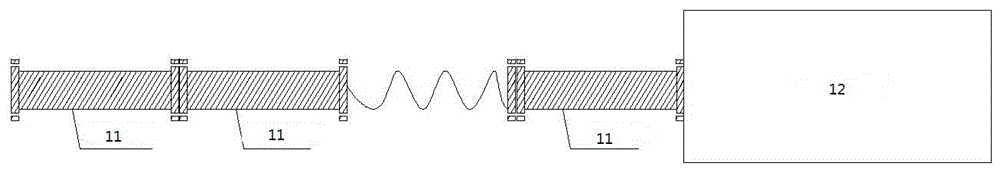

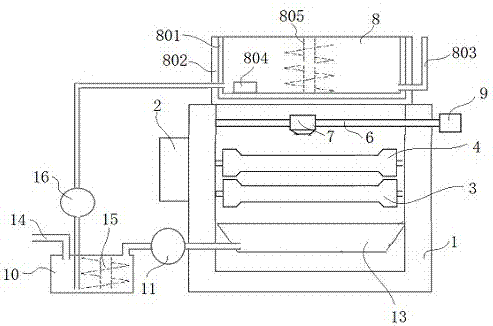

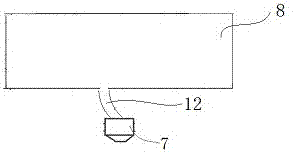

Multifunctional sand dust environment simulation device with changeable test section

A multifunctional sand dust environmental simulation device with a changeable test section is characterized in that a circulation air flue (1) is included, the circulation air flue (1) comprises a changeable test section, and the changeable test section comprises a test chamber (2) and mobile air flue parts (101, 102, 103 and 104). The invention provides the multifunctional sand dust environmental simulation device which can be used for carrying out integral testing to large-scale test subjects (such as armored vehicles). The multifunctional sand dust environmental simulation device not only can be used for carrying out sand blowing and dust blowing tests to small and medium-sized test objects, but also can be used for carrying out sand blowing and dust blowing tests to the entireties of the large-scale test objects (such as vehicles), can form gas-solid two-phase flow with uniform sand dust concentration and velocity distribution inside an effective experimental space, thereby achieving the technical effects of meeting testing conditions and improving equipment utilization ratio.

Owner:BEIHANG UNIV

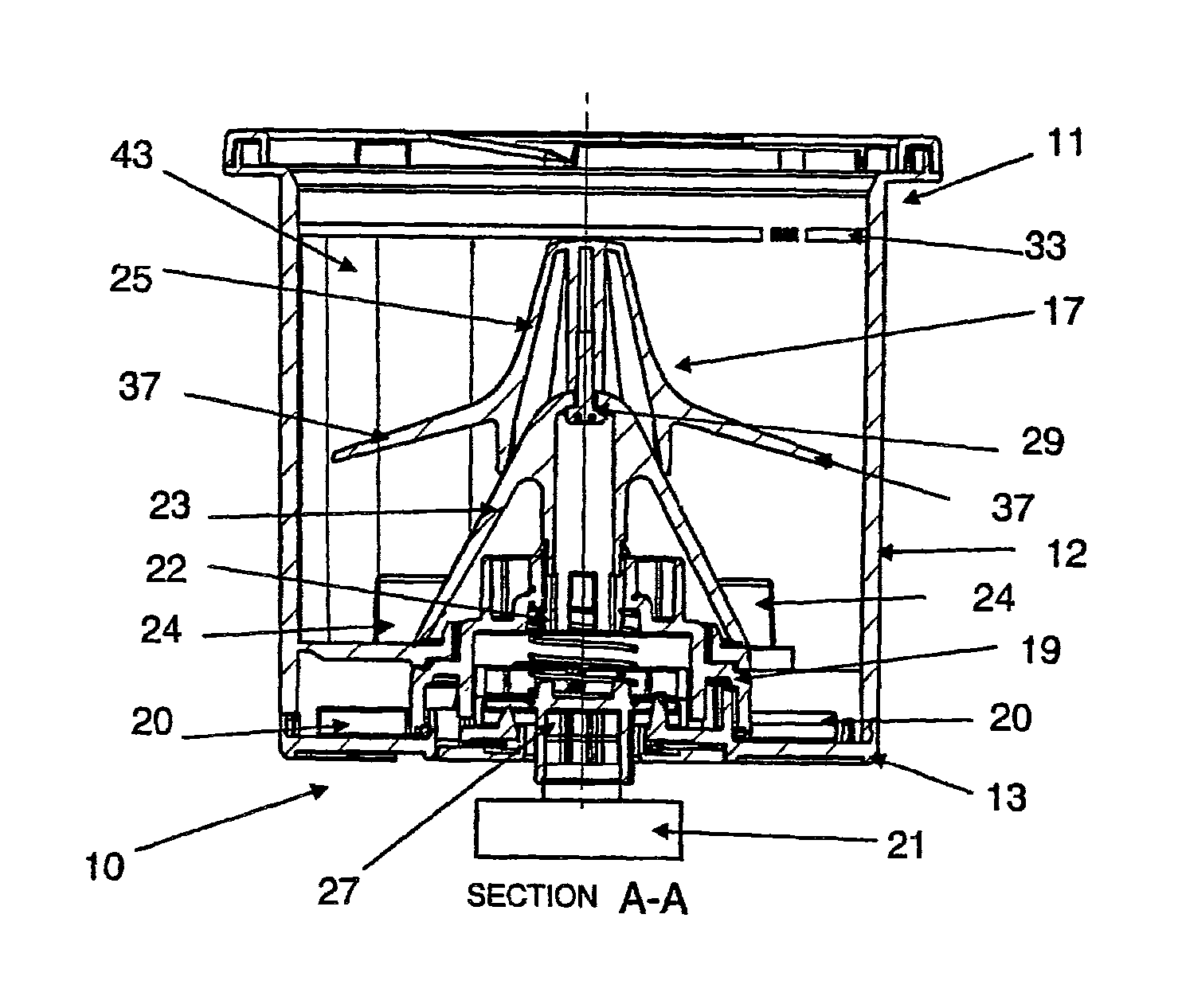

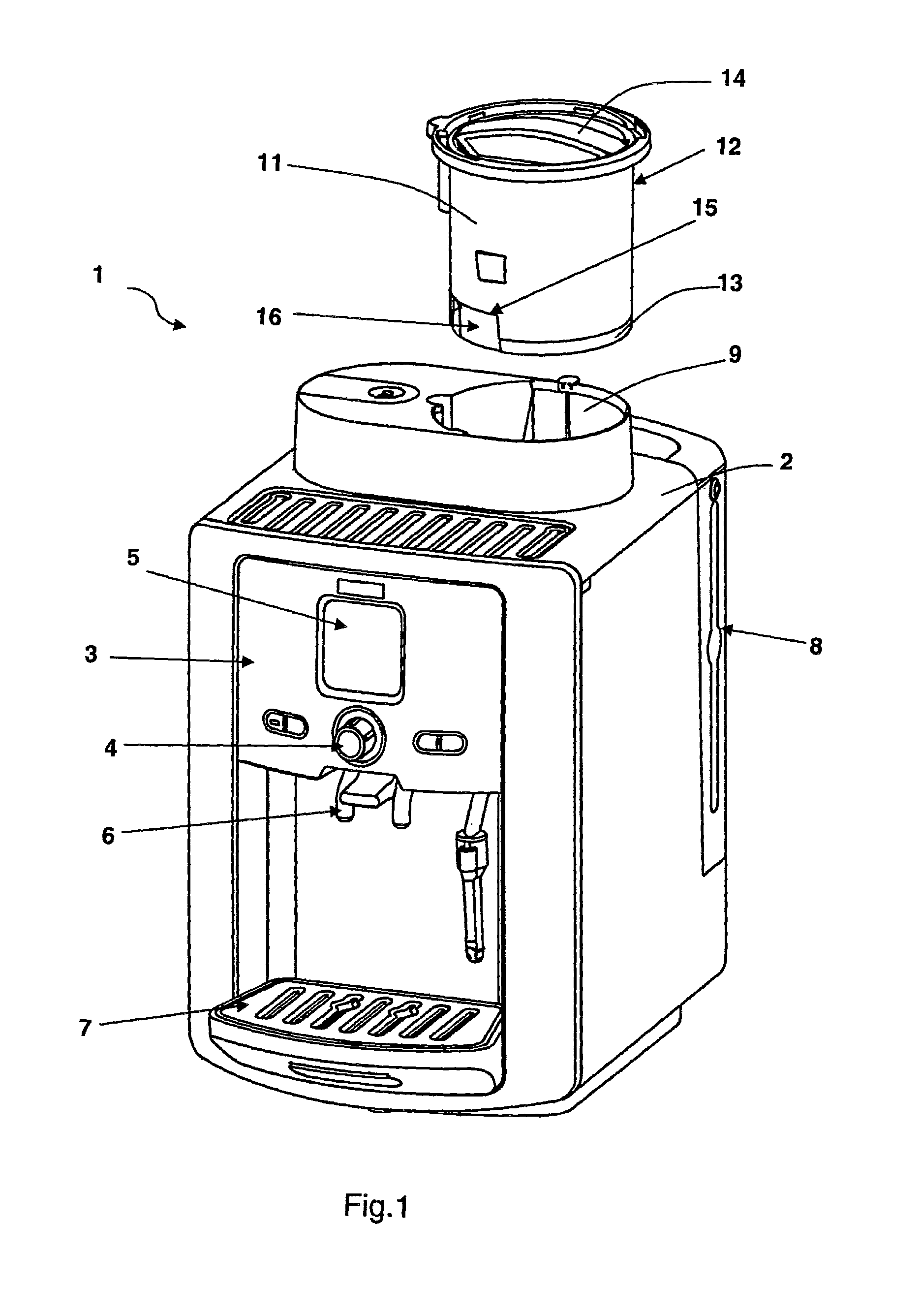

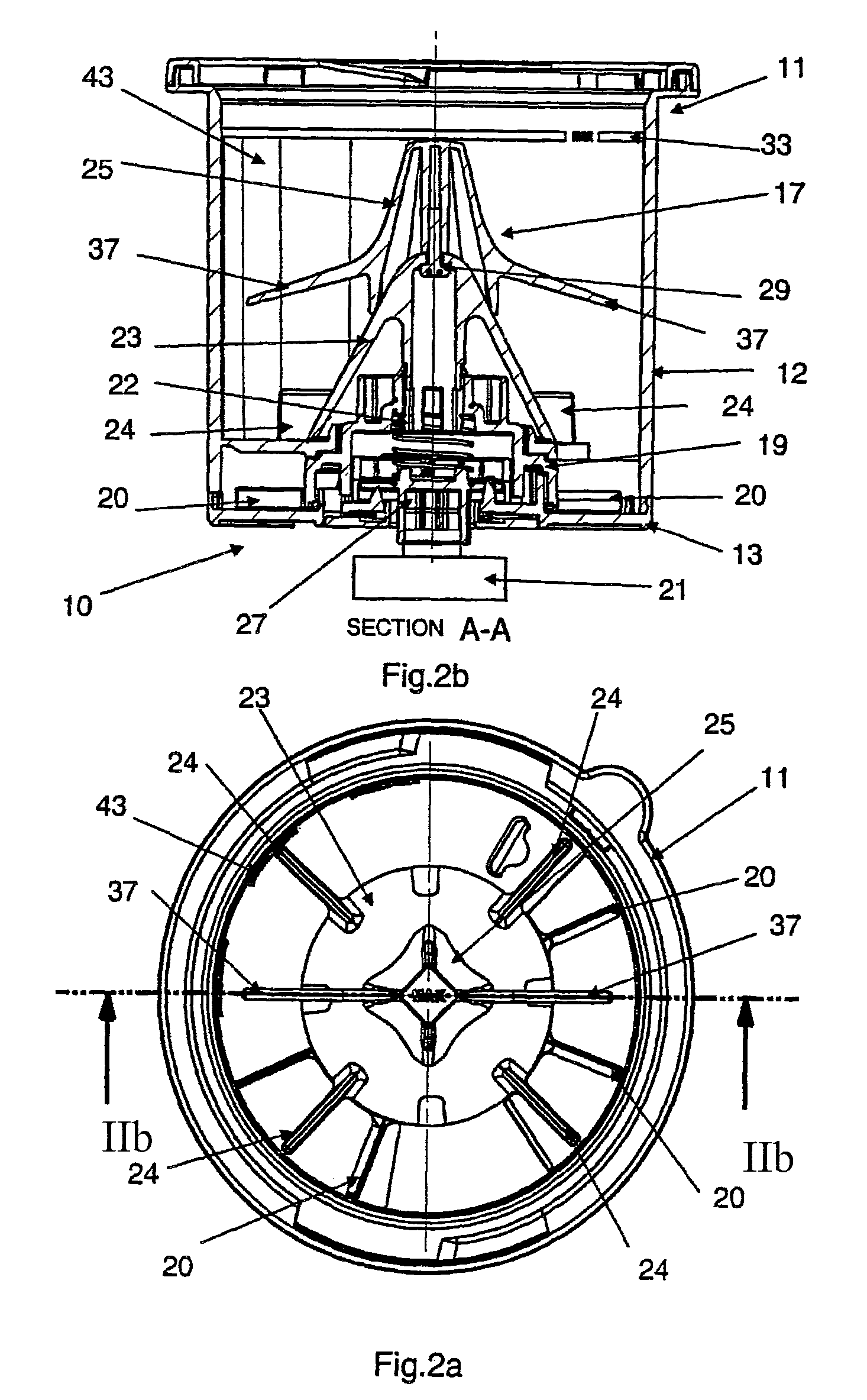

Automatic ground-coffee dispenser

InactiveUS8439235B2Less effortGood flowTransportation and packagingRotary stirring mixersAutomotive engineeringVertical axis

An automatic ground-coffee dispenser with a ground-coffee storage vessel designed to be mounted on an automatic coffee maker. The storage vessel includes rotary serving paddles for transferring a predetermined quantity of ground coffee through an outflow opening formed in the bottom of the storage vessel and a cone-shaped driver with rotary paddles located above the outflow opening turned by a motor about a vertical axis of the storage vessel. The internal wall of the storage vessel includes at least one longitudinal rib projecting into the storage vessel.

Owner:SEB SA

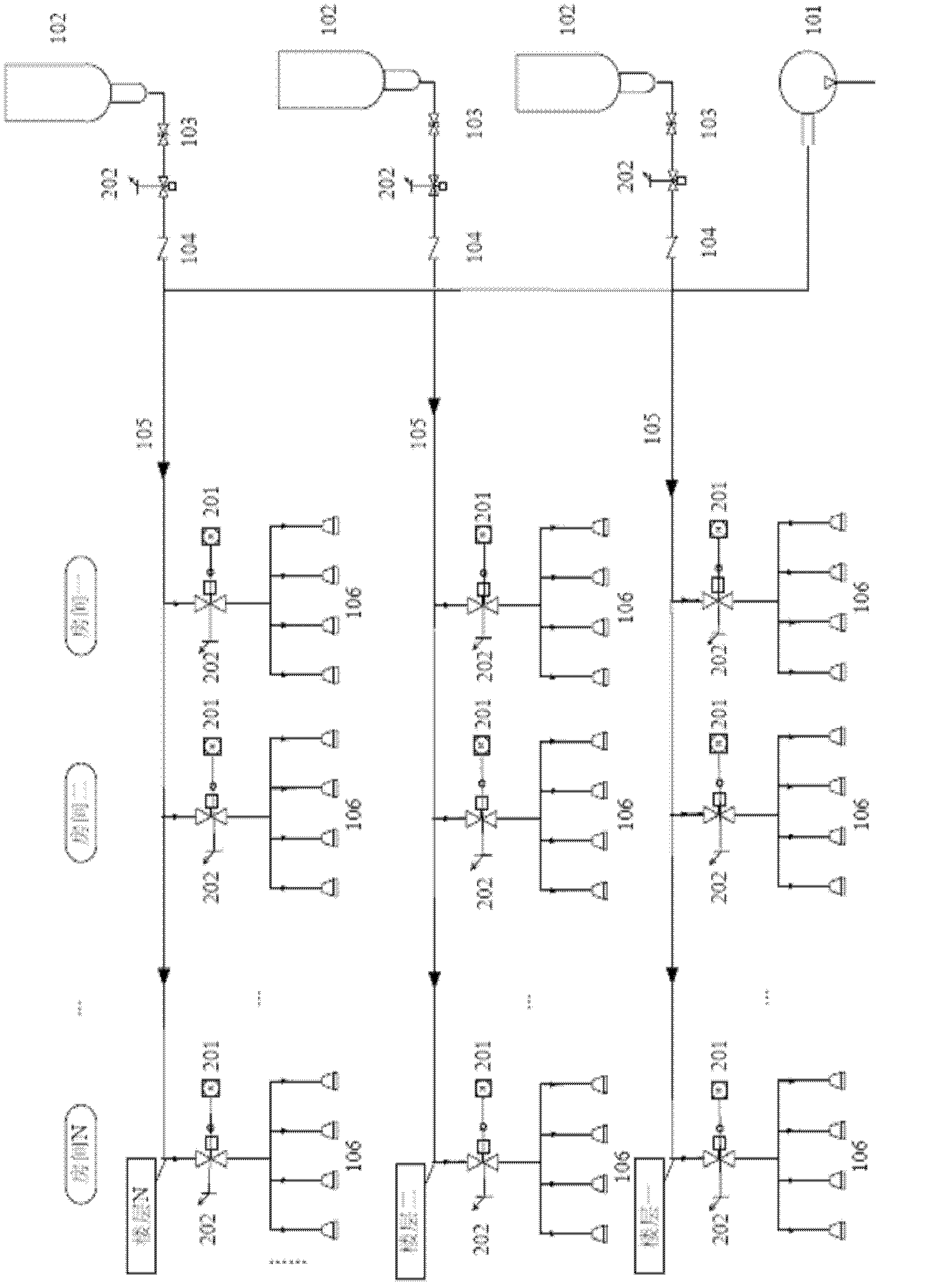

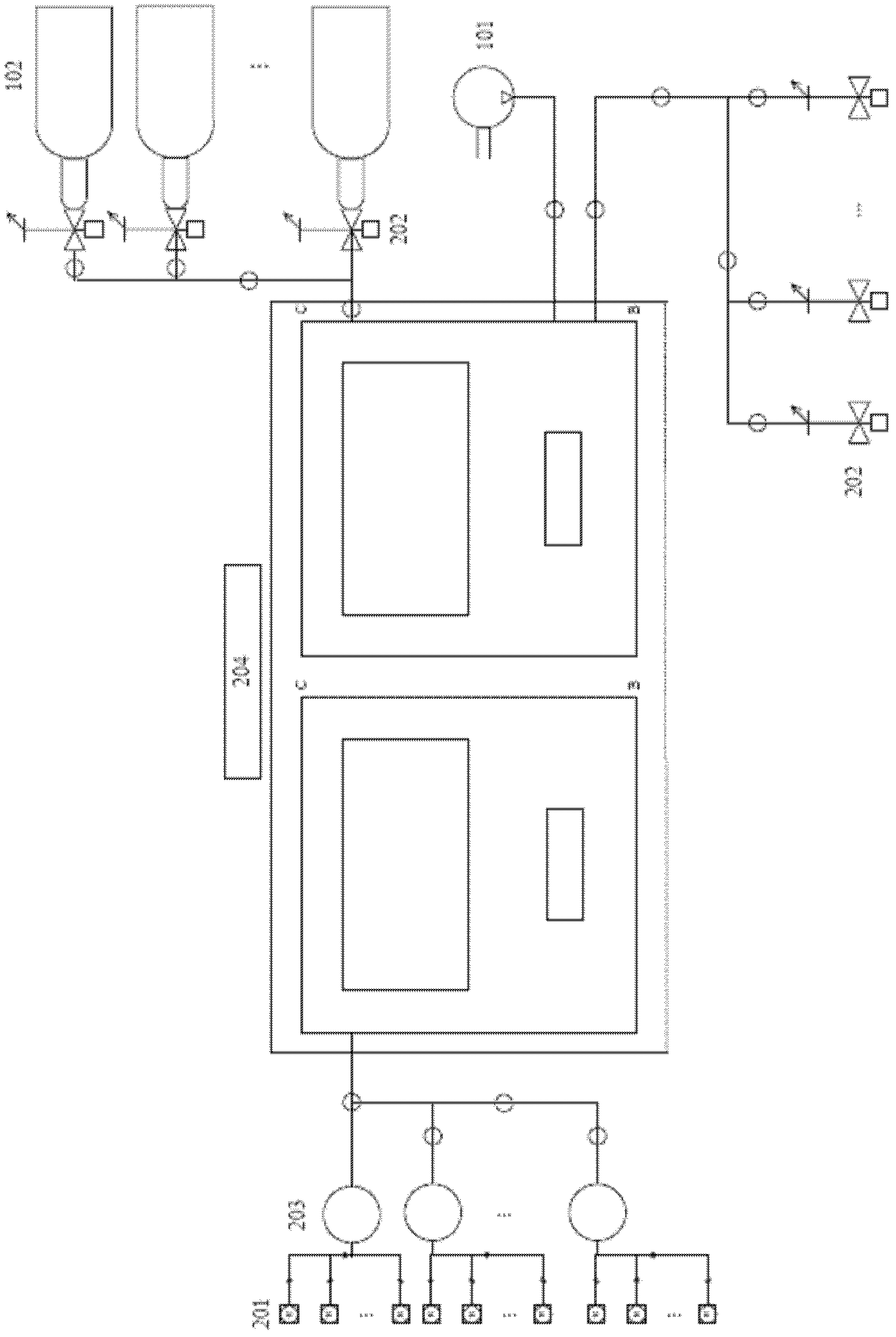

Fire fighting system using superfine dry powder as extinguishing agent and using method thereof

ActiveCN102247682AWide range of fire extinguishingEasy to cleanFire rescueFire alarmsPhosphateSpray nozzle

The invention relates to a fire fighting system using superfine dry powder as an extinguishing agent. The fire fighting system comprises two parts, i.e., a delivery subsystem and a control subsystem, wherein parts of the control subsystem are connected with the delivery subsystem through a pipe network of the delivery subsystem; the delivery subsystem comprises an air compressor, a high-pressure gas cylinder, a safety valve, a check valve, the pipe network, a dry powder extinguishing agent spray nozzle and novel superfine monoammonium phosphate extinguishing power; and the control subsystem comprises a detector, an electric valve, an alarm and a fire fighting control center. A using method of the fire fighting system using the superfine dry powder as the extinguishing agent comprises seven major steps. The fire fighting system disclosed by the invention can be widely used for the extinguishment of the pipe network of a large-scale closed building and has an extensive application prospect and practical significance in the technical field of public security fire fighting.

Owner:BEIHANG UNIV

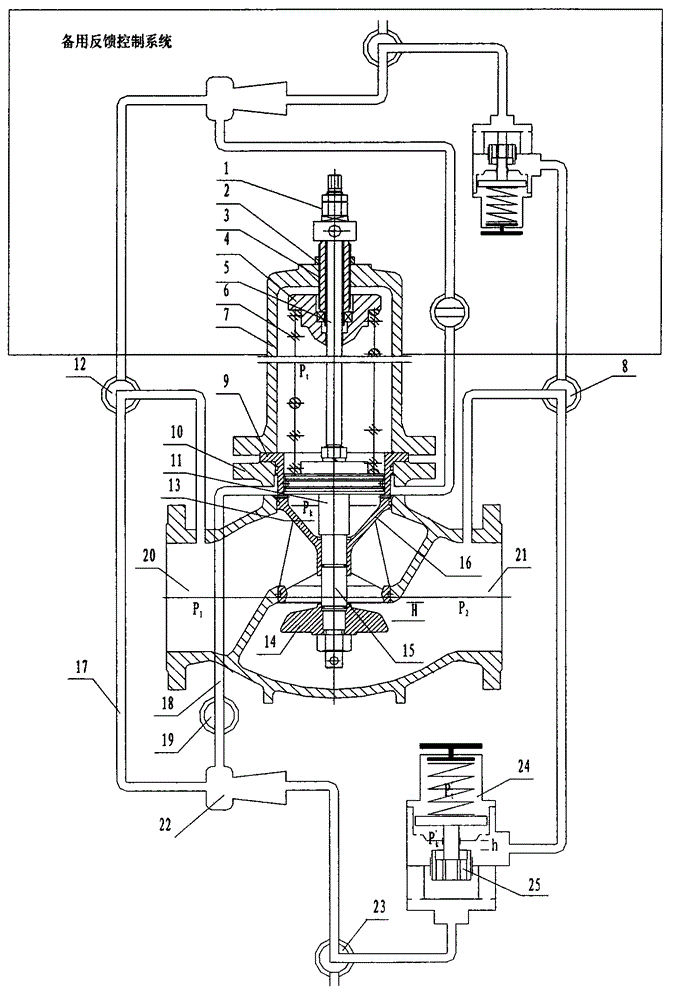

Piston type pressure reducing valve

InactiveCN105485389AGood flowReduce noiseOperating means/releasing devices for valvesEqualizing valvesWater qualityControl system

A piston type pressure reducing valve comprises a valve body with an inlet and an outlet. The valve body comprises a bonnet, a main spring, a piston and a piston rod, and the main spring is positioned in the bonnet. The piston type pressure reducing valve is characterized in that the valve body is provided with two symmetric feedback control systems, and each feedback control system comprises a backflushing blowdown structure; a safe locking device is arranged in the center of the bonnet, a spring seat is fixed on the upper part of the bonnet, and the piston is arranged on the lower part of the bonnet; the main spring capable of pushing the piston to move downwards is arranged between the piston and the spring seat; a valve seat fixedly connected with the bonnet is arranged under the piston; a pressure adjusting cavity is formed between the valve seat and the piston and is isolated from an inlet pressure cavity and an outlet pressure cavity; the piston rod is arranged in the center of the valve seat; the upper end of the piston rod is fixedly connected with the center of the piston; and a throttling cone is arranged at the lower end of the piston rod. The piston type pressure reducing valve provided by the invention is long in service life, high in adjustment sensitivity, good in outlet pressure characteristics, wide in pressure adjusting range, high in response speed, good in flow characteristics, small in noise vibration and high in water quality adaptive capacity.

Owner:湘潭中基电站辅机制造有限公司

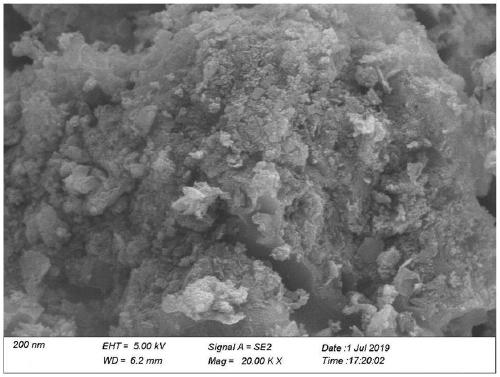

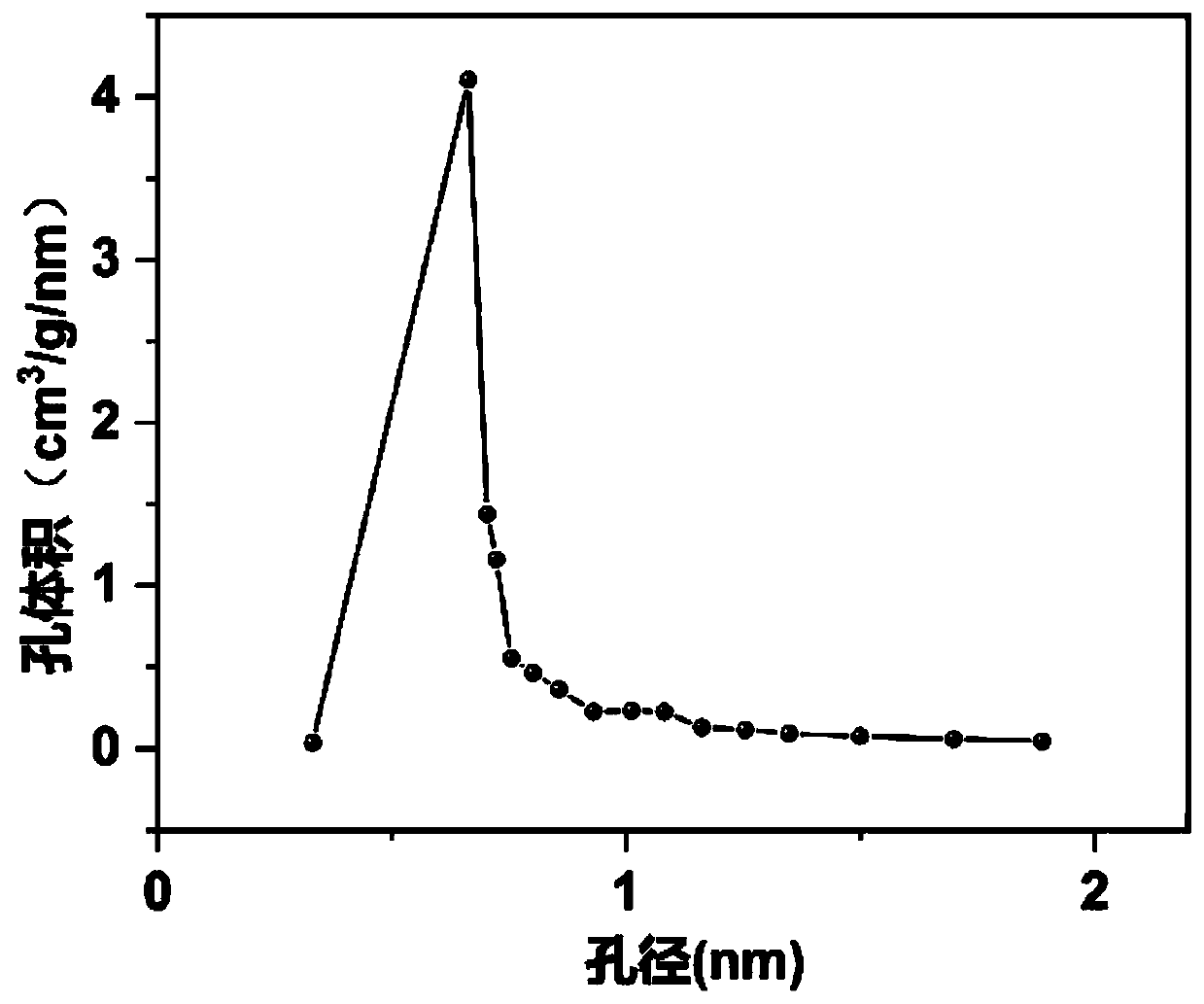

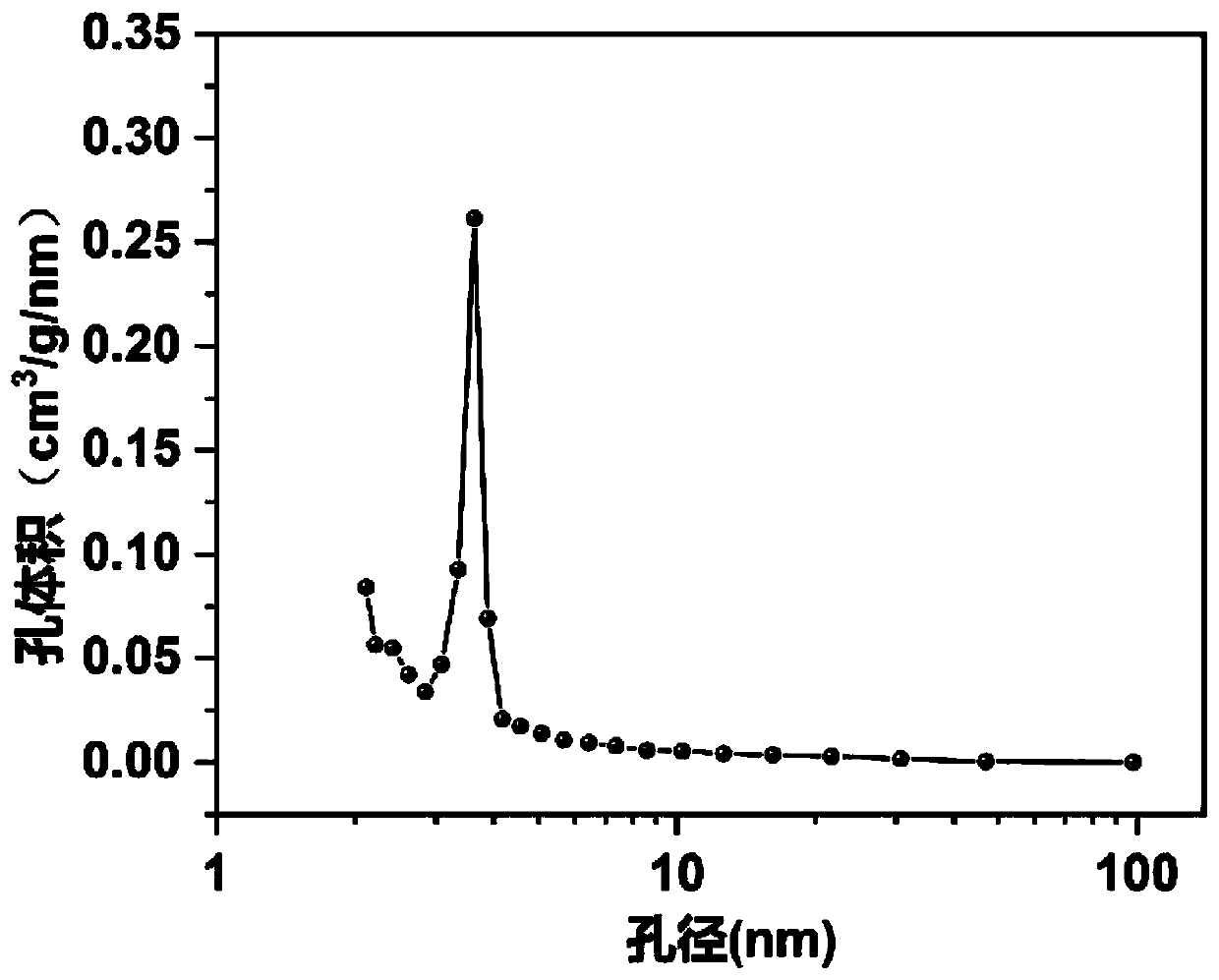

Natural mineral/activated carbon composite material and preparation method thereof

InactiveCN110479209AGood flowImprove wettabilityOther chemical processesWater contaminantsFiltrationSlurry

The invention discloses a preparation method of a natural mineral / activated carbon composite material, which comprises the following steps: (1) mixing a carbon-containing precursor, an activator and anatural mineral, and pulverizing the mixture to obtain a powdery mixture; (2) carrying out roasting treatment on the mixture, cooling the mixture to room temperature, washing the reaction product with acid, washing the reaction product with water to be neutral, carrying out suction filtration, and drying the product to obtain a natural mineral / activated carbon composite material; wherein the carbon-containing precursor is one or more of catalytic cracking slurry oil, asphalt and vacuum residuum. According to the invention, natural minerals and activated carbon are activated and compounded, sothat the prepared composite material not only can improve the adsorption performance of organic matters and chloride ions in sewage, but also can significantly reduce the production cost.

Owner:邓晖

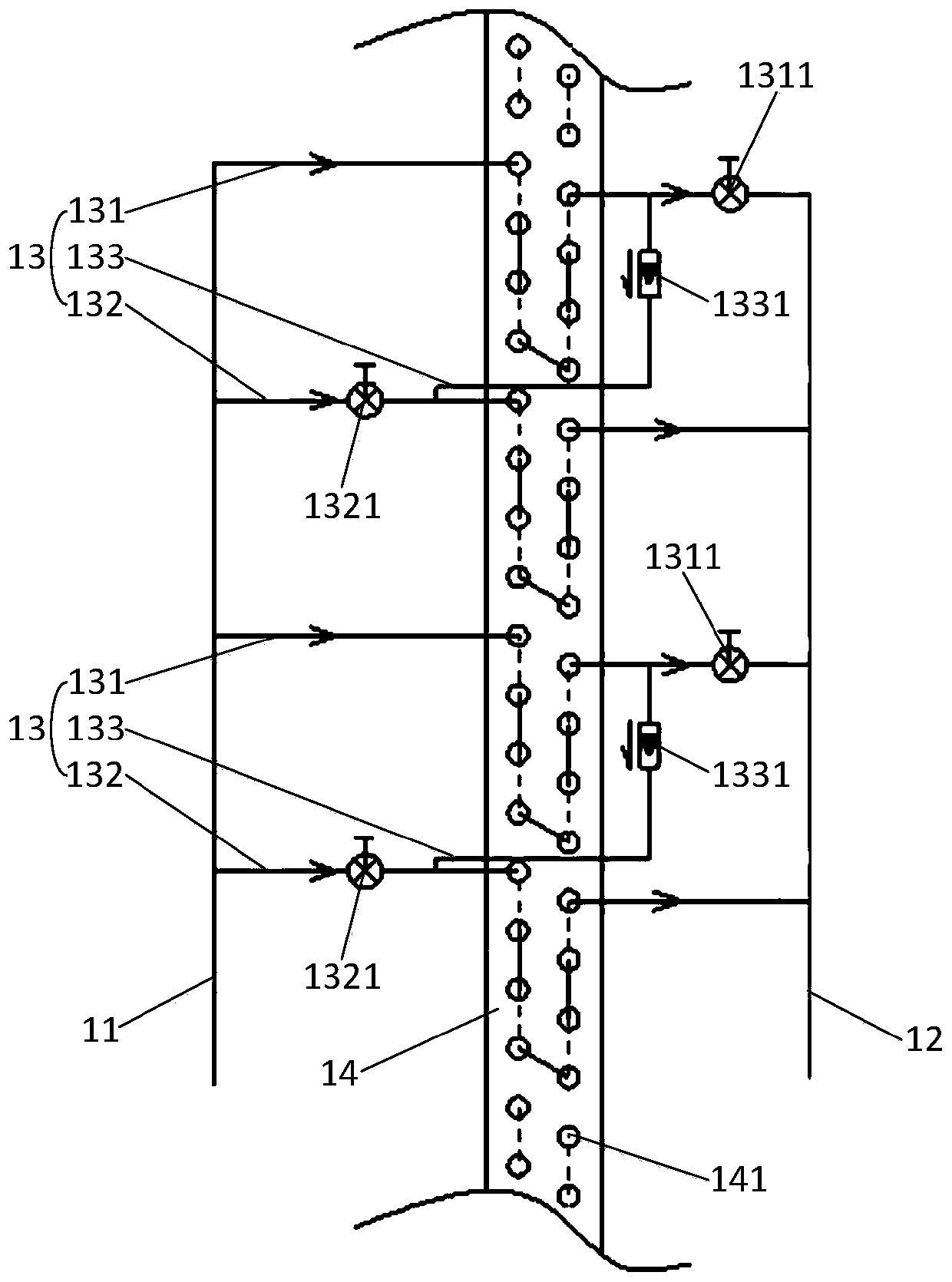

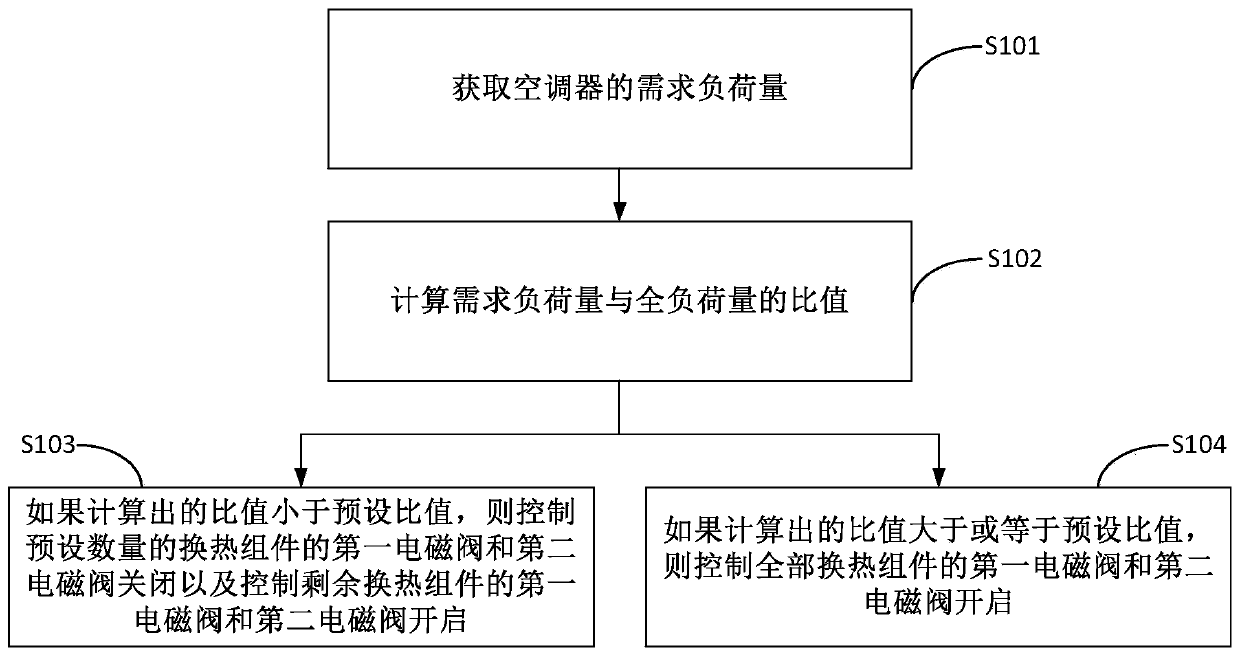

Heat exchange device, air conditioner and control method of air conditioner

PendingCN111426103AIncrease flow lengthGuaranteed flow areaMechanical apparatusSpace heating and ventilation safety systemsRefrigerantMechanical engineering

The invention belongs to the technical field of heat exchange, and particularly provides a heat exchange device, an air conditioner and a control method of the air conditioner. The heat exchange device, the air conditioner and the control method of the air conditioner aims to solve the problem that an existing air conditioner is low in energy efficiency under the partial load working condition. The heat exchange device comprises a plurality of heat exchange assemblies, each heat exchange assembly comprises a first heat exchange branch and a second heat exchange branch which are connected in parallel, first switch valves are arranged on the first heat exchange branches, second switch valves are arranged on the second heat exchange branches, communication branches are arranged between the first heat exchange branches and the second heat exchange branches, one-way valves are arranged on the communication branches, one ends of the communication branches are connected to the upstream of thefirst switch valves of the first heat exchange branches, and the other ends of the communication branches are connected to the downstream of the second switch valves of the second heat exchange branches. According to the heat exchange device, the air conditioner and the control method of the air conditioner, each first heat exchange branch and the corresponding second heat exchange branch can becombined into one refrigerant channel so that the flowing speed of refrigerants can be guaranteed under the low-load working condition, and then the heat exchange efficiency of the air conditioner iseffectively guaranteed.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

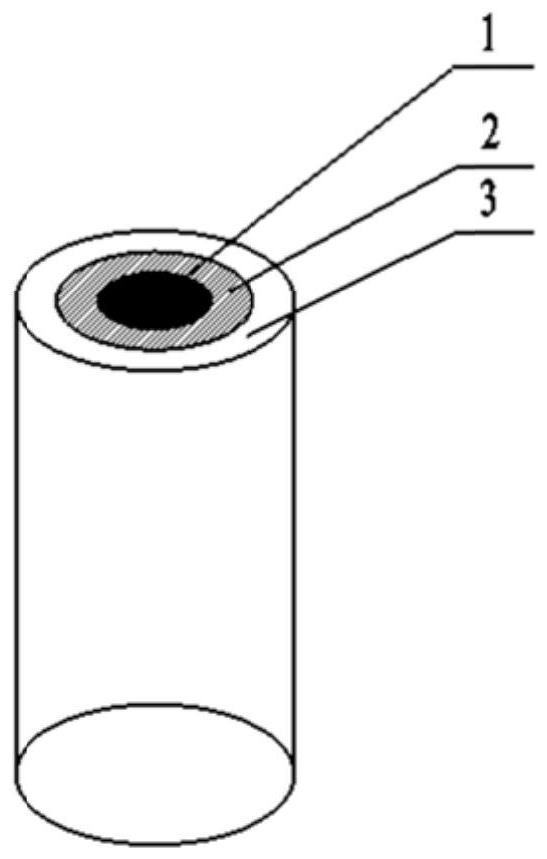

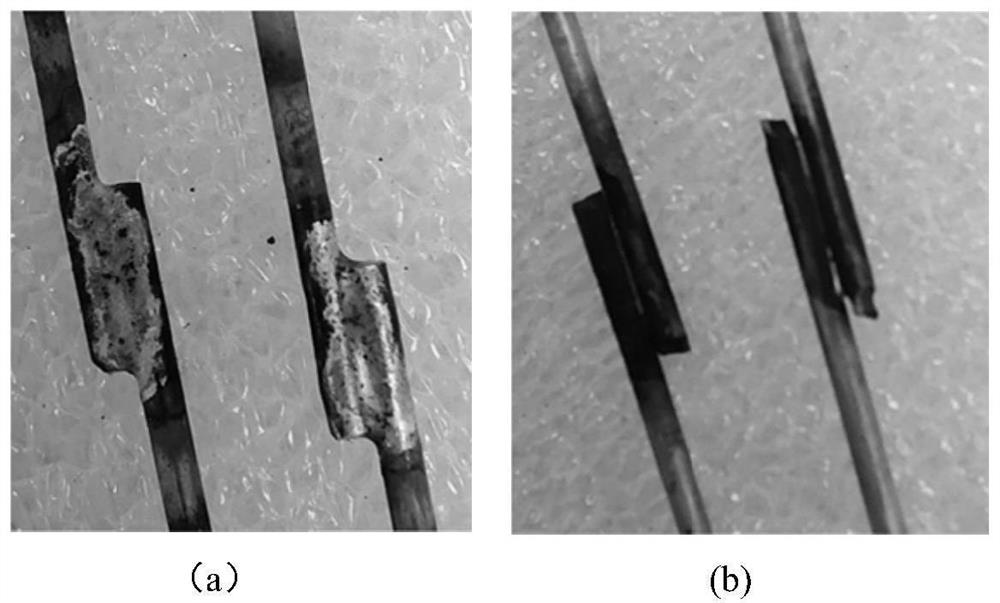

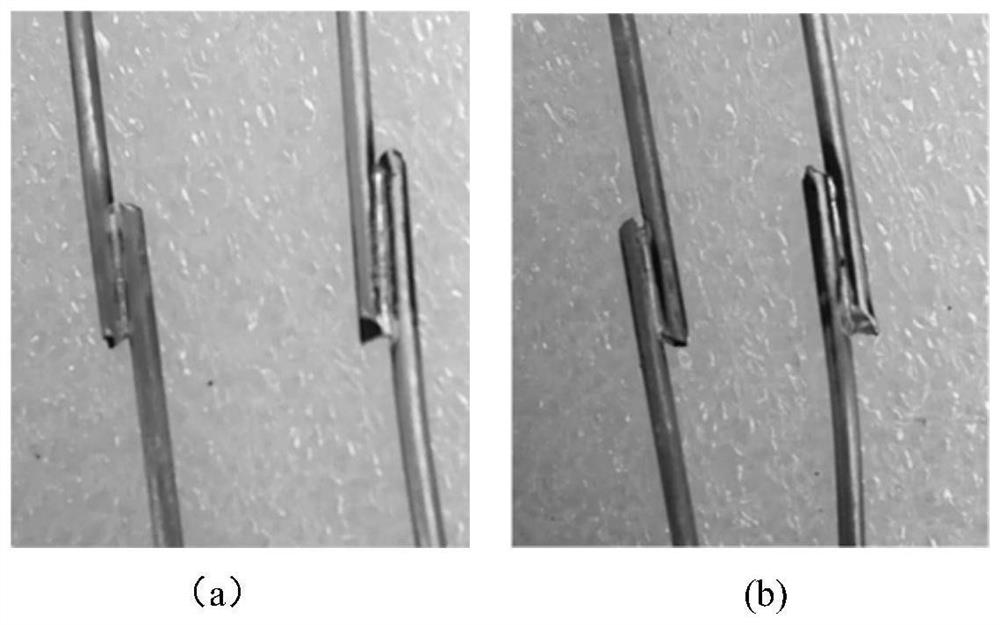

Multi-layer flux-cored silver solder and preparation method thereof

PendingCN113084390AImprove plasticityImprove liquidityWelding/cutting media/materialsSoldering mediaAlloySoldering process

The invention belongs to the technical field of soldering materials, and particularly relates to a multi-layer flux-cored silver solder and a preparation method thereof. The multi-layer flux-cored silver solder comprises an inner core layer, a middle layer attached to the surface of the inner core layer and an outermost layer wrapped on the middle layer. The inner core layer is an alloy wire, the middle layer is a silver soldering flux layer, and the outermost layer is a silver-based solder metal skin. And the melting point of the alloy wire is lower than that of the silver soldering flux layer. According to the multi-layer flux-cored silver solder, the melting temperature of the alloy wire of the core part is lower than that of soldering flux, in the soldering process, the alloy wire is firstly melted and then adheres to the soldering flux, the soldering flux is driven to flow out in advance and permeate into a soldering seam, and therefore the seam filling performance and flowing performance of the soldering flux are improved. The problems that conventional flux-cored silver solder is poor in fluidity and not prone to seam crossing during soldering, and the soldering flux is accumulated on the front face during soldering are solved, and therefore the soldering effect is improved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Apparatus and method for lifting up, compacting and forming concrete in steel-pipe column (wall)

InactiveCN106065690AImprove performanceImprove good performanceStrutsWallsEngineeringCounter current

The invention provides an apparatus and a method for lifting up, compacting and forming concrete in a steel-pipe column (wall). The apparatus comprises the following components: a material pressing structure node, a counter current preventing apparatus, a pressure regulating apparatus, and a pumping system; the material pressing structure node is arranged at the side surface of the bottom of the steel-pipe column (wall), and the material pressing structure node is connected to the counter current preventing apparatus, the pressure regulating apparatus, and the pumping system in order. The pumping system is used, a pressure conveying principle is used in order to lift concrete from the bottom of the steel-pipe column (wall) to the top of the column (wall), and the concrete is compacted and formed in the steel-pipe column (wall) by pressure. The apparatus and the method for lifting up, compacting and forming concrete in the steel-pipe column (wall) use local materials for processing and producing, pressure in a transfer pump is used for carrying out the lifting-up work for the concrete, so that the common concrete reaches effects of self-compaction concrete, and the apparatus and the method have the advantages of substantially reduced construction cost, simple operation, good quality, low cost, and substantial economic effects; the apparatus and the method can be applied to concrete construction of various steel-pipe columns (walls) with application and promotion values.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

Glue spreading method of soundproof cotton glue spreader

ActiveCN107362951AEvenly distributedImprove uniformityLiquid surface applicatorsCoatingsEngineeringRubber sheet

The invention discloses a glue spreading method of a soundproof cotton glue spreader and belongs to the technical field of glue spreaders. The glue spreading method of the soundproof cotton glue spreader comprises the following steps that (1) devices are started up, specifically, a glue spreading mechanism, a glue discharging mechanism, a recycling mechanism and a belt conveying mechanism on the soundproof cotton glue spreader are started up; (2) glue is spread, specifically, glue flowing out from the glue discharging device flows downwards along the gap between a gluing roller and a glue adjusting roller, a rubber sheet needing to be spread with glue is driven by the gluing roller to move in the gap between a glue spreading roller and the gluing roller as well as the gap between the glue spreading roller and the glue adjusting roller in sequence, and thus glue spreading is conducted; and (3) glue spreading is completed, specifically, the rubber sheet spread with the glue is conveyed to the tail of a conveying platform through conveying belts, the lower surface of the rubber sheet is in friction contact with the upper surfaces of cushion blocks, the moving speed of the rubber sheet is decreased, and glue spreading is completed after a worker takes the rubber sheet away. Through the glue spreading method, the purpose for overcoming the defects that glue spreading is uneven, and waste glue cannot be effectively recycled is achieved.

Owner:HEBEI LANGE SOUND INSULATION MATERIAL CO LTD

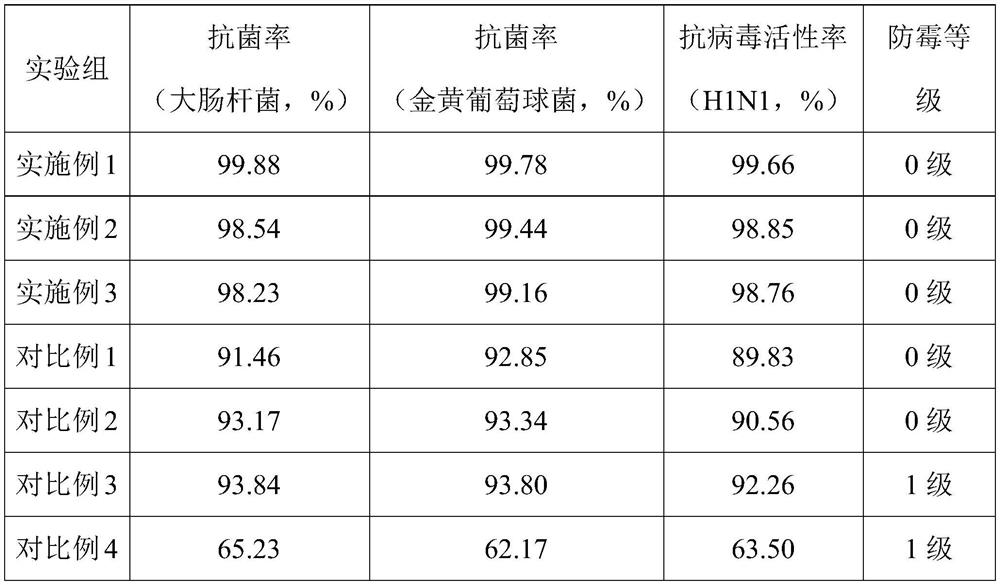

Antibacterial, mildew-proof and antiviral porous ceramic as well as preparation method and application thereof

InactiveCN112960990AAntibacterial and antifungalDoes not affect specific surface areaOther chemical processesSpecific water treatment objectivesMicroorganismNano zinc oxide

The invention provides antibacterial, mildew-proof and antiviral porous ceramic. The surface of the antibacterial, mildew-proof and antiviral porous ceramic is coated with antibacterial glaze; and the antibacterial glaze comprises an inorganic silver-loaded antibacterial agent, nano zinc oxide, a binder and a ceramic glaze. The inorganic silver-carrying antibacterial agent and the nano zinc oxide are added into the ceramic glaze to prepare the antibacterial glaze, the surface of the porous ceramic is coated with the antibacterial glaze, and the inorganic silver-carrying antibacterial agent, the nano zinc oxide, the binder and the ceramic glaze are fully mixed in a reasonable proportion. The prepared antibacterial glaze not only has excellent antibacterial, mildew-proof and antiviral performance, but also has a sound flowing state, so that the antibacterial, mildew-proof and antiviral porous ceramic not only has antibacterial performance, but also can adsorb microorganisms such as pathogenic bacteria, fungi and viruses through the porous structure, and the effect of purifying air or water is achieved.

Owner:同曦集团有限公司

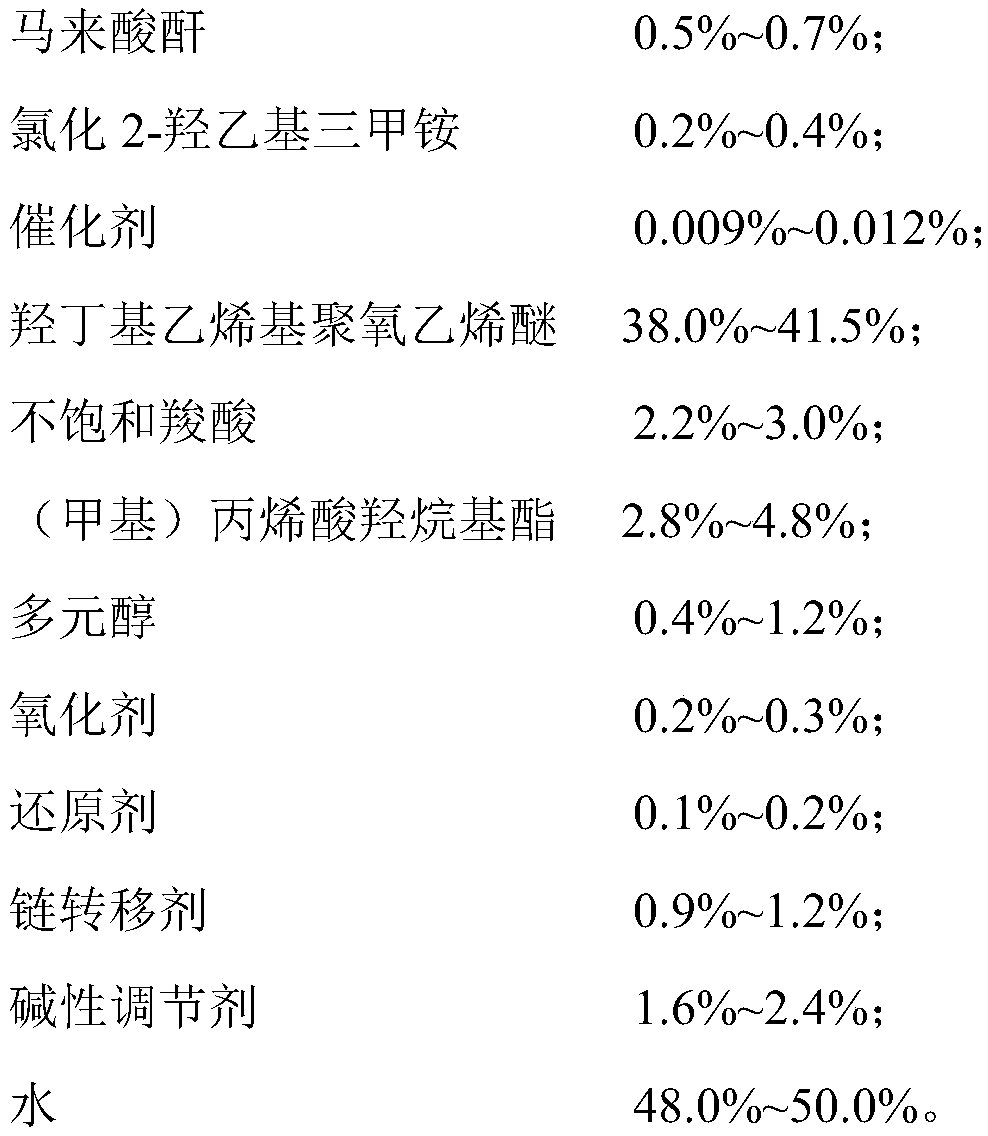

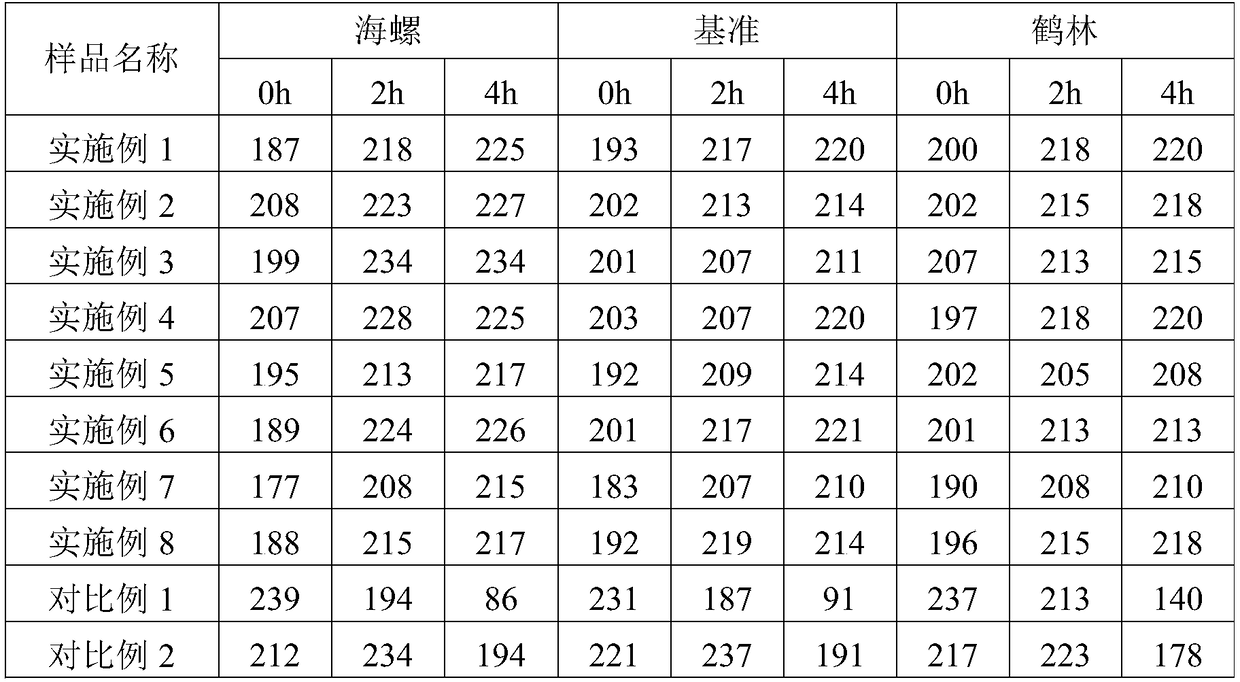

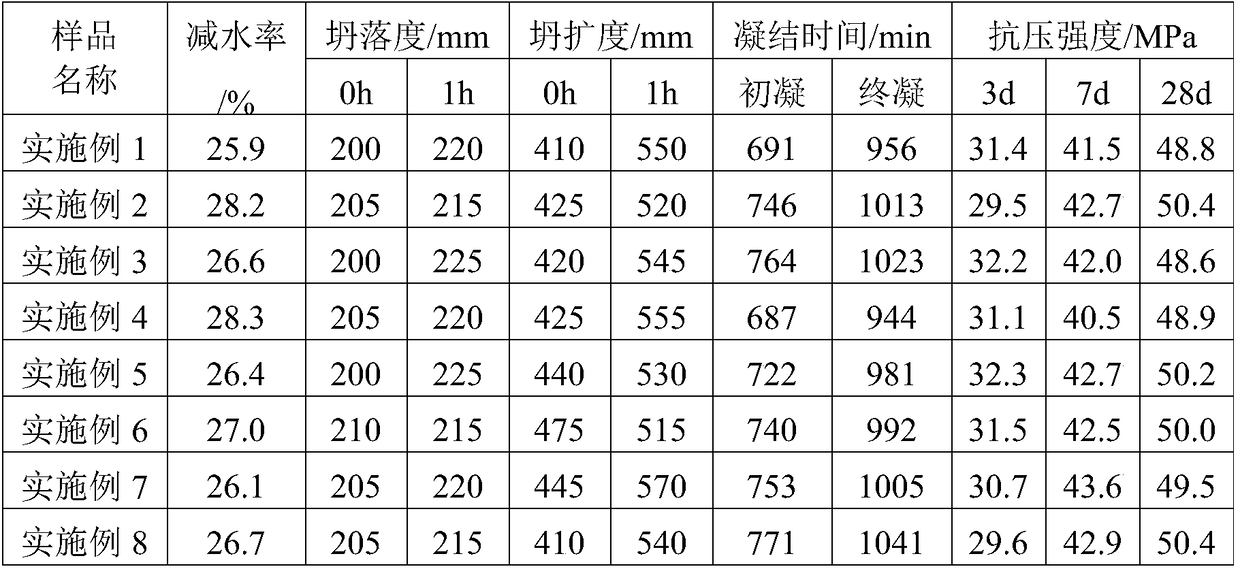

Super-retarding polycarboxylic acid type water-reducer as well as preparation method and application thereof

InactiveCN109306038AAvoid clotting time anomaliesReduce process2-hydroxyethyl-trimethyl-ammoniumCompound a

Owner:安徽瑞和新材料有限公司 +1

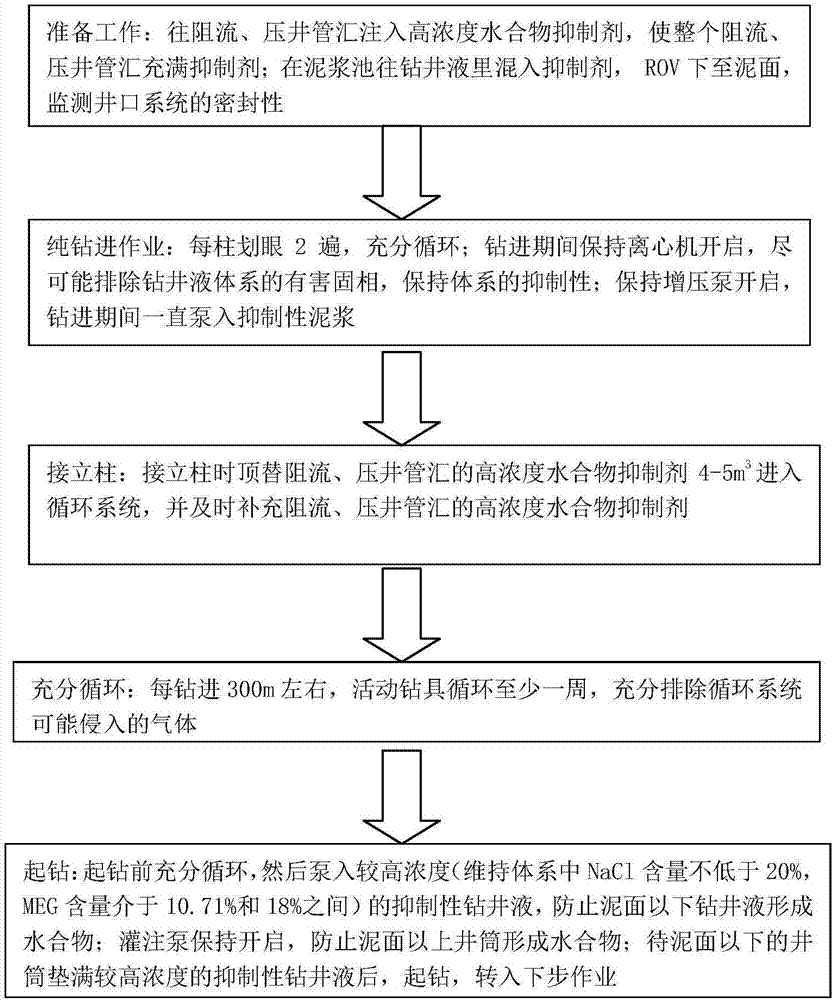

Hydrate prevention method during deep well drilling period

InactiveCN108005599AIncreased build temperatureAvoid complicationsFlushingDrilling compositionHigh concentrationWell drilling

The invention discloses a hydrate prevention method during a deep well drilling period. The hydrate prevention method during the deep well drilling period includes the steps that S1, preparatory workis carried out, specifically, a high concentration hydrate inhibitor is injected into a choke and kill manifold, and an inhibitor is mixed in drilling fluid in a mud pit; S2, actual drilling operationis carried out, specifically, all columns are subjected to reaming operation for two times and sufficient circulation, and a centrifugal machine and a booster pump maintain opening condition; S3, vertical columns are connected, specifically, 4-5m3 of the high concentration hydrate inhibitor replaces the choke and kill manifold to enter a circulation system and further supplements the high concentration hydrate inhibitor of the choke and kill manifold; S4, full circulation is carried out, specifically, a moving drilling tool circulates for at least one circle when drilling to one of predetermined distances; and S5, the drilling tool is pulled out of the well, specifically, the drilling tool is fully circulated before the drilling tool is pulled out of the well, inhibitive drilling fluid ispumped in the well to prevent the drilling fluid below mud surface from forming the hydrate, a charge pump maintains the opening condition to prevent a shaft above the mud surface from forming the hydrate, the drilling tool is pulled out of the well when higher concentration inhibitive drilling fluid is filled the shaft below the mud surface, and next operation is continued. The hydrate prevention method during the deep well drilling period can solve the problem that the hydrate is prone to be formed in the deep water drilling process.

Owner:CHINA NAT OFFSHORE OIL CORP +1

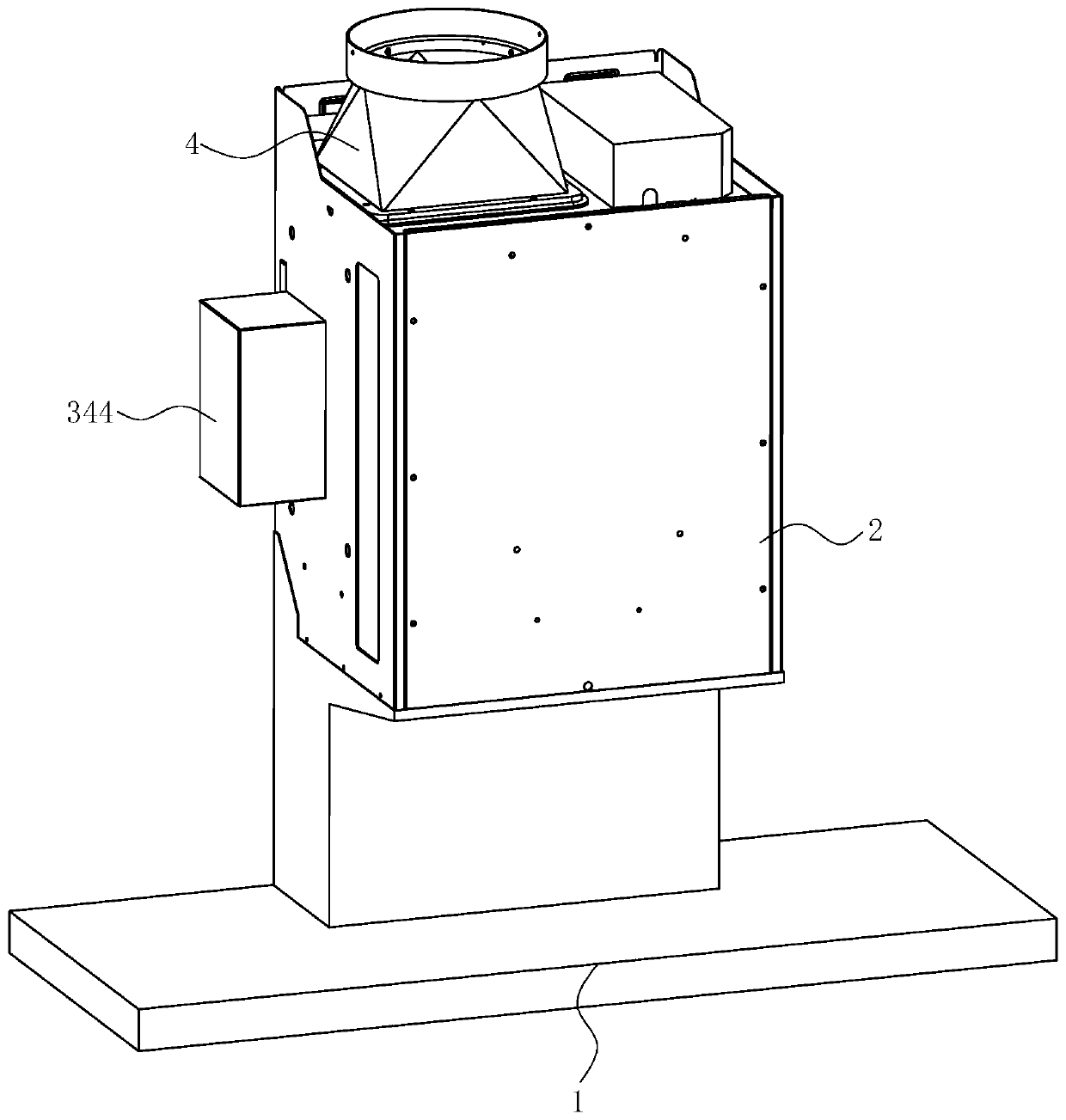

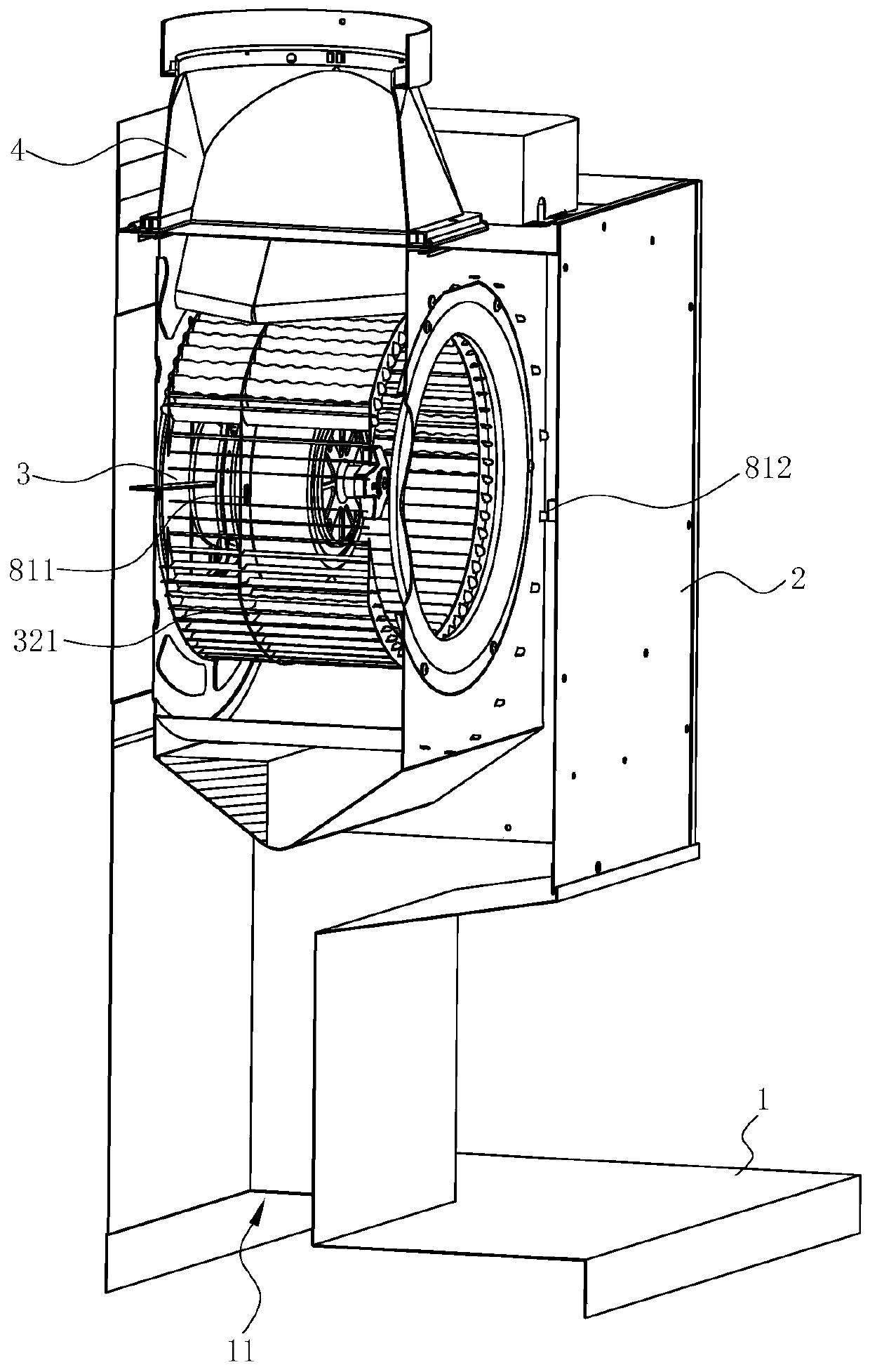

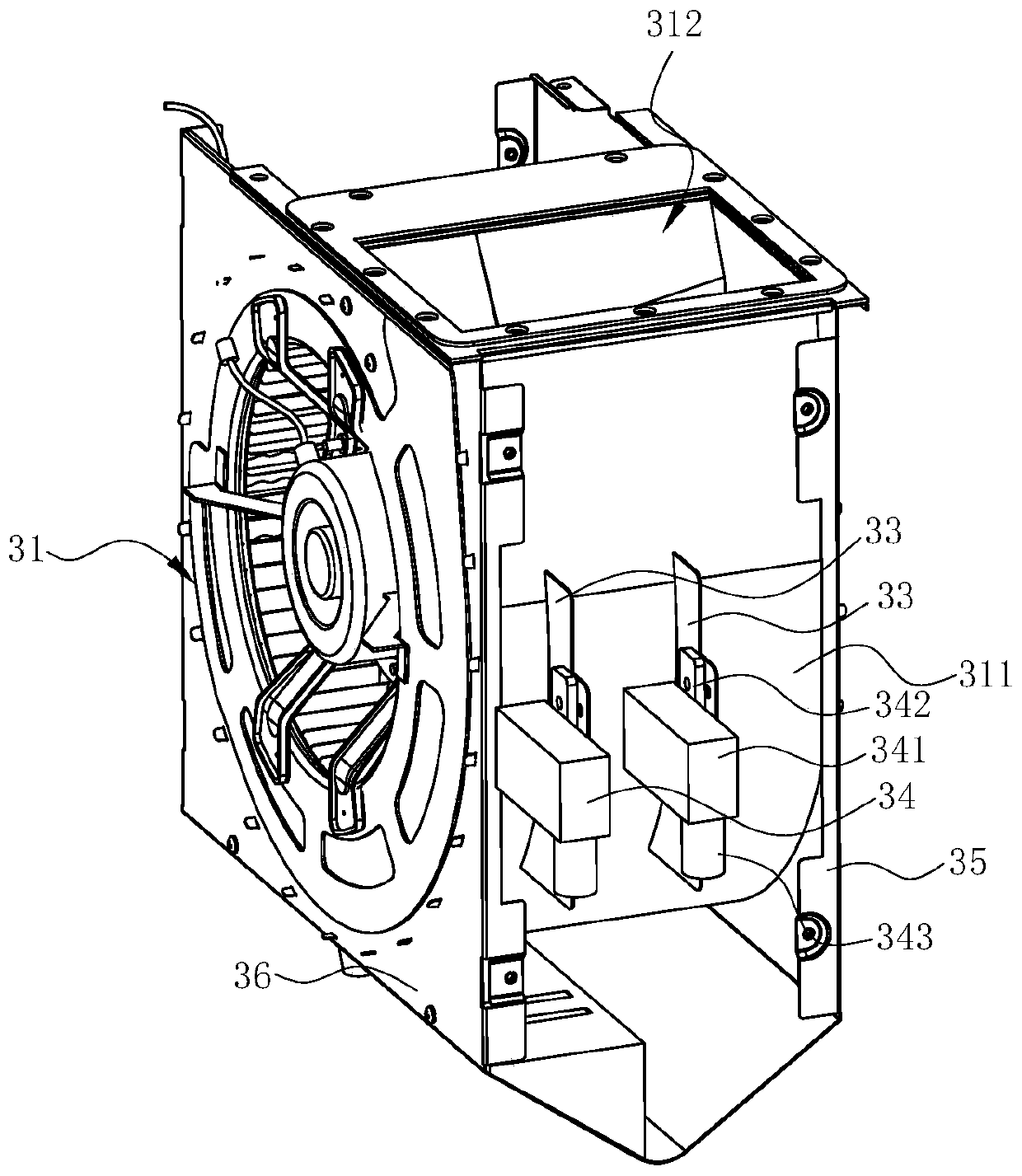

Centrifugal fan, extractor hood applying same and control method

ActiveCN111434929AReduce lateral flowImprove secondary flowDomestic stoves or rangesPump componentsStructural engineeringCentrifugal fan

The invention discloses a centrifugal fan. The centrifugal fan comprises a volute, the volute comprises a ring wall, and it is characterized in that fairing plates are further included, the positions,on the rear segment of a molded line of the volute, of the fairing plates penetrate through the ring wall from the outer portion of the ring wall to be inserted into the volute, outlines, inserted into the volute and away from the side face of the ring wall, of the fairing plates are consistent with molded lines of the crossing parts of the volute and the fairing plates, an extractor hood applying the centrifugal fan and a control method of the extractor hood are included, and compared with the prior art, the centrifugal fan, the extractor hood applying the same and the control method have the advantages that the fairing plates can damage the vortex center in the volute, transverse flowing of the airflow on the wall face of the volute can be reduced, the secondary flowing in the volute can be improved, the vortex on an outlet is optimized, an automatic adjusting device automatically adjusts the height of the fairing plates according to different working conditions to adapt to airflowflowing under different pipeline resistances, transverse secondary flowing in the volute under the different working conditions can be improved, and the extractor hood has the optimal flowing state under the various working conditions.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Preparation method of efficient fire extinguishing superfine dry powder extinguishing agent

The invention discloses a preparation method of an efficient fire extinguishing superfine dry powder extinguishing agent. The preparation method comprises the following steps of uniformly mixing monoammonium phosphate, ammonium chloride, light calcium carbonate, dolomite powder, dicyandiamide, phenolic resin, magnesium chloride, borax, copper acetate and trimethyl ethyoxyl silane, carrying out warming, spraying methyl phenyl silicone oil in a stirring state, and uniformly stirring the mixture to obtain a mixed material; and crushing the mixed material, adjusting the temperature, and stirring and drying the mixed material to obtain the high-efficiency fire extinguishing superfine dry powder extinguishing agent. According to the preparation method of the efficient fire extinguishing superfine dry powder extinguishing agent, the water repellent property, fluidity, the jetting property and the anti-caking property of the obtained dry powder extinguishing agent are excellent, the price is low, furthermore, the specific surface area is large, fire extinguishing efficiency is high, the use amount is less during the extinguishing process of the fire disaster with the same level, and the fire extinguishing cost is low.

Owner:安徽云联知识产权运营有限公司

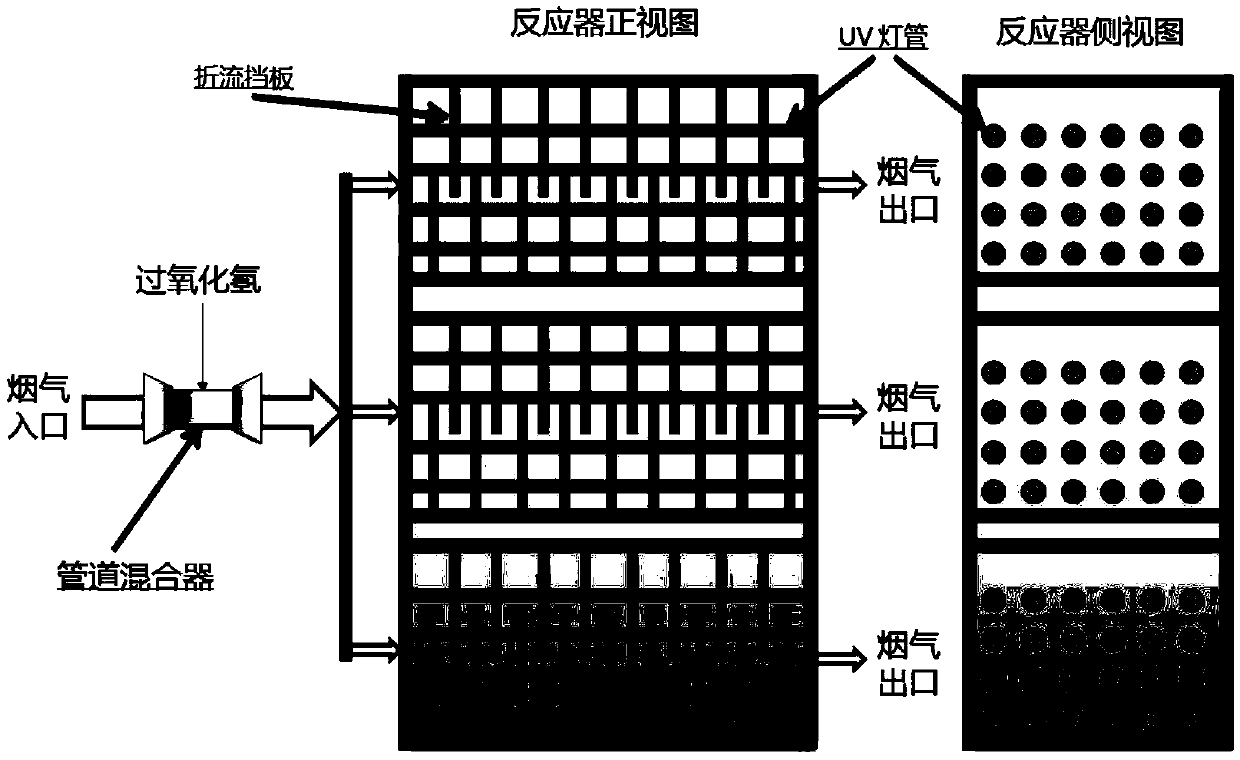

Method for removal of NOx from flue gas by UV catalytic oxidation

InactiveCN109603523AGood flowUniform irradiationGas treatmentDispersed particle separationFlue gasCatalytic oxidation

The invention discloses a method for removal of NOx from flue gas by UV catalytic oxidation. Based on the principle of oxidation of NO in flue gas by UV catalysis of H2O2, the method employs a modularreactor, can effectively improve the oxidation conversion rate of NO, saves investment and is low in cost, thus having good market promotion prospects.

Owner:TSINGHUA UNIV

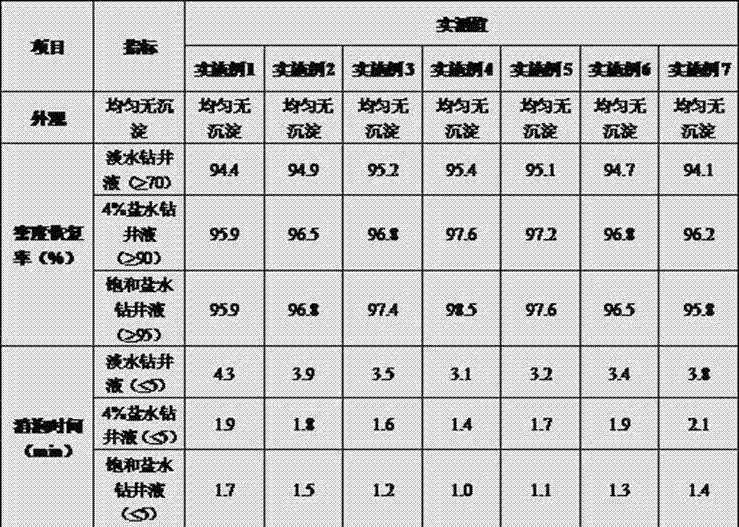

Silicone oil defoamer for drilling fluid and production process thereof

InactiveCN107955588AImprove pour point depressing effectImprove solubilityDrilling compositionSolubilityALUMINUM STEARATES

The invention provides a silicone oil defoamer for drilling fluid and a production process thereof. Kerosene is adopted as a solvent of aluminum stearate, so that solubility of aluminum stearate can be improved effectively; kerosene has excellent coagulation reducing effect, so that antifreezing coefficient of the defoamer can be remarkably improved, the defoamer still has high fluidity at low temperature of minus 20 DEG C, low-temperature defoaming performance of the defoamer is improved effect, and application occasions of the product are expanded; methyl silicon oil having excellent thermostability is introduced, so that thermostability of the defoamer can be improved effectively, the defoamer is small in evaporation loss at high temperature of 120 DEG C, and high-temperature defoamingperformance of the defoamer is improved effectively; excellent defoaming efficacy can be realized by only adding the defoamer accounting for 0.2-0.4% of volume of the drilling fluid; for fresh-water drilling fluid, 4% saline drilling fluid and saturated saline drilling fluid, density recovery rates of the defoamer can reach 95.4%, 97.6% and 98.5% respectively, and defoaming time is only 3.1min, 1.4min and 1.0min; the defoamer has potential industrial practical value.

Owner:YUMEN OIL FIELD KEDA CHEM

Catalytic converter with electrically heatable heating plate

ActiveUS20190383193A1Good flowReduce distributionInternal combustion piston enginesSilencing apparatusMetal foilHoneycomb structure

A catalytic converter having a honeycomb structure for the aftertreatment of exhaust gases of an internal combustion engine and having an electrically heatable heating plate, wherein the heating plate is formed from a plurality of metal foils which are stacked on top of one another to form a layer stack and are finally wound to form a honeycomb structure having a plurality of flow ducts, wherein the heating plate has arranged therein an insulating means via which electrical insulation is formed between at least two mutually adjacently arranged wound metal foils.

Owner:VITESCO TECH GMBH

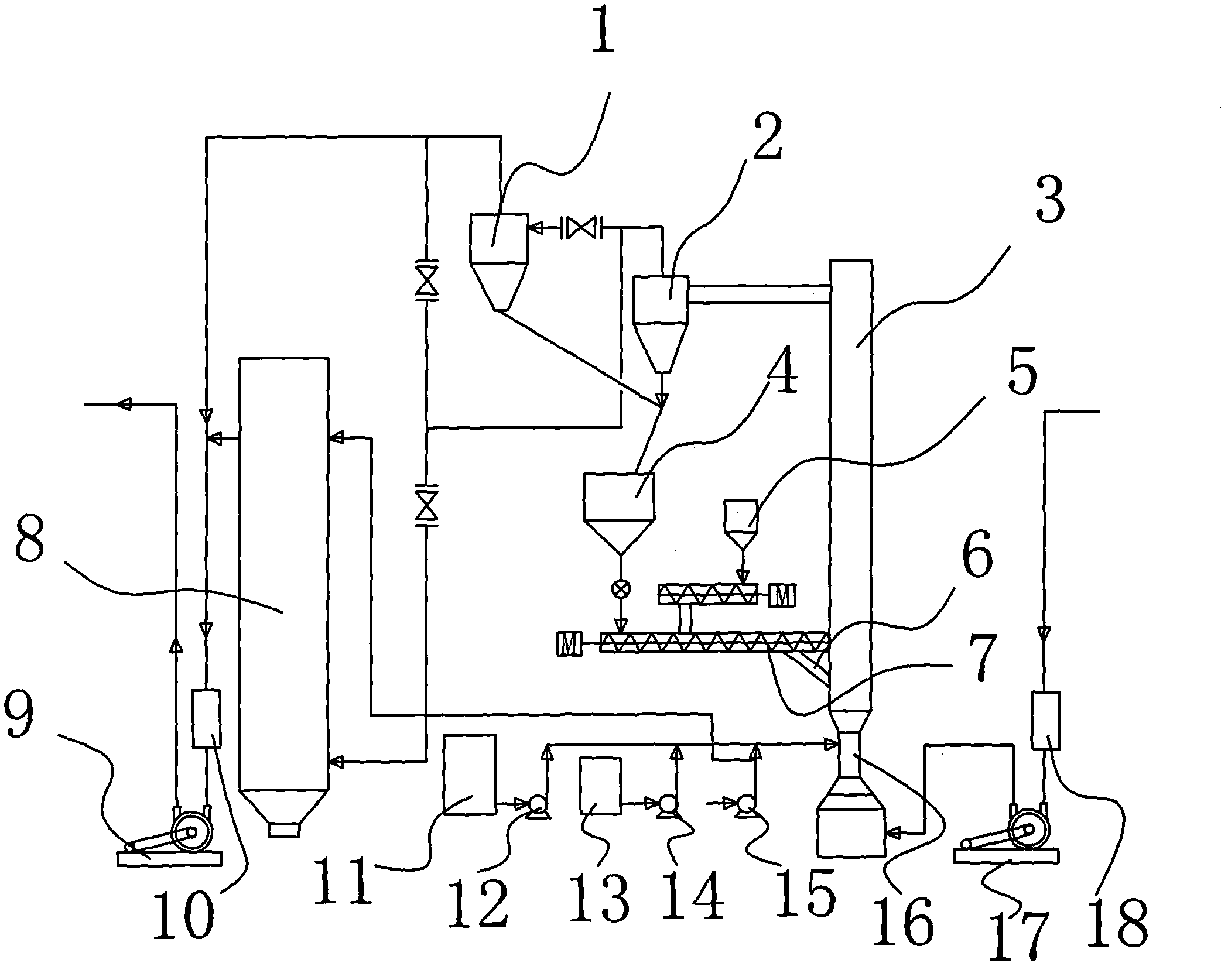

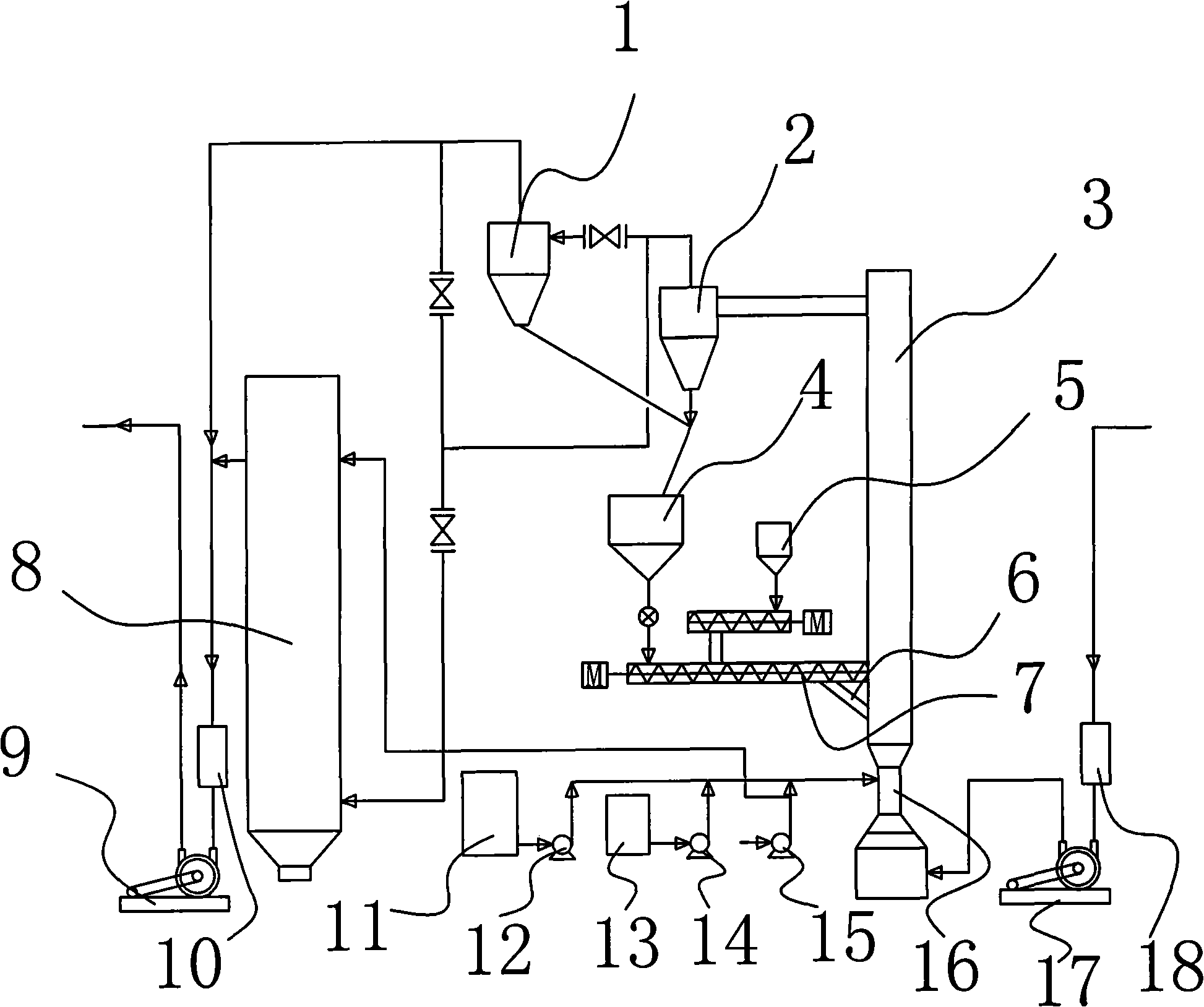

Flue gas desulfurization system for sintering machines

InactiveCN101972600AGuaranteed differential pressureReduce humidityCombination devicesFlue gasProcess engineering

The invention discloses a flue gas desulfurization system for sintering machines, which comprises a reactor, a flue gas induced draft unit, a state separating unit, a solid feedback and filling unit, an absorbent addition unit and a data acquisition unit. Flue gas from the sintering machine enters the reactor from the bottom after passing through a pre-deduster; the bottom of the reactor is in a venturi structure, and glue gas is accelerated when flowing through the bottom of the reactor; after being accelerated when passing through the venturi part on the bottom of the reactor, the flue gas enters a circulating fluid bed body on the upper part; the absorbent is injected into the bottom of the reactor through an injection device, and circulating desulfurization ash is send into the reactor from the other side of the bottom of the reactor; the absorbent and circulating desulfurization ash are suspended to form a fluid bed under the impact action of the accelerated flue gas; the material in the circulating fluid bed forms a gas-solid two-phase flow mechanism under the action of gas flow, thereby greatly strengthening mass transfer and heat transfer between gas and solid; and thus, the material is thoroughly mixed with the flue gas to complete the desulfurization reaction. The invention has the advantages of high desulfurization efficiency, low device abrasion, low operating cost and reliable operation.

Owner:UNIVERSTAR SCI & TECH SHENZHEN

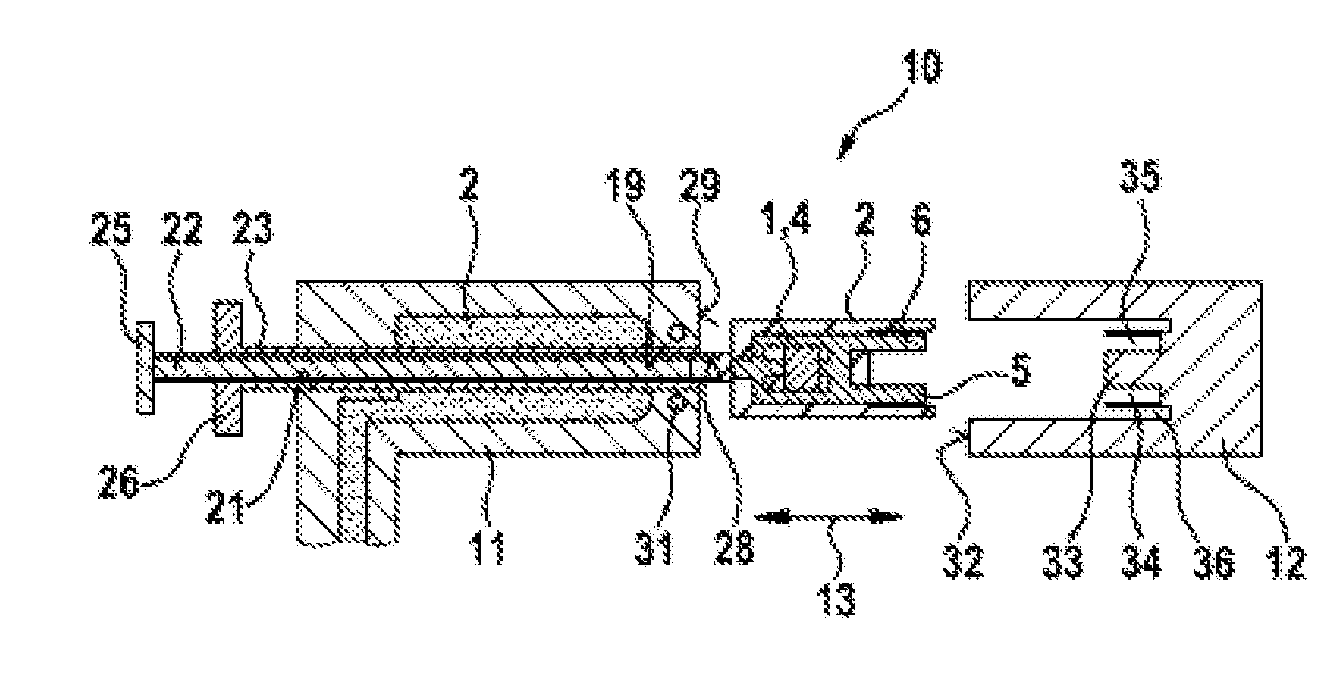

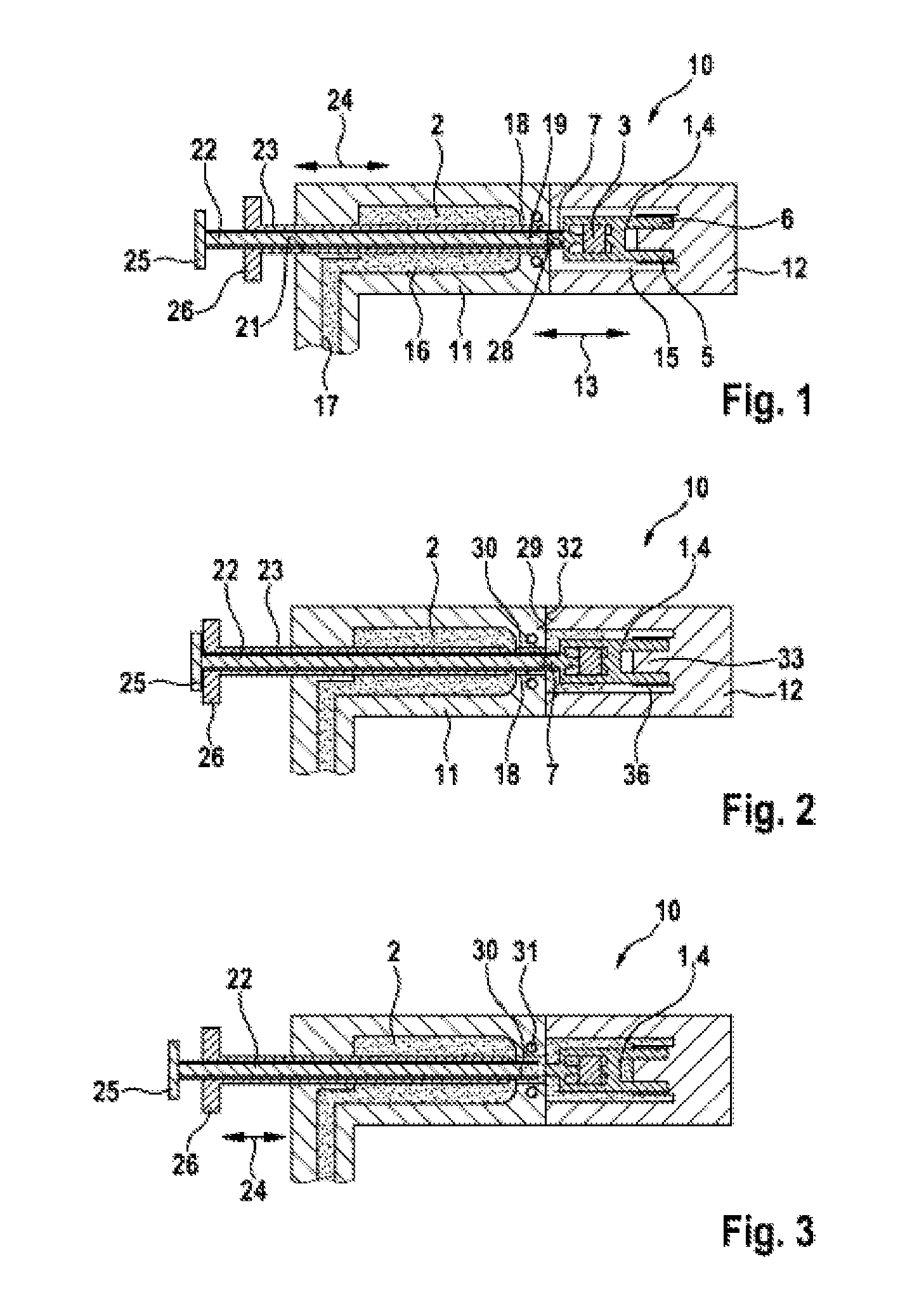

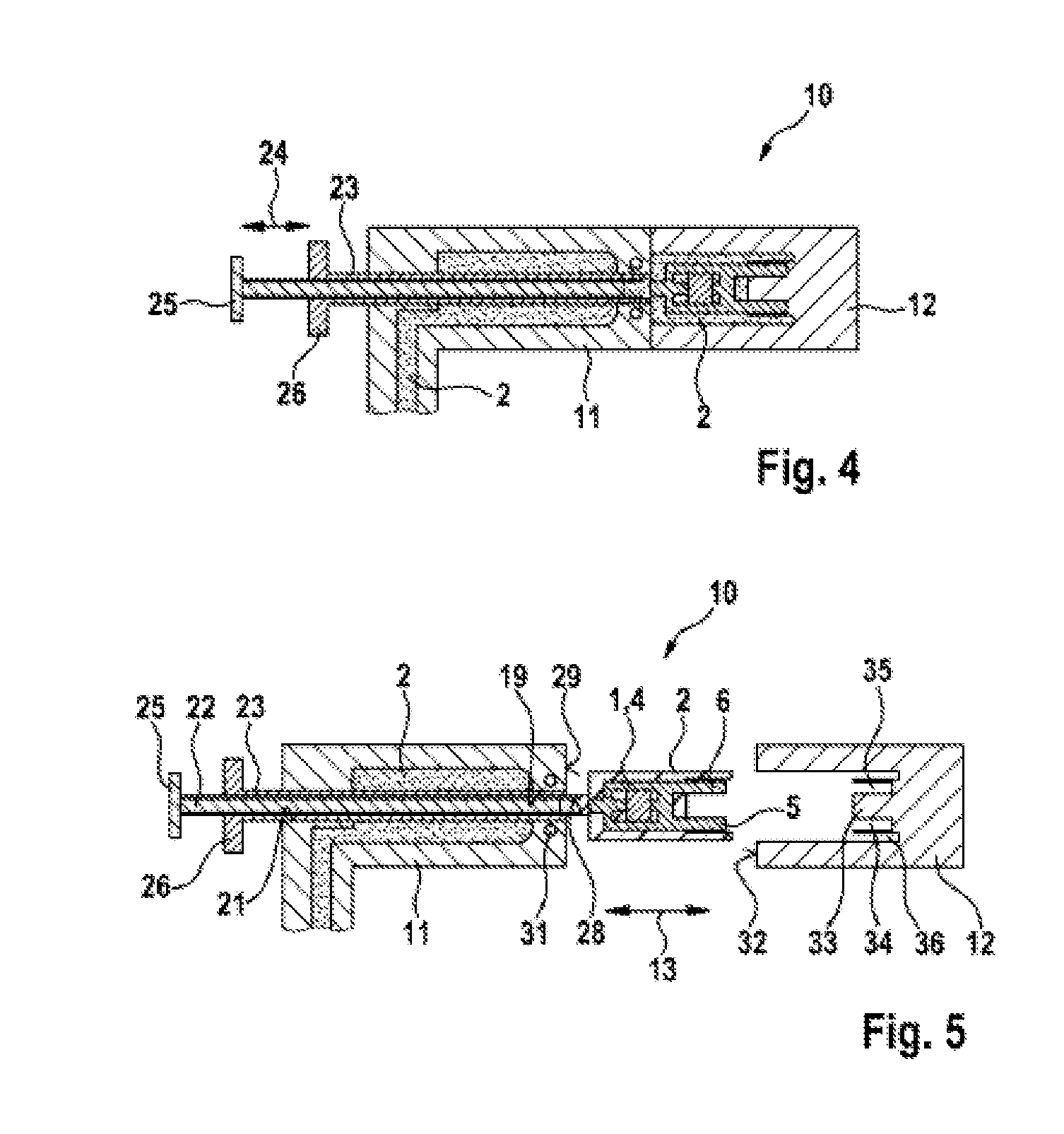

Device for encapsulating a component with plastics material

ActiveUS20140093601A1Reduce loadGood flowTailstocks/centresConfectioneryManufacturing engineeringPlastic materials

Owner:ROBERT BOSCH GMBH

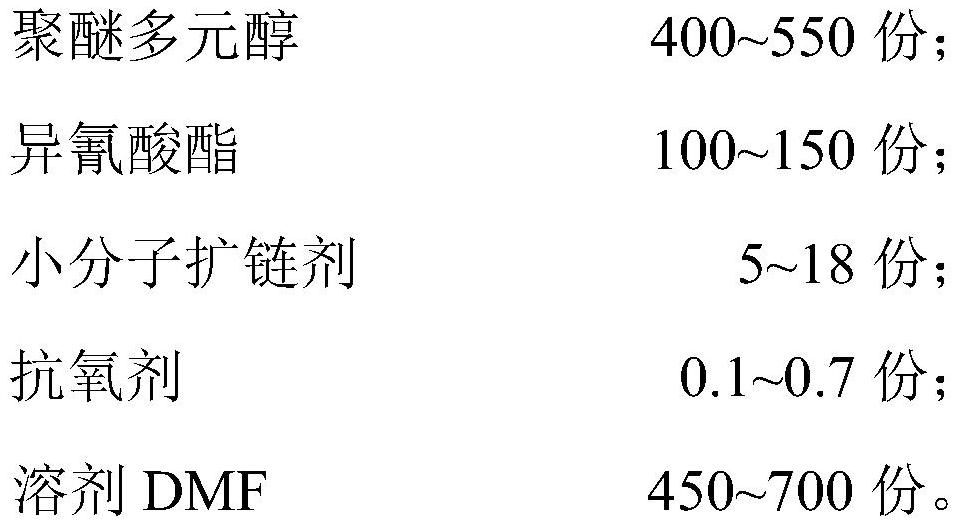

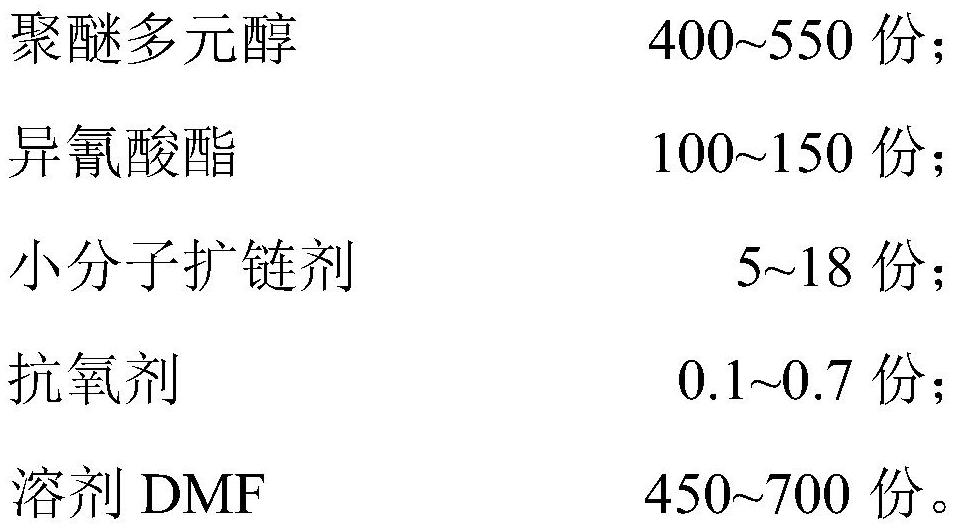

Method for preparing solvent-free multicomponent polyurethane synthetic leather based on steam injection coating

InactiveCN103031736BSolve environmental pollutionQuality improvementLaminationLamination apparatusAlcoholFoaming agent

The invention discloses a method for preparing solvent-free multicomponent polyurethane synthetic leather based on steam injection coating. The method comprises the following steps: firstly, adding polyhydric alcohol, isocyanate, chain extender, vulcanizing agent, catalyst, coupling agent, foaming agent, foam stabilizer, colorant, component absorbing carbon dioxide and water and filler into a plurality of stock tanks of a polyurethane casting machine; secondly, conveying the raw materials to a mixing head of the casting machine for mixing by regulating a metering pump on the raw material tank to obtain mixed size; coating the mixed size on release paper by a steam injection spreader, fitting base cloth on the mixed size layer of the release paper and then drying the base cloth; and finally, continuously reacting the mixed size by post curing till complete curing, and peeling the release paper after cooling to obtain the solvent-free multicomponent polyurethane synthetic leather. No solvent is used in the production process, so that the environmental pollution problem of DMF, TOL, MEK, THF and other solvents generated by the existing solvent polyurethane synthetic leather can be solved.

Owner:SHAANXI UNIV OF SCI & TECH

Polyether polyol as well as preparation method and application thereof

PendingCN113493563AHas the characteristics of green environmental protectionEasy to usePolymer sciencePolyol

The invention relates to polyether polyol as well as a preparation method and application thereof, CO2-based polyether polyol with low molecular weight is prepared through reaction by matching a qualified bimetallic catalyst with a polyether monomer, an initiator and the like in a proper proportion, and the CO2-based polyether polyol is applied to polyurethane resin for crease-free mirror leather. According to the polyhydric alcohol prepared by the invention, flexible polyether chains are doped into the polyhydric alcohol, so that the polyhydric alcohol can keep a good flowing state even under a low-temperature condition in winter, and the polyhydric alcohol is convenient to use in a production workshop; the prepared polyurethane resin for the mirror surface leather has good biodegradation and mechanical and physical properties; and the obtained synthesis leather has the structural characteristic of no bubbles, and can keep the characteristic of no creases under the condition of repeated bending. After a product prepared from the synthesis leather is used for a long time and is discarded, the synthesis leather can be completely biodegraded in a compost degradation mode, and the ecological environment cannot be polluted. The polyether polyol has the advantages of wide raw material source, lower cost, less energy consumption and simple preparation process.

Owner:YANGZHOU POLYTECHNIC INST

Method for preparing chitosan in situ gel agent

InactiveCN101327183BGood flowExpand the delivery methodPharmaceutical delivery mechanismPharmaceutical non-active ingredientsGel preparationOrganic solvent

The invention discloses a preparation method of chitosan in situ gel preparation, which belongs to the medicine technical field. The invention comprises the steps as follows: first, dissolving chitosan into water solution and / or water solution with cosolvent; second, adding medicine into the chitosan solution and stirring sufficiently; third, adding strong base-weak acid salt into the chitosan solution slowly in CO2 atmosphere and under the stirring condition, and keeping stirring; fourth, distributing the evenly mixed chitosan collosol into sterile bottles with stoppers for sealing or filling chitosan collosol into an atomizing device under the protection by CO2 and then obtaining the chitosan in situ gel preparation. The invention not only avoids using organic solvent in the cause of preparation production but also simplifies the preparation production flow and widens the preparation application ways.

Owner:SHANGHAI JIAOTONG UNIV

Catalyst stuffing and stuffing bed for seawater desulfurization process

InactiveCN102211045BReduce oxidationSmooth releasePhysical/chemical process catalystsDispersed particle separationCatalytic oxidationSULFATE ION

The invention provides a catalyst stuffing and stuffing bed for a seawater desulfurization process. The surface of the catalyst stuffing is coated with a catalyst, and the catalyst stuffing is composed of a three-layered cellular ring structure which comprises (a) a middle cellular ring (100), (b) an upper cellular ring (200) and a lower cellular ring (300) as well as (c) a supporting structure (400) connected with the upper cellular ring (200), the middle cellular ring (100) and the lower cellular ring (300). The catalyst stuffing has a good contacting surface, a relatively low pressure dropand an effect of catalytic oxidation, and can catalytically oxidize the SO2 absorbed in seawater into stable sulfate ions. Sulfite ions are further stabilized into the sulfate ions on the basis of improving the desulfurization efficiency; the oxidation quantity in the later stage of the seawater desulfurization process is reduced, so that an aeration basin and the aeration quantity can be reduced.

Owner:SHANGHAI HUOLIN ENG PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com