Multi-layer flux-cored silver solder and preparation method thereof

A technology of silver solder and flux core, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of insufficient gap filling and fast flow, achieve good gap filling and fast flow, and improve filling Seam performance and flow performance, and the effect of improving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of above-mentioned multi-layer flux-cored silver solder comprises the following steps:

[0038] Step 1. According to the mass fraction and mass ratio of the alloy wire, calculate the mass fraction of Ga particles, Sn block, and In foil raw materials and weigh them respectively. First, put Sn in a graphite crucible and heat it to a certain temperature. Sn is melted into For molten metal, wrap Ga grains with In foil and press into the bottom of the molten metal with a bell jar, stir with a glass rod until it is completely melted and mixed evenly, then cast into the mold cavity, and cool to obtain an alloy ingot;

[0039]Step 2, extruding and drawing the alloy ingot to obtain a fixed-ratio alloy wire with a certain diameter;

[0040] Step 3: Weigh the silver brazing flux powder in parts by mass, configure the silver brazing flux powder and polyethylene glycol-400 binder to form a paste brazing flux, and apply the paste brazing flux evenly on the allo...

Embodiment 1

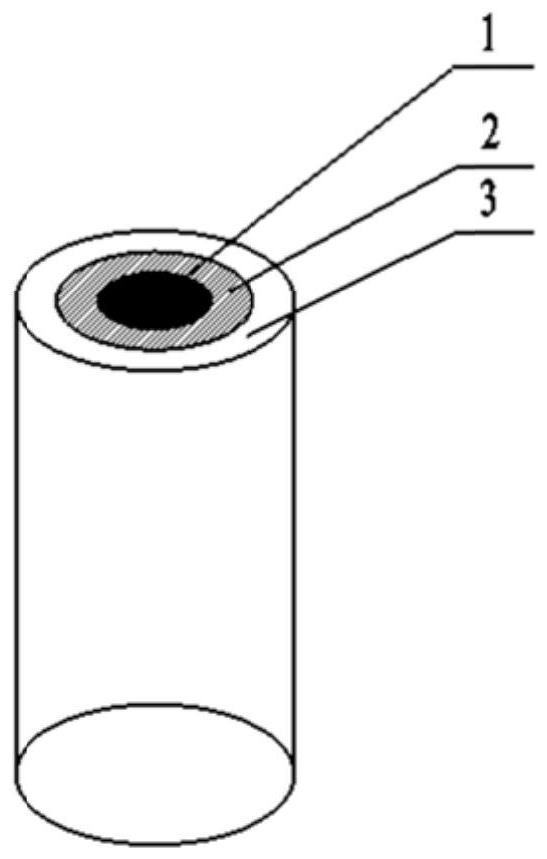

[0051] The multi-layer flux-cored silver solder of this embodiment includes an inner core layer, an intermediate layer attached to the surface of the inner core layer, and an outermost layer wrapped on the intermediate layer.

[0052] The three-layer components of the multi-layer flux-cored silver solder are composed in parts by weight: 5 parts for the inner core layer, 6 parts for the middle layer, and 70 parts for the outermost layer.

[0053] The inner core layer is Ga-Sn-In alloy wire (fixed ratio alloy wire), and the mass ratio of Ga, Sn, and In in Ga-Sn-In alloy wire is 8:12:1.

[0054] The middle layer is a silver flux layer, which is composed of silver flux and polyethylene glycol-400 binder in a mass ratio of 90:10. The silver brazing flux is composed of sodium fluoride, potassium fluoroborate and boric anhydride in a mass ratio of 20:45:35.

[0055] The outermost layer is a silver-based solder metal skin, consisting of the following components by weight: 5 parts of ...

Embodiment 2

[0058] The multilayer flux-cored silver solder of the present embodiment differs from the introduction of embodiment 1 in that the parts by weight of the three-layer components of the multilayer flux-cored silver solder consist of: 6 parts of the inner core layer, 7 parts of the middle layer parts, the outermost layer is 75 parts.

[0059] Wherein, the components by weight of the outermost silver-based solder metal skin consist of: 10 parts of Ag, 40 parts of Cu, 30 parts of Zn, 1.5 parts of Ni, 1.2 parts of Mn, 0.1 part of Si, 0.1 part of Li, P0.1 share.

[0060] The diameter of the fixed-ratio alloy wire is 1.5mm; the fixed-ratio alloy wire and the silver brazing flux layer form the coated alloy wire, and the diameter of the coated alloy wire is determined by its mass fraction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com