Antibacterial, mildew-proof and antiviral porous ceramic as well as preparation method and application thereof

A porous ceramic, anti-bacterial and anti-mildew technology, applied in chemical instruments and methods, other chemical processes, sterilization/microdynamic water/sewage treatment, etc., can solve the problems of inability to purify air or water, and achieve excellent adsorption of polluted water Effects of pathogenic microorganisms, excellent antibacterial, antifungal, and antiviral properties, and good flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

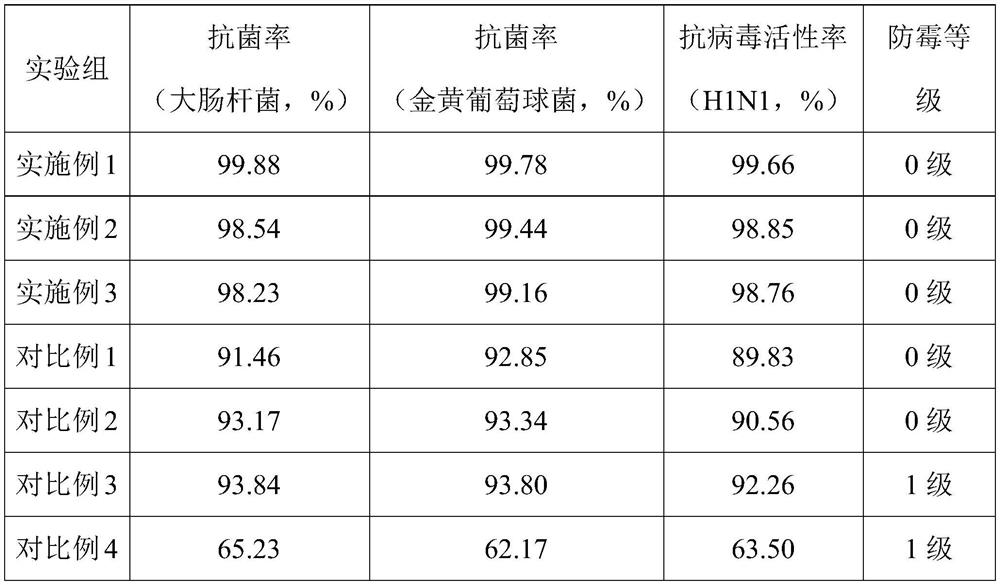

Examples

Embodiment 1

[0056] This embodiment provides an antibacterial, mildew, and anti-virus porous ceramic, the surface of the antibacterial, mildew, and anti-virus porous ceramic is coated with an antibacterial glaze;

[0057] The antibacterial glaze comprises 2 parts of silver-loaded hydroxyapatite, 3 parts of silver-loaded clay minerals, 3 parts of nano zinc oxide, 1 part of methylcellulose, 2 parts of sodium methylcellulose and 100 parts of ceramic glaze (dry The mass ratio of glaze and water is 1:1), and the aperture of described porous ceramics is 100ppi;

[0058] The preparation method of the antibacterial, mildew-proof and anti-virus porous ceramics comprises the following steps:

[0059] (1) Mix silver-loaded hydroxyapatite, silver-loaded clay minerals, nano-zinc oxide, methylcellulose, sodium methylcellulose and ceramic glaze in proportion, ball mill for 3 hours, and pass through a 200-mesh sieve to obtain an antibacterial glaze ;

[0060] (2) The porous ceramics were ultrasonically ...

Embodiment 2

[0063] This embodiment provides an antibacterial, mildew, and anti-virus porous ceramic, the surface of the antibacterial, mildew, and anti-virus porous ceramic is coated with an antibacterial glaze;

[0064] The antibacterial glaze comprises 2 parts of silver-loaded zirconium phosphate, 1 part of nano-zinc oxide, 1 part of sodium methylcellulose and 100 parts of ceramic glaze (the mass ratio of dry glaze and water is 1.2:1), and the porous ceramic The aperture is 200ppi;

[0065] The preparation method of the antibacterial, mildew-proof and anti-virus porous ceramics comprises the following steps:

[0066] (1) Mix silver-loaded zirconium phosphate, nano-zinc oxide, sodium methylcellulose and ceramic glaze in proportion, ball mill for 1 hour, and pass through a 300-mesh sieve to obtain the antibacterial glaze;

[0067] (2) The porous ceramics were ultrasonically cleaned with water and absolute ethanol for 15 minutes, dried in an oven at 110°C, and cooled to room temperature; ...

Embodiment 3

[0070] This embodiment provides an antibacterial, mildew, and anti-virus porous ceramic, the surface of the antibacterial, mildew, and anti-virus porous ceramic is coated with an antibacterial glaze;

[0071] Described antibacterial glaze comprises 0.5 part of silver-loaded calcium phosphate, 0.5 part of nano-zinc oxide, 0.5 part of polyvinyl alcohol and 150 parts of ceramic glaze (the mass ratio of dry glaze and water is 0.5:1), and the aperture of described porous ceramic is 50ppi;

[0072] The preparation method of the antibacterial, mildew-proof and anti-virus porous ceramics comprises the following steps:

[0073] (1) Mix silver-loaded calcium phosphate, nano-zinc oxide, polyvinyl alcohol and ceramic glaze in proportion, ball mill for 0.5h, and pass through a 100-mesh sieve to obtain the antibacterial glaze;

[0074] (2) The porous ceramics were ultrasonically cleaned with water and absolute ethanol for 10 min, dried in an oven at 100°C, and cooled to room temperature; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com