Non-combustible heat preservation wall material and manufacturing method thereof

A technology for wall materials and powder materials, which is applied in the fields of fire prevention, architectural decoration, and thermal insulation materials, and can solve the problems of non-fire resistance of thermal insulation boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

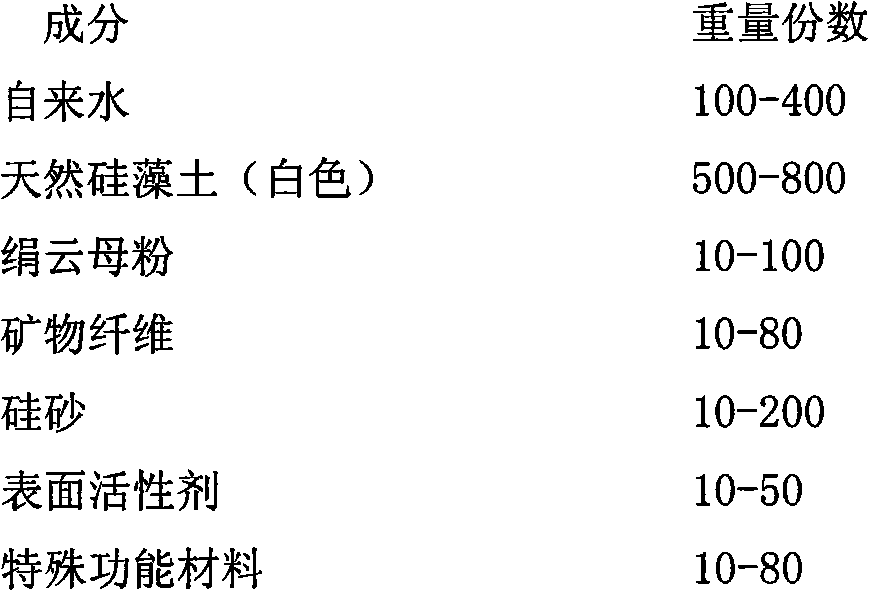

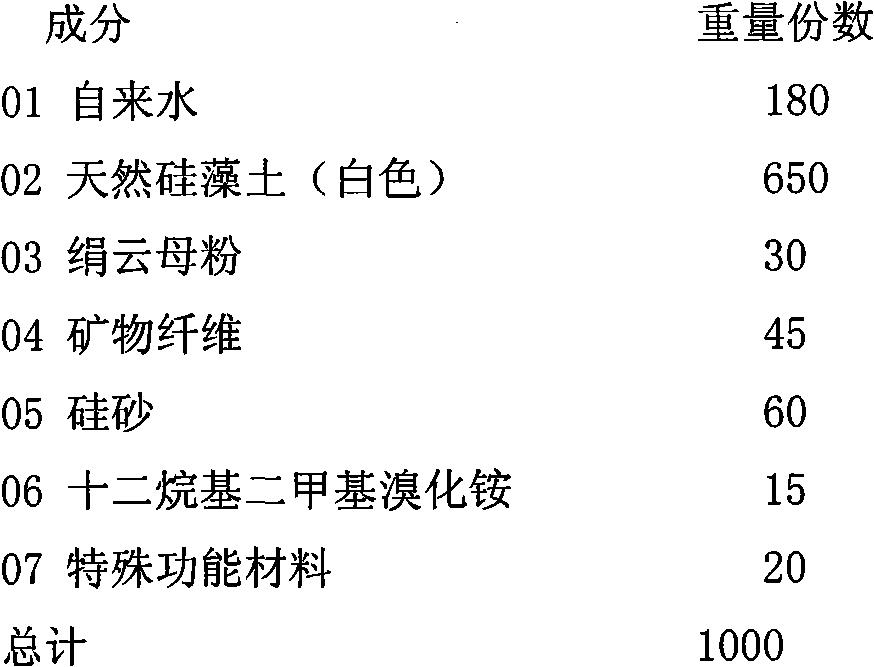

[0012] Example 1: powder preparation, its main composition is (kg):

[0013]

[0014] Production process: In the case of low-speed stirring of the kneader, add the above-mentioned materials No. 01-07 in sequence according to the formula amount, stir for 30 minutes at a medium speed, and then blow into the 900-degree rotary furnace by wind force, and quickly pipe it after high-temperature calcination in the rotary furnace Water-cooled, dehumidified and dried, then sent to a high-pressure airflow crushing device, crushed by an airflow mill to a specified particle size, collected and packaged to obtain the finished product.

[0015] Main indicators of materials:

[0016] serial number Test items Test results 1 Bulk density 450Kg / m 3 2 High temperature resistant Greater than 1200℃ 3 Moh's hardness 2-2.5 4 Thermal Conductivity Thermal conductivity less than 0.15W / (M.K)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com