Patents

Literature

151results about How to "Antibacterial and antifungal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing dried sweet potato food

InactiveCN1502265AHardened embrittlementWith color protection and anti-browningFood preparationAcetic acidOrganic acid

The method for producing dried sweet potato food is characterized by preparing its multi-functional additive and its formula. Said additive is composed of five organic acids of citric acid, phytic acid, lactic acid, propionic acid and acetic acid or its sodium salt, potassium salt and magnesium salt, and has the functions of hardening, crisping, protecting colour, resisting browning, regulating and controlling pH value, resisting bacteria, preventing mold and reducing water content activity. Said invention can produce low-sugar, high water content and sulfur-free (or microsulfur) dried sweet potato food.

Owner:福建超大现代农业集团有限公司

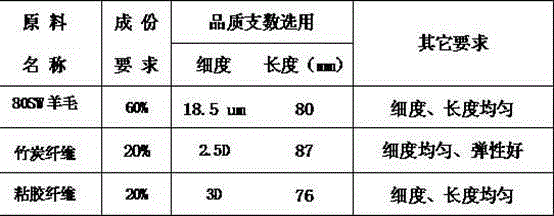

Preparation method of fabric with far-infrared warm keeping function

InactiveCN105200620AStrong and goodGood warmth retentionShrinkingHeating/cooling textile fabricsPlasma technologyWool

The invention discloses a preparation method of a fabric with a far-infrared warm keeping function. The fabric is prepared from the following materials: 60 to 70 percent of 80S wool, 10 to 30 percent of 2.5D bamboo charcoal fiber, and 10 to 30 percent of viscose. The preparation method comprises the following steps: sufficiently tendering bamboo charcoal according to a cold plasma technology, carrying out repeated ball milling with a planetary ball mill to obtain sub-nanometer bamboo charcoal particles, uniformly blending the sub-nanometer bamboo charcoal particles into polyester fiber according to a melt spinning program, and carrying out drawnwork according to a biochemical technology to obtain bamboo charcoal fiber which is relatively high in strength. The fabric has the advantages that the favorable performance of bamboo charcoal fiber is sufficiently played; the variety of woolen fabric is enriched; the grade and the added value of the fabric are improved; not only are the functions of temperature adjustment, humidification, anion release for air purification, far infrared ray release for heat storage and heat preservation, bacterium resistance, mold prevention and the like realized, but also the flexible, smooth, soft and warm characteristics of wool / viscose fiber are embodied, so that the fabric is an ideal fabric for production of female suits and male casual wear.

Owner:JIANGSU JIANLU WOOLEN

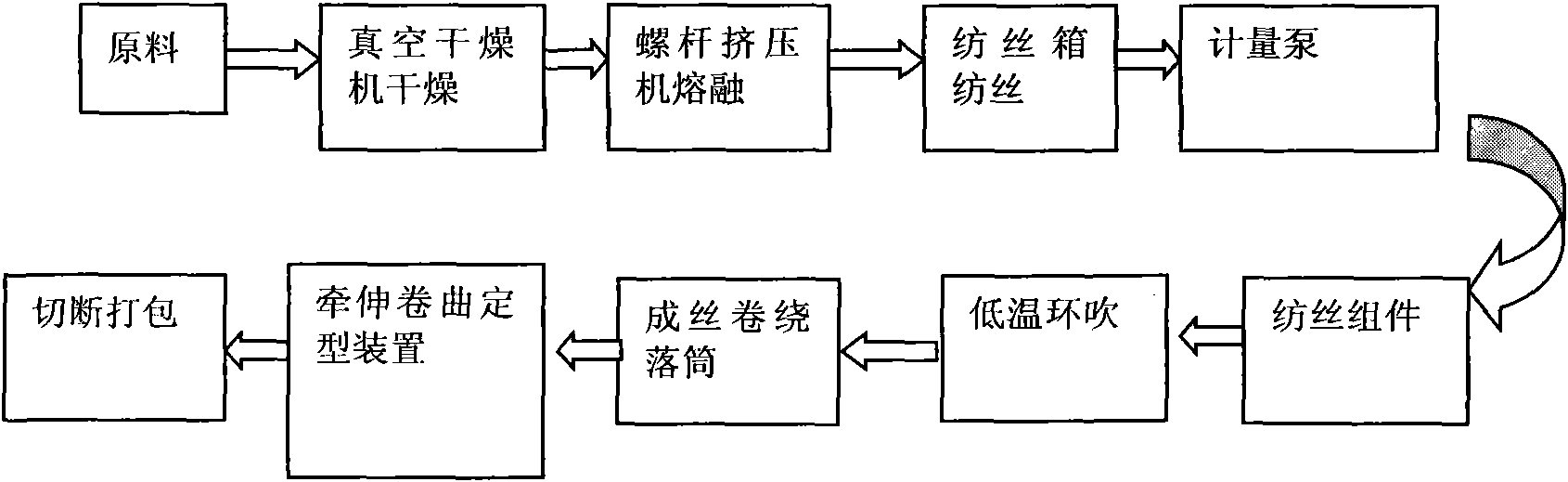

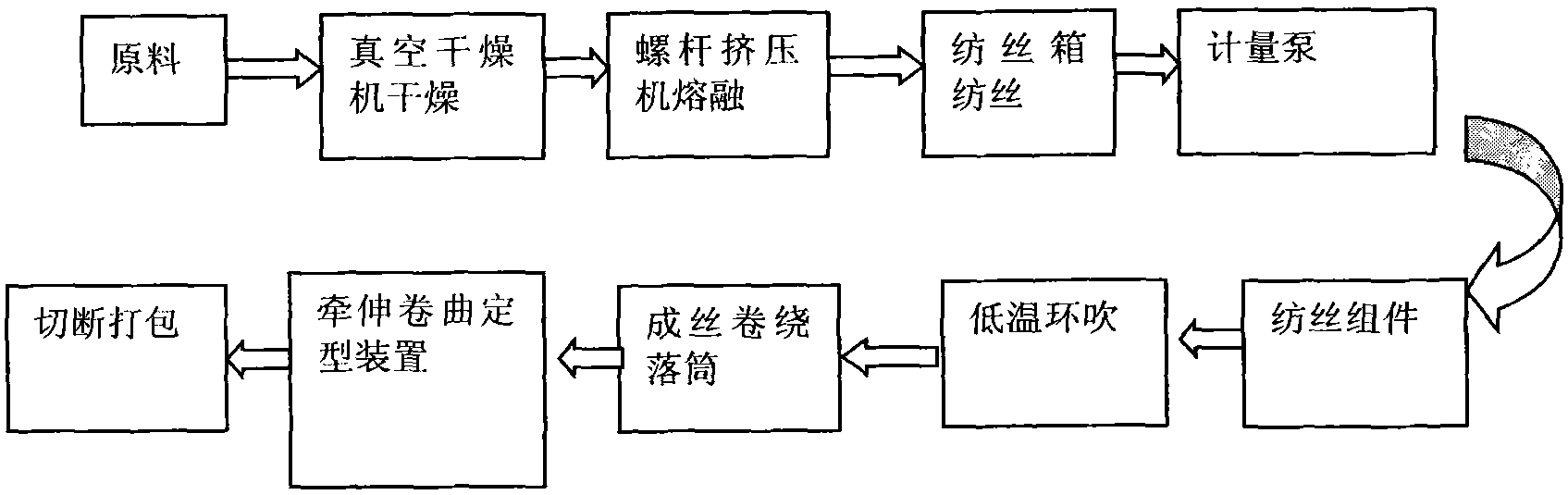

Process for producing nanometer bamboo carbon fiber by adopting polylactic acid group

ActiveCN101857981AGreen production processNo petrochemicalMelt spinning methodsMonocomponent polyesters artificial filamentFiberSpinning

The invention discloses a process for producing nanometer bamboo carbon fiber by adopting a polylactic acid group. In the process, the nanometer bamboo carbon fiber is produced from polylactic acid as a carrier and nanometer bamboo carbon powder by a dry spinning technology. The nanometer bamboo carbon fiber produced by the invention has the advantages of greenness, environmental protection, easy recovery and degradation, low carbon emission during production, simple production process, easy operation and low cost.

Owner:ANHUI HANLIAN TEXTILE CO LTD

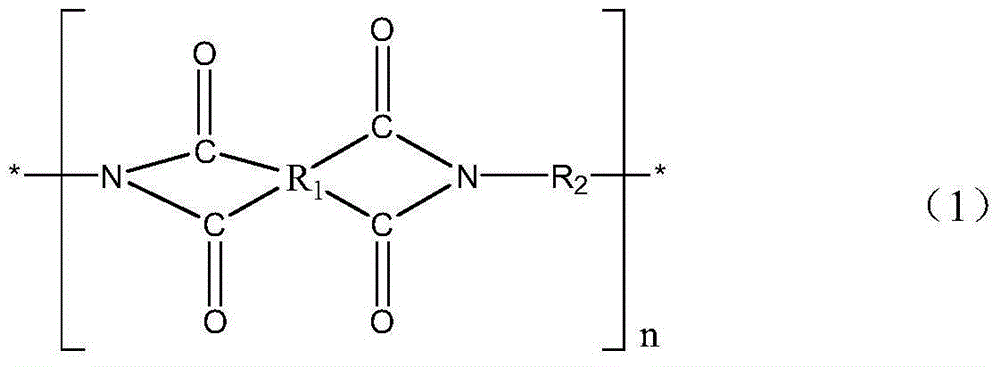

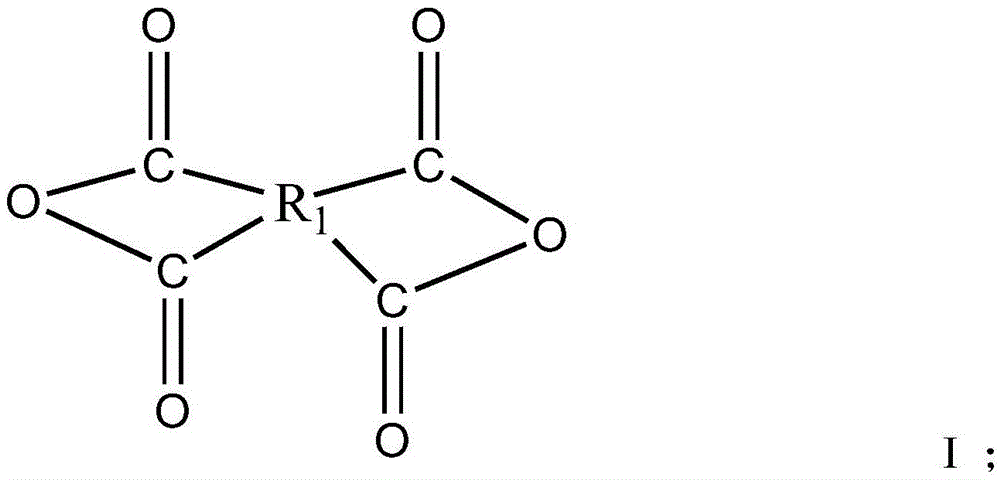

Polyimide nanofiber flocculus, preparation method and application thereof

InactiveCN105019141AImprove filtration efficiencyImprove breathabilityHeating/cooling textile fabricsFiltration separationAir filtrationFiber

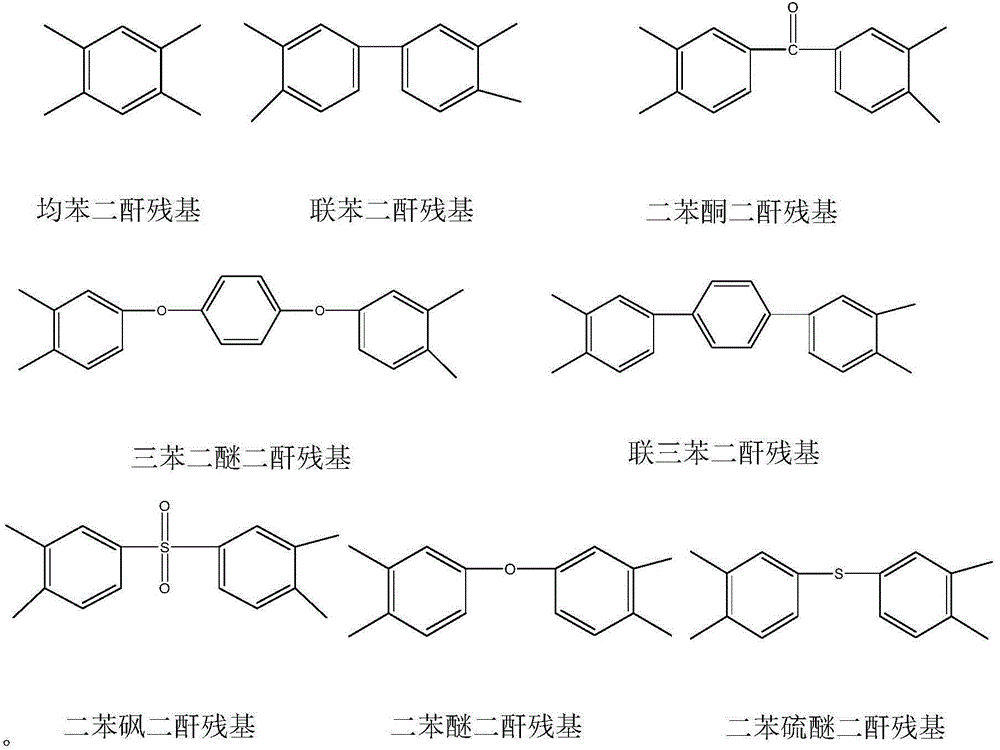

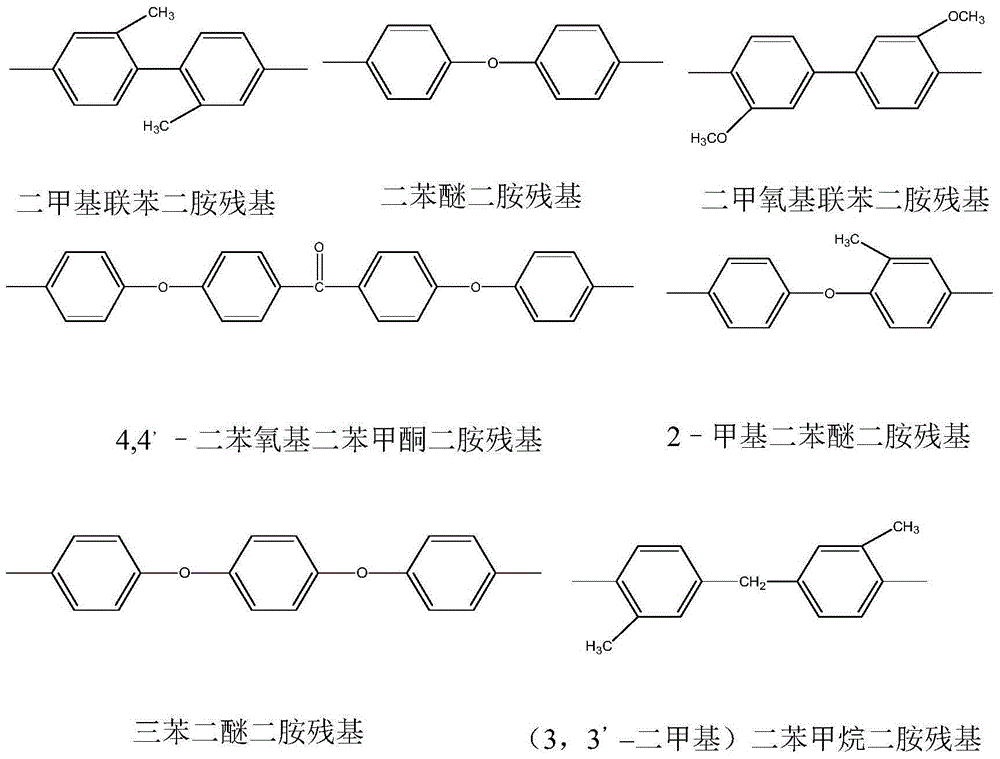

The invention provides a polyimide nanofiber flocculus, a preparation method and application thereof. The structure of the polyimide nanofiber flocculus is described in the following formula (1). In the formula (1), R1 denotes dianhydride residues of aromatic-containing rings. R2 denotes diamine residues of romatic-containing rings. N is an integer larger than 100. The polyimide nanofiber flocculus provided by the invention is featured by being high in filtration efficiency, good in air permeability, permanent in flame retardance and endurable in high temperature and is less susceptible to deformation and has anti-bacteria, mould-proof and electrostatic adsorption functions and has an extensive application prospect in air filtrations fields such as high-temperature filtration, high-end filtration and sterile filtration.

Owner:JIANGXI ADVANCED NANOFIBER S&T CO LTD

Novel environment-friendly waterborne inorganic paint and preparation method thereof

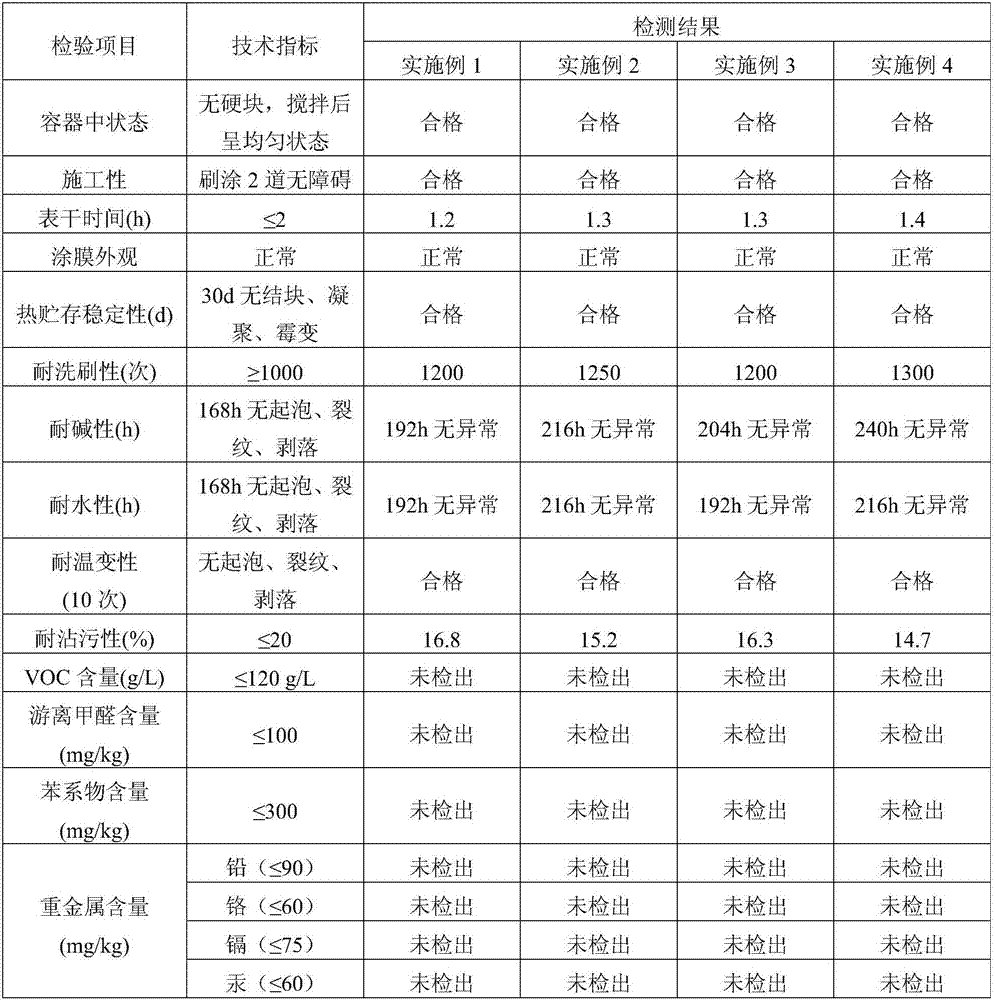

InactiveCN107266944AFire retardantAntibacterial and antifungalFireproof paintsAntifouling/underwater paintsPolyvinyl alcoholFire resistance

The invention discloses novel environment-friendly waterborne inorganic paint and a preparation method thereof. The novel environment-friendly waterborne inorganic paint is prepared from, by weight, 55-65 parts of kaolin, 12-20 parts of sodium silicate, 20-30 parts of titanium dioxide, 1-5 parts of nano zinc oxide, 5-10 parts of ultrafine wollastonite powder, 1-10 parts of nano calcium carbonate, 1-5 parts of ultrafine white mica powder, 7-15 parts of polyvinyl alcohol, 1-4 parts of ultrafine molybdenum disulfide powder, 2-10 parts of nano silicon dioxide, 2-12 parts of nano magnesium oxide, 2-12 parts of nano aluminum oxide, 1-3 parts of magnesium chloride, 1-3 parts of a sodium silicate hardening accelerator, 2-5 parts of a pH value regulating agent, 1-8 parts of a waterproof agent, 6-10 parts of an antifoaming leveling agent, 1-3 parts of a thickening anti-settling agent and 280-310 parts of water. The novel environment-friendly waterborne inorganic paint which is environment-friendly waterborne inorganic paint for buildings is high in storage stability, excellent in water resistance and alkali resistance, strong in adhesion, high in fire resistance, high in strength and hardness, resistant to scratching and contamination, excellent in corrosion resistance and antibacterial property, free of formaldehyde, benzene compounds, VOC (volatile organic compounds) and heavy metal elements, completely environmental friendly and nontoxic, suitable for industrial production, easy for painting and convenient and quick in construction.

Owner:CHENGDU POLYTECHNIC

Polyimide nanofiber yarn and preparation method thereof suitable for industrial production

ActiveCN105603561AGood warmth retentionAntibacterial and antifungalMonocomponent synthetic polymer artificial filamentYarnYarnFiber

The invention provides a polyimide nanofiber, which is obtained by electrospinning a polyimide precursor solution, wherein the polyimide precursor is obtained by copolymerization of triphenyl diether dianhydride, dimethyl benzidine and other monomers with specific structures. A nanofiber yarn is prepared from polyimide containing a flexible group in a main chain as the raw material; the nanofiber yarn is endowed with a plurality of characteristics of the polyimide, and the properties of high temperature resistance, good thermal insulation effect, antibacterial mouldproof performance, permanent flame retardant property and the like; and meanwhile, the flexibility of the nanofiber yarn can also be improved. Through introduction of flexible monomers triphenyl diether dianhydride and dimethyl benzidine, electrospinning of the polyimide nanofiber with high bulkiness and certain elasticity in industrial production is facilitated; the polyimide nanofiber capable of keeping the original shape can also be obtained after imidization; meanwhile, the obtained yarn has relatively good flexibility. Meanwhile, the invention further provides a preparation method of the polyimide nanofiber yarn suitable for industrial production.

Owner:JIANGXI ADVANCED NANOFIBER S&T CO LTD

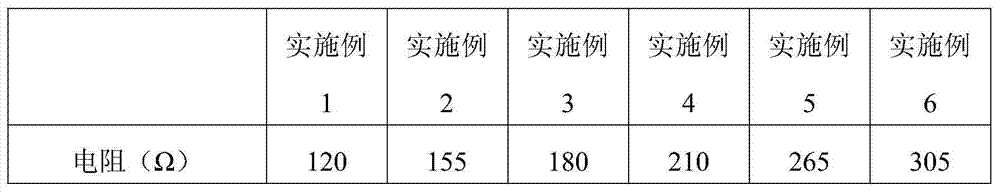

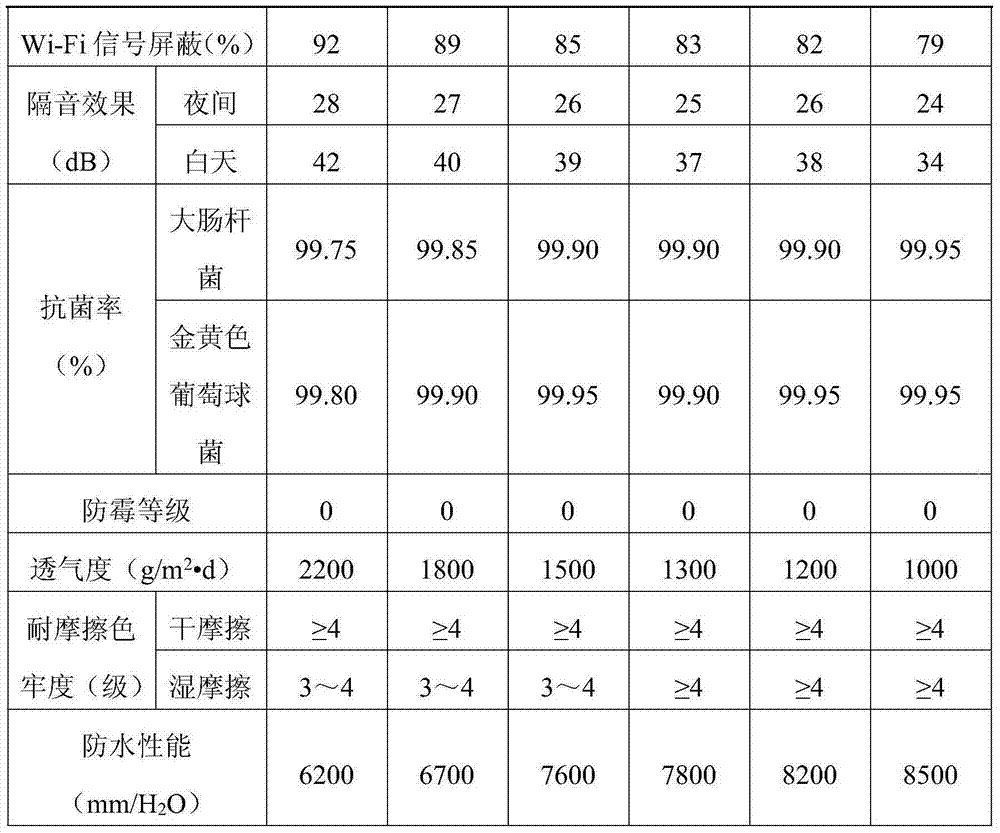

Multifunctional wallpaper capable of shielding Wi-Fi signals and production method thereof

InactiveCN103924758AConductiveWith sound insulation and noise reductionAntifouling/underwater paintsLamination ancillary operationsWater basedElectricity

The invention relates to multifunctional wallpaper capable of shielding Wi-Fi signals and a production method thereof. The multifunctional wallpaper comprises a base, a multifunctional layer on the base, and a pattern layer printed on the multifunctional layer. The production method of the multifunctional wallpaper includes the steps of selecting base material; preparing material of the multifunctional layer; preparing evenly-dispersed slurry; preparing uniform water-based paint; preparing the multifunctional layer; printing the multifunctional layer; producing a finished product. The multifunctional wallpaper has the functions of shielding Wi-Fi signals, conducting electricity, insulating, decreasing noise, inhibiting bacteria, preventing molds, proofing moisture and the like, human, equipment and information security can be protected, and application range of the wallpaper is widened.

Owner:宋旭 +1

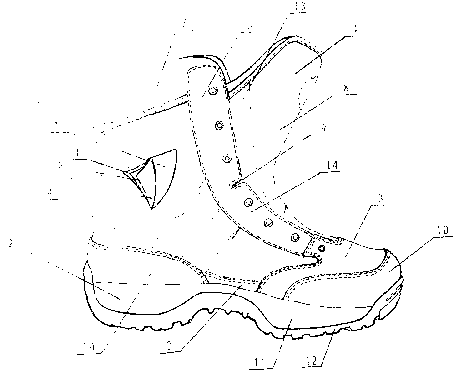

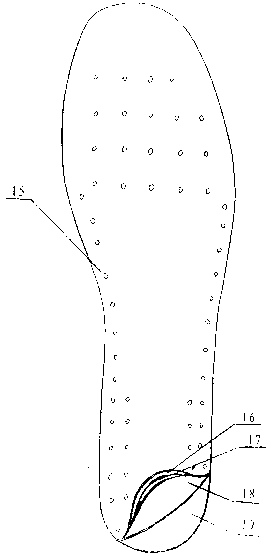

Training boots for special policeman

ActiveCN103315442APuncture resistant withWaterproof and breathableSolesInsolesGlass fiberHigh density

The invention discloses a pair of raining boots for special policeman. Each raining boot comprises an upper, a sole and an insole, wherein the upper comprises an oxford fabric and an ecological functional polyurethane synthetic leather material matched with the oxford fabric; the insole refers to an insole with a Kevlar puncture-resistant function; the hooked core refers to a hooked core made of a glass fiber resin material; the lining of the upper comprises a waterproof breathable film, a high-density sponge layer and a cloth base material layer; the sole comprises an upper polyethylene sole and a lower rubber anti-slip sole; the insole comprises a dermis layer, an antibacterial clean-up bed, an insole high-density sponge layer and an insole cloth base material layer from top to bottom. The pair of raining boots for special policeman has the high-performance and multifunctional characteristics that the pair of training boots is waterproof, breathable, puncture-resistant, antibacterial, mould-proof, shock-absorbing, damping, safe, anti-slip, and the like.

Owner:青岛足谱科技有限公司

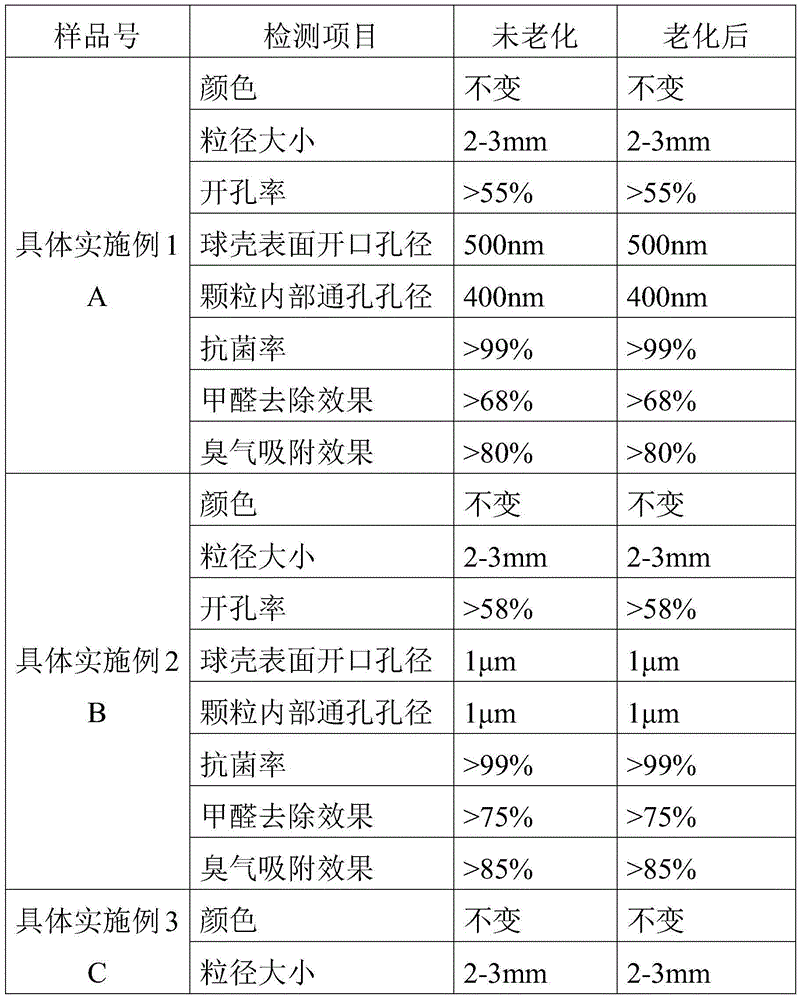

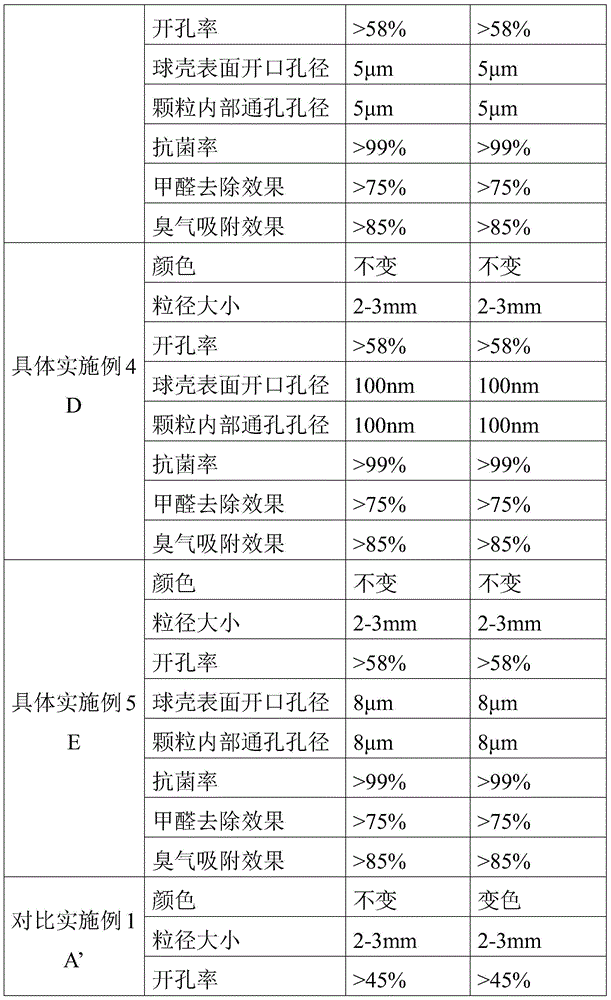

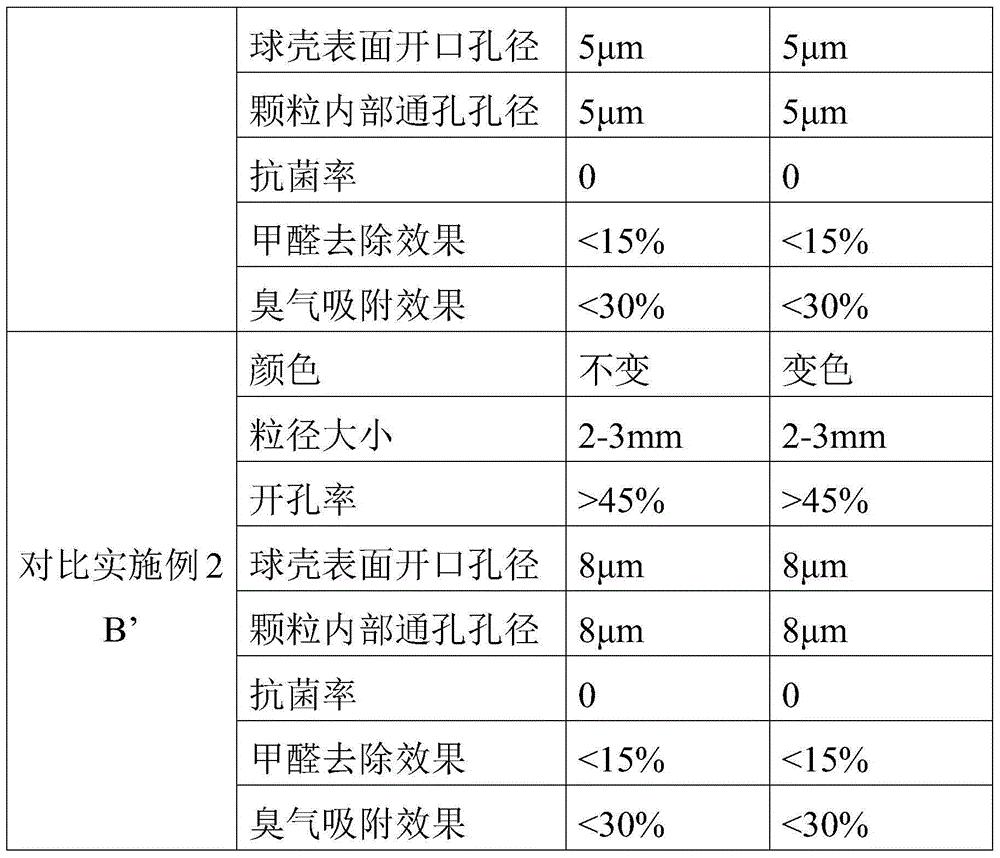

Multifunctional opening foaming polymer particle and preparation method thereof

The invention provides a multifunctional opening foaming polymer particle and a preparation method thereof. The method includes the steps that nano-titanium dioxide or nano-zinc oxide or nano silver powder or nano zinc sulfide is used as a multifunctional auxiliary, an appropriate coupling agent, polymeric dispersant, antioxygen and polymer resin are further adopted, a twin-screw extruder is used for achieving melt blending to conduct extrusion and particle cutting, functional nano powder is wrapped in matrix resin so that polymer particles can be formed, then the polymer particles are foamed by supercritical carbon dioxide gas, the multifunctional opening foaming polymer particle with excellent performance can be prepared, the particle has a surface opening through hole structure and an inner continuous large hole structure, the particle size is 0.5-5 mm, and the opening hole diameter and the inner through hole diameter of the surface of a particle spherical shell both can reach 50 nm-10 microns. The preparation method is simple in technology, convenient and easy to implement. The prepared opening foaming polymer particle has the functions of absorption, filtering, antibacteria and mold prevention, catalysis, odor removal, formaldehyde removal, anti-ultraviolet ageing and the like.

Owner:BILIC FORTUNE TECH

Multifunctional decoration paint

InactiveCN101161740AShield electromagnetic wavesSave energyCoatingsIndoor air qualitySilicon dioxide

The invention is aimed at providing a multifunctional decorative coating which has the following specific components: quaternary latex 25-60 percent consisting of methacrylic acid, butyl acrylate, styrene and methyl metharcrylate, nanometer silver 0.1-5 percent, nanometer sodium meta-silicate 0.2-2 percent, nanometer ferric oxide 0.3-4 percent, nanometer silicon dioxide 0.3-3 percent, calcium carbonate 0.8-2 percent, deionized water 3-12 percent, superfine talc powder 1-4 percent, calcium carbonate superfine powder 3-16 percent, white titanium pigment 3-5 percent, as well as a plurality of auxiliary agents such as dispersant, wetting agent, rheologic agent, thickener, color paste and anti-foaming agent. Besides common decorative function, the coating also has the functions of energy conservation, indoor humidity regulation, antibiosis property and mildew resistance, air purification, acoustic insulation, electromagnetic wave screening, as well as far-infrared ray emission. The coating is mainly used for internal wall decoration for buildings, in particular for public places which have higher requirements on environment and on indoor air quality and humiture such as hospitals, office buildings, museums, meeting halls.

Owner:SHENGHONG GRP CO LTD

High-strength ultraviolet-proof antibacterial type textile fabric

InactiveCN106739215AImprove fitImprove breathabilitySynthetic resin layered productsCellulosic plastic layered productsSurface layerCarbon fibers

The invention discloses a high-strength ultraviolet-proof antibacterial type textile fabric and a preparation process thereof, and relates to the field of textile fabrics. The high-strength ultraviolet-proof antibacterial type textile fabric comprises a surface layer, a middle layer and an inner layer, wherein the surface layer is made of ultraviolet-proof fabrics; the middle layer comprises a first fabric layer, a second fabric layer and a third fabric layer; each of the first fabric layer and the second fabric layer is formed by 40 to 60 weight percent of bamboo carbon fiber, 10 to 30 weight percent of Shengma fiber and 10 to 30 weight percent of gossamer through blended spinning and weaving; the second fabric layer is formed by weaving 100 weight percent of bamboo carbon fiber; the inner layer is formed by 30 to 40 weight percent of bamboo charcoal fiber, 20 to 30 weight percent of heating fiber and 40 to 50 weight percent of cotton through blended spinning and weaving. The high-strength ultraviolet-proof antibacterial type textile fabric provided by the invention has the efficacies that the strength is high; the wear resistant performance is good; the ultraviolet-proof effect is achieved; bacteria resistance and bacteriostasis are realized; the hand feeling is comfortable; ventilation and heat insulation are realized, and the like. The preparation process is simple and reasonable; the production efficiency is high.

Owner:WUHU SUNYANG INFORMATION CONSULTATION

Colorful concrete tile paint for building

InactiveCN101629051AGood physical propertiesWith thermal insulationAntifouling/underwater paintsPaints with biocidesEmulsionInorganic compound

The invention discloses colorful concrete tile paint for a building, which takes the mixture of pure silicone resin emulsion and self-crosslinking acrylic emulsion as a base material, rutile titanium dioxide and color paste as pigment, hollow silica-alumina-based ceramic beads and inorganic infrared radiation powder as a filling and nanometer Tio2 and an anion antibacterial agent as an additive. The single-component colorful concrete tile paint for an organic and inorganic compound bonding system is prepared by adopting the following manufacturing process: grinding, agitating, mixing, oscillating and dispersing, thickening and filtering, packaging and the like under the cooperation of various assistants. The invention has the advantages of excellent physical and chemical properties, smooth and bright coating layer, air purification, health and environment protection, heat insulation, bacteria and mould resistance, anti-fouling and self-cleaning, good decoration effect and low cost, is widely applied to the painting and the decoration of colorful concrete tiles for the building and has wide market prospect.

Owner:唐山市思远涂料有限公司

Weaving method of jutecell/modal siro spinning functional fabric

InactiveCN102634919AEnhanced softness and comfort performanceSolve poor cohesionWeft knittingYarnWoven fabricYarn

The invention relates to a weaving method of a jutecell / modal siro spinning functional fabric, which is characterized by being formed by weaving fabric weaves with single-surface plains; and yarns are formed by stranding two 32S 60% jutecells and 40% modal siro spinning yarns with the twist of 900-1100 twists / m and twist coefficient of 380-430. The finally made fabric is smooth in hand feel, is bright in appearance color, is bright and clean in cloth surface, is excellent in flexibility and elasticity, and has a remarkable vision effect. The jutecell / modal siro spinning functional fabric has the characteristics of excellent moisture absorbing and exhausting properties, good air permeability, bacterium resistance, mildew proofing, and no fluffing and pilling.

Owner:JIANGYIN XIANGFEI APPAREL

Novel putty powder and preparation method thereof

The invention discloses a novel putty powder, which is prepared from the following raw materials in parts by weight: 10 to 30 parts of white portland cement, 15 to 45 parts of magnetite powder, 8 to 20 parts of modified attapulgite clay, 5 to 12 parts of desulfurized gypsum, 18 to 48 parts of humidity regulating functional materials, 10 to 30 parts of white bentonite, 7 to 18 parts of polished round-grained rice, 2 to 8 parts of carboxymethylcellulose, 3 to 6 parts of tourmaline powder negative ion additives, 2 to 5 parts of nanoscale porous silicon dioxide, 1.2 to 2.6 parts of mildew preventives, 1 to 2 parts of sodium dodecylbenzene sulfonate and 1 to 3 parts of nanometer inorganic antibacterial agents. The novel putty powder has the advantages that green and environment-friendly effects are achieved; the functions of regulating the humidity, resisting bacteria, preventing mildew and purifying air are realized; the service life is long; the novel putty powder is suitable for being popularized.

Owner:合肥易美特建材有限公司

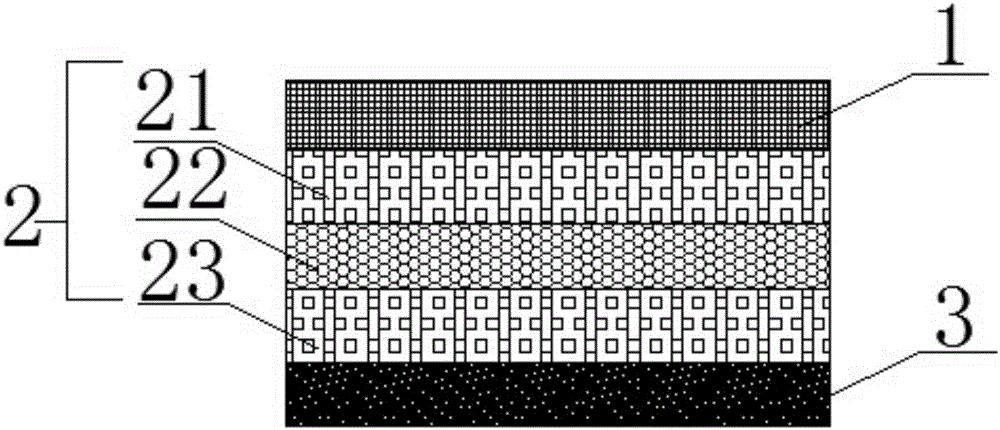

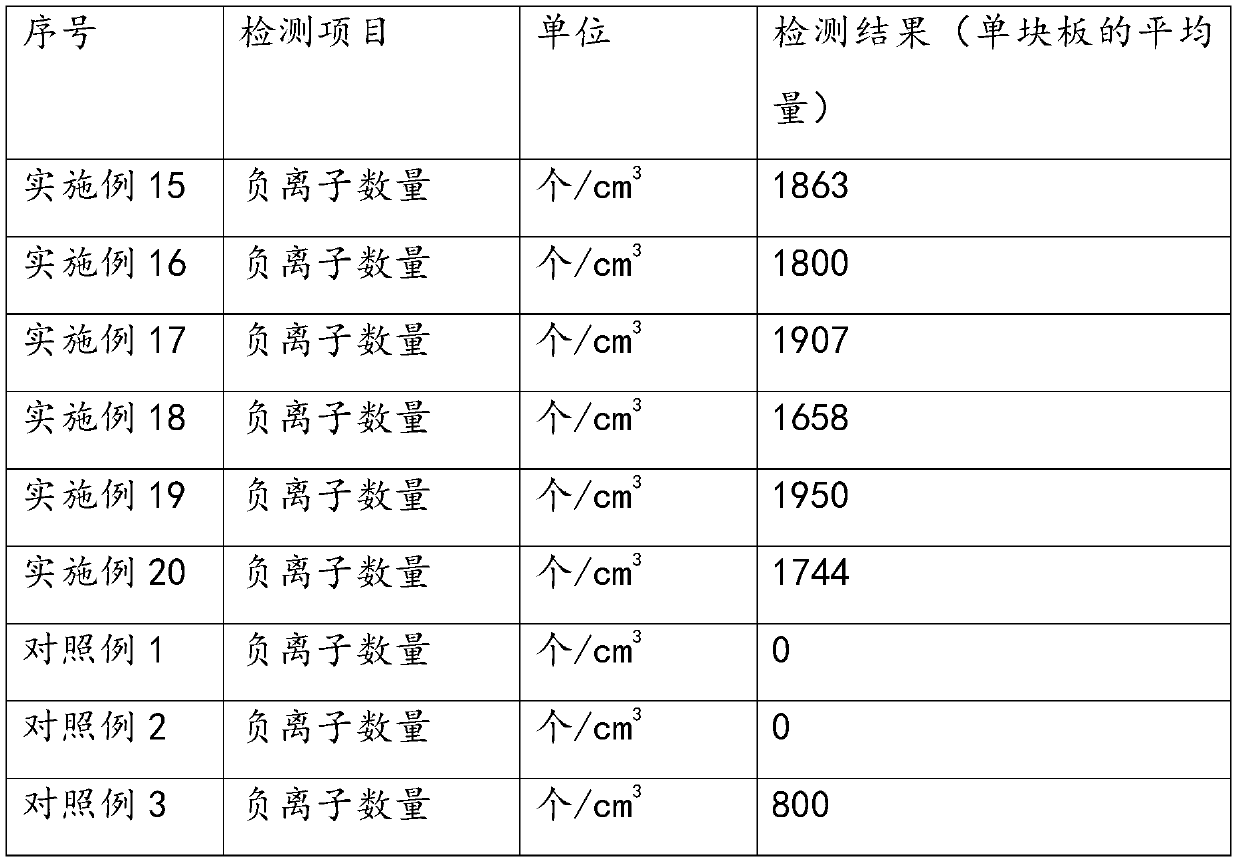

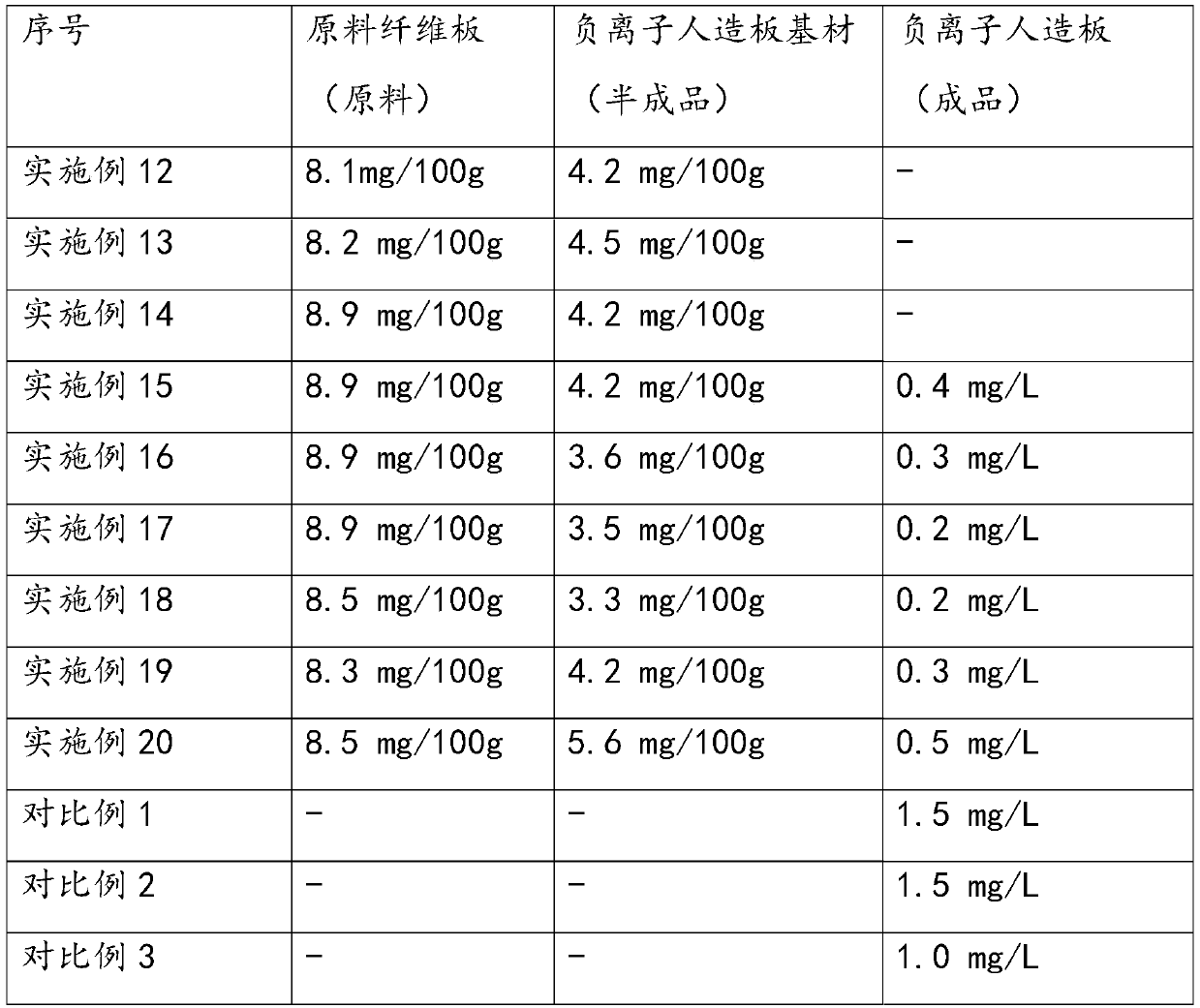

Production method of anion dipping paper/anion decorative artificial board base material/anion decorative artificial board

ActiveCN109763382AImprove antibacterial propertiesStrong anti-corrosion and anti-mildewSpecial paperPaper coatingIonChemistry

The invention discloses a production method of anion dipping paper / an anion veneer artificial board base material / an anion veneer artificial board. The production method of the dipping paper comprisesthe steps that S1 anion mixed liquid is prepared from the following components in parts by weight: 30-40 parts of tourmaline powder, 5 parts of borax, 5 parts of aluminum oxide, 3 parts of nano silver, 10 parts of nano zinc, 1 part of sodium fluosilicate and 40-70 parts of deionized water; S2 the anion mixed liquid prepared in the step S1 and melamine glue are utilized to prepare an anion glue solution at the weight ratio of 1 to 25,wherein the density of melamine glue is 1.0-1.25g / cm<3>, the viscosity is 20-70 MPa.s, the pH value is 8-9.5, and the mass percentage content of solid is higher than or equal to 30%; and S3 to-be-dipped paper is dipped into the anion glue solution prepared in the step S2 and then dried, so thatthe dipping paper is obtained.

Owner:成都市美康三杉木业有限公司

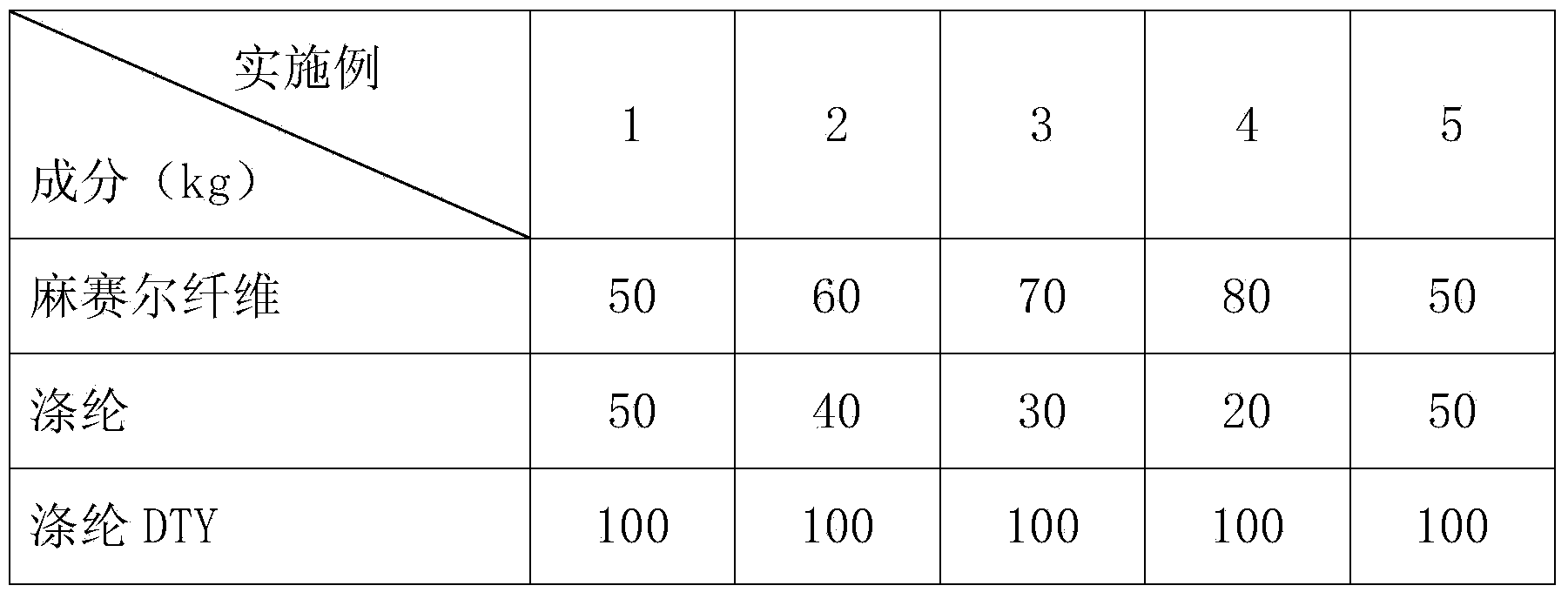

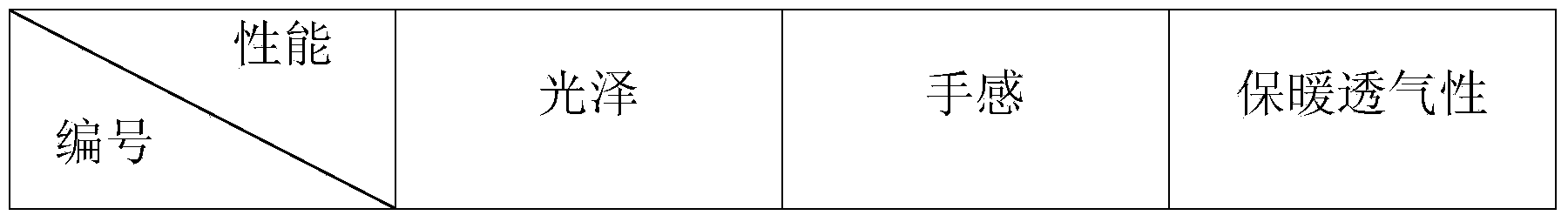

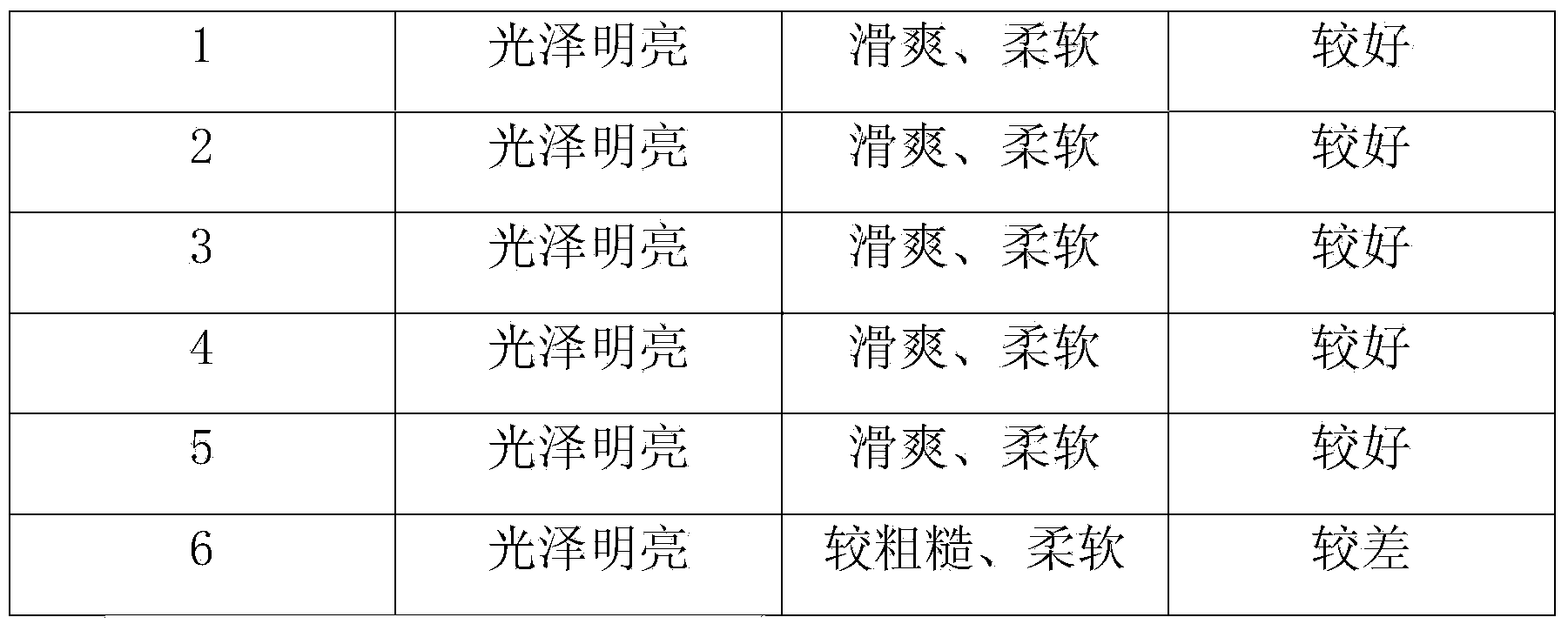

Jutecell fiber Raschel blanket and technology for manufacturing Jutecell fiber Raschel blanket

ActiveCN104109940ALight and thinAntibacterial and antifungalWarp knittingLiquid/gas/vapor removalFiberPulp and paper industry

The invention belongs to the field of production of functional Raschel blankets and relates to a Jutecell fiber Raschel blanket and the technology for manufacturing the Jutecell fiber Raschel blanket. The Jutecell fiber Raschel blanket comprises face yarn and ground yarn, wherein the face yarn is composed of, by weight, 50%-80% of Jutecell fibers and 20%-50% of Dacron fibers, and the ground yarn is composed of, by weight, 100% of DTY. The Jutecell fiber Raschel blanket is formed by weaving blended yarn of 50% of Jutecell fibers and 50% of Dacron fibers and long Dacron filaments on a warp knitting machine. The Jutecell fiber Raschel blanket obtained through weaving is smooth in hand feeling, bright in color and full and smooth in cloth tissue, has the good moisture absorbing and discharging function and the good anti-bacteria and anti-mold function, and is capable of absorbing moisture, breathable, fluffy, soft, extremely comfortable and skin-friendly.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

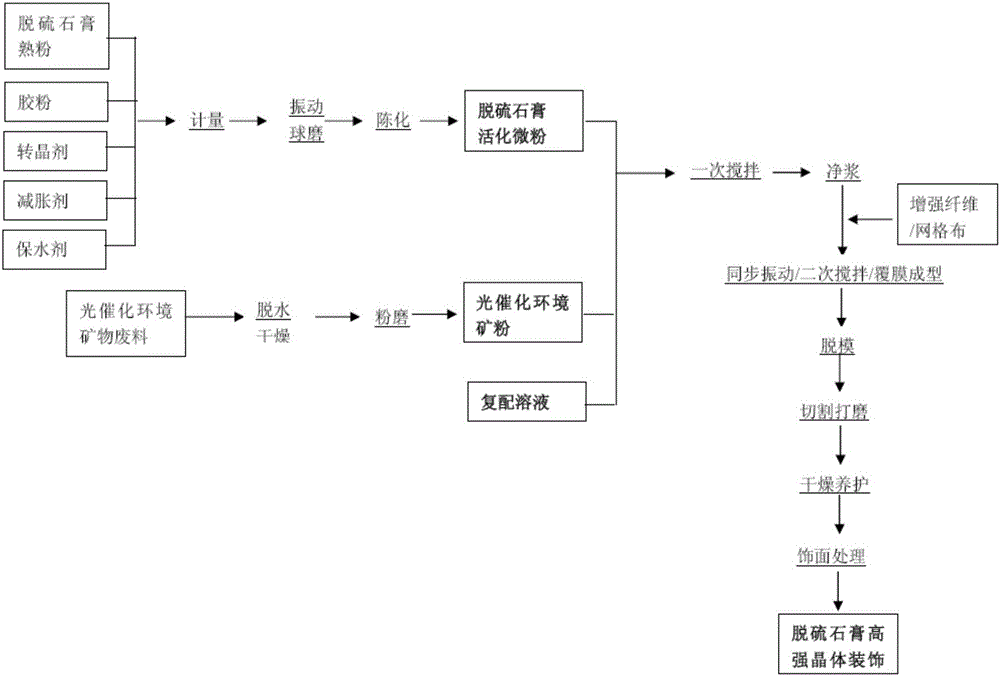

Flue gas desulfurization gypsum high-strength crystal decorative sheet and manufacturing method thereof

The invention discloses a flue gas desulfurization gypsum high-strength crystal decorative sheet and its manufacturing method. the method comprises the following steps: mixing flue gas desulfurization gypsum prepared powder, rubber powder, a crystal modifier, a swelling reducer and a water-retaining agent according to the weight ratio of 95-99.6: 0.1-1.2: 0.02-0.05: 0.2-1.0: 0.1-2.8 so as to prepare flue gas desulfurization gypsum activated micro-powder; stirring the flue gas desulfurization gypsum activated micro-powder, photocatalysis environmental mineral wastes, a waterproof agent, a complex glue solution and reinforced fiber / gridding cloth according to the weight ratio of 100: 0.5-12: 0.1-1.8: 60-75: 0.8-7.0, vibrating, carrying out secondary stirring, carrying out double-face locating and film-mulching forming, demoulding, cutting and polishing, drying and maintaining, and processing by a facing treatment so as to obtain the decorative sheet. The problems of fast coagulation time, unstable strength, high swelling rate and large particle density existing in the prior art are solved. The prepared decorative sheet has formaldehyde-purifying, negative oxygen ion induction and self-humidity-control ecological features. Resource ecological utilization of industrial wastes is realized, full-automatic standard production is achieved, and standardized control of appearance quality and performance of the product is realized.

Owner:HUBEI SENLV ENVIRONMENTAL PROTECTION MATERIAL CO LTD

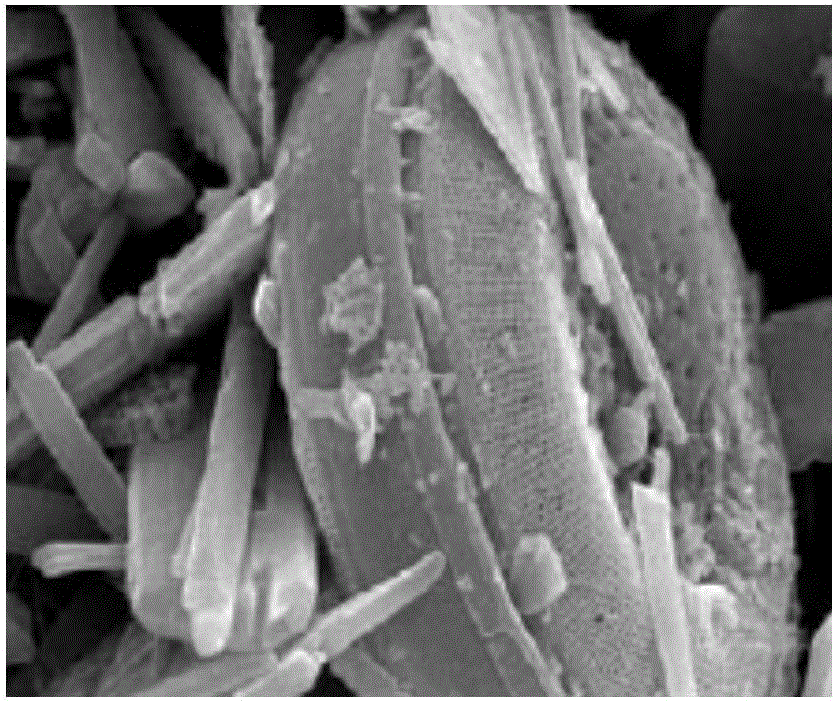

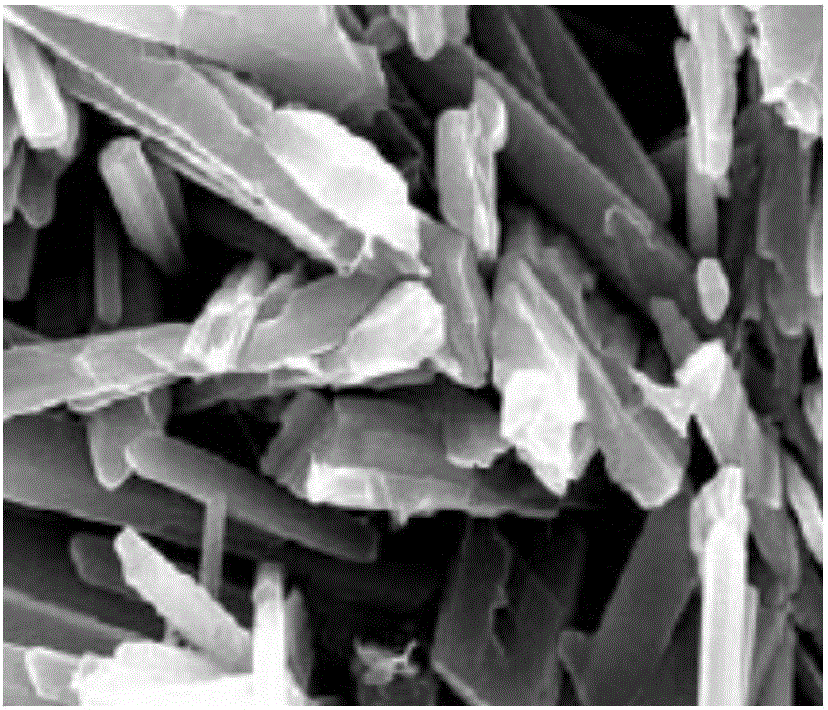

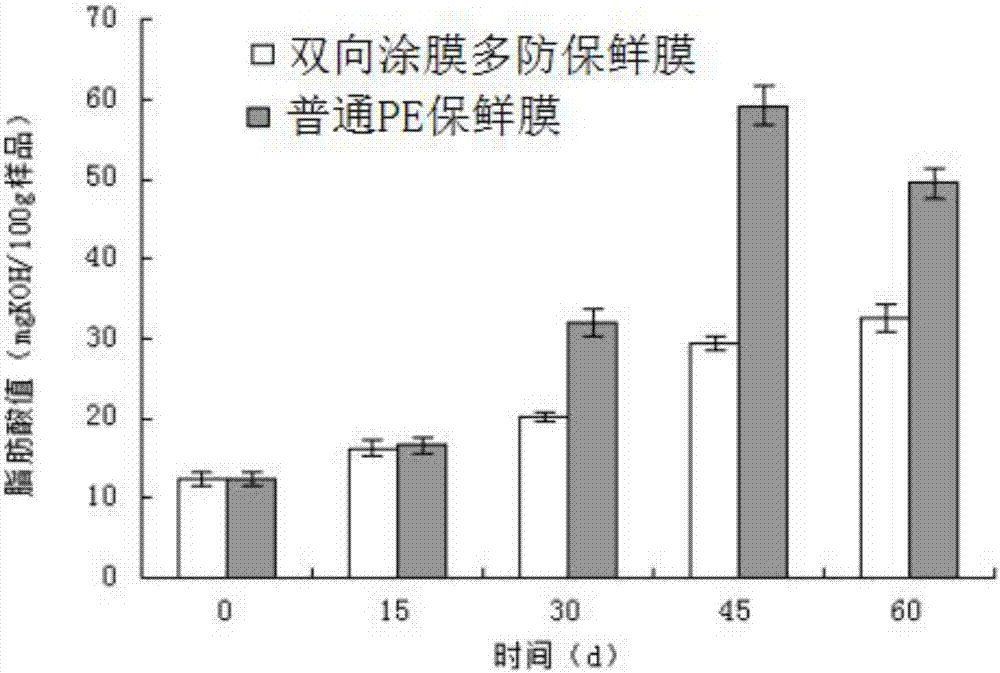

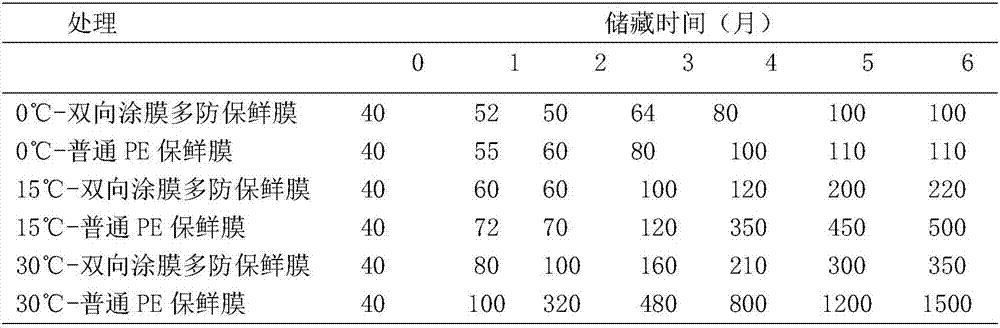

Cereal powder dual-coated multi-preventive biological fresh keeping film and preparation method thereof

ActiveCN107509808AInsect-resistantWith biological antioxidantEdible seed preservationFlat articlesLow-density polyethyleneAdhesive

The invention relates to a cereal powder dual-coated multi-preventive biological fresh keeping film and a preparation method thereof. The inner layer of the film is composed of the following components in parts by weight: 80 to 100 parts of microencapsulated plant essential oil insect-proof mildew preventive, 5 to 10 parts of mildew-proof film forming agent, 2 to 5 parts of antioxidant, and 75 to 84 parts of dispersant. The middle support layer of the film is composed of the following components in parts by weight: 20 to 35 parts of low density polyethylene resin, 70 to 100 parts of low density linear polyethylene resin, and 1 to 3 parts of mildew preventive. The outer coating is composed of the following components in parts by weight: 10 to 15 parts of microencapsulation agent of garlicin and capsaicin, and 5 to 8 parts of adhesive. The inner layer and the outer coating are sprayed on the middle support layer to prepare the cereal powder dual-coated multi-preventive biological fresh keeping film. The biocontrol mechanism is utilized, biological source fresh keeping materials are used to prepare the dual-coated film with a mildew-proof function, the oxidation and slow release problems of the coating functional material are solved by a microencapsulation treatment; the activity of fatty acid oxidase is inhibited for a long time; and the film can prevent insects, mold, aging, and mice and can delay the rancidity of cereals.

Owner:天津市雅锋食品科技发展有限公司

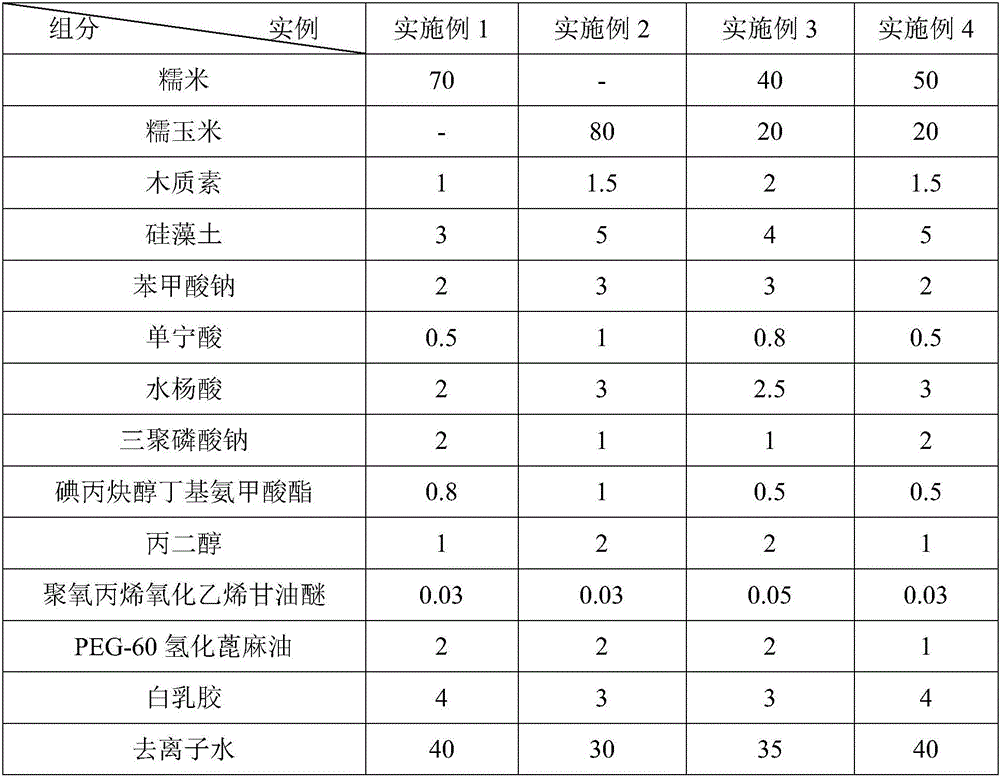

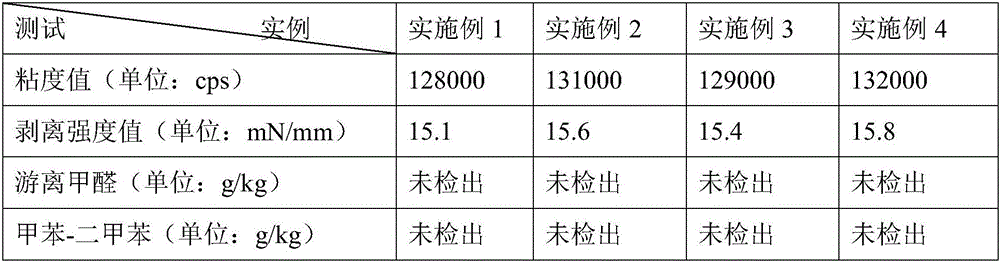

Antibacterial glutinous rice glue and preparation method thereof

ActiveCN106281112ANo irritating smellAntibacterial and antifungalMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesCastor oilIodopropynyl butylcarbamate

The invention relates to glue for wallpaper and in particular relates to antibacterial glutinous rice glue and a preparation method thereof. The antibacterial glutinous rice glue is prepared from the following raw materials in parts by weight: 60 to 80 parts of glutinous rice starch, 1 to 2 parts of lignin, 3 to 5 parts of diatomite, 2 to 3 parts of sodium benzoate, 0.5 to 1 part of tannic acid, 2 to 3 parts of salicylic acid, 1 to 2 parts of sodium triphosphate, 0.5 to 1 part of iodopropynyl butylcarbamate, 1 to 2 parts of propylene glycol, 0.03 to 0.05 part of polyoxypropylene oxyethylene glycol ether, 1 to 2 parts of PEG-60 (Polyethylene Glycol-60) hydrogenated castor oil, 3 to 4 parts of white latex and 30 to 40 parts of de-ionized water. According to the antibacterial glutinous rice glue, the raw material lignin has a sterilization effect and the tannic acid has an antibacterial effect; meanwhile, the sodium benzoate has a mildew-proof effect and athe antibacterial glutinous rice glue has the effect of inhibiting mold.

Owner:GAREFU TECH CO LTD

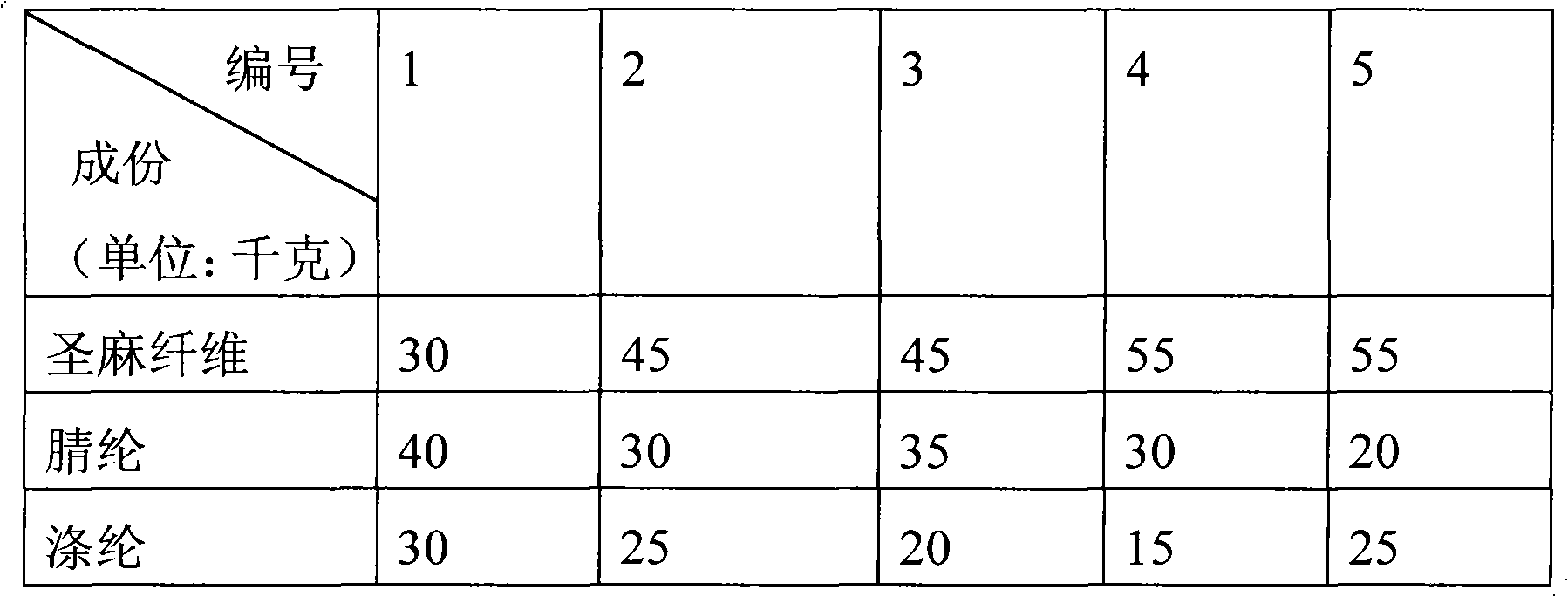

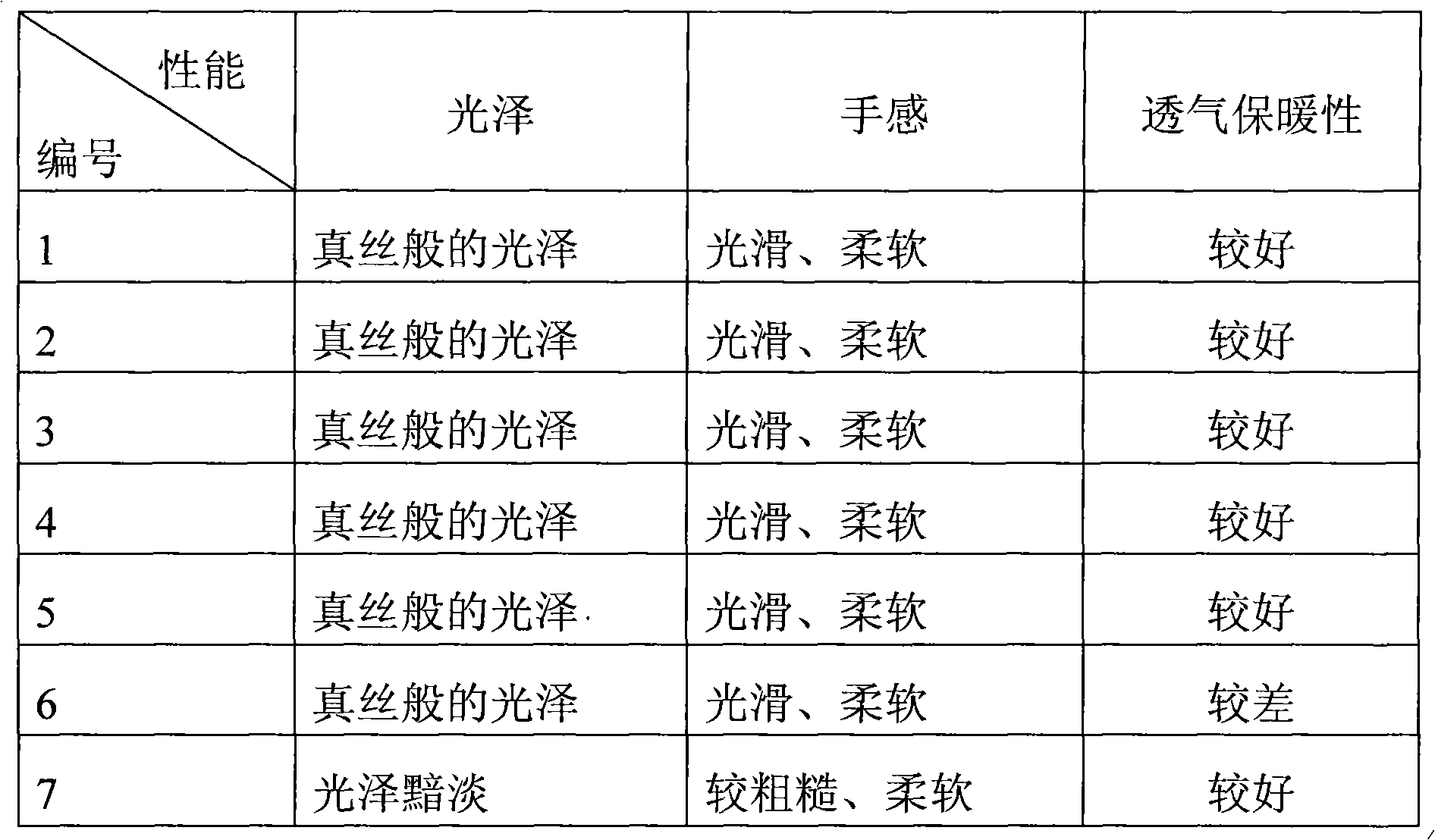

Sheng-bast fiber raschel blanket

The invention relates to a raw material for manufacturing blankets and a finished product thereof, in particular to a Shengma fiber raschel blanket which is woven with acrylic fiber, Shengma fiber and polyester as materials, belonging to the blanket technical field. The invention provides the Shengma fiber raschel blanket which is woven with acrylic fiber, Shengma fiber and polyester as materials mainly according to the disadvantages existing in the raschel blanket. The raw materials of the Shengma fiber raschel blanket comprise the following components in percentage by weight: 30-55 percent of Shengma fiber, 20-35 percent of acrylic fiber and 15-30 percent of polyester.

Owner:ZHEJIANG TRUELOVE GROUP

Long-acting water-based antirust agent and preparation method thereof

The invention discloses a long-acting water-based antirust agent. The long-acting water-based antirust agent is characterized in that the long-acting water-based antirust agent is prepared from the following raw materials in parts by weight: 8 to 12 parts of beta-cyclodextrin, 3 to 5 parts of hydroxypropyl methyl cellulose, 2 to 4 parts of rosin, 0.5 to 1 part of methyl salicylate, 1 to 2 parts of xanthan gum, 0.5 to 1 part of sodium lignin sulfonate, 0.5 to 1 part of sodium methylene bis-m-naphthalene sulfonate, 0.5 to 1 part of rosin-polythylene oxide ester, 6 to 8 parts of a performance additive, 0.05 to 0.1 part of carnosic acid, 0.1 to 0.2 part of sodium benzoate, and 40 to 50 parts of water. The antirust agent provided by the invention has the characteristics of safety and environment friendliness, has certain slow-release effect, and can protect metal products for a long time; a formed film is highly stable, and has a certain tolerance for salt-spray environments and hygrothermal environments.

Owner:HEFEI DAAN PRINTING

Green and environment-friendly water-based antirust agent and preparation method thereof

InactiveCN104312348AGood film formingIsolated contactAnti-corrosive paintsProtein coatingsSodium polyacrylateCitrate sodium

The invention discloses a green and environment-friendly water-based antirust agent. The green and environment-friendly water-based antirust agent is characterized in that the water-based antirust agent is prepared from the following raw materials in parts by weight: 0.5-1 part of chitosan, 0.3-0.5 part of citric acid, 0.1-0.2 part of tea polyphenol, 0.5-1 part of polyaspartic acid, 6-8 parts of gelatin, 1-2 parts of sodium citrate, 0.1-0.2 part of cocoalkanoylamido propyl betaine, 8-10 parts of pure acrylic emulsion, 1-2 parts of sodium dihydrogen phosphate, 0.2-0.4 part of polysorbate-80, 0.5-1 part of sodium polyacrylate, 6-8 parts of a modified additive and 30-40 parts of water. The antirust agent disclosed by the invention is good in the film-forming property on metal surfaces, can isolate the metal surface from being in contact with oxygen and water vapor, and the purpose of rust protection is achieved; moreover, the antirust agent is safe, pollution-free, green and environment-friendly, and has good environmental benefits.

Owner:HEFEI DAAN PRINTING

Traditional Chinese medicine residue heat preserving mortar and preparation method thereof

The invention discloses traditional Chinese medicine residue heat preserving mortar. The traditional Chinese medicine residue heat preserving mortar is characterized by being prepared from the following raw materials in parts by weight: 300 to 360 parts of white portland cement, 150 to 180 parts of barium carbonate residue, 190 to 210 parts of calcium bentonite, 70 to 90 parts of traditional Chinese medicine residue, 8 to 11 parts of urea, 10 to 13 parts of calcium hydroxide, 30 to 50 parts of nanometer titania, 90 to 110 parts of calcium carbonate powder, 90 to 130 parts of straw sorghum, 8 to 13 parts of calcium nitrite, 9 to 11 parts of nylon fiber, 7 to 9 parts of milled profiled steel fiber, and 3 to 7 parts of assistants. The heat preserving mortar added with the traditional Chinese medicine has anti-bacterial and anti-mildew performances, and other assistants added are used in match with the raw materials, so that the heat preserving mortar has the advantages of being waterproof, resistant to crack, and high in adhering performance; because of the same service life as a building, the heat preserving motor can be directly used as a plastering mortar layer for an inner wall and an outer wall; in addition, the heat preserving mortar is small in volume weight, so that the thickness of the wall surface in construction is reduced, and the construction is saved on the premise that the heat preserving performance of a wall body is ensured.

Owner:安徽众凯架业有限责任公司

Environmental-friendly wallpaper

InactiveCN106283791AImprove moisture resistanceImprove anti-agingAgeing prevention agents additionCovering/liningsFiberDimethyl siloxane

The invention discloses environmental-friendly wallpaper. The environmental-friendly wallpaper is prepared from the following materials in parts by weight: 20-30 parts of old clothes, 10-20 parts of cane trash, 10-20 parts of jute, 2-5 parts of nano zinc oxide, 1-2 parts of polydimethylsiloxane, 2-8 parts of sodium sulfide, 10-25 parts of sodium hydroxide, 5-10 parts of green bean starch, 2-5 parts of butyl acrylate, 1-2 parts of a silane coupling agent, 1-3 parts of cationic polyacrylamide, 1-2 parts of sodium dodecyl benzene sulfonate, 1-2 parts of ammonium persulfate, 60-100 parts of deionized water and 20-30 parts of ethanol. According to the environmental-friendly wallpaper disclosed by the invention, the old clothes, cane trash and jute serve as fiber base materials, the resources are effectively utilized, resource waste is avoided, and an environmental-friendly effect is achieved.

Owner:南宁东印时代广告有限公司

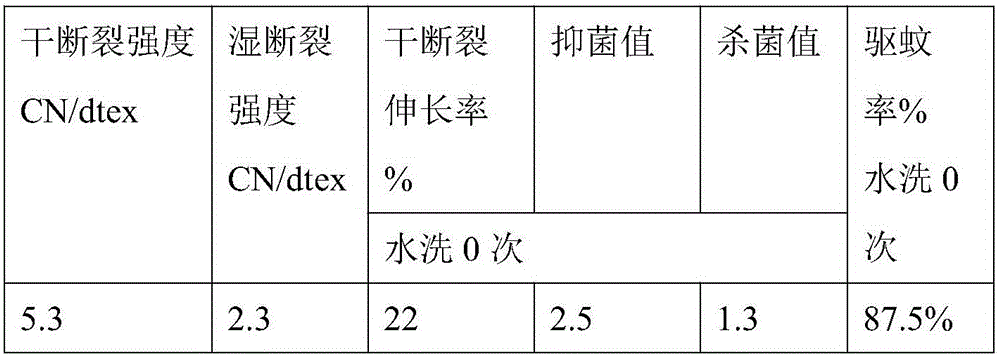

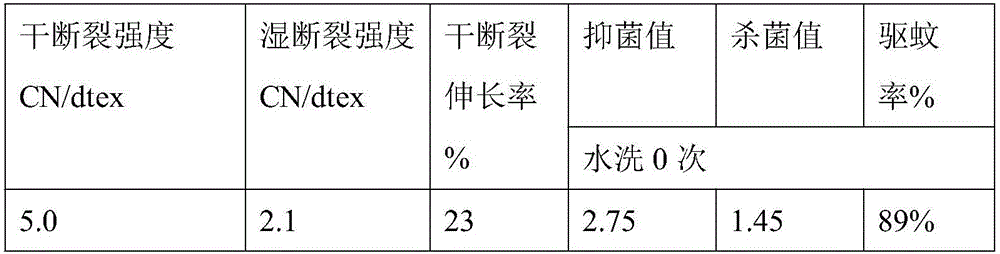

Multifunctional protein fiber and preparation method thereof

ActiveCN106012092AGood disinfection and sterilization functionEliminate odorConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsSkin coolingPolyvinyl alcohol

The invention discloses a multifunctional protein fiber and a preparation technology thereof. The preparation technology comprises adding natural additives with functions of antibiosis, mildew resistance, mosquito and insect prevention and cooling into main fiber raw materials such as soybean protein, polyvinyl alcohol (PVA) and carboxymethyl chitosan to obtain a spinning stock solution with a plurality of functions, preparing a fiber semi-finished product from the spinning stock solution through a wet spinning technology and carrying out finishing so that mechanical properties of the protein fiber are improved and the multifunctional protein fiber with excellent mechanical properties is obtained. The multifunctional protein fiber and the preparation technology solve the problem that the common protein fiber on the market has a single function, is produced by complex processes, has no lasting effects and has a high production cost. The multifunctional protein fiber has effects of softness, skin adaptability, moisture absorption, humidity elimination, antibiosis, mildew resistance, mosquito repellency, insect prevention and skin cooling and has a good market prospect.

Owner:广东安之伴实业有限公司

Anti-seepage waterproof anti-cracking unfired hollow brick and preparation method thereof

InactiveCN104628333AThe formula is scientific and reasonableGood waterproof and anti-crack effectThermal insulationCoal gangue

The invention discloses an anti-seepage waterproof anti-cracking unfired hollow brick. The invention is characterized in that the unfired hollow brick is prepared from the following raw materials in parts by weight: 30-35 parts of coal gangue, 10-12 parts of ordinary Portland cement, 1-1.2 parts of alunite powder, 1-1.5 parts of sodium pyrophosphate, 3-5 parts of emulsified asphalt, 0.8-1 part of 3% potassium methylsilicate, 15-18 parts of limestone, 9-13 parts of intumescent vitrified microbead, 20-24 parts of clay, 15-18 parts of synergist and a right amount of water. The formula is scientific and reasonable; and under the combined actions of the alunite powder and cement, the mixture has favorable waterproof and anti-cracking effects. By adding the emulsified asphalt and 3% potassium methylsilicate, the brick has favorable waterproof and anti-seepage effects and favorable air permeability; and by compounding the intumescent vitrified microbead, the brick is air-permeable and thermally insulating. By adding the synergist, the brick has the characteristics of light weight, high strength, water resistance, thermal insulation and bacteria resistance. By adopting the unfiring technique, the brick has the advantages of energy saving, consumption reduction and emission reduction, and has favorable anti-seepage, waterproof, thermal-insulation, air-permeable and antiseismic effects.

Owner:HUOQIU GAOXIN BUILDING MATERIAL

Sound-absorption heat-insulation foamed brick and preparation method thereof

InactiveCN104370574AImprove thermal insulationImprove sound absorptionCeramicwareBrickPolyvinyl alcohol

The invention discloses a sound-absorption heat-insulation foamed brick. The invention is characterized in that the foamed brick is prepared from the following raw materials in parts by weight: 50-60 parts of waste glass, 5-10 parts of expanded vermiculite, 10-15 parts of pumice, 5-10 parts of nutshell, 3-5 parts of sawdust, 3-5 parts of calcium carbonate, 3-5 parts of peat, 1-2 parts of sodium phytate, 0.5-1 part of dimethyl silicone oil, 0.5-1 part of xylitol, 0.5-1 part of Turkey red oil, 1-2 parts of lauryl sodium sulfate, 0.5-1 part of polyvinyl alcohol, 2-4 parts of modifying assistant and 50-60 parts of water. The foamed brick has the advantages of favorable heat-insulation property and favorable sound-absorption effect, can effectively reduce noise and create a good living environment, and is suitable for use in habitable rooms.

Owner:HEFEI KANGLING HEALTH TECH

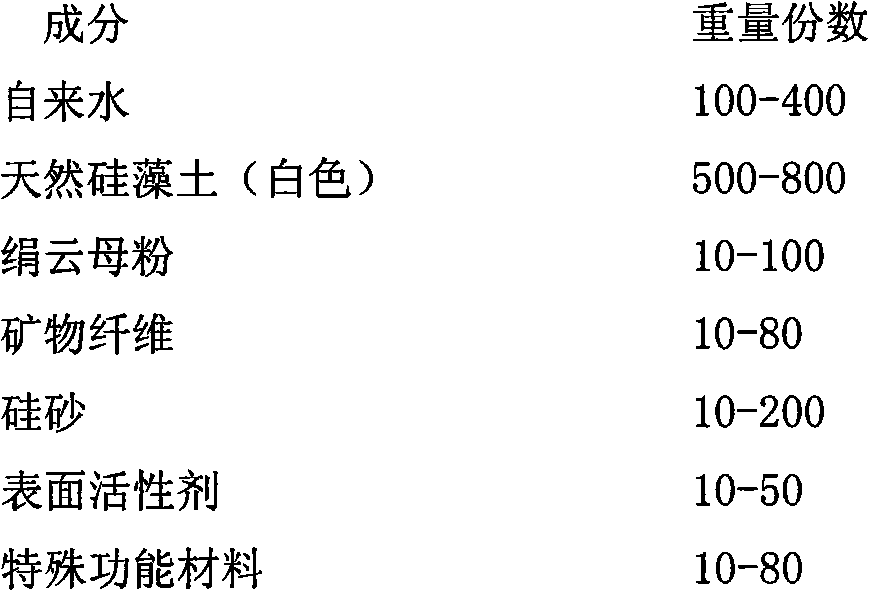

Non-combustible heat preservation wall material and manufacturing method thereof

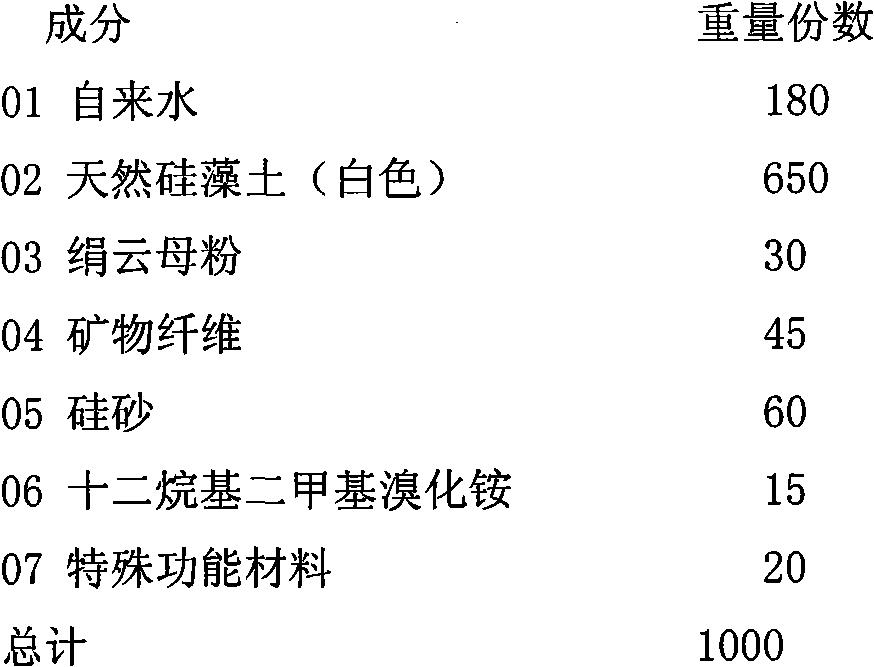

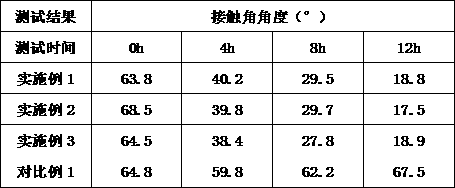

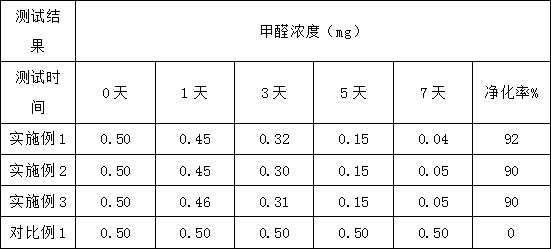

The invention discloses a non-combustible heat preservation wall material and a manufacturing method thereof. According to the invention, natural kieselguhr, sericite powder, mineral fibre, silica sand, surface active agent, materials with special functions and other inorganic materials are manufactured into a functional environment-friendly heat insulation and heat preservation wall material through the steps of calcining fusion, foaming molding, winnowing pelleting, dehumidification drying and the like. The material not only has the characteristics of small density, no combustion, no combustion supporting, heat insulation, heat preservation, environment protection and the like, but also has the special functions of decomposing formaldehyde, ammonia and other harmful gases, resisting bacterium, preventing mildew and the like. The material can be manufactured into putty to be coated on the surface of a building, the inner wall of a boiler, a metal storage tank and a pipeline surface, and can also be directly pressed into plates to be applied for building surface decoration. The thermal conductivity of the material is less than 0.2W / (M.K), and the material can resist the high temperature of 1200 DEG C.

Owner:BEIJING DONGXUYANG LOW CARBON BUILDING MATERIAL TECH CO LTD

Preparation method of high-performance self-cleaning curtain fabric

PendingCN110241609ASelf-cleaning withWith air purificationLiquid/gas/vapor treatment of propelled fabricsBiochemical fibre treatmentPre treatmentDyeing

The invention relates to the technical field of chemical engineering, in particular to a preparation method of a high-performance self-cleaning curtain fabric. The method comprises the steps of S1, pretreatment, wherein a to-be-treated curtain gray fabric is placed in an overflow dyeing machine at 130-150 DEG C for dyeing, the dyeing time is 1-2 hours, the temperature is decreased to the room temperature, after washing, dewatering is conducted, and a pretreated fabric is obtained; S2, material preparation, wherein according to the bath ratio demand, the matched amount of water is added into the overflow dyeing machine, a photocatalyst finishing agent with the concentration of 5-10% is added, and a photocatalyst treatment solution is obtained; S3, the pretreated fabric obtained in S1 is placed in the overflow dyeing machine placed in S2, at the temperature of 130-150 DEG C, treatment is conducted for 1-2 hours, dewatering and formation are conducted, and a dry photocatalyst treated fabric is obtained; S4, re-treatment, wherein the dry fabric obtained in S3 is sprayed with an environment-friendly spraying agent, and a re-treated fabric is obtained; S5, acquisition of a finished product, wherein the re-treated fabric in S4 is taken and subjected to microwave drying at 2,300-2,500 DEG C, and the high-performance durable environment-friendly self-cleaning photocatalyst curtain fabric is obtained. According to the preparation method of the high-performance self-cleaning curtain fabric, by adding a photocatalyst technology, the curtain fabric produced through the method has the functions of air purification, bacterium and mold resistance, odor removal, self-cleaning and the like.

Owner:浙江迈实科技有限公司 +1

Non-pilling antistatic comfortable blended fiber

InactiveCN107366067AAnti-staticAntibacterial and antifungalYarnCuprammonium rayonMoisture absorption

The invention discloses a non-pilling antistatic comfortable blended fiber which comprises a first fiber and a second fiber. The first fiber and the second fiber are blended and woven to form the non-pilling antistatic comfortable blended fiber. Color cotton fibers, modal fibers, tencel fibers and chitin fibers are blended and woven to obtain the first fiber, and copper ammonia fibers and bamboo pulp fibers are blended and woven to obtain the second fiber. The non-pilling antistatic comfortable blended fiber has the advantages of high moisture regain, good moisture absorption and breathability, softness, comfortableness and antistatic, non-pilling, antibacterial and mildew-proof properties.

Owner:太仓市天茂化纤有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com