Polyimide nanofiber flocculus, preparation method and application thereof

A nanofiber and polyimide technology, which is applied in the field of air filtration and purification, can solve the problems of poor durability, weak electrospinning layer strength, easy peeling or damage, etc., and achieve high filtration efficiency and good air permeability , the effect of huge application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

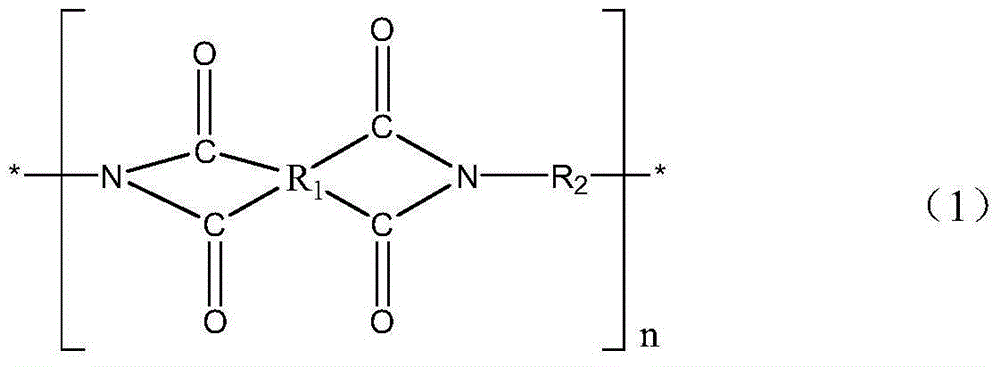

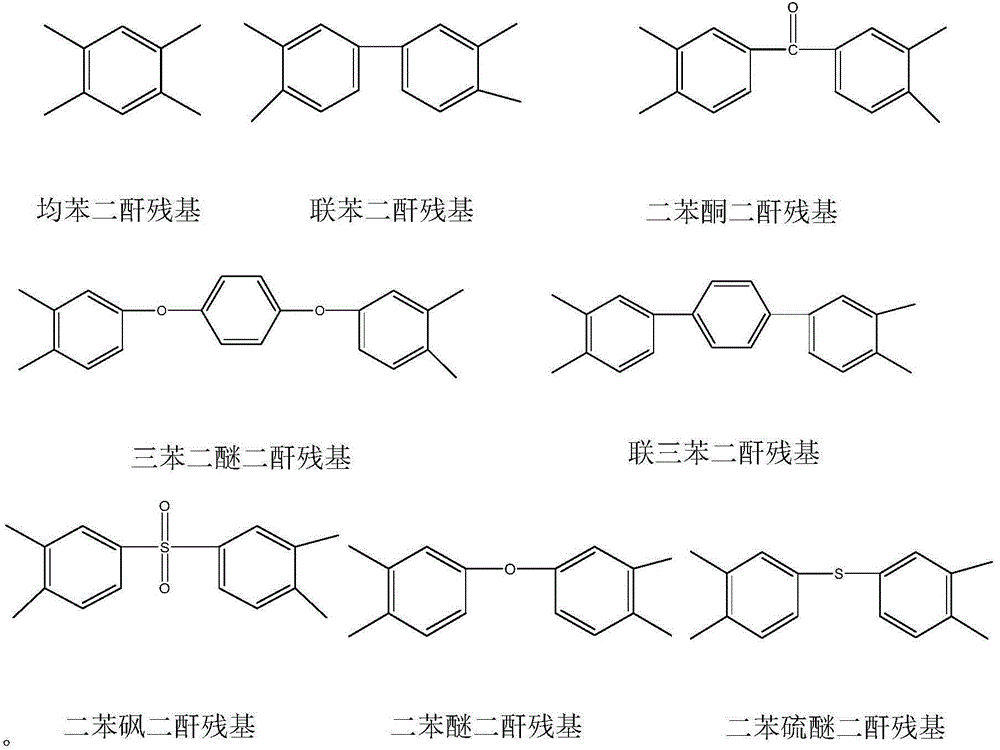

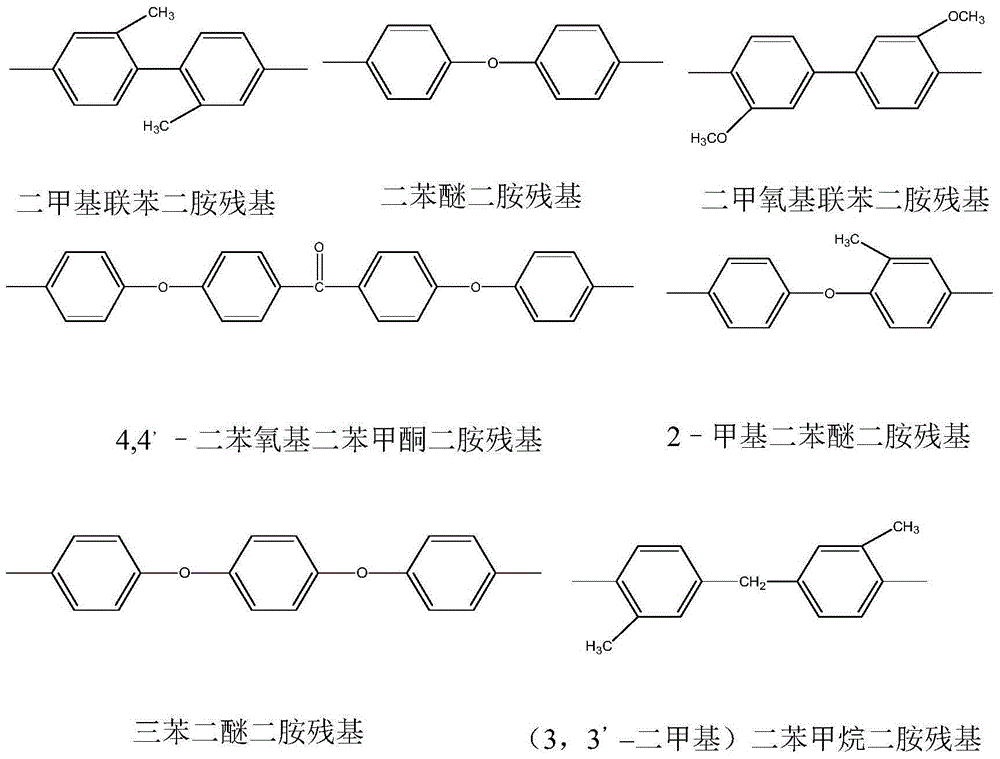

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: Preparation of pyromphthalic anhydride / diphenyl ether diamine / dimethyl benzidine diamine (PMDA / ODA / DMB) copolymerized polyimide nanofiber flakes

[0050] Preparation steps (1) Synthesis and electrospinning of spinning solution: take a certain amount of perphthalic anhydride (PMDA), diphenyl ether diamine (ODA) and dimethyl benzidine diamine in a molar ratio of 1:0.7:0.3 (DMB) and N,N-dimethylacetamide (DMAC), stirred in a polymerization reactor at 10°C for about 8 hours to obtain a polyamic acid solution, and added tetrahydrofuran to adjust the solid content of the solution to obtain a mass concentration of 18%. , tetrahydrofuran accounted for 45% of the total solvent content, absolute viscosity of 1.5Pa.s polyamic acid spinning solution. The polyamic acid spinning solution was electrospun in an electric field with an electric field strength of 30KV / m, and the nanofiber flakes were collected by a negatively charged, 1m wide, and 0.7m diameter seamless stai...

Embodiment 2

[0053] Embodiment 2: the preparation of pyrophthalic anhydride / biphenyl dianhydride / benzophenone dianhydride / diphenyl ether diamine (PMDA / BPDA / BTDA / ODA) copolymerized polyimide nanofiber flakes

[0054] Preparation steps (1) Synthesis and electrospinning of spinning solution: take a certain amount of pyrphthalic dianhydride (PMDA), biphenyl dianhydride (BPDA), benzophenone dianhydride ( BTDA), diphenyl ether diamine (ODA) and N,N-dimethylacetamide (DMAC), stirred in a polymerization reactor at 10°C for about 8 hours to obtain a polyamic acid solution, and added tetrahydrofuran to adjust the solidification of the solution. content, to obtain a polyamic acid spinning solution with a mass concentration of 20%, tetrahydrofuran accounting for 46% of the total solvent content, and an absolute viscosity of 1.8 Pa.s. The polyamic acid spinning solution was electrospun in an electric field with an electric field strength of 40KV / m, and the nanofiber flakes were collected by a negativel...

Embodiment 3

[0057] Embodiment 3: Physophthalic anhydride / triphenylene ether dianhydride / diphenoxybenzophenone diamine / diphenyl ether diamine (PMDA / HQDPA / BABP / ODA) copolymerized polyimide nanofiber flakes preparation of

[0058] Preparation steps (1) Synthesis and electrospinning of spinning solution: Take a certain amount of pyrphthalic anhydride (PMDA), triphenylene dianhydride (HQDPA), diphenoxy Benzophenone diamine (BABP), diphenyl ether diamine (ODA) and N,N-dimethylacetamide (DMAC), stirred in a polymerization reactor at 10°C for about 8 hours to obtain a polyamic acid solution , adding tetrahydrofuran to adjust the solid content of the solution to obtain a polyamic acid spinning solution with a mass concentration of 20%, tetrahydrofuran accounting for 50% of the total solvent content, and an absolute viscosity of 2.0 Pa.s. The polyamic acid spinning solution was electrospun in an electric field with an electric field strength of 50KV / m, and the nanofiber flakes were collected by a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com