Multifunctional protein fiber and preparation method thereof

A protein fiber and multifunctional technology, which is applied in the textile industry, can solve the problems of PVA and protein fiber copolymerization, which are not resistant to water and heat, do not have the function of disinfection and sterilization, and do not have the function of insect repellent and mosquito repellent, so as to increase the stability of molecular structure and eliminate No smell, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

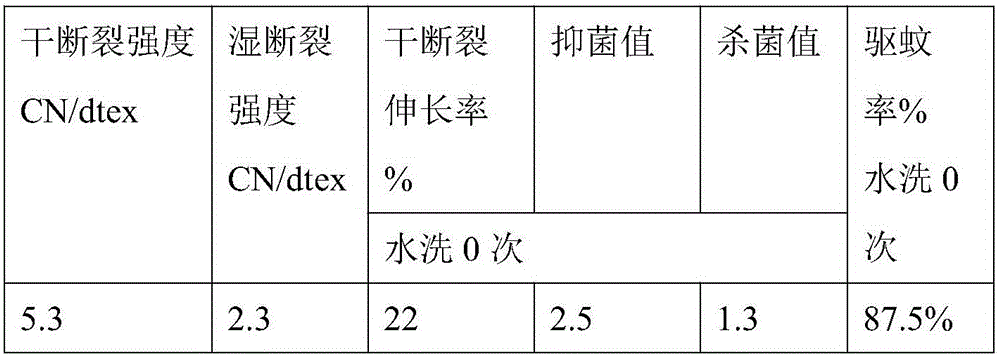

Embodiment 1

[0041] Weigh raw materials: soybean protein 3kg, polyvinyl alcohol (DP=2000) 5kg, carboxymethyl chitosan 1kg, calcium gluconate 0.5kg,

[0042] Functional additives 0.45kg (berberine 120g, aloe extract 100g, natural mosquito repellent 80g, menthol 80g, bamboo charcoal powder 70g), a lot of water.

[0043] Preparation of multifunctional protein fibers:

[0044]Preparation of regenerated plant protein spinning base liquid: dissolve soybean protein in 48kg water, use a temperature-controllable heater, heat up to 60-80°C, add carboxymethyl chitosan while stirring continuously to make it dissolve evenly, and heat up to 80°C ℃, adjust the pH value to 8 by adding hydrochloric acid and sodium hydroxide, add polyvinyl alcohol in high-speed stirring, so that soybean protein, carboxymethyl chitosan and polyvinyl alcohol are fully dissolved and mixed evenly, and the speed of the high-speed stirring is 250 revolution / second;

[0045] (2) Functional additive preparation: add berberine to ...

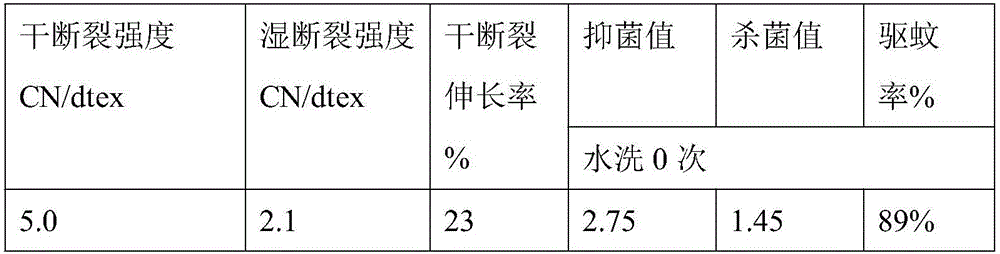

Embodiment 2

[0061] Weigh raw materials: soybean protein 3.5kg, polyvinyl alcohol (DP=3000) 5kg, carboxymethyl chitosan 1.5kg, calcium gluconate 0.4kg, functional additive 0.5kg (berberine 150g, aloe extract 120g, natural defense Mosquito spray 80g, menthol 80g, bamboo charcoal micropowder 70g), a lot of water.

[0062] (1) Preparation of regenerated vegetable protein spinning base liquid: dissolve soybean protein in 50kg water, use a temperature-controllable heater, heat up to 60°C, add carboxymethyl chitosan while stirring continuously, make it dissolve evenly, and heat up to 60°C 100°C, adjust the pH value to 8 by adding hydrochloric acid and sodium hydroxide, add polyvinyl alcohol in high-speed stirring, so that soybean protein, carboxymethyl chitosan and polyvinyl alcohol are fully dissolved and mixed uniformly, the speed of the high-speed stirring is 250 rev / s;

[0063] (2) Functional additive preparation: add berberine, aloe vera extract, natural mosquito repellent, menthol, bamboo...

Embodiment 3

[0071] Weigh raw materials: soybean protein 3.5kg, polyvinyl alcohol 5.2kg, carboxymethyl chitosan 1.2kg, calcium gluconate 0.6kg,

[0072] Functional additives 0.4kg (berberine 120g, aloe extract 100g, natural mosquito repellent 60g, menthol 80g, bamboo charcoal powder 40g), a lot of water.

[0073] Preparation of multifunctional protein fibers:

[0074] (1) Preparation of regenerated plant protein spinning base solution: dissolve soybean protein in 60kg of water, use a temperature-controllable heater, heat up to 80°C, add carboxymethyl chitosan while stirring continuously, make it dissolve evenly, and heat up to 80°C 90°C, adjust the pH value to 9 by adding hydrochloric acid and sodium hydroxide, add polyvinyl alcohol in high-speed stirring, so that soybean protein, carboxymethyl chitosan and polyvinyl alcohol are fully dissolved and mixed uniformly, the speed of the high-speed stirring is 300 rev / s;

[0075] (2) Preparation of functional additives: add berberine, aloe ver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com