Novel environment-friendly waterborne inorganic paint and preparation method thereof

A technology of inorganic coatings and environmentally friendly water, applied in the field of coatings, can solve the problems of reducing the service life of coatings, poor water resistance, and restricting large-scale applications, and achieve enhanced curing strength, improved mechanical strength and toughness, and enhanced photocatalytic degradation of volatile organic compounds. The effect of the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

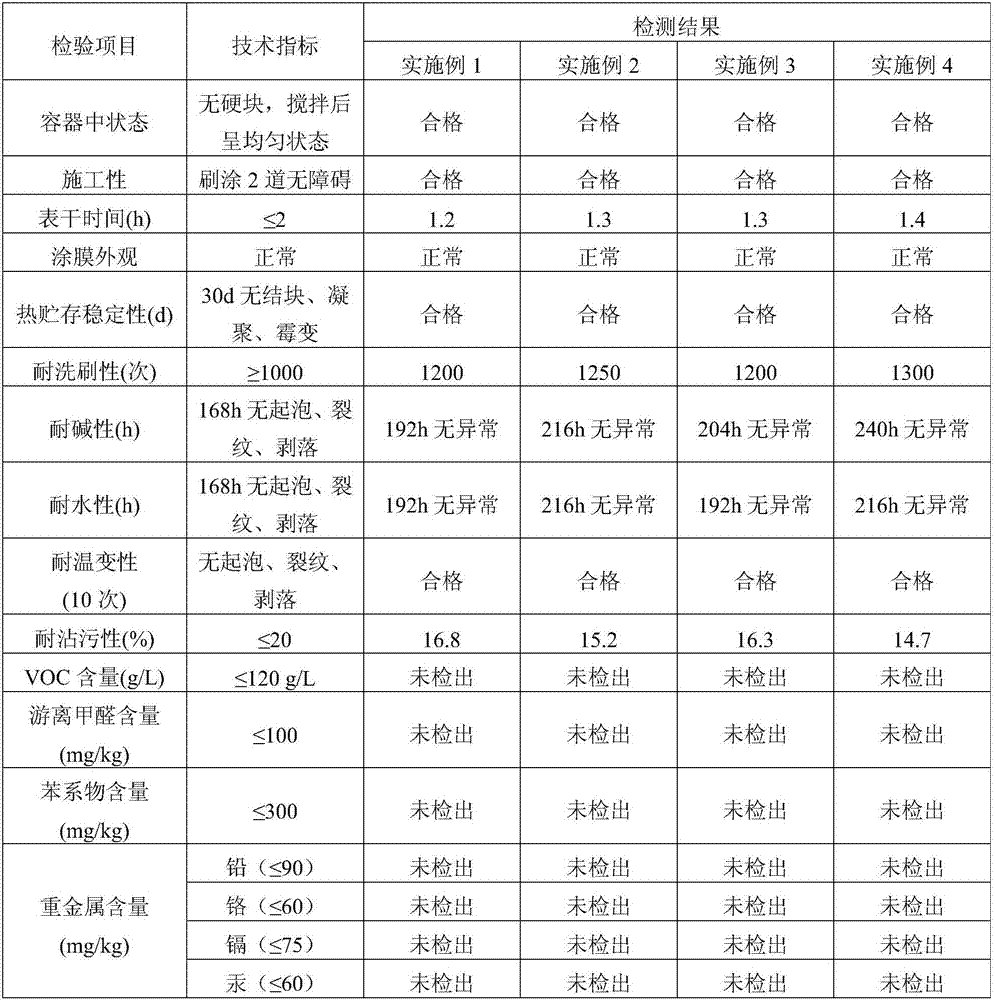

Examples

Embodiment 1

[0032] A new type of environmentally friendly water-based inorganic paint, including the following raw materials in parts by weight: 50 parts of kaolin, 30 parts of titanium dioxide, 12 parts of sodium silicate, 1 part of calcium chloride, 3 parts of nano-zinc oxide, 10 parts of superfine wollastonite powder, 8 parts of nano-calcium carbonate, 2 parts of ultra-fine muscovite powder, 14 parts of polyvinyl alcohol 1799, 4 parts of ultra-fine molybdenum disulfide powder, 6 parts of nano-silica, 4 parts of nano-magnesia, 6 parts of nano-alumina, 1 part of magnesium chloride, 3 parts of crystalline aluminum chloride, 3 parts of sodium methyl silicate, 10 parts of defoaming and leveling agent (the mass ratio of stearic acid, polyacrylate and silicone oil in the defoaming and leveling agent is 3:2 : 5), 2 parts of sodium bentonite, 290 parts of water.

[0033] The preparation method of above-mentioned novel environment-friendly water-based inorganic coating comprises the following st...

Embodiment 2

[0038] A new type of environmentally friendly water-based inorganic paint, including the following raw materials in parts by weight: 58 parts of kaolin, 28 parts of titanium dioxide, 15 parts of potassium silicate, 2 parts of calcium chloride, 2 parts of nano-zinc oxide, 6 parts of superfine wollastonite powder, 6 parts of nano-calcium carbonate, 3 parts of ultra-fine muscovite powder, 9 parts of polyvinyl alcohol 1799, 2 parts of ultra-fine molybdenum disulfide powder, 4 parts of nano-silica, 6 parts of nano-magnesia, 8 parts of nano-alumina, 2 parts of magnesium chloride, 2 parts of polyaluminum chloride, 3 parts of sodium methyl silicate, 8 parts of defoaming and leveling agent (the mass ratio of stearic acid, polyacrylate and silicone oil in defoaming and leveling agent is 2:1 : 5), 3 parts of calcium-based bentonite, 305 parts of water.

[0039] The preparation method of above-mentioned novel environment-friendly water-based inorganic coating comprises the following steps...

Embodiment 3

[0044]A new type of environmentally friendly water-based inorganic paint, including the following raw materials in parts by weight: 63 parts of kaolin, 22 parts of titanium dioxide, 7 parts of sodium silicate, 8 parts of potassium silicate, 1.5 parts of calcium chloride, 5 parts of nano zinc oxide, ultrafine 5 parts of wollastonite powder, 2 parts of nano-calcium carbonate, 4 parts of ultra-fine muscovite powder, 12 parts of polyvinyl alcohol 1799, 4 parts of ultra-fine molybdenum disulfide powder, 10 parts of nano-silicon dioxide, 5 parts of nano-magnesia, 4 parts of nano-alumina, 2.5 parts of magnesium chloride, 2 parts of ferric chloride hexahydrate, 7 parts of sodium methyl silicate, 7 parts of defoaming and leveling agent (stearic acid, polyacrylate and silicone oil in defoaming and leveling agent The mass ratio is 3:1:3), 0.5 parts of calcium-based bentonite, 1.5 parts of sodium-based bentonite, and 295 parts of water.

[0045] The preparation method of above-mentioned n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com