Flue gas desulfurization gypsum high-strength crystal decorative sheet and manufacturing method thereof

A desulfurized gypsum and decorative board technology, which is applied to the desulfurized gypsum high-strength crystal decorative board containing the activated fine powder of the desulfurized gypsum and the preparation thereof, the desulfurized gypsum high-strength crystal decorative board and the preparation field thereof, and can solve the problems of fast setting time, high particle density, The problem of high expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

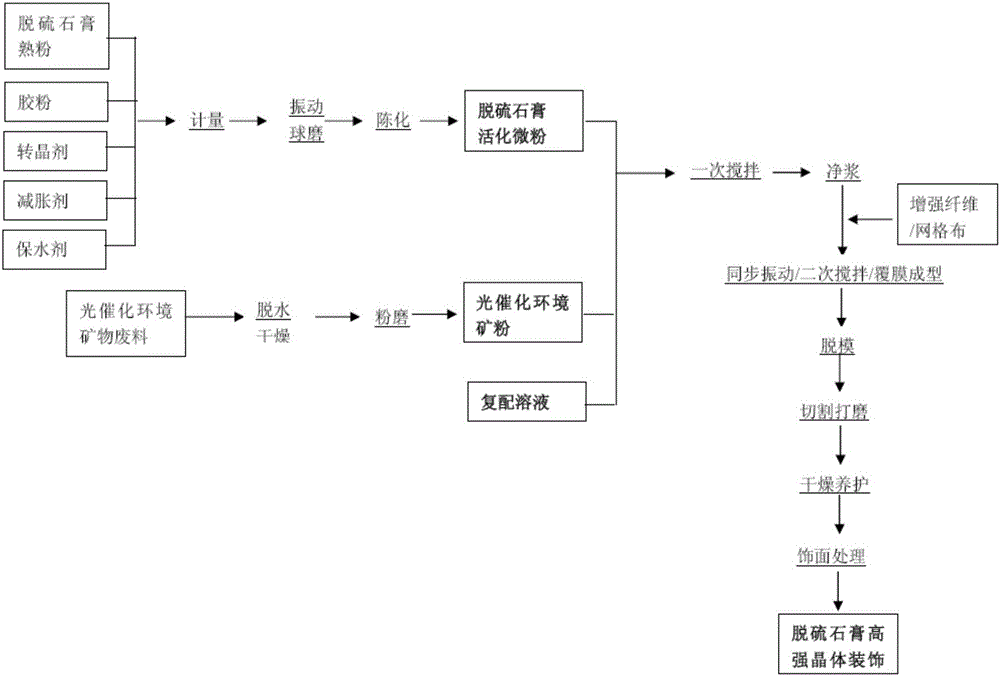

[0048] A desulfurized gypsum high-strength crystal decorative board, the flow chart is as follows figure 1 As shown, it is prepared by the following method:

[0049] (1) Preparation of desulfurized gypsum activated micropowder:

[0050] ①Ball mill crystal conversion activation: 99.36 parts of ordinary β-desulfurized gypsum cooked powder, 0.3 parts of dispersible latex powder, 0.02 parts of potassium aluminum sulfate, 0.02 parts of sodium citrate, 0.2 parts of sodium pyrophosphate, hydroxypropyl methylcellulose ( After 0.1 part of HPMC) is mixed evenly, it is added to the ball mill for ball milling to activate the crystal transformation, and the material enters into two storage tanks after ball milling for about 50 minutes;

[0051] ② Homogenization and aging: The materials prepared in the two storage tanks in step ① are discharged at the same time, and are homogenized by a screw conveyor and then transported to a moisture-proof package, and naturally aged for about 10 days to...

Embodiment 2

[0068] A desulfurized gypsum high-strength crystal decorative board is prepared by the following method:

[0069] (1) Preparation of desulfurized gypsum activated micropowder:

[0070] ①Ball mill crystal conversion activation: 95.75 parts of ordinary β-desulfurized gypsum cooked powder, 1.2 parts of vegetable gum powder, 0.02 parts of sodium citrate, 0.03 parts of calcium chloride, 0.2 parts of sodium pyrophosphate, 0.3 parts of trisodium citrate, hydroxypropyl After mixing 0.5 parts of HPMC and 2.0 parts of pregelatinized starch evenly, add them to the ball mill for ball milling to activate the crystal transformation, and the materials are ball milled for 50-55 minutes and then enter into two storage tanks;

[0071] ② Homogenization and aging: The materials prepared in the two storage tanks in step ① are discharged at the same time, and are homogenized by a screw conveyor and then transported into a moisture-proof package, and naturally aged for 12 days to obtain stable perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com