Healthy and environment-friendly negative ion indoor coating preparation method

An anion-friendly, environmentally friendly technology, applied in the field of coatings, can solve problems affecting product appearance, color and stability, additive dosage control product impact, and failure to purify the air, so as to inhibit the growth of mold, improve scrub resistance, and air quality. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

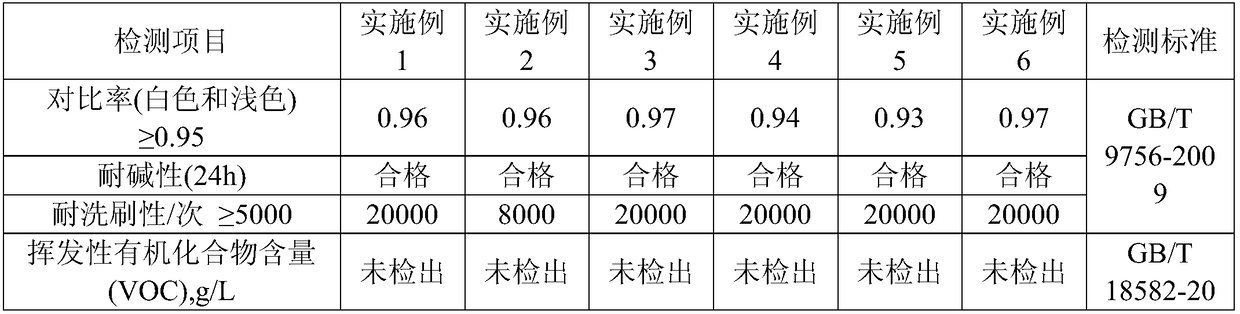

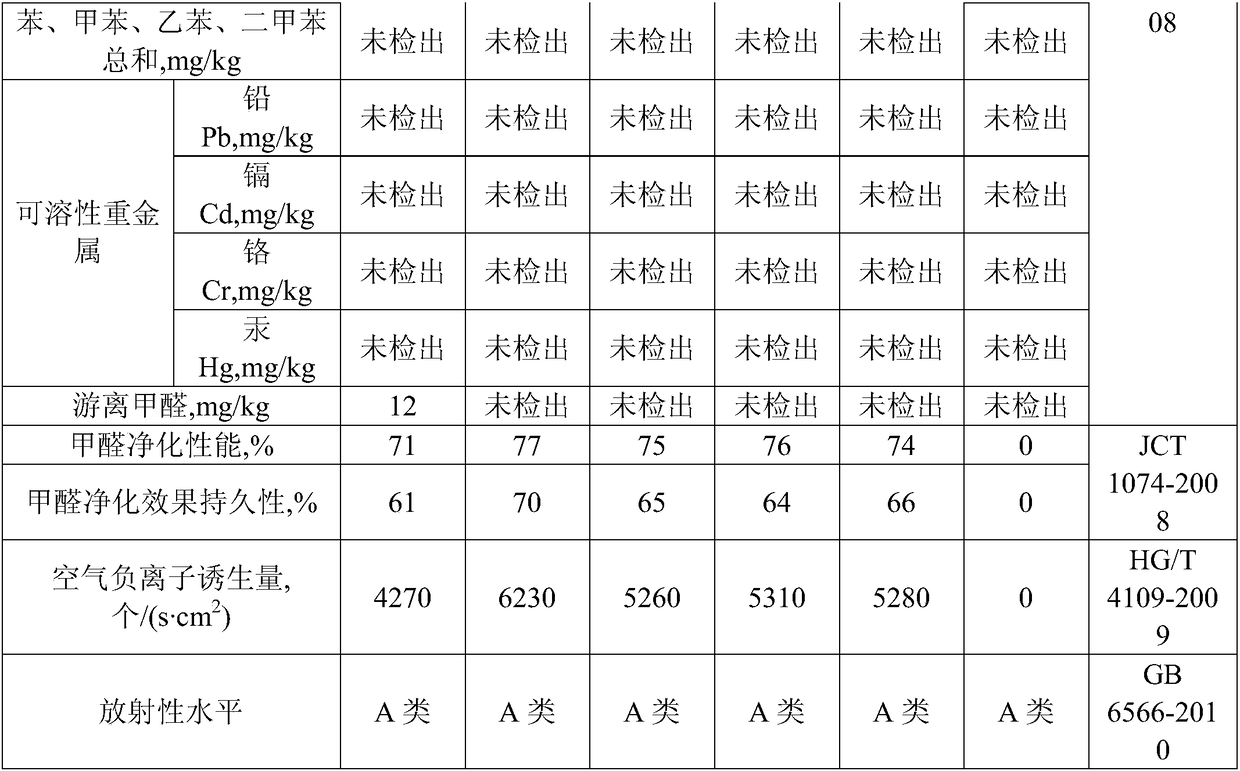

Examples

Embodiment 1

[0044] One, the healthy and environment-friendly anion indoor paint of the present embodiment comprises the raw material composition of following weight portion:

[0045] 0.1 parts by weight of wetting agent; 1.2 parts by weight of dispersant; 0.3 parts by weight of defoamer; 0.6 parts by weight of film-forming aid; 0.3 parts by weight of antifreeze; 0.1 parts by weight of bactericide; 0.5 parts by weight of bactericide; 0.1 parts by weight of multifunctional additive; 25 parts by weight of titanium dioxide; 6 parts by weight of calcium carbonate; 5 parts by weight of calcined kaolin; 2 parts by weight of mica powder; 0.5 parts by weight of anion mineral additives; 40 parts by weight of water-resistant and environmentally friendly adhesives; 3 parts by weight of covering polymer emulsions; 18 parts by weight of deionized water.

[0046] The raw material information of each component is as follows: the wetting agent is BYK-347 of BYK Company; the dispersant is Disperbyk-102 of ...

Embodiment 2

[0054] One, the healthy and environment-friendly anion indoor paint of the present embodiment comprises the raw material composition of following weight portion:

[0055] 0.4 parts by weight of wetting agent; 0.5 parts by weight of wetting agent; 0.9 parts by weight of defoamer; 0.2 parts by weight of film-forming aid; 0.5 parts by weight of mildew agent; 0.1 parts by weight of bactericide; 0.4 parts by weight of multifunctional additive; 15 parts by weight of titanium dioxide; 8 parts by weight of calcium carbonate; 7 parts by weight of calcined kaolin; 3 parts by weight of mica powder; Parts by weight: 1.8 parts by weight of negative ion mineral additives; 20 parts by weight of water-resistant and environmentally friendly adhesive; 8 parts by weight of covering polymer emulsion; 25 parts by weight of deionized water.

[0056] The raw material information of each component is as follows: wetting agent is Wet 510 of Tego Company; Dispersant is the Dispersogen 4387 of Clariant ...

Embodiment 3

[0064] One, the healthy and environment-friendly anion indoor paint of the present embodiment comprises the raw material composition of following weight portion:

[0065] 0.2 parts by weight of wetting agent; 0.7 parts by weight of dispersant; 0.7 parts by weight of defoamer; 0.4 parts by weight of film-forming aid; 0.5 parts by weight of antifreeze; 0.3 parts by weight of agent; 0.3 parts by weight of fungicide; 0.3 parts by weight of multifunctional additive; 18 parts by weight of titanium dioxide; 11 parts by weight of calcium carbonate; 9 parts by weight of calcined kaolin; 8 parts by weight of mica powder; 1.0 parts by weight of negative ion mineral additives; 30 parts by weight of water-resistant and environmentally friendly adhesives; 5 parts by weight of covering polymer emulsion; 22 parts by weight of deionized water.

[0066] The raw material information of each component is as follows: the wetting agent is EnviroGem 360 of Air Product Company; the dispersant is COAT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com