Floating type pellets in stomach and preparation method thereof

A gastric flotation and pellet technology, which is applied in the field of medicine, can solve the problems of negative impact on flotation performance, high blood drug concentration in patients, enhanced tensile strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Expandable polystyrene beads (particle size 1800-300um) are softened when placed in a batch pre-expansion machine and heated by steam to above 92°C. Adjust the pre-expansion temperature, steam pressure and feed amount to volatilize the blowing agent The volume of the escaped particles slowly expands to 20 times, and then the foam particles are allowed to fall freely into the aging chamber made of mesh anti-static gauze for 8 hours. Enter the fluidized bed for drying to obtain pellet cores with a particle size of 500-800um. Then sieve according to the needs, and sieve out the pellet core of 700um-800um; its density is about 0.05g / cm 3 Then it is put into the fluidized bed and sprayed with stomach-dissolving coating liquid, which can further increase the particle diameter and density of the pellet core and make the appearance smoother.

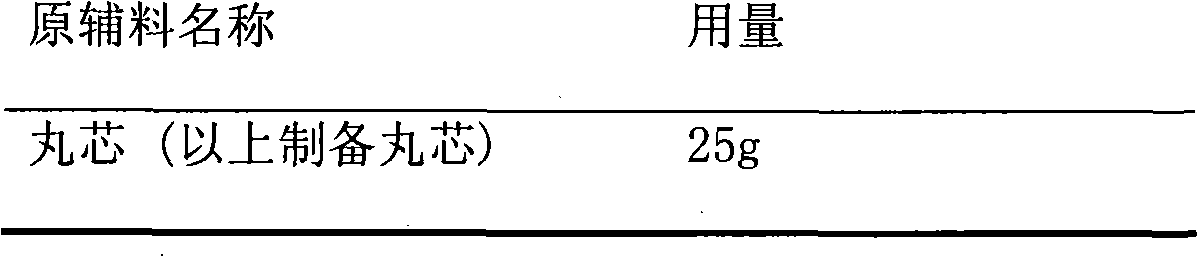

[0022] Ball core prescription:

[0023]

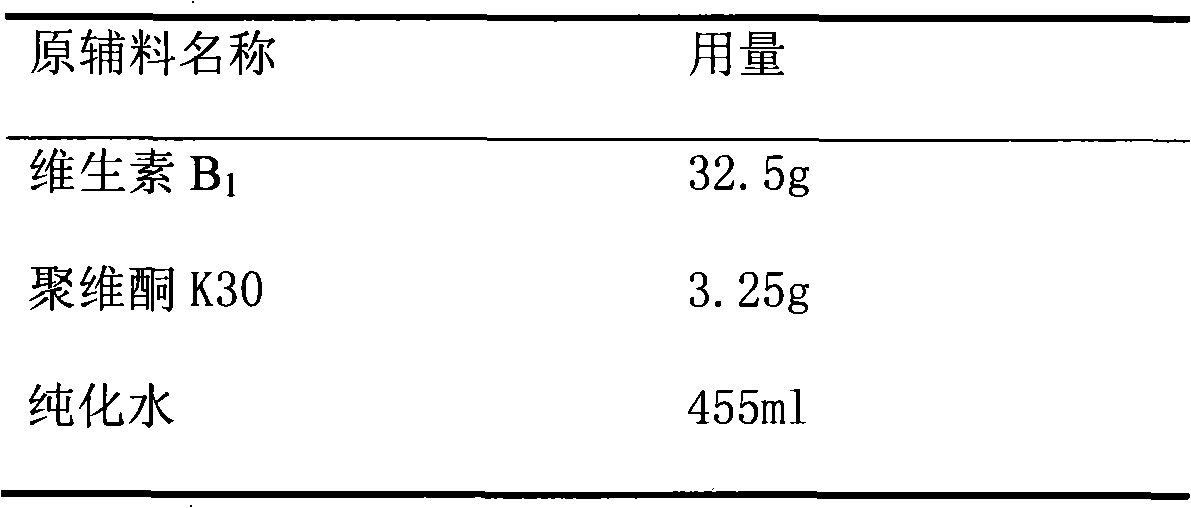

[0024] drug coating solution

[0025]

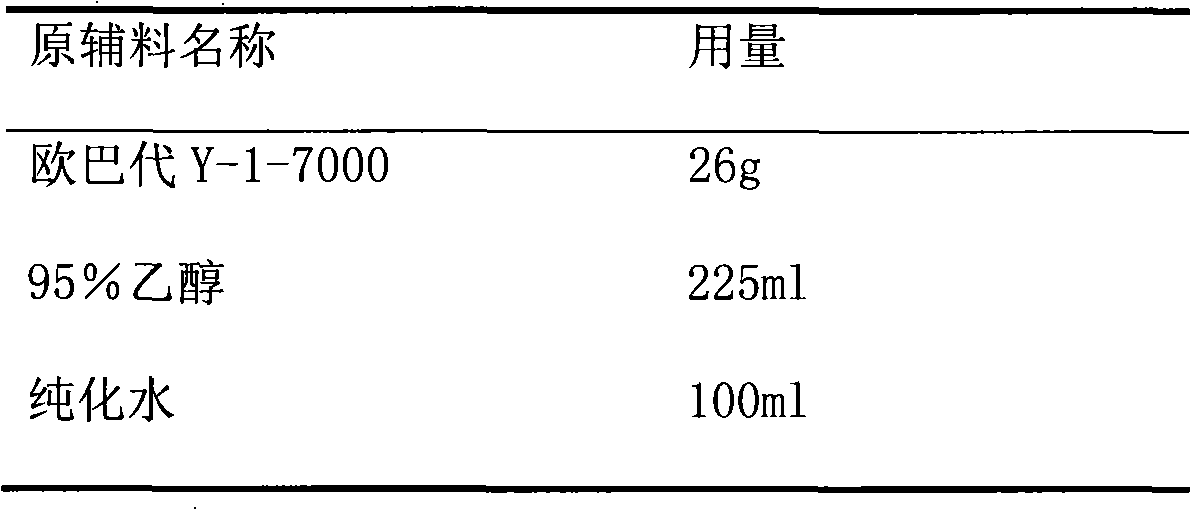

[0026] protective coating solution

[0027] ...

Embodiment 2

[0045] Expandable polystyrene beads (particle size 180-300um) are softened when placed in a batch pre-expansion machine and heated by steam to above 92°C. Adjust the pre-expansion temperature, steam pressure and feed amount to volatilize the blowing agent The volume of the escaped particles slowly expands to 20 times, and then the foam particles are allowed to fall freely into the aging chamber made of mesh anti-static gauze for 8 hours. Enter the fluidized bed for drying to obtain pellet cores with a particle size of 500-800um. Then sieve according to the needs, and sieve out the pellet core of 700um-800um; its density is about 0.05g / cm 3

[0046] Ball core prescription:

[0047]

[0048] drug coating solution

[0049]

[0050] protective coating solution

[0051]

[0052] Sustained release layer coating solution

[0053]

[0054] 1. Preparation of drug coating solution

[0055] Weigh Povidone K30 according to the prescribed amount and dissolve it in 455ml w...

Embodiment 3

[0069] Ball core preparation:

[0070] Expandable polystyrene beads (particle size 180-300um) are softened when placed in a batch pre-expansion machine and heated by steam to above 92°C. Adjust the pre-expansion temperature, steam pressure and feed amount to volatilize the blowing agent The volume of the escaped particles slowly expands to 20 times, and then the foam particles are allowed to fall freely into the aging chamber made of mesh anti-static gauze for 8 hours. Enter the fluidized bed for drying to obtain pellet cores with a particle size of 500-800um. Then sieve according to the needs, and sieve out the pellet core of 700um-800um; its density is about 0.05g / cm 3 Then it is put into the fluidized bed and sprayed with stomach-dissolving coating liquid, which can further increase the particle diameter and density of the pellet core and make the appearance smoother.

[0071] above core

[0072]

[0073] drug coating solution

[0074]

[0075] protective coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com