Patents

Literature

507results about How to "Decorative" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

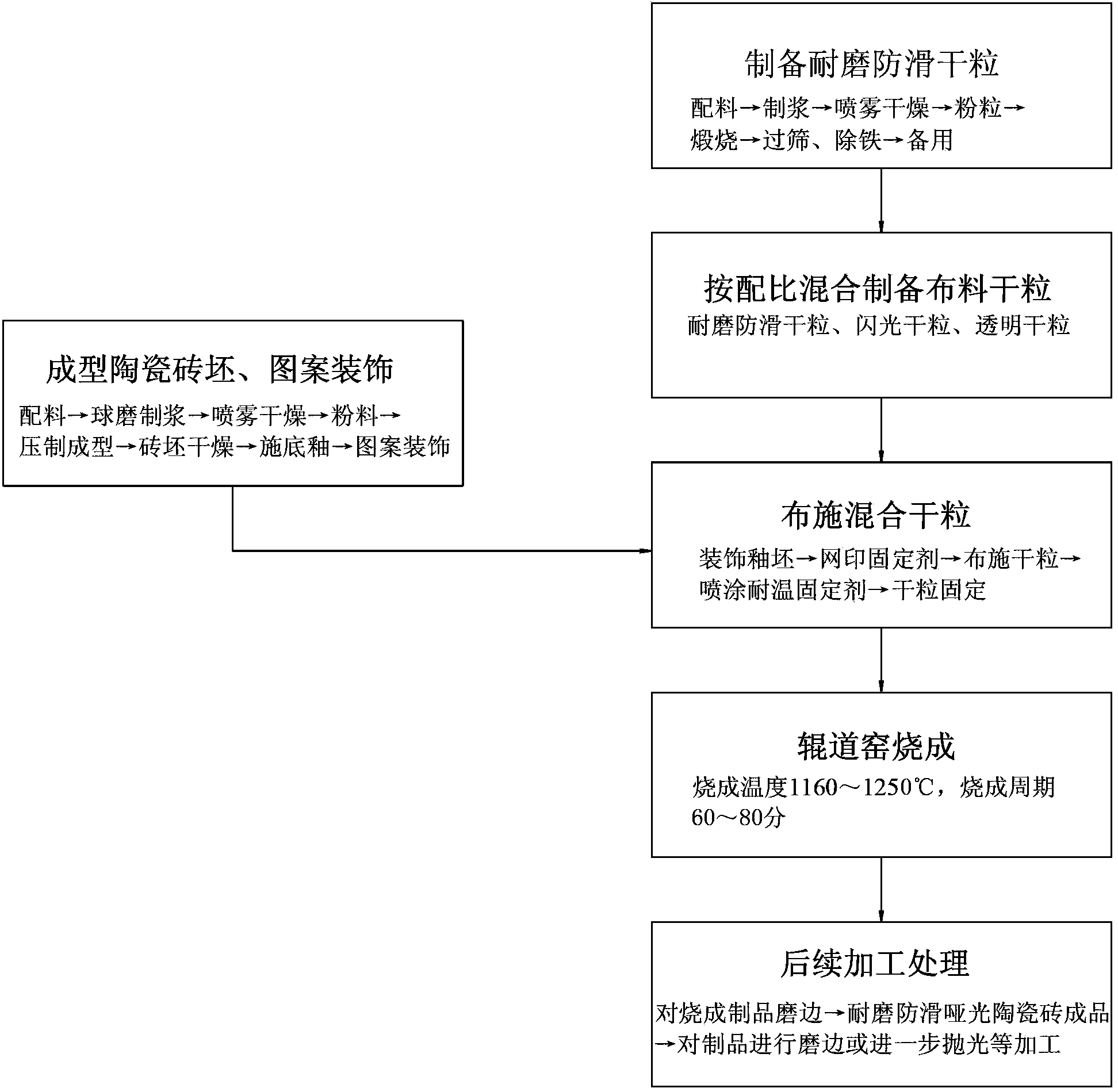

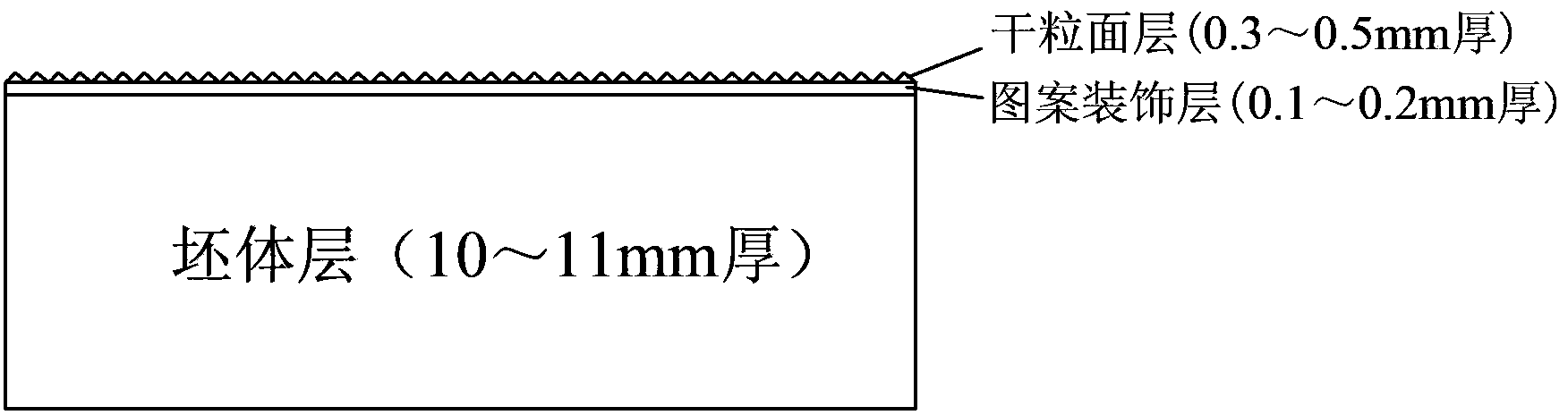

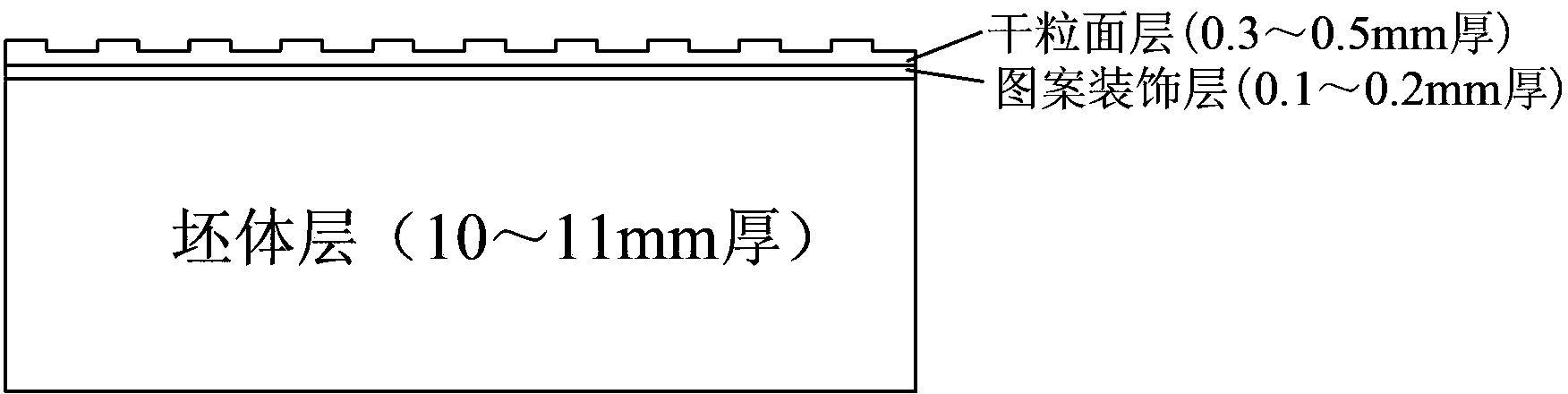

Method for manufacturing wear-resistant antiskid dry-particle ceramic tile

The invention relates to a method for manufacturing a wear-resistant antiskid dry-particle ceramic tile, which comprises the following steps: (1) forming a ceramic tile plane matrix and carrying out pattern decoration; (2) preparing dry particles with wear-resistant and antiskid properties; (3) mixing the wear-resistant antiskid dry particles, flashing dry particles and transparent dry particles according to a certain proportion for distribution; (4) applying the mixed dry particles to the surface of a decorative glazed body and spraying a temperature-resistant fixing agent; (5) conveying the obtained product to a roller kiln for firing and preparing the finished product of the ceramic tile through subsequent processes. According to the method for manufacturing the wear-resistant antiskid dry particle ceramic tile, the dry particles with good wear resistance are mixed with the transparent dry particles and the flashing dry particles, a dry powder distribution mode is adopted and the wear-resistant antiskid dry particles are bulged due to different melting performance of various dry particles in the firing process, so that the problems of wear resistance of the surface and thickness of a wear-resistant layer are solved; by distributing the transparent dry particles, a decorative pattern has a stereoscopic decorating effect under the covering of a glass layer, so that unification of wear-resistant and antiskid properties and decoration of the ceramic tile is achieved.

Owner:JIANGXI HEMEI CERAMICS

Aqueous environmental protection ultration expansion type steel structure fireproof paint and its preparation method

InactiveCN1824716ADecorativeReduce dosageFireproof paintsLiquid spraying apparatusAdditive ingredientPhosphate

The present invention provides a water environment-protecting superthin expanded type steel structure fire-retardant coating. Said fire-retardant coating uses water as dispersion medium, uses flake expandable graphite as expansion reinforcing material, uses one or several kinds of emulsions of acrylic emulsion and others as film-forming material, and its expansion system adopts the ingredients of polyammonium phosphate, pentaerythritol and tripolycyanamide. Said invention also provides its preparation method and concrete steps.

Owner:北京首纳东方科技有限公司

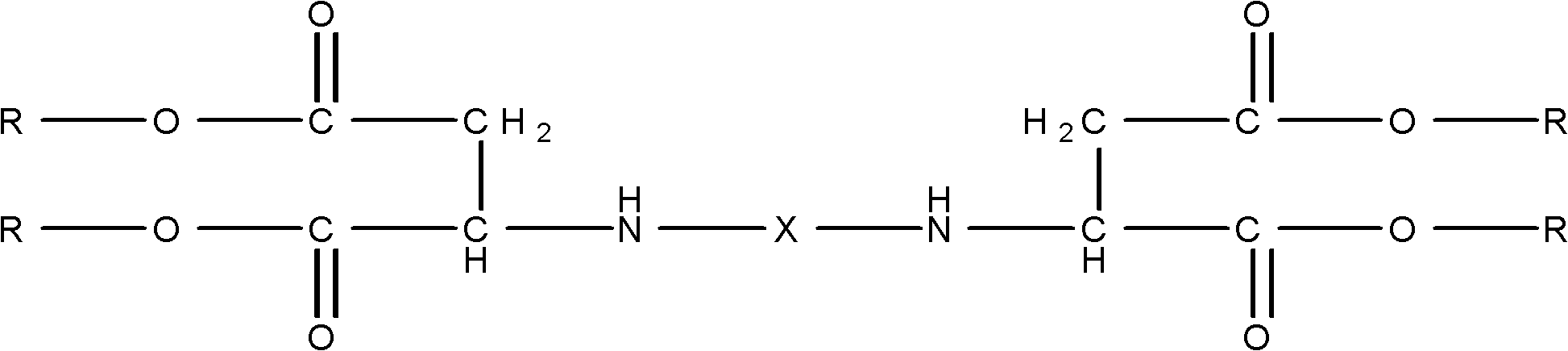

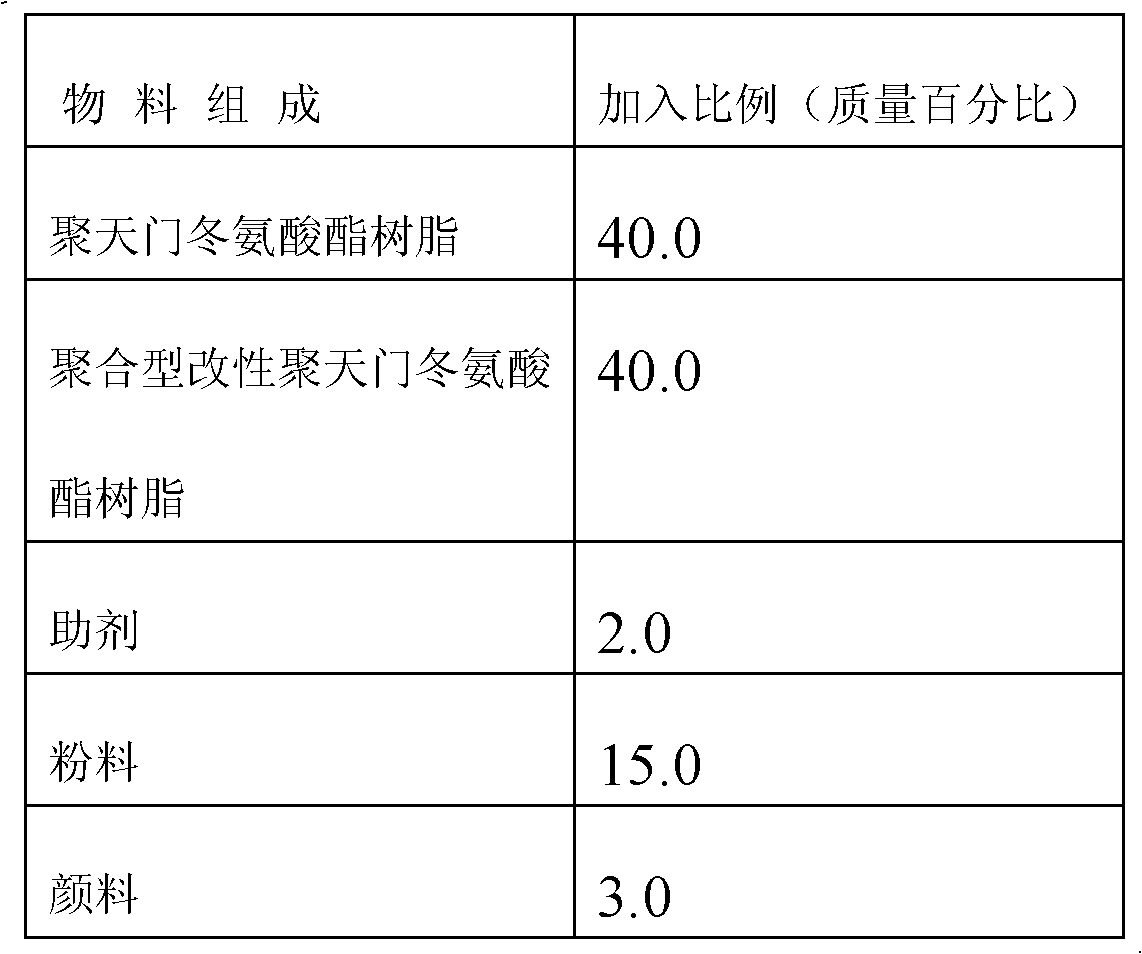

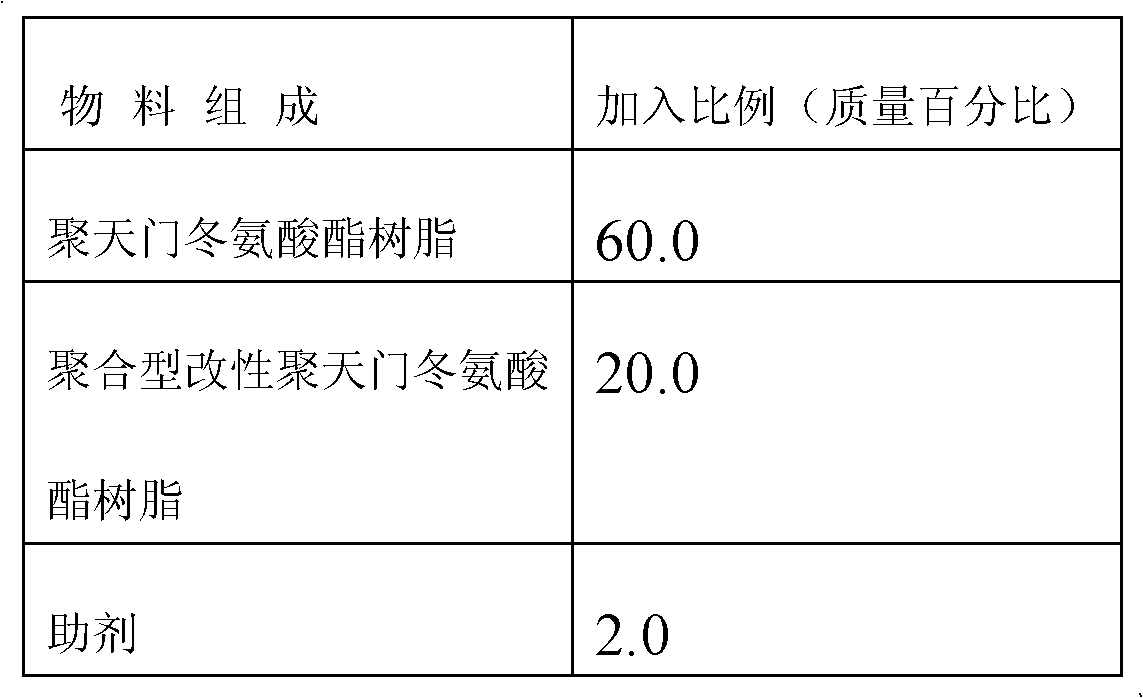

Solvent-free polyaspartic acid ester polyurea elastic waterproof paint

ActiveCN103031045AGood elongation at breakEasy constructionPolyurea/polyurethane coatingsSolventIsocyanate

The invention relates to paint and a preparation method thereof and discloses solvent-free polyaspartic acid ester polyurea elastic waterproof paint. The solvent-free polyaspartic acid ester polyurea elastic waterproof paint is composed of a component A and a component, wherein the component A comprises 2%-35% of polyisocyanate and 65%-98% of end seal isocyanate prepolymer by weight percent; and the component B comprises 20%-60% of polyaspartic acid ester, 10%-40% of polymeric modified poly aspartic acid ester, 5%-30% of stuffing and a small amount of additives by weight percent. Compared with the polyurea paint processed by the polyaspartic acid ester, the solvent-free polyaspartic acid ester polyurea elastic waterproof paint processed by raw materials has the advantages that the construction is convenient, a special large-scale spraying device is not needed, the gelation time is prolonged, the surface drying time is shortened, the tensile strength is enhanced, the elongation at break is increased, and the elastic coating film hardness is increased, does not have a solvent, is environment-friendly and harmless to a human body.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

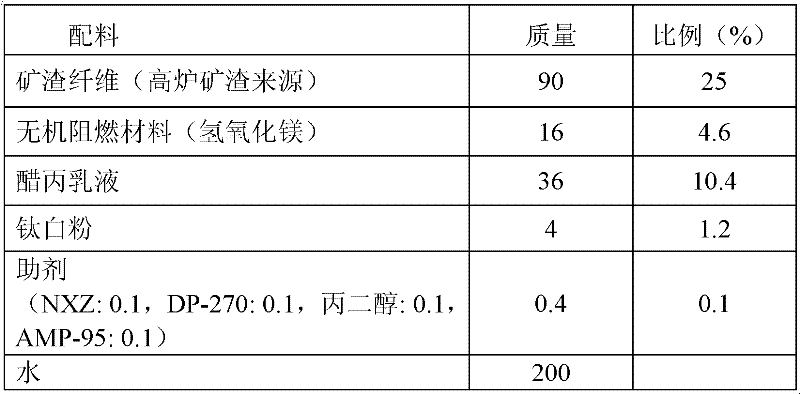

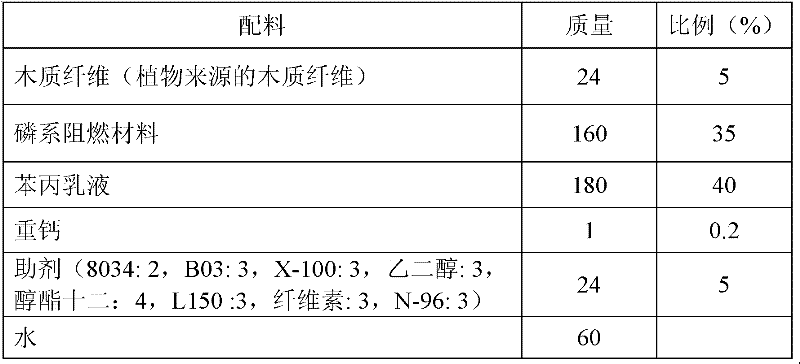

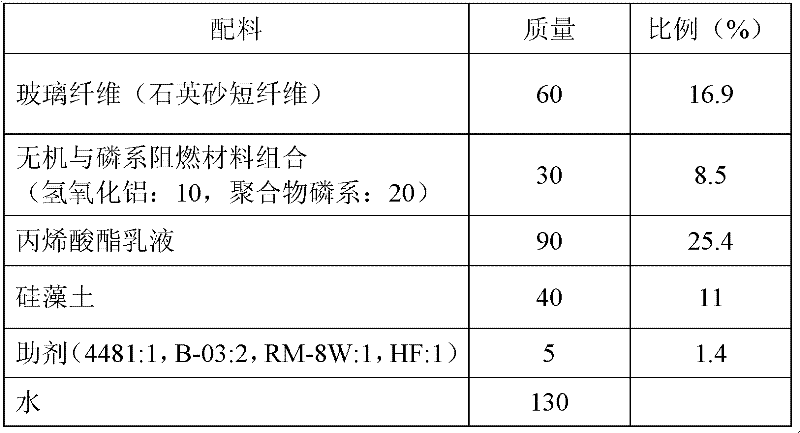

Sound-absorbing coating material and preparation method thereof

ActiveCN102533016AImprove sound absorptionNon-combustibleCoatingsNoise reduction coefficientGlass fiber

The invention discloses a sound-absorbing coating material, wherein every 100 parts by mass of coating contains 5-50 parts by mass of sound-absorbing function materials, 0.1-35 parts by mass of flame retardant materials, 10-40 parts by mass of binding materials, and the balance of an inorganic filling, an assistant and water in a common coating. The sound-absorbing function materials are selected from one or composite of some of materials such as slag fibers, mineral fibers, glass fibers and wood fibers, with fiber structures, and the sound-absorbing function materials are subjected to waterproof modification treatment. According to the invention, NRC (Noise Reduction Coefficient) of the coating material is tested to be more than 0.4 by using a standing wave tube method, and the sound-absorbing coating material has a good sound-absorbing denoising performance, excellent flame resistance and low heat conductivity coefficient, can be used for reducing the energy consumption of a building, is an environmental-friendly functional sound-absorbing coating material integrated with functions of sound absorption, flame resistance and decoration, and can be used on the surface of the building.

Owner:CHINA BUILDING MATERIALS ACAD

Preparation method and construction process of waterborne marble-imitated multicolor paint

ActiveCN101693800AGood water and rub resistanceGood environmental performanceMulticolor effect coatingsChemistryDispersed media

The invention discloses a preparation method and the construction process of a waterborne marble-imitated multicolor paint, in particular to a compounding technology and the construction process of the water-in-water type multicolor external wall paint. The paint consists of a disperse phase and a disperse medium, wherein the waterborne multicolor dispersoid containing water-soluble colloid is taken as the disperse phase and the water is taken as the disperse medium, namely the multicolor dispersoid is uniformly dispersed in the water-dispersed medium containing the film-forming substance. The wall paint has excellent wall decoration and protection performance and high performance-to-price ratio; and as the coating is thin and light and has elasticity and stain resistance, the paint can be applicable to the high-rise external walls and the external heat-preservation coating decoration, thus solving the problem that the self-weight is large in the practical application process of the marbles, the wall bricks and the glass curtain walls. In the invention, the wall paint solves the construction localization that the special spraying gun is only used for the waterborne multicolor paint, the normal spraying gun for building can be used, therefore, the construction is convenient and is easy for operation, and the wall paint has wider application prospect.

Owner:鳄鱼尼卡(上海)新材料有限公司

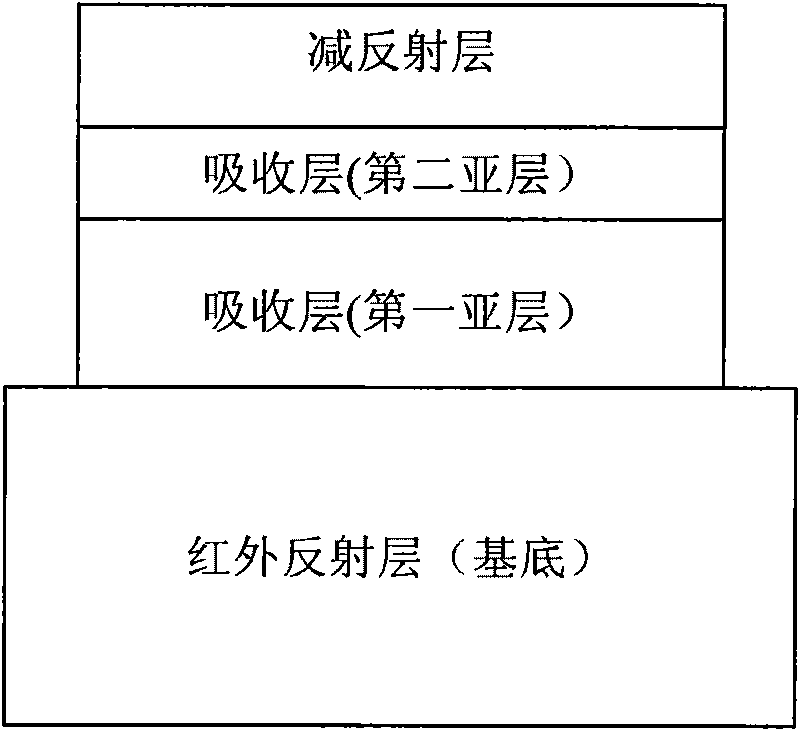

Solar spectrum selective absorbing coating and preparation method thereof

ActiveCN101737983AImprove thermal stabilityMeet the requirements of sustainable developmentSolar heat devicesLayered productsRefractive indexAlloy

The invention relates to a solar spectrum selective absorbing coating which is prepared by adopting magnetron sputtering technology. The absorber of the coating comprises the following three layers of films from substrate to top: a first layer adopts copper with infrared reflectivity or aluminium substrate as an infrared reflecting layer; a second layer uses a metalloid layer and a medium type layer which have different refractive indexes and thicknesses; and a third layer uses SiON film as an antireflection layer. The preparation method comprises the following steps: the first layer (infrared reflecting layer): cleaning copper or aluminium sheets with ultrasonic wave or polishing the copper or aluminium sheets; the metalloid layer of second layer: using two metals as alloy target, argon gas as sputtering gas and nitrogen gas as reaction gas and adopting DC electrical source to perform reactive sputtering; the medium type layer of the second layer: using two metals as alloy target, argon gas as sputtering gas and nitrogen and oxygen gas as reaction gas and adopting DC electrical source to perform reactive sputtering; the third layer (antireflection layer): uses SiN as target, argon gas as sputtering gas and nitrogen and oxygen gas as reaction gas and adopting radio frequency power source to perform reactive sputtering; and finally obtaining the absorber.

Owner:安徽科鑫光热技术有限公司

Waterborne epoxy floor level coating and preparation method thereof

ActiveCN104087120AIn line with the concept of environmental protectionWill not polluteEpoxy resin coatingsPolymer scienceTap water

The invention discloses a waterborne epoxy floor level coating and a preparation method thereof. The coating comprises a waterborne epoxy seal primer, a waterborne epoxy floor level intermediate coat and waterborne epoxy floor level coating finish, wherein the primer, the intermediate coat and the finish are same in component A which comprises 85-95 parts of liquid epoxy resin and 5-15 parts of an epoxy active diluent; the components B are different according to different characteristics of the primer, the intermediate coat and the finish but the main components consist of a waterborne epoxy curing agent and tap water. The waterborne epoxy floor level coating disclosed by the invention is environment-friendly, low in VOC content, good in wear-resisting property, high in hardness and excellent in chemical corrosion-resisting property.

Owner:西北永新涂料有限公司

Ultra-high-performance decorative concrete and preparation method thereof

InactiveCN108264289AWide variety of sourcesConducive to ecological green sustainable developmentFiberSuperplasticizer

The invention discloses ultra-high-performance decorative concrete and a preparation method thereof. The concrete consists of cement, industrial waste residues, fine aggregates, pigment, a defoamer, ahigh-efficiency water reducing agent, water and fibers. The prepared ultra-high-performance decorative concrete uses an active mineral additive and thus has good grain composition, the mechanical property of the ultra-high-performance decorative concrete is good, the appearance color can also be adjusted randomly, and the decorative concrete has certain decorative and artistic effect while beingused as a load-bearing structure; the prepared ultra-high-performance decorative concrete has excellent mechanical property, durability, decorative property, artistry and construction property; and plasticity of the concrete and constitutional features of the material are fully utilized, appropriate measures are taken during forming of walls and components, and therefore, the surfaces of the wallsand the components have decorative lines, patterns, textures, qualities and colors.

Owner:NANJING UNIV OF SCI & TECH

Manufacture of photochromic sunglasses

InactiveCN1403836AStrong adhesionQuality improvementOptical partsOptical elementsAlkanePhotochromic sunglasses

The manufacture of photochromic sunglasses includes the preparation of photochromic coating liquid through mixing solvent alkane or its derivative or substituent, cyclane, arene or its derivative, or alcohol, filming agent organosilicon resin, acrylic acid resin, carbonate, polycarbonate or polystyrene, photochromic matter, ultraviolet ray absorbent and antioxidant; and painting or soaking the photochromic coating liquid to the sunglasses base sheet in the conditions of 15-30 deg.c temperature, 20-60 % humidity and 0.02-0.2 sq cm / s speed. The said photochromic sunglasses is antiaging and uvioresistant.

Owner:CHINA YAOHUA GLASS GRP CORP CO LTD +1

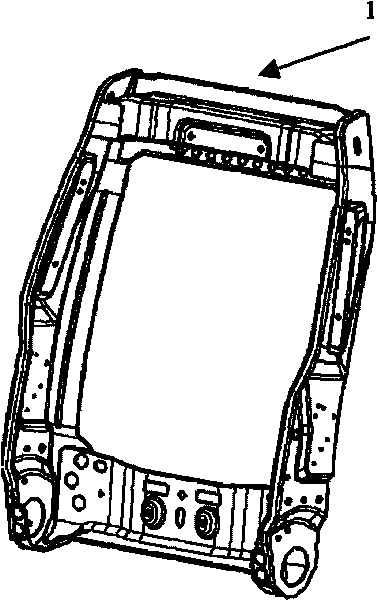

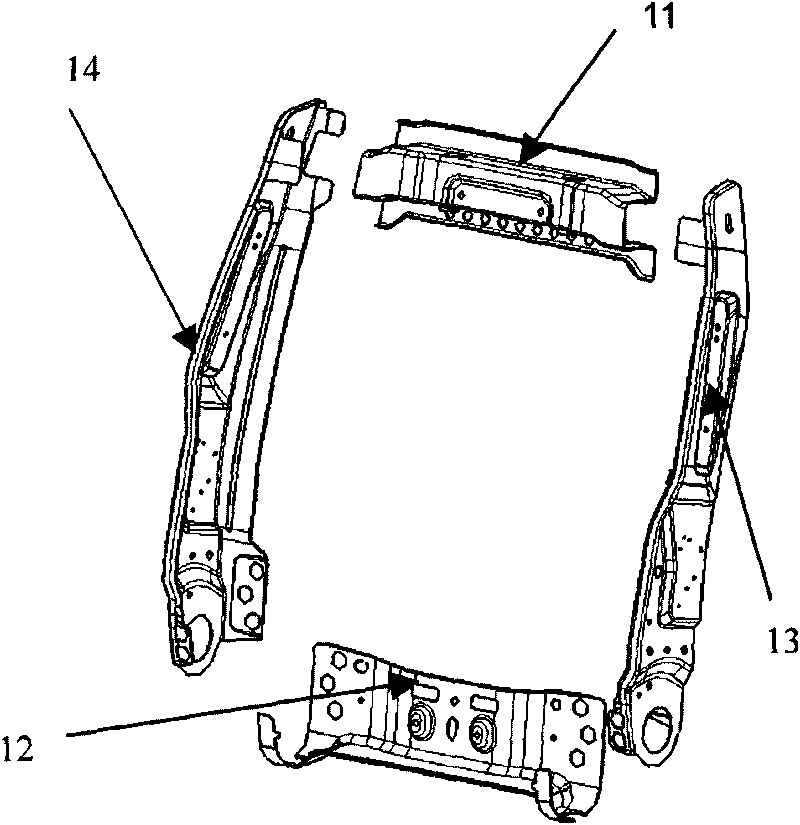

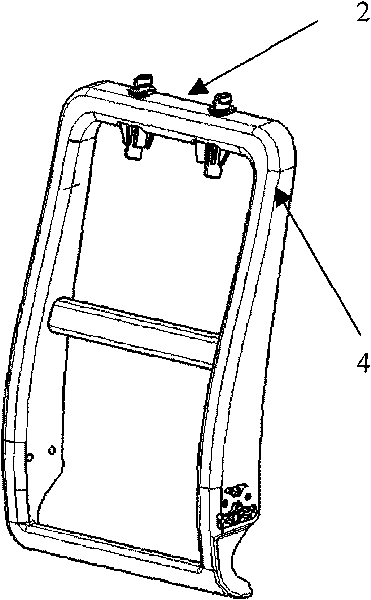

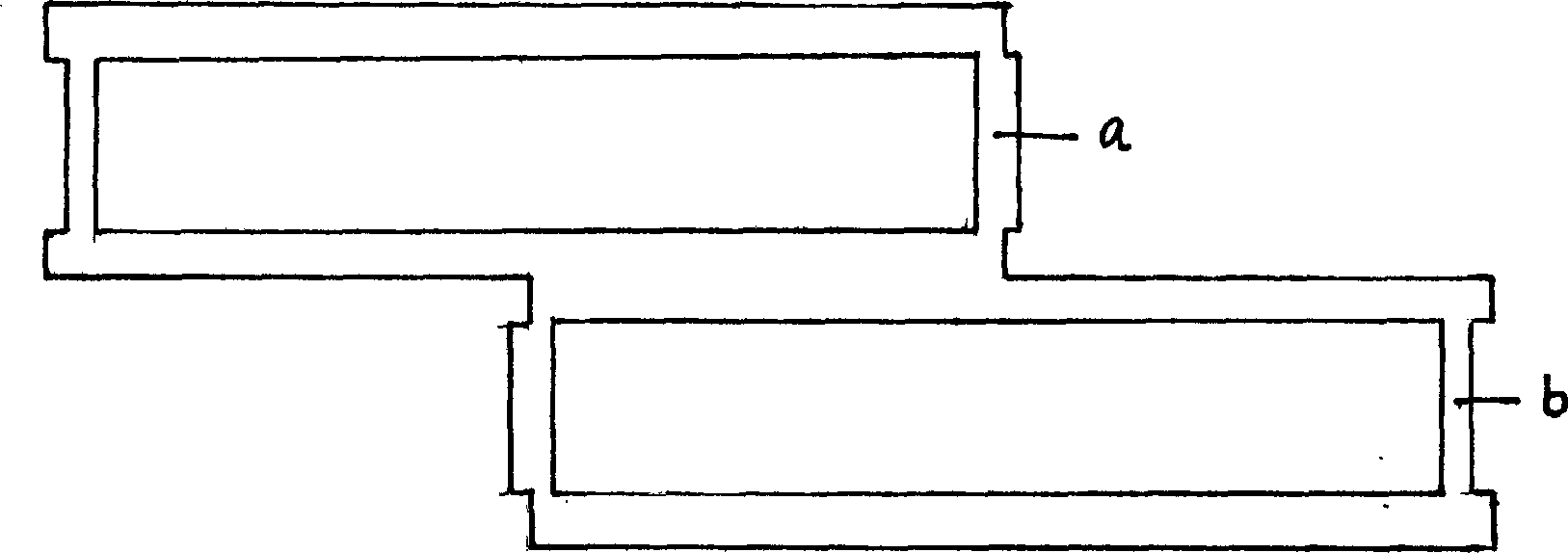

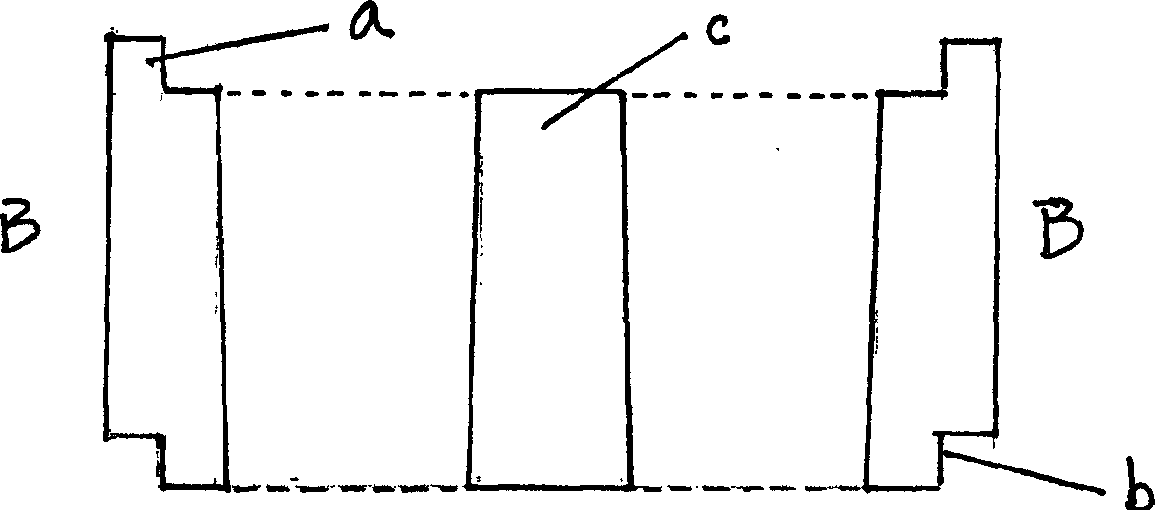

Car seat back skeleton

The invention provides a plastic car seat back skeleton which is made from plastic material through one-step forming and is provided with a shell extending along the circumference, wherein the lateral section of the shell is n-shaped, the inside of the shell with the n-shaped section is provided with honeycomb reinforcing ribs; the position which bears larger stress, of the shell with the n-shaped section has larger thickness; and the honeycomb reinforcing ribs on the whole skeleton can have different height and / or thickness. The car seat back skeleton of the invention is made from plastic instead of metal so that the weight of the car seat back skeleton can be greatly reduced; in addition, the corrosion resistant of the plastic material is better so as to prolong the service life of the product.

Owner:YANFENG ADIENT SEATING CO LTD

Thermal insulating coating integrated composite plate and preparation method thereof

ActiveCN106930492AImprove thermal insulation performanceLow thermal conductivityFireproof paintsCovering/liningsThermal insulationThermal printing

The invention belongs to the technical field of building thermal insulating and energy saving decoration integration materials. A thermal insulating coating integrated composite plate is characterized in that an acrylic emulsion, a silicone acrylic emulsion, silicon dioxide gel, aerogel, hollow glass microspheres, polypropylene fibers and hydroxyethyl cellulose (HEC) are adopted for preparing mucilage, the mucilage is smeared onto an alkali-resisting glass fiber net, and a thermal insulating coating layer is prepared; and a thermal insulating coating material prepared from an acrylic emulsion, a silicone acrylic emulsion, thermal insulation pigments, protection glue, aerogel, hollow glass microspheres and a multifunctional additive is sprayed to the thermal insulating coating layer, a thermal insulating coating material layer is prepared, and the thermal insulating coating integrated composite plate is obtained. The thermal insulating coating integrated composite plate has the effects of ultra low heat conduction coefficient, good thermal insulating performance, good flexibility, good decoration effect, durability, contamination resistance, high combustion level, high tensile strength, and safe, convenient and fast construction.

Owner:湖北邱氏节能建材高新技术股份有限公司

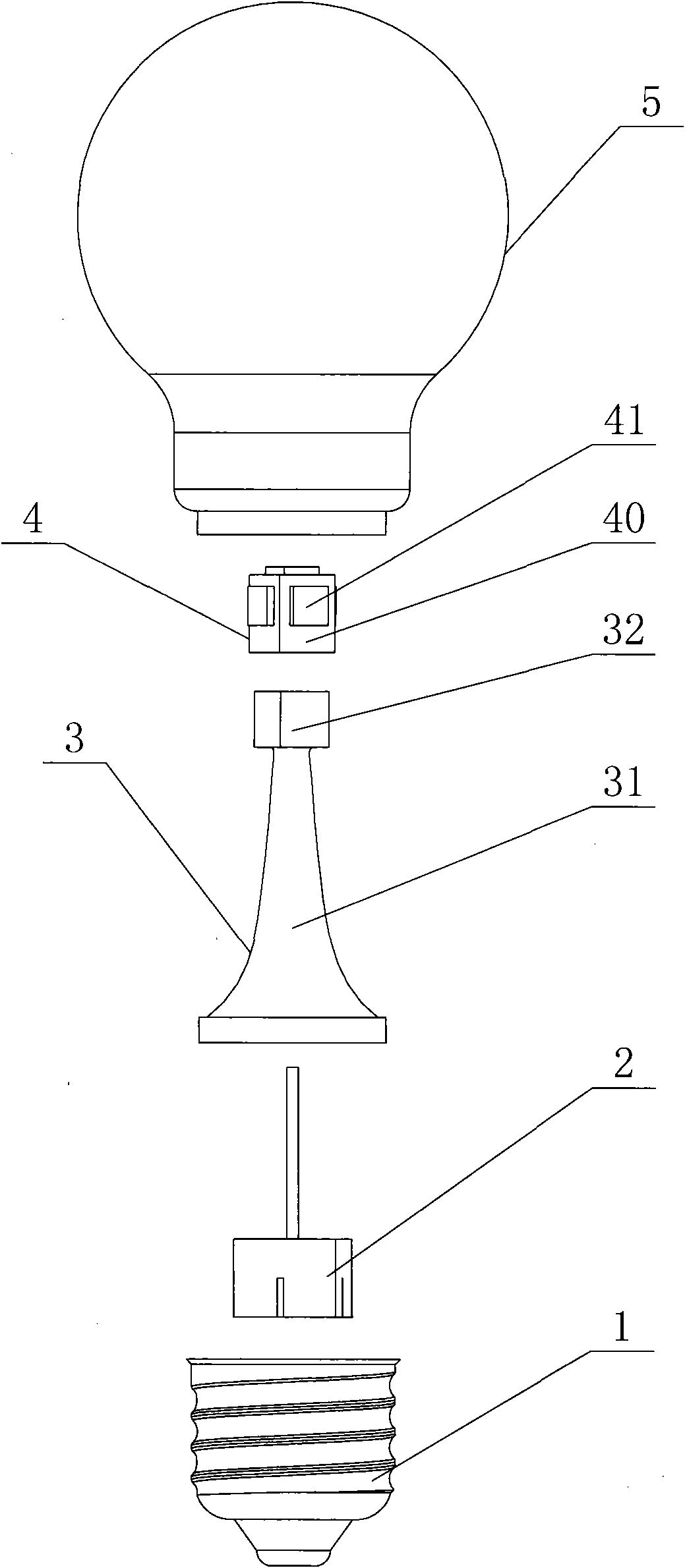

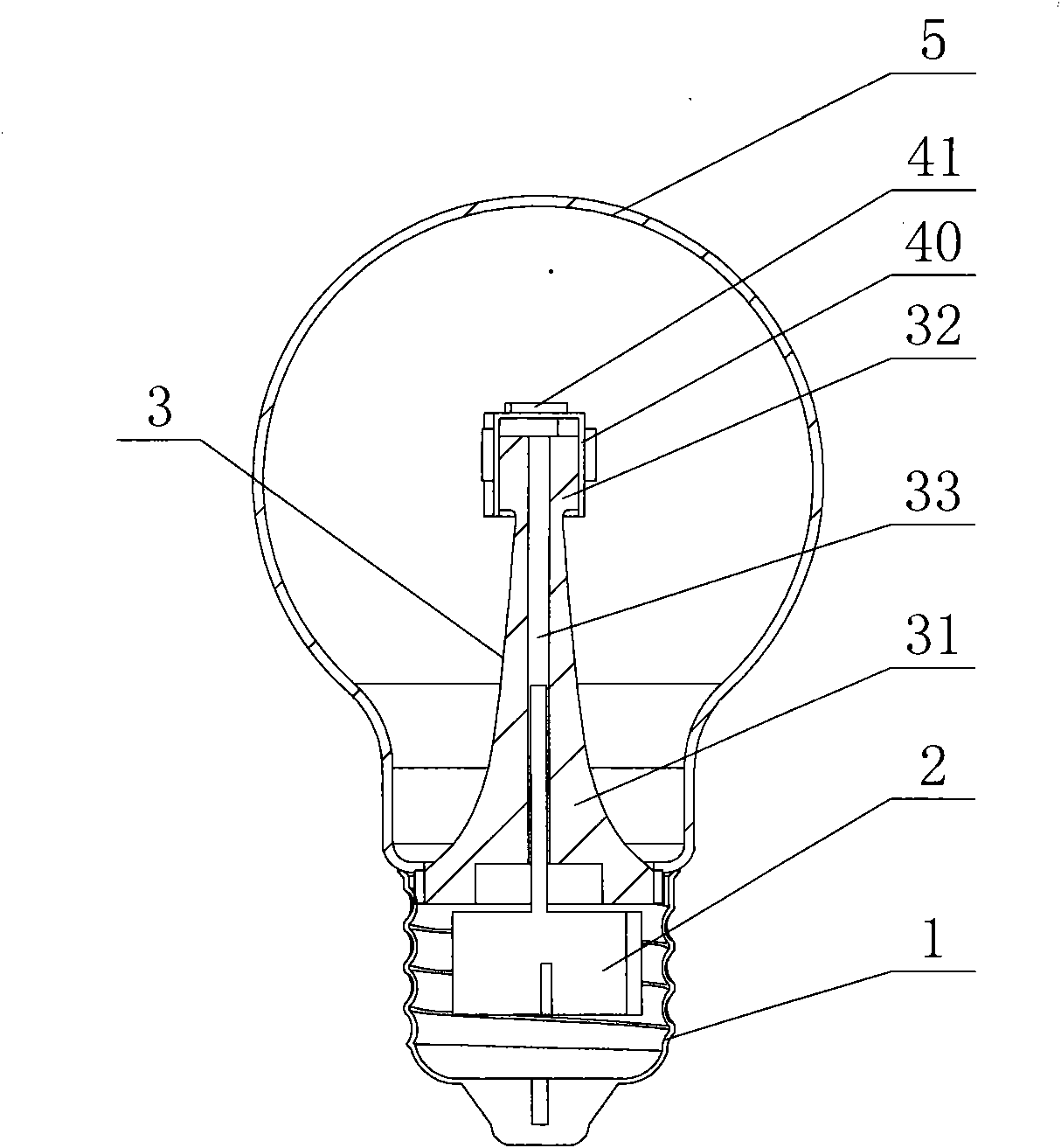

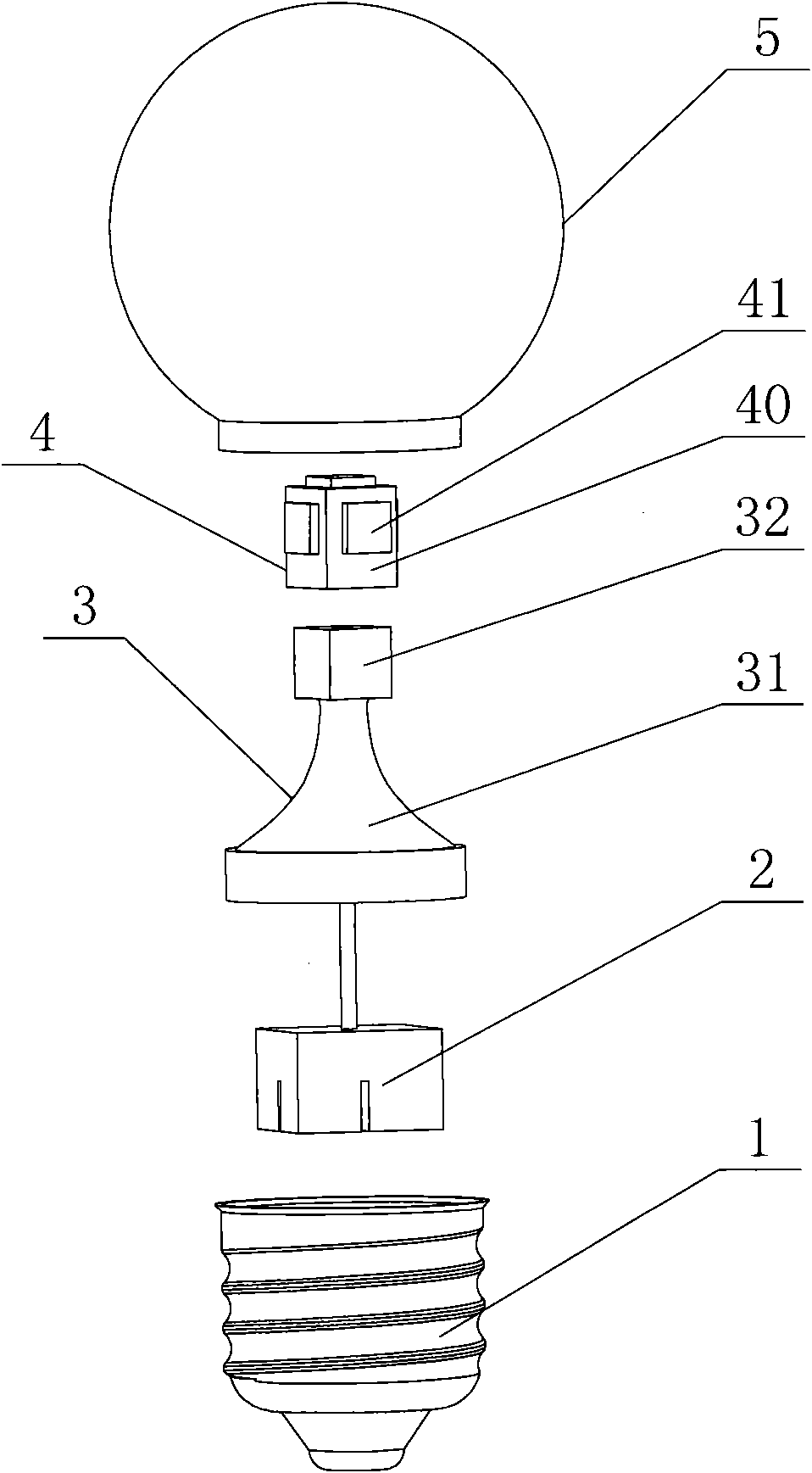

LED bulb

InactiveCN101598272ADoesn't look obtrusiveObtrusive appearancePoint-like light sourceElectric circuit arrangementsBus-holderLight head

The invention discloses an LED bulb, which has good light transmitting performance and has the same light emitting mode, volume and shape as common incandescent light bulbs. The LED bulb comprises a bulb holder (1), a driving circuit component (2), a light source support (3), an LED light source (4) and a bulb case (5), wherein the light source support (3) comprises a pedestal (31) and a polyhedron (32) and is made of metal; the internal axial center of the pedestal (31) is provided with a wire hole (33); the polyhedron (32) is positioned on the top of the pedestal (31); the lower part of the pedestal (31) and the inner wall of the bulb holder (1) are contacted tightly for heat conduction; the LED light source (4) comprises heat dissipating baseplates (40) and LED chips (41) positioned on the heat dissipating baseplates (40); the heat dissipating baseplates (40) are directly fixed on each surface of the polyhedron (32) in the circumferential direction, and the LED chips (41) give out light in all directions by taking surfaces of the polyhedron (32) in the circumferential direction as the reference surfaces; and the driving circuit component (2) is electrically connected with the bulb holder (1) and the LED light source (4) through leads.

Owner:SMALUX ELECTRICAL MFG

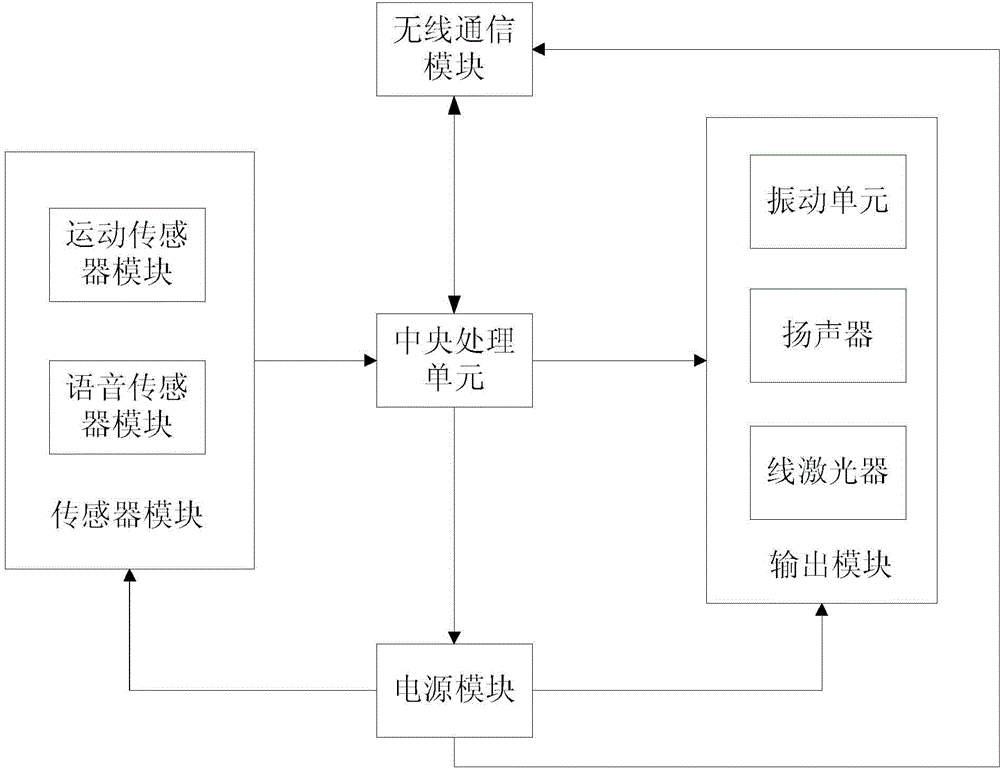

Smart bracelet capable of relieving gait freezing of patient suffering from Parkinson's disease

The invention discloses a smart bracelet capable of relieving gait freezing of a patient suffering from a Parkinson's disease. The smart bracelet comprises a bracelet body and a control system, wherein the control system is placed in the bracelet body and specifically comprises a sensor module, a central processing unit and an outputting module; the sensor module comprises a motion sensor module and a voice sensor module; and the outputting module comprises a vibrating unit, a loudspeaker and a laser line generator. Gait freezing of the patient suffering from the Parkinson's disease is relieved by modes of touch stimulation, hearing stimulation or visual stimulation, and treatment on the disease of the patient suffering from the Parkinson's disease is facilitated. Moreover, the smart bracelet is light in weight and convenient to carry and has a certain decorating effect. The patient wearing the smart bracelet does not resist the smart bracelet, and the living quality of the patient is improved. Moreover, the smart bracelet can be set individually according to demands of different patients, and is high in flexibility and practicality.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

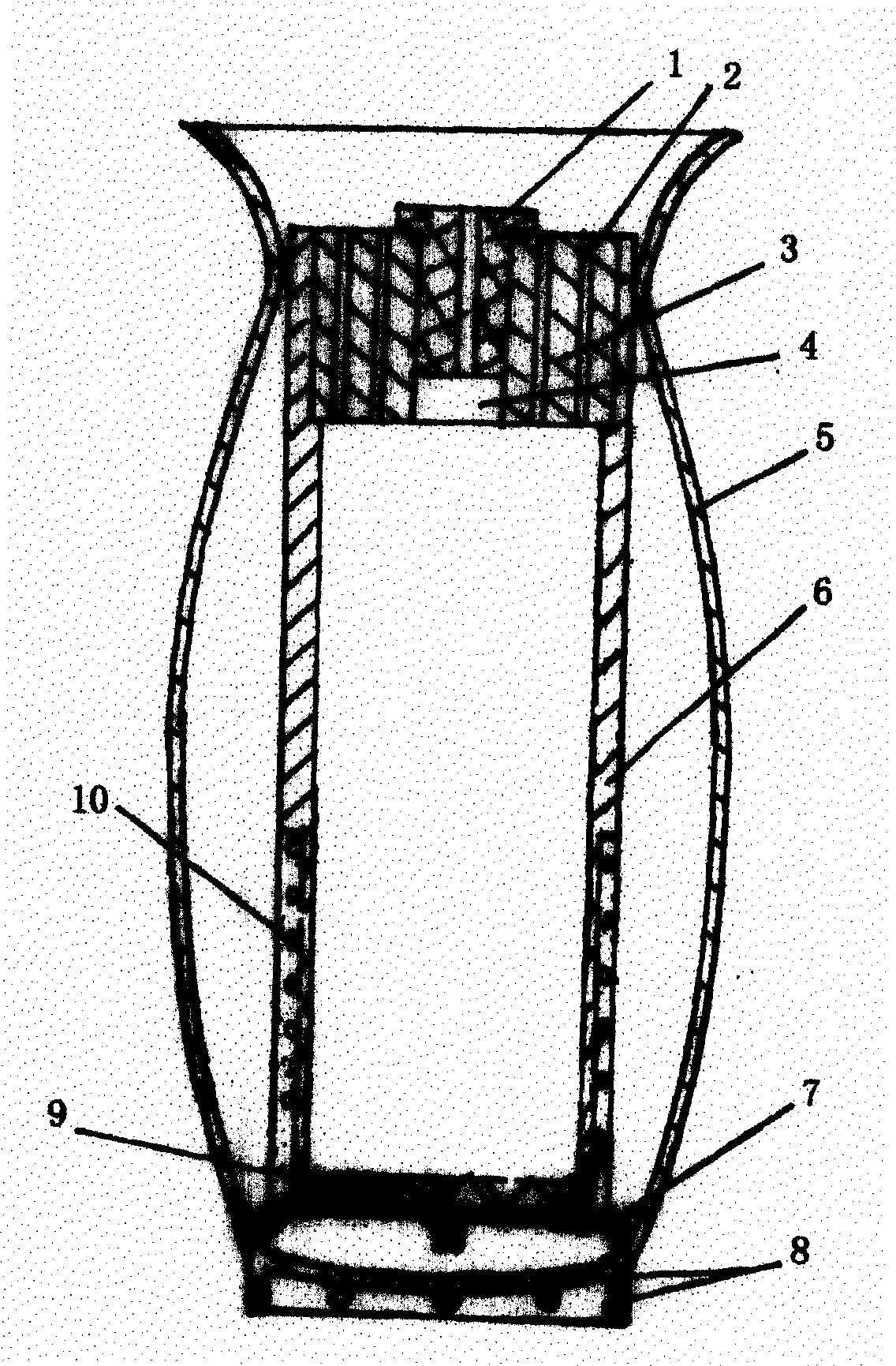

Anti-cold Chinese medicine sterilizing fumet and fumigation stove

InactiveCN1554243ARelieve respiratory secretionsEliminate bad breathBiocideAnimal repellantsIndoor airMedicine

The present invention relates to Chinese medicine product for sterilizing and preventing diseases. The fumigation stove consists of fumigation chamber with electrothermal roastig board in the lower part, filter with upper fume outlet holes and material feeding opening and four claw support inside the outer casing. The casing is vase-shaped or in other decorative form. The fumet has moxa as main component and contains also eight kinds of Chinese medicinal materials, including basket kern, agastache, calamus, etc. The present invention is used in purifying and aromatizing indoor air, especially in disease spreading period. The medicated air has obvious effect of killing bacteria and inhibiting virus.

Owner:张留印

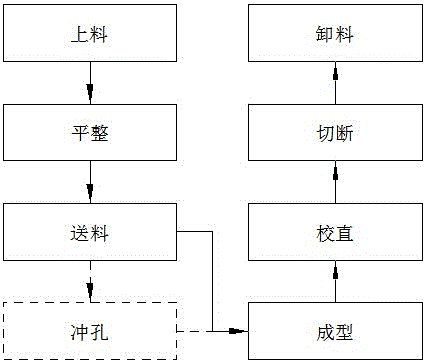

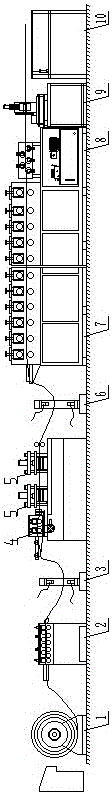

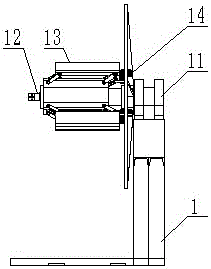

Production method and system of profile

InactiveCN106826137AImprove the decorative effectBeautiful decorationOther manufacturing equipments/toolsPunchingMethods of production

The invention discloses a production method and system of a profile. The system comprises a charging device, a feeding device, a molding device and a cutoff device; and centralized control and linkage are achieved through a centralized control box. The procedures of molding, punching, pattering and cutoff of a guardrail profile can be completed once, and automatic discharging can also be completed. The production method and system have the characteristics that welding is not needed for profile molding, the automatic degree is high, the mechanical property of a product is good, the production process is more environment-friendly, the processing accuracy is higher, the decorating property is good and the cost is low.

Owner:HUBEI MEILI PROTECTING FACILITY TECH

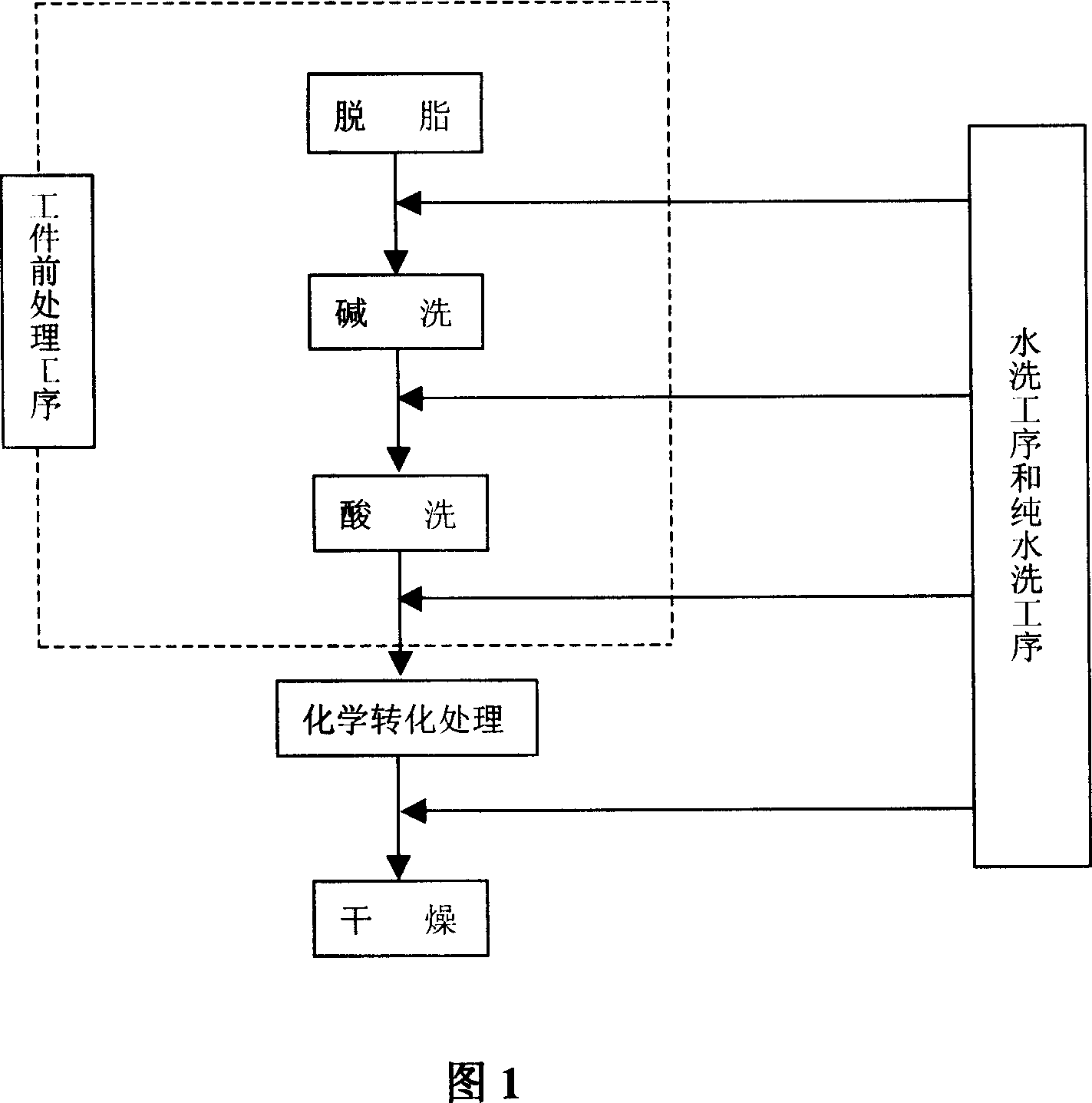

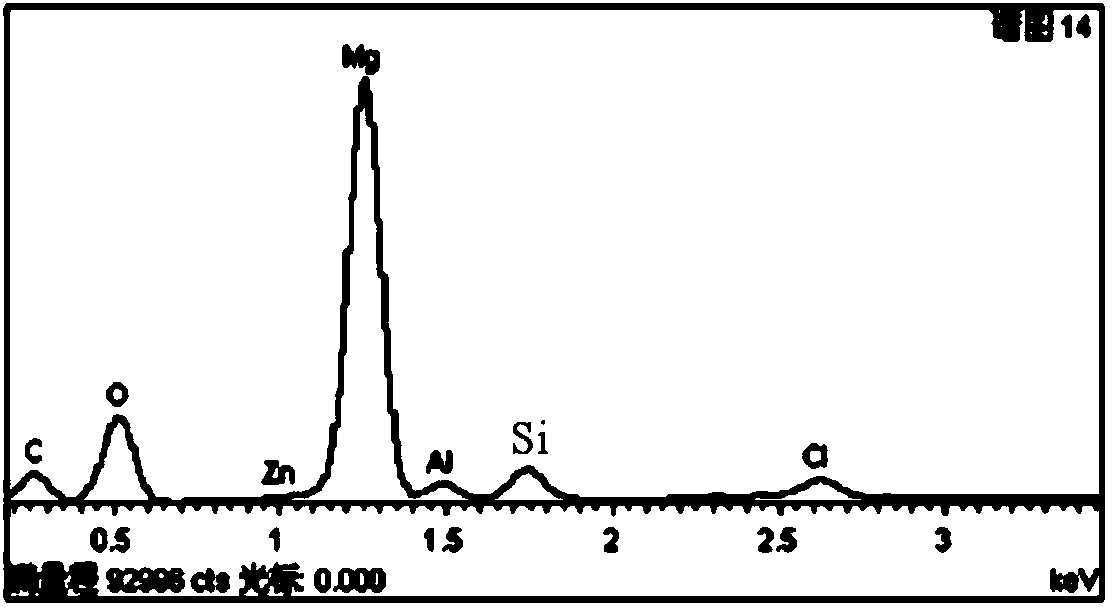

Method of treating magnesium alloy work-piece surface

InactiveCN101016627AProtectiveDecorativeMetallic material coating processesElectrolysisChemical transformation

The invention discloses a surface disposing method of electron alloys work piece, which is characterized by the following: including work piece fore treatment, chemical transformation treatment, drying treatment and washing treatment of each interprocess; dipping electron alloys work piece into inverting liquid of main filming matter and assistance filming matter as chemical transformation treatment; setting main filming matter as one or several zircon salt, manganic salt, molybdate and tungstate and so on transient metal salt; converting to Na2MoO4.2H2O content with density at 5-150g / L; setting the assistance filming matter as one or several nitrate and sulfate of lithium, sodium and potassium alkali metal; converting to LiNO3 content with density at 0.5-20g / L and pH value of inverting liquid at 2-6; controlling the disposing temperature at 10-90 deg.c and disposing time at 5-30 min. This surface film possesses properties of protection and decoration.

Owner:CHONGQING UNIV

Z-shaped small-sized cement concrete hollow filled non-clod bridge thermal insulation building block and its making method

InactiveCN1702253AHigh compressive strengthStrong collision resistanceWallsThermal insulationAcoustic energy

This invention relates to a Z-shape small cement concrete hollow filled insulating building block, which belongs to the acoustic and heat-insulating material of the architecture field. The technical project is: designing the building outline to Z-shape hollow, filling the straw, chaff or the crushed wheat strew, corn stalk, waste aerated plastics particles which are packed and sealed with the aluminized plastic film. The insulating block obstructs the end wall interlaced through double layer insulating material, and eliminates the self-cold bridge, which increases the insulating property of the wall greatly; in addition, the loose insulating material can absorb acoustic energy and has good deafening effect. The Z-shape block is mainly used in laying the exterior wall and the separated production wall.

Owner:周荣标

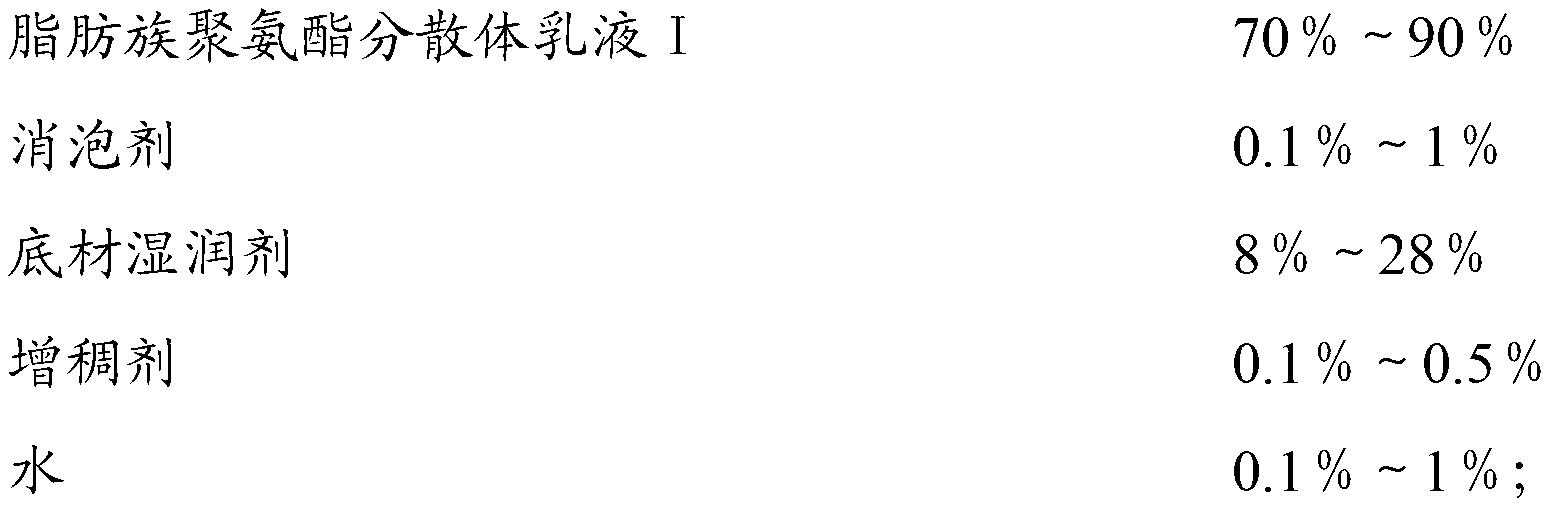

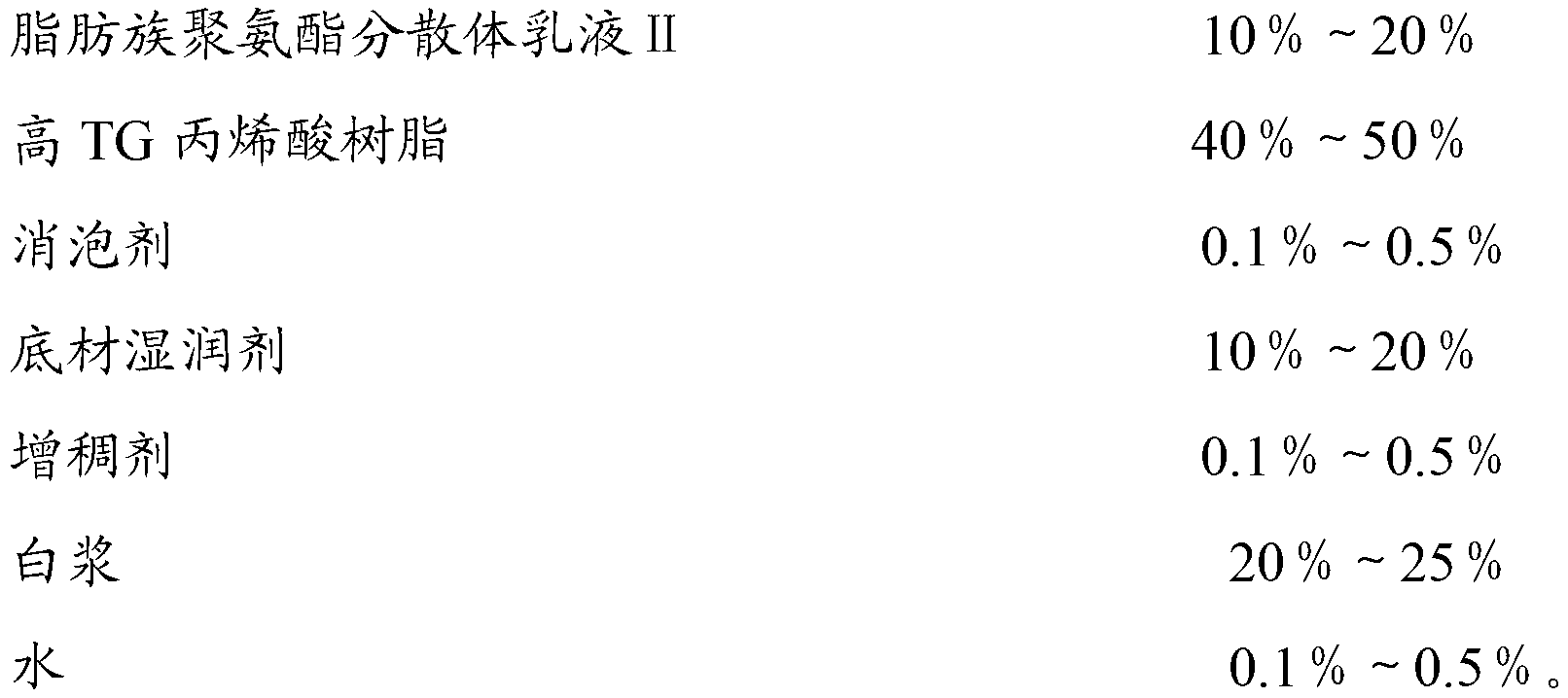

Water-based crack paint as well as preparation method and application method thereof

The invention relates to the technical field of coatings, in particular to a water-based crack paint as well as a preparation method and an application method thereof. The water-based crack paint comprises a water-based crack base paint and a water-based crack finish paint, wherein the water-based crack base paint comprises an aliphatic polyurethane dispersoid emulsion I, a defoamer, a substrate wetting agent, a thickener and water; and the water-based crack finish paint comprises an aliphatic polyurethane dispersoid emulsion II, high-TG (glass-transition temperature) acrylic acid resin, a defoamer, a substrate wetting agent, a thickener and water. A film can be formed by the specific high-TG acrylic acid resin and aliphatic polyurethane dispersoid emulsions without addition of a pigment, filler and a film-forming additive, so that the environment is protected; and after the water-based crack paint is applied, a beautiful and vivid crack decoration effect can be formed on the upper surface of a base material to be decorated and the base material can be protected and decorated.

Owner:东莞大宝化工制品有限公司 +1

Steel structure fireproof paint by taking expanded and vitrified small ball as base material

The invention provides a preparation method of a steel structure fireproof paint by taking expanded and vitrified small ball as a base material, which is characterized in that on the basis of a traditional organic inorganic clad steel structure fireproof paint, and expanded and vitrified small ball and phenolic resin are used for obtaining the steel structure fireproof paint with excellent performance. According to the invention, expanded and vitrified small ball in the inorganic component replace a traditional lightweight aggregate, thereby the paint has the advantages of low density, high strength, stable physical and chemical performance, and has excellent performances of aging resistance and weatherability, heat insulation, fire resistance, sound insulation and insulation; phenolic resins can replace a traditional film forming agent in the organic component, no fire retardant is applied, so that the coating has the advantages of difficult combustion, good heat stability, low smoke, low toxicity, high mechanical strength, and strong anti-corrosion capability and weather resistance. The paint overcomes the disadvantages of poor flame resistance and toxic flue gas release due to thermal decomposition of the common organic resin.

Owner:BEIJING BUILDING TECH DEV

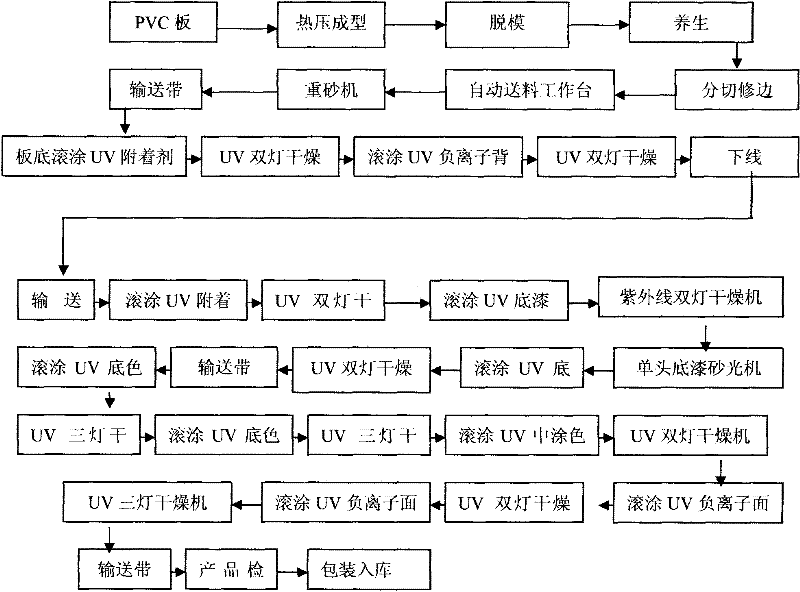

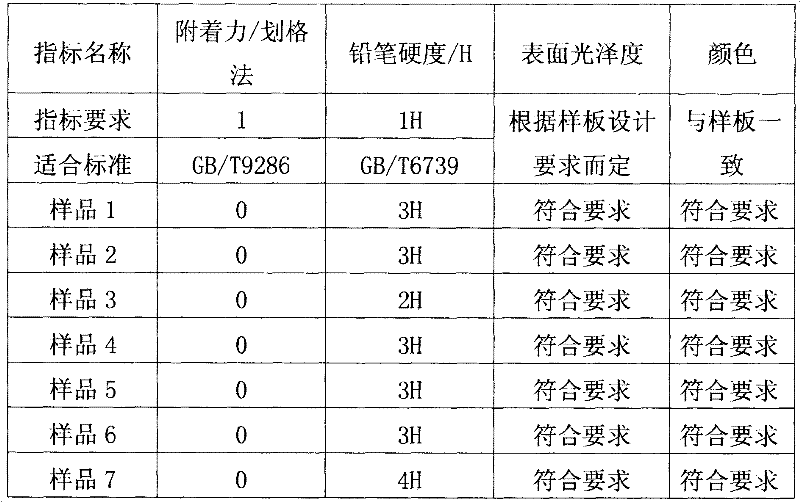

Waterborne single-component thermoplastic plastic paint and production method and construction method thereof

ActiveCN102146243AAvoid long-term contactReduce pollutionCoatingsSpecial surfacesPolymethyl methacrylatePolycarbonate

The invention provides waterborne single-component thermoplastic plastic paint and a production method and construction method thereof. The plastic paint is suitable for the coating of plastic cabinet prepared from ABS (Acrylonitrile Butadiene Styrene), PS (poly styrene), HIPS (High Impact Polystyrene), PC (polycarbonate), PMMA (polymethyl methacrylate) and the like, has good adaptability to the surface of the material and also has good adhesive force, thus the adhesive force problem of the waterborne paint on the plastic substrate can be solved. A waterborne system is adopted for the paint mainly adopts, the production and using processes are safe; and water is used as diluent, and the paint has the advantages of low toxicity, low pollution, extremely low volatile organic compound (VOC) emission and the like and meets various laws and regulations on environmental protection. Meanwhile, the paint can use different color pastes for coloring; and the paint has better decorative propertyon the substrate while the properties can not be affected. Compared with the common solvent thermoplastic acrylic paint, the paint only uses a small amount of low-toxicity alcohol ether type organic solvent, thus the influence on the plastic substrate is extremely small; and the paint film has bright colour, full appearance effect and good performances.

Owner:深圳市嘉卓成科技发展有限公司

Novel non-cement-based inorganic artificial stone slab and preparation method thereof

ActiveCN101948293AStable structureImprove mechanical propertiesSolid waste managementPhysical chemistryEngineering

The invention discloses a novel non-cement-based inorganic artificial stone slab and a preparation method thereof. The novel non-cement-based inorganic artificial stone slab consists of inorganic micropowder, emulsion, an inorganic pigment and an aggregate. The preparation method comprises the following steps of: stirring and mixing the components uniformly, sealing, vacuumizing, releasing into amold when the vacuum degree reaches a certain value, vibrating and pressing in the vacuum state to form a big blank, demolding, processing by procedures such as dragsaw cutting, polishing and protecting, and preparing the inorganic artificial stone facing slab at normal temperature. The gelling system of the non-cement-based inorganic artificial stone slab has a three-dimensional netty macromolecular structure with certain gelling performance and main Al-O-Si bonds, which is formed under the coaction of the inorganic micropowder and emulsion. Through data detection, the non-cement-based inorganic artificial stone slab has the advantages of stable structure, no combustion, ageing resistance, and resistance to corrosion of salt mist, salinization, seawater and other chemical media, has the appearance and texture of resin artificial stones after polishment, also has the advantages of good decoration effect, no toxin, environmental protection and long service life, and can be widely applied to various interior and exterior decoration projects related to natural stones and resin artificial stones.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

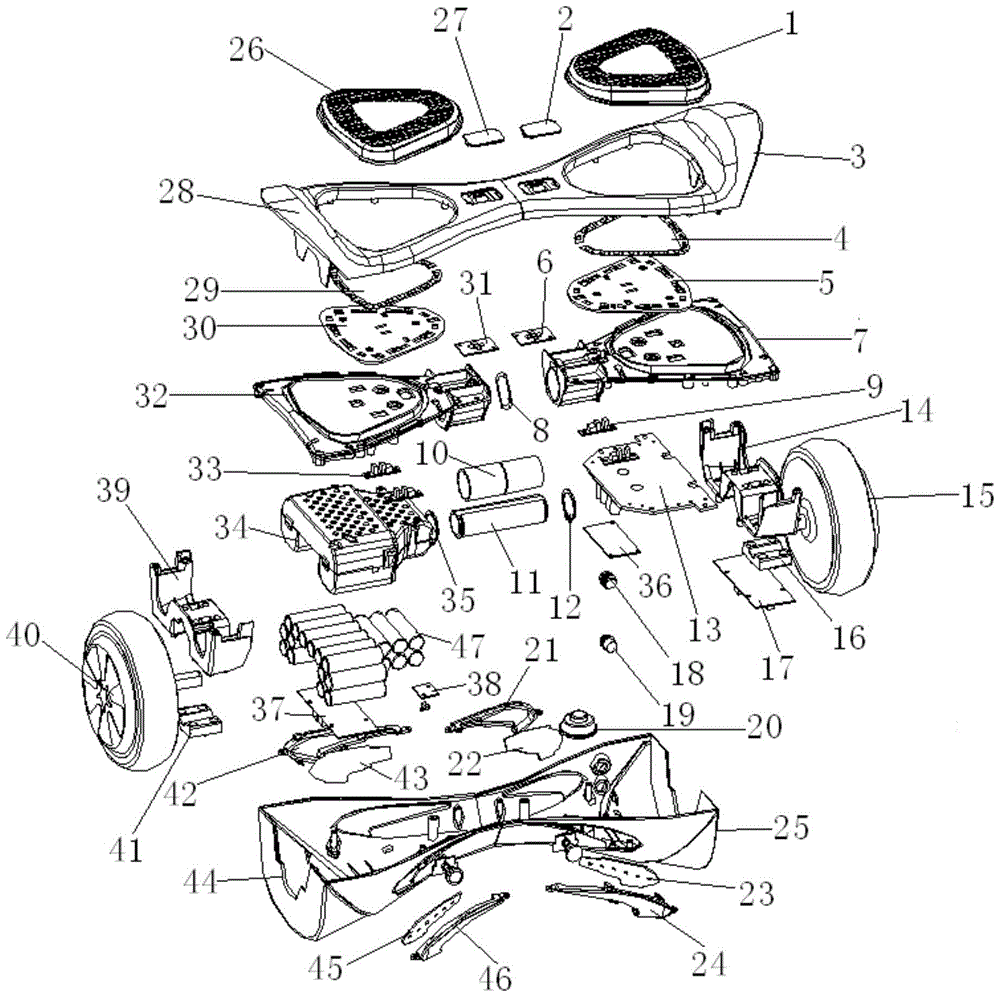

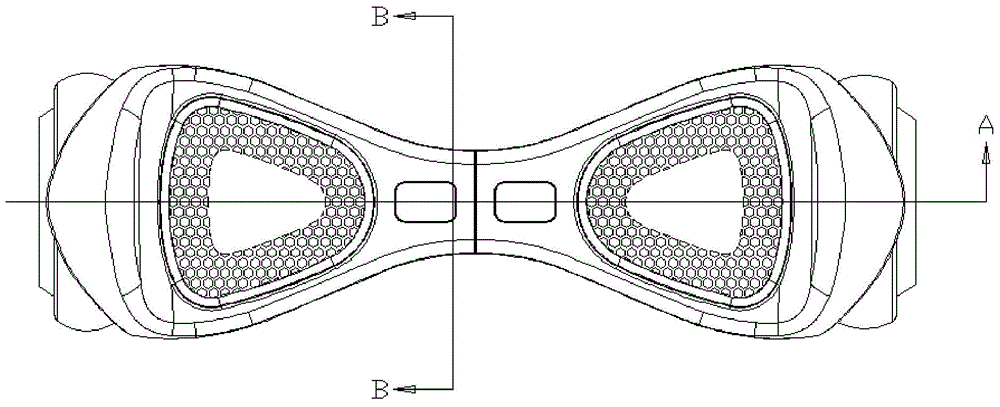

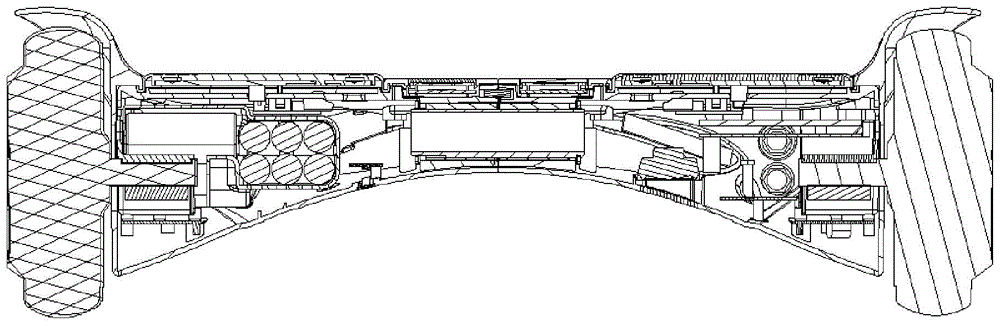

Electrodynamic balance scooter

InactiveCN105730576AHigh degree of intelligenceEasy to operateMotorcyclesBicyclesLoudspeakerBattery holder

The invention discloses an electrodynamic balance scooter. The electrodynamic balance scooter comprises foot pads, indicator lenses, upper casing covers, light-emitting rings, foot pad brackets, battery work lamps, frameworks, a middle axle ring sheet, balance sensing brackets, a framework middle axle cylinder, a middle axle, snap spring sheets, a control mainboard, motor brackets, motors, motor press blocks, balance assistant boards, a power switch, a charging interface, a loudspeaker, headlamp hoods, headlamps, tail lamps, tail lamp hoods, low casing covers, a battery holder, a lamp line board, a bluetooth module and a battery. According to the electrodynamic balance scooter disclosed by the invention, the scooter is controlled by an intelligent control board, so that the electrodynamic balance scooter is convenient to operate, reasonable in internal structure design, and low in consumption; various working indicator lamps and relevant components convenient to operate by users are designed externally, and a bluetooth module, a sound module, and an sending control module are arranged, so that the intelligent degree is high. In general, the electrodynamic balance scooter is reasonable in structural design, convenient to operate, diversified in functions, good in reliability, good in stability, beautiful in appearance, high in intelligent degree and good in user experience.

Owner:SHENZHEN HONGXUJIN TECH CO LTD

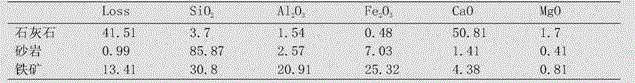

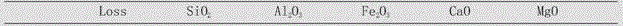

Autogenously-pulverizable low calcium cement, and making method of prefabricated products thereof

ActiveCN105347706ALower firing temperatureReduce production processHigh concentrationShrinkage cracking

The invention relates to an autogenously-pulverizable low calcium cement, and a making method of a prefabricated product thereof. The autogenously-pulverizable low calcium cement is made from limestone, sandstone and iron ore, the CaO content of the prepared autogenously-pulverizable low calcium cement is 40-60%, and the main mineral phase of the autogenously-pulverizable low calcium cement is CS, C3S2, gamma-C2S and a liquid phase. The activity of the cement is excited by using high-concentration CO2 gas in a short period (8h) to make the prefabricated products of the autogenously-pulverizable low calcium cement, and the prefabricated products can be a sheet, a building block, a brick and a tile, and can also be solid or hollow or porous high-strength prefabricated products. The problems of long curing period, high energy consumption and shrinkage cracking of ordinary Portland cement prefabricated products are solved in the invention; and additionally, the autogenously-pulverizable low calcium cement has the advantages of low energy consumption in the baking process, small CO2 discharge amount, high early strength, and slow increase of the later strength, and the product of the autogenously-pulverizable low calcium cement has the advantages of excellent physical and mechanical performances, good durability, fire and corrosion resistance, good decorativeness and processability, environmental protection, energy saving and emission reduction, and very good social, economic and environmental benefits.

Owner:HENAN POLYTECHNIC UNIV

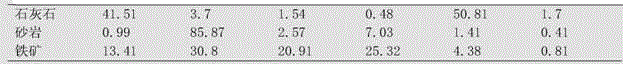

Ultra-level highlight powder coating formula and preparation method thereof

InactiveCN104745042AImprove the level ofDecorativePowdery paintsEpoxy resin coatingsEpoxyAntioxidant

The invention relates to the technical field of preparation for powder coatings with special performances, and particularly relates to an ultra-level highlight powder coating formula and a preparation method thereof. The powder coating has the following formula components in parts by mass: 28-34 parts of epoxy resin, 28-34 parts of polyester resin, 1.5-3.5 parts of a levelling agent, 22-25 parts of titanium dioxide, 2.5-4.8 parts of barium sulphate, 0.1-0.6 part of benzoin, 0.2-0.6 part of an antioxidant, 0.02-0.28 part of ultramarine, 0.002-0.004 part of carbon black and 0.2-0.35 part of silicon dioxide. The coating film of the powder coating obtained by the technical scheme disclosed by the invention has a good levelling performance, the interface cured by the powder coating has good decoration performance, and the powder coating can be applied to surface protection on automobiles, household appliances, furniture and the like, as well as is low in use cost and suitable for popularization and application.

Owner:JIANGSU HUAGUANG NEW MATERIAL TECH CO LTD

Gypsum-based building material prepared from plant fibers for treating indoor formaldehyde and application method thereof

The invention relates to gypsum building materials, and particularly relates to a gypsum-based building material prepared from plant fibers for treating indoor formaldehyde and an application method thereof. The gypsum-based building material is formed by adding water to a mixture and then stirring the watered mixture, wherein the mixture is formed by mixing the following components by percent: 5-20% of semi-carbonization plant fiber, 30-70% of gypsum for buildings, 1-20% of semi-hydrated gypsum whisker, 1-20% of hydrated lime, 1-10% of white cement, 1-20% of expanded vermiculite, 0.1-1% of water reducing agent, 0.1-1% of retarder, 0.01-1% of thickening agent, 0.1-1% of antistatic agent and 0.1-1% of inorganic pigment, and the mass of the water accounts for 20-50% of the mass of the mixture. The utilization rate of wastes is realized; the prepared material has high formaldehyde adsorption property; the gypsum-based building material has the advantages of heat retaining property, good water resistance, small deformation, high mechanical strength, good decorative property and the like.

Owner:WUHAN UNIV OF TECH

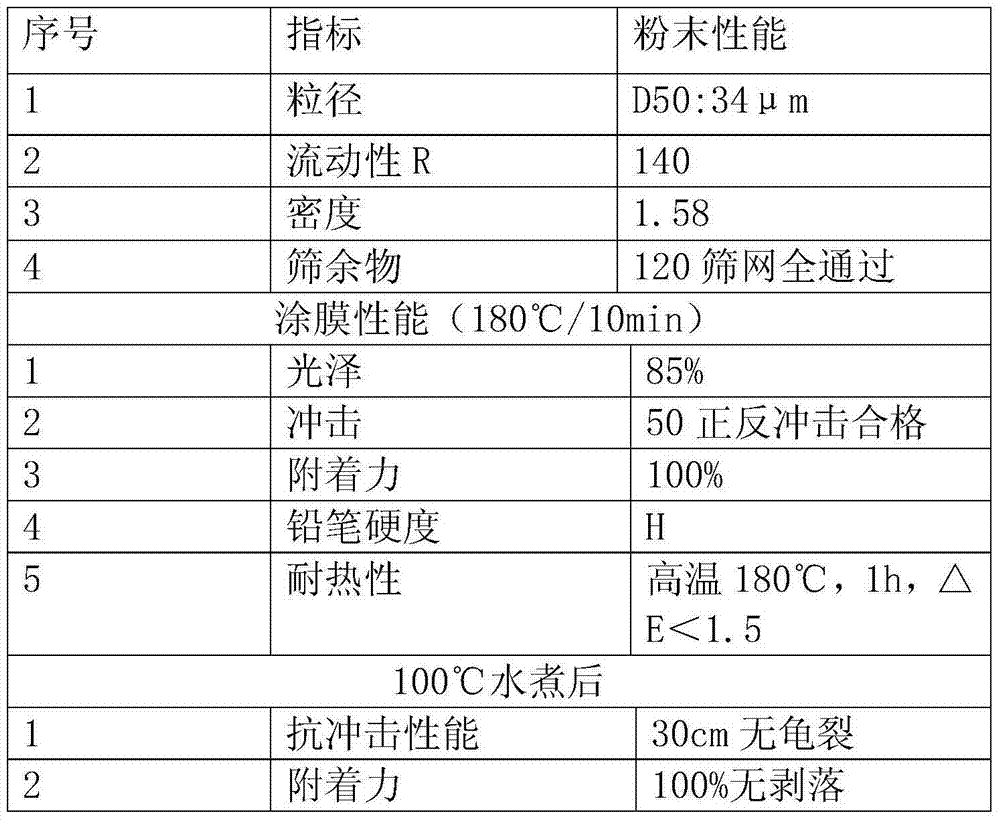

Petal-containing paper-based decorative material and preparation method thereof

ActiveCN106283928APlay natural lifelikeDecorativeSpecial paperVegetable material additionSolubilityFiber

The invention discloses a petal-containing paper-based decorative material and a preparation method thereof. The decorative material comprises a surface layer, a core layer and a bottom layer, wherein the surface layer and the bottom layer comprise softwood fiber pulp, water-soluble PVA (Polyvinyl Acetate) fiber pulp and double-component fiber pulp; and the core layer comprises softwood fiber pulp, hardwood fiber pulp and petal dispersant. According to the petal-containing paper-based decorative material, the surface layer and the bottom layer are rich in water-soluble polyvinyl alcohol fibers with high strength, water solubility and hot-melting adhesive effect, so that mechanical strength and interlayer adhesive force are provided for the material. The core layer supports the surface layer, and petals are natural, vivid, decorative and beautiful. Each layer adopts the same wet making method, the interlayer spray chemical aid is added for strengthening bonding, and the composite molded and hot-pressed interface is good in an adhesive status and is not layered.

Owner:SHAANXI UNIV OF SCI & TECH

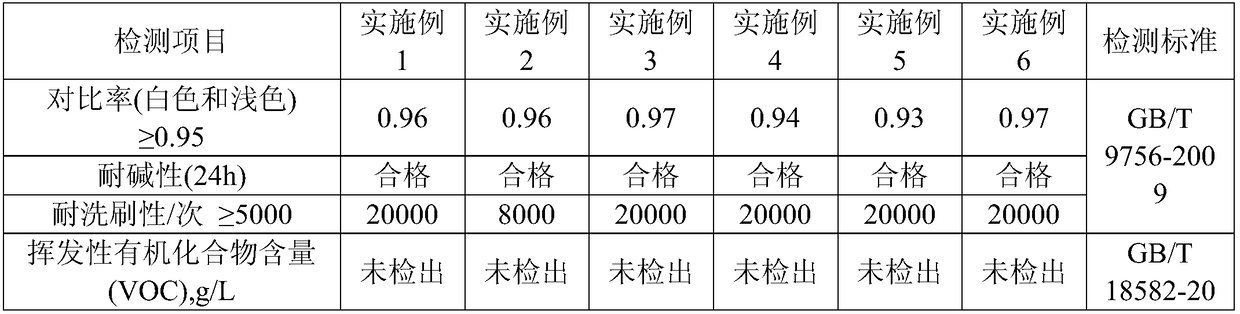

Healthy and environment-friendly negative ion indoor coating preparation method

InactiveCN108373668ASustained releaseImprove water resistanceAntifouling/underwater paintsPaints with biocidesIndoor air qualityAdhesive

The invention belongs to the technical field of coatings, and particularly relates to a healthy and environment-friendly negative ion indoor coating preparation method. By the aid of water-resistant environment-friendly adhesive and covering polymer emulsion combination technology, a healthy and environment-friendly coating is prepared from assisted optimized efficient negative ion mineral additives and healthy and environment-friendly auxiliaries and is non-toxic, environmentally friendly, good in water resistance and strong in covering power, growth of various mildews is effectively inhibited, negative ions can be continuously released, harmful gas in air is removed, the air quality of a living condition is effectively improved, human immunity is improved, and health of people is promoted. The healthy and environment-friendly coating can be widely used for residential houses and places with dense crowds such as shopping malls, office buildings, hospitals, schools, hotels, undergroundgarages and industrial building, the indoor air quality of the places is effectively improved, and protective and decorative functions are achieved.

Owner:SHANGHAI BIOASIA LIFE TECH

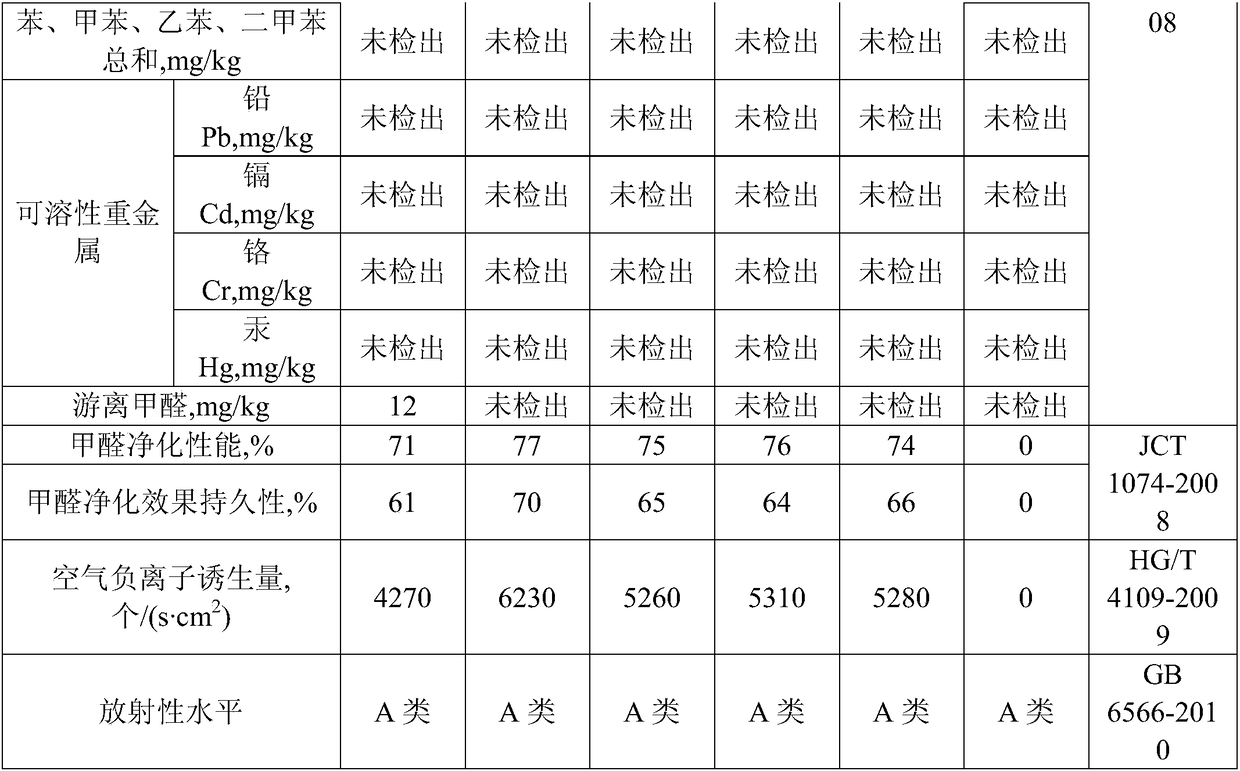

Corrosion resistant film prepared by magnesium alloy surface hydrothermal method and preparation technology thereof

ActiveCN103614717ASmall atomic radiusImprove polarization performanceMetallic material coating processesSolubilityLithium

The invention discloses a corrosion resistant film prepared by a magnesium alloy surface hydrothermal method and a preparation technology thereof, belongs to the technical field of magnesium surface processing, and solves the problem of bad corrosion resistant property of magnesium alloy in the prior art. The technology provided by the invention comprises the following steps: placing a processed magnesium alloy sample into a hydrothermal reactor, then injecting a treating fluid into the reactor according to a certain filling degree, and putting the reactor into a thermotank to maintain the temperature. The treating liquid comprises sodium hydroxide and lithium salt, sodium hydroxide provides a proper alkaline environment for film forming, lithium salt has a large solubility in water, Li+ can hydrolyze in water with a great amount at a certain temperature, so the pH value of the solution is improved so as to promote the film forming reactions on the magnesium alloy surface to move in the positive direction, the obtained film in situ grows on the magnesium alloy surface; the force between the film and the substrate body is excellent, the film is uniform, compact and ultra-thin, and has an excellent corrosion resistant property; the corrosion current density of the conversion film is increased by five magnitude orders compared to that of the substrate body, and reaches 10<-9> A / cm<2> magnitude grade.

Owner:曾荣昌

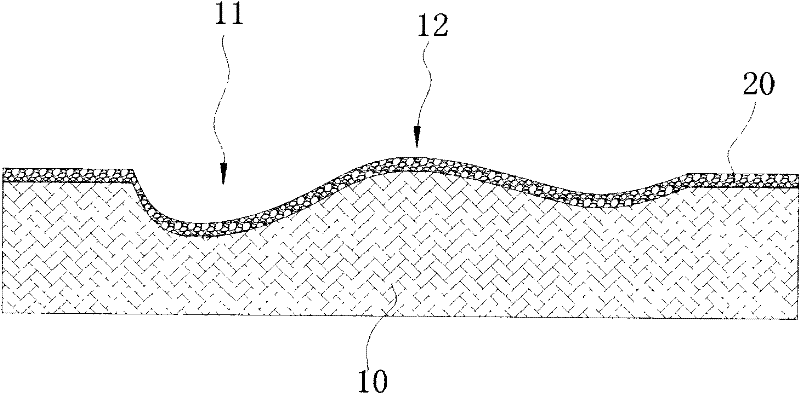

Art decoration wall panel and method of manufacturing the same

InactiveCN102296774ADecorativeGood to purify the environmentCovering/liningsCoatingsMetal sheetHardness

The present invention relates to art decoration boards, especially U-PVC foaming decoration boards, and the art decoration boards have the function of generating negative ions; the art decoration wall boards include a board body, at least one surface of the board body is coated with paint, and the paint adds 10-15% (parts by weight) of negative ion powder, the negative ion powder used is tourmaline powder with a particle size of 0.01-0.05 microns; the production steps include: shallow relief processing, deep relief processing, and paint coating; wherein the used powder for paint coating The paint is prepared by directly adding the anion powder into the UV curing paint in a proportion of 10-15% (parts by weight) and stirring evenly; the anion powder used is tourmaline powder with a particle size of 0.01-0.05 microns; It has a decorative effect, and has a better effect of purifying the environment; it is convenient to use; at the same time, the adhesion of the paint and the hardness after film formation are significantly improved.

Owner:GUANGZHOU GUANGYANG FU BULGARI HOME MATERIAL

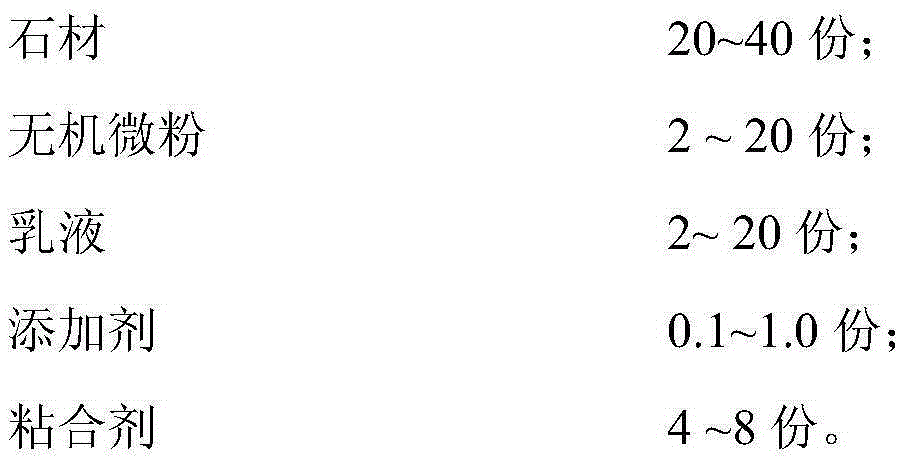

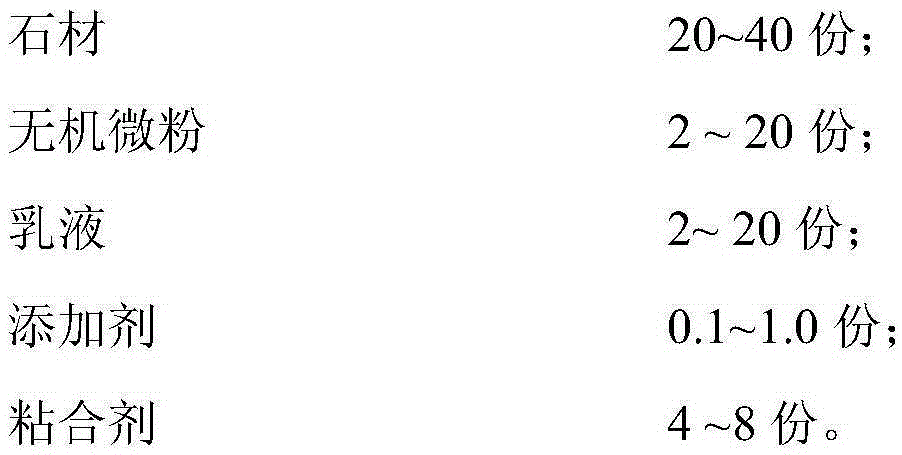

Composite stone material and preparation method of same

ActiveCN105236853ADecorativeImprove thermal insulation performanceWater-setting substance layered productEmulsionSurface layer

The invention discloses a composite stone material and a preparation method of the same. The composite stone material includes a stone material base layer and a sheet material layer, wherein the composite stone material includes the following raw materials, by weight: 20-40 parts of a stone material, 2-20 parts of inorganic micro powder, 2-20 parts of emulsion, 0.1-1.0 part of an additive and 4-8 parts of a binder. The preparation method includes the steps of: uniformly stirring the inorganic micro powder, the additive and other components according to certain process, and performing die-filling, allowing the materials to stand to foam the materials, maintaining the materials, and drying, cutting and polishing the materials to obtain the light-weight energy-saving sheet material; and binding the stone material to the light-weight heat-preservation sheet material through the binder, wherein the stone material is the decorative surface layer and the light-weight heat-preservation sheet material is a lining layer, to produce the composite stone material when the binder is hardened. The preparation method is simple. The composite stone material is excellent in comprehensive mechanical performance and is low in heat conductive coefficient, has a heat-preservation and -insulation effect, is green, energy-saving and environment-friendly, and can be widely used in various indoor and outdoor decoration projects having strict energy-saving demand.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com