Water-based crack paint as well as preparation method and application method thereof

A water-based crack paint and crack primer technology, applied in the field of coatings, can solve problems such as poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A water-based crack paint, comprising a top coat and a primer, wherein:

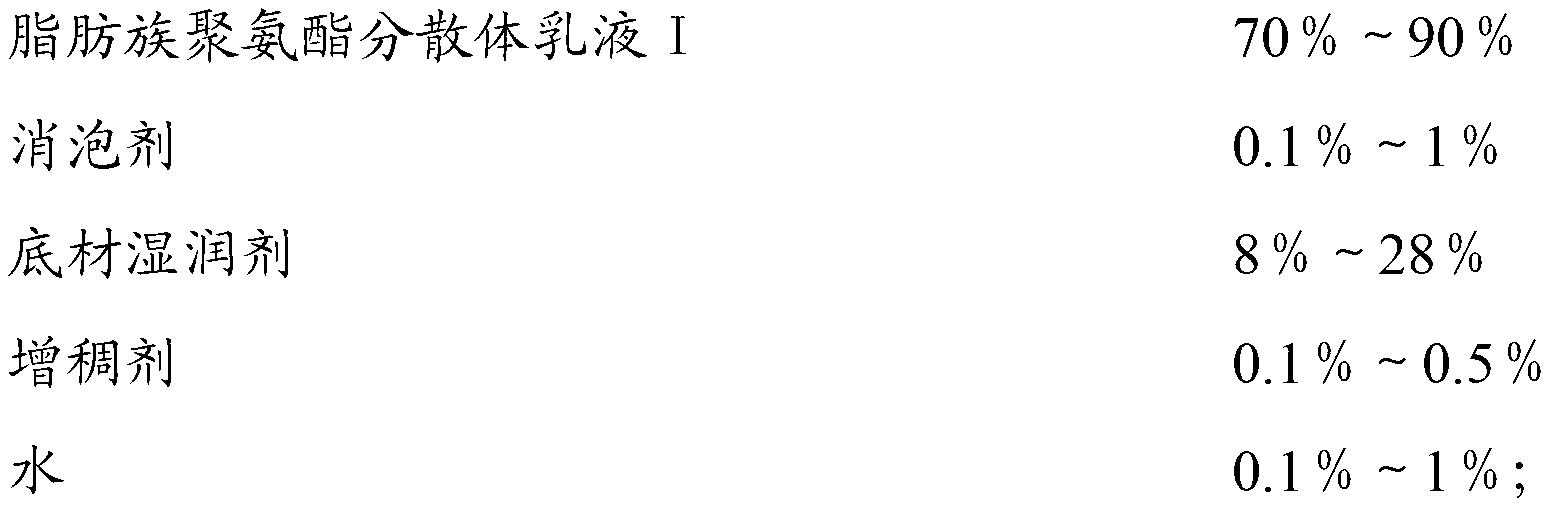

[0054] A water-based crack primer comprising the following substances in weight percent:

[0055] Aliphatic polyurethane dispersion emulsion 70%, defoamer 1%, substrate wetting agent 0.5%, thickener 1%, water 27.5%.

[0056] The method for preparing described water-based crack primer:

[0057] First place the aliphatic polyurethane dispersion emulsion in a stirring tank; then, add the defoamer, water, and substrate wetting agent under stirring, and stir for 15 minutes at 800rpm; finally add the thickening agent, stirred at 800rpm for 15 minutes to obtain the crack primer.

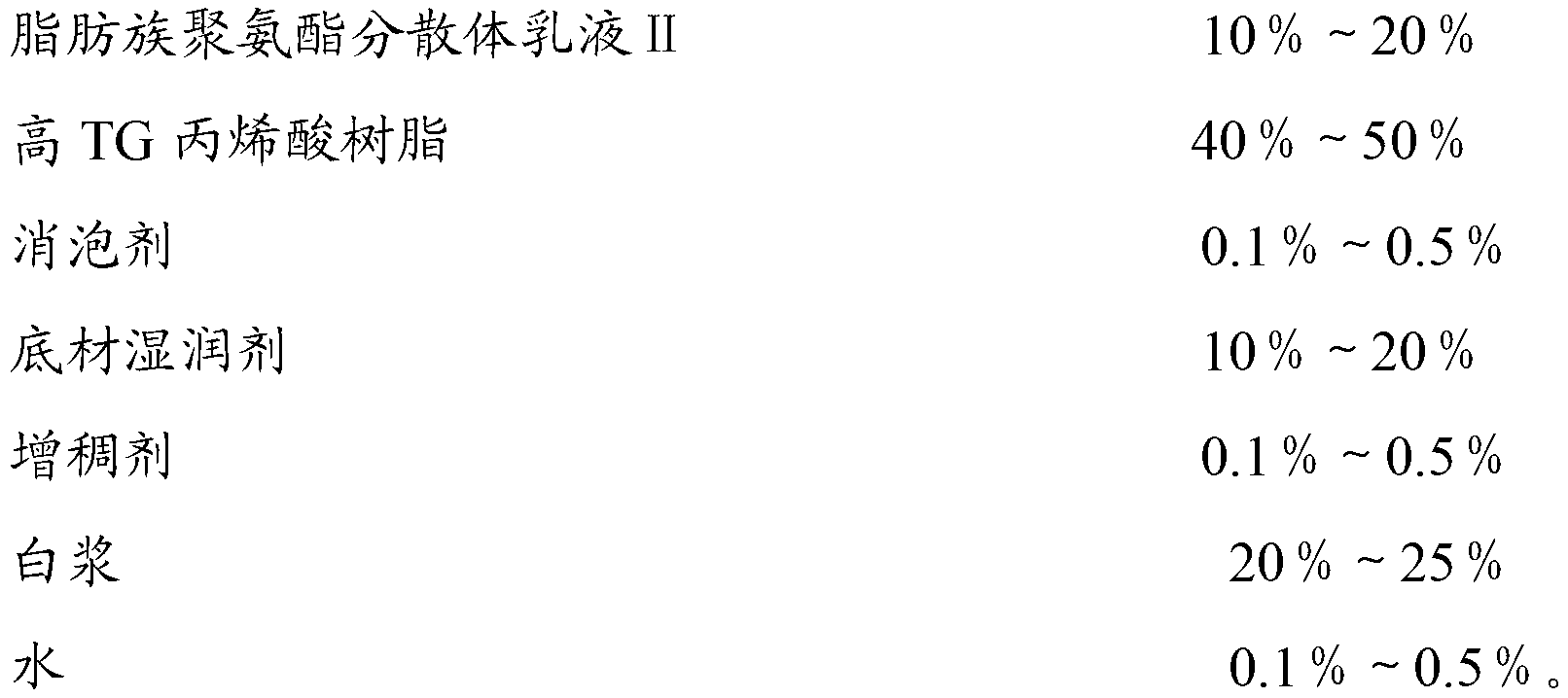

[0058] A water-based cracking topcoat comprising the following substances in weight percent:

[0059] Aliphatic polyurethane dispersion emulsion 10%, high TG acrylic resin 50%, defoamer 0.1%, substrate wetting agent 0.1%, thickener 0.1%, white paste 20%, water 19.7%.

[0060]Wherein, the white slurry includes the following ...

Embodiment 2

[0080] A water-based crack paint, comprising a top coat and a primer, wherein:

[0081] A water-based crack primer comprising the following substances in weight percent:

[0082] Aliphatic polyurethane dispersion emulsion 90%, defoamer 0.1%, substrate wetting agent 0.1%, thickener 0.1%, water 9.7%.

[0083] The method for preparing described water-based crack primer:

[0084] First place the aliphatic polyurethane dispersion emulsion in a stirring tank; then, add the defoamer, water, and substrate wetting agent under stirring, and stir for 5 minutes at 1200rpm; finally add the thickening agent, stirred at 1200rpm for 5 minutes to obtain the crack primer.

[0085] A water-based cracking topcoat comprising the following substances in weight percent:

[0086] Aliphatic polyurethane dispersion emulsion 20%, high TG acrylic resin 40%, defoamer 0.5%, substrate wetting agent 0.5%, thickener 0.5%, white paste 25%, water 13.5%.

[0087] Wherein, the white slurry includes the follow...

Embodiment 3

[0095] A water-based crack paint, comprising a top coat and a primer, wherein:

[0096] A water-based crack primer comprising the following substances in weight percent:

[0097] Aliphatic polyurethane dispersion emulsion 82%, defoamer 0.5%, substrate wetting agent 0.3%, thickener 0.5%, water 16.7%.

[0098] The method for preparing described water-based crack primer:

[0099] First place the aliphatic polyurethane dispersion emulsion in a stirring tank; then, add the defoamer, water, and substrate wetting agent under stirring, and stir for 10 minutes at 1000 rpm; finally add the thickening agent, stirred at 1000rpm for 10 minutes to obtain the crack primer.

[0100] A water-based cracking topcoat comprising the following substances in weight percent:

[0101] Aliphatic polyurethane dispersion emulsion 15%, high TG acrylic resin 45%, defoamer 0.3%, substrate wetting agent 0.4%, thickener 0.3%, white pulp 22%, water 17%.

[0102] Wherein, the white slurry includes the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com