Autogenously-pulverizable low calcium cement, and making method of prefabricated products thereof

A technology of pre-products and cement, which is applied in the field of preparation of self-pulverizing low-calcium cement and its pre-products. It can solve the problems of reduced cement performance, unsuitability for industrial applications, and low growth rate, and achieves reduced cement power consumption and short production cycles. , the effect of slowly increasing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of preparation method of self-pulverizing low-calcium cement pre-product is as follows:

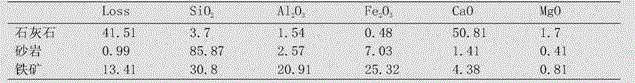

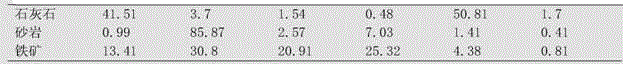

[0024] Step 1. Mix 70 parts of limestone, 20 parts of sandstone and 10 parts of iron ore. The chemical composition of the raw materials is shown in Table 1. After crushing and grinding, they are calcined in a rotary kiln at a calcining temperature of 1250 ° C and cooled naturally, which is obtained from Powdered low-calcium cement clinker, the CaO content in the cement is 52%, and the fineness of the raw material after grinding is controlled below 10%;

[0025] Step 2, 90 parts of the self-powdering low-calcium cement clinker prepared in step 1 was added to 10 parts of tap water, and after stirring evenly, the test block of 40×40×40 was obtained by extrusion molding on the molding equipment;

[0026] Step 3. Put the test block prepared in step 2 into the curing kettle, and feed high concentration CO 2 Industrial waste gas, control the pressure in the curing kettle at 0.5MPa...

Embodiment 2

[0030] A kind of preparation method of self-pulverizing low-calcium cement pre-product is as follows:

[0031] Step 1. Mix 70 parts of limestone, 20 parts of sandstone and 10 parts of iron ore. The chemical composition of the raw materials is shown in Table 2. After being crushed and ground, they are calcined in a rotary kiln at a calcining temperature of 1250° C. and cooled naturally, which is obtained from Powdered low-calcium cement clinker, the CaO content in the cement is 52%, and the fineness of the raw material after grinding is controlled below 10%;

[0032] Step 2. Add 90 parts of the self-powdering low-calcium cement clinker prepared in step 1 to 10 parts of tap water, stir evenly, and then extrude on a molding device to obtain a 100×100×10 sheet;

[0033] Step 3. Put the thin plate prepared in step 2 into the curing kettle, and pass high concentration CO 2 Industrial waste gas, control the pressure in the curing kettle at 0.5MPa, room temperature, curing for 5 hour...

Embodiment 3

[0038] A kind of preparation method of self-pulverizing low-calcium cement pre-product is as follows:

[0039] Step 1. Mix 60 parts of limestone, 35 parts of sandstone and 5 parts of iron ore. The chemical composition of the raw materials is shown in Table 3. After being crushed and ground, they are calcined in a rotary kiln at a calcining temperature of 1200° C. and cooled naturally, which is obtained from Powdered low-calcium cement clinker, the CaO content in the cement is 42%, and the fineness of the raw material after grinding is controlled below 10%;

[0040] Step 2, 90 parts of the self-powdering low-calcium cement clinker prepared in step 1 was added to 10 parts of tap water, and after stirring evenly, the test block of 40×40×40 was obtained by extrusion molding on the molding equipment;

[0041] Step 3. Put the test block prepared in step 2 into the curing kettle, and feed high concentration CO 2 Industrial waste gas, control the pressure in the curing kettle at 0.6M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com