Production method and system of profile

A production system and production method technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of easy-to-crack saw blades, decreased precision, and the inability to process profiles at one time, so as to achieve good decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preferred embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: It should be understood that the preferred embodiments are only for illustrating the present invention, not for limiting the protection scope of the present invention.

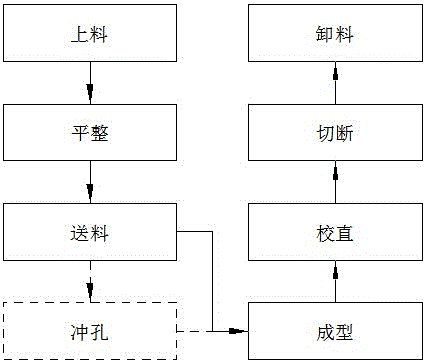

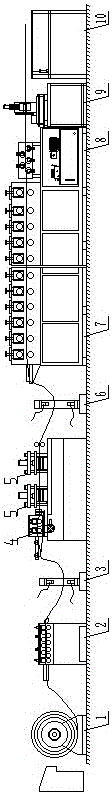

[0043] Such as Figure 1~13 Among them, a production method of profiles, which includes feeding, feeding, forming and cutting processes, the process steps are as follows:

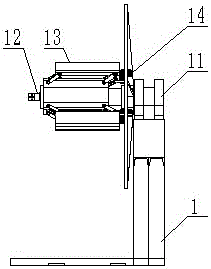

[0044] Loading, place the steel coil formed by the steel strip on the rotating shaft of the feeding device base, and fasten or limit the position through the tensioning device and the limiting device;

[0045] Feeding, the steel belt is pressed tightly by the feeding roller group, and enters the next process under the power drive;

[0046] Forming, the steel strip is rolled and bent by the forming roller to form an integrated profile, and the profile is inserted into the pressing device, and the pressing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com