Thermosetting acrylic resin for powder coating as well as synthesis method and applications of thermosetting acrylic resin

A technology of acrylic resin and powder coating, applied in coating and other directions, can solve the problems of lack of promotion, high price, complex synthesis process, etc., and achieve the effects of no industrial waste pollution, uniform molecular weight, excellent surface hardness and high gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

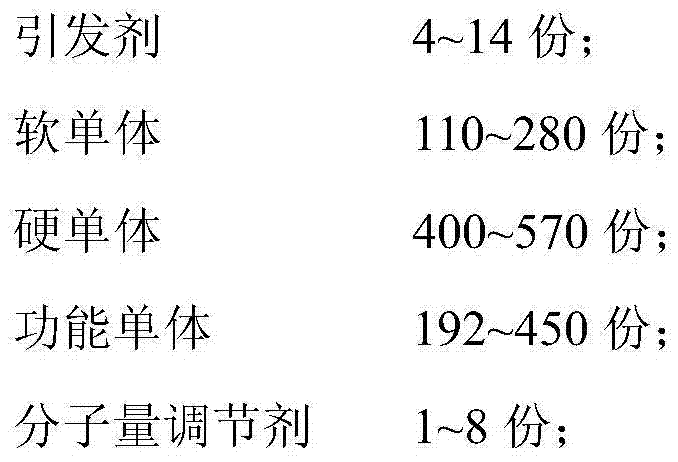

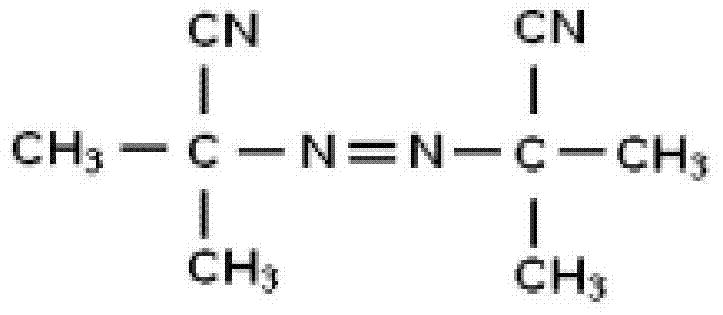

[0053] A thermosetting acrylic resin for powder coatings, its raw material components and parts by weight are as follows:

[0054]

[0055] The synthetic method of thermosetting acrylic resin for powder coating as mentioned above, the steps are as follows:

[0056] (1) Pump 950L of xylene solvent (accounting for 95% of the total amount of solvent, the remaining 5% with 10% of the initiator is mixed for the final addition), fill the nitrogen protection from the bottom of the reaction kettle, start the stirrer, and slowly raise the temperature, and raise the temperature of the solvent in the kettle to 120±3°C (120±3°C) within 30 to 60 minutes ℃ is the temperature when xylene or ethylene glycol monomethyl ether is used as the solvent, if toluene is used as the solvent, it is 110 ℃), maintain the temperature and fill the whole process with nitrogen protection;

[0057] (2) The first five kinds of materials in the present embodiment are weighed in parts by weight, mixed with in...

Embodiment 2

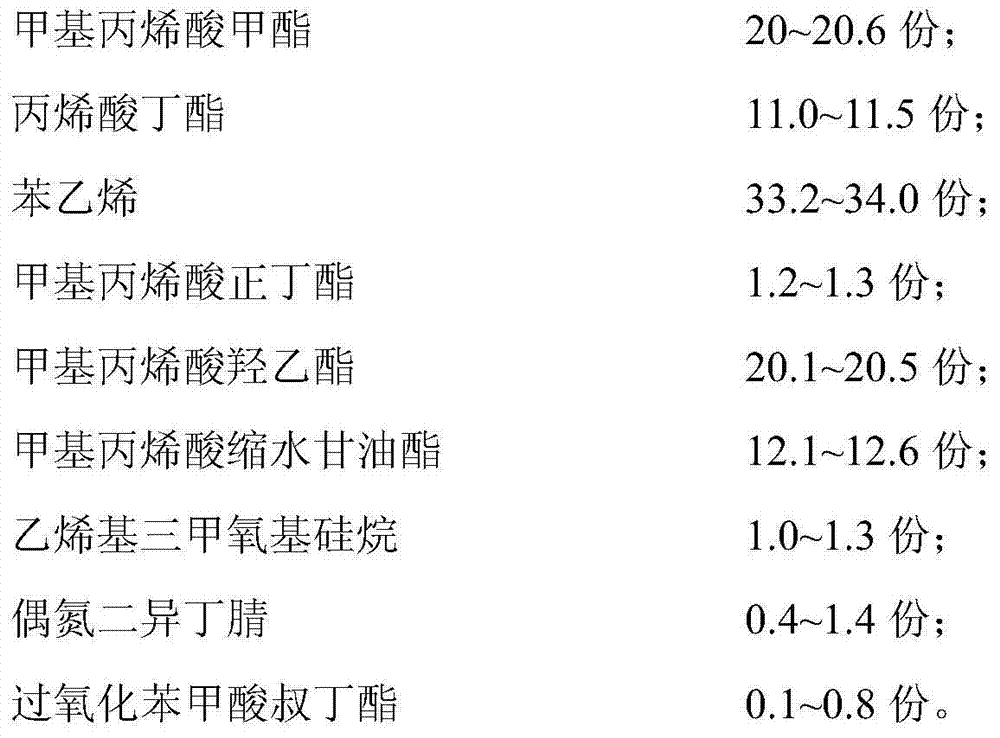

[0063] A thermosetting acrylic resin for powder coatings, its raw material components and parts by weight are as follows:

[0064]

[0065]

[0066] The synthetic method of thermosetting acrylic resin for powder coating as mentioned above is the same as that of Example 1.

Embodiment 3

[0068] A thermosetting acrylic resin for powder coatings, its raw material components and parts by weight are shown in Table 1:

[0069] Table 1 The components and contents of thermosetting acrylic resin for powder coatings

[0070]

[0071] The synthetic method of thermosetting acrylic resin for powder coating as mentioned above is the same as that of Example 1.

[0072] The indexes of thermosetting acrylic resin for powder coating of the present invention are as follows:

[0073]

[0074] It can be seen from the above indicators that the thermosetting acrylic resin for powder coatings meets the standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com