Patents

Literature

78 results about "Noise reduction coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Noise Reduction Coefficient (commonly abbreviated NRC) is a logarithmic representation of the decay rate (dB/s) due to a panel or object with a defined surface area absorbing energy compared to the decay rate in a standard reverberant room without the panel or object. An NRC of 0 indicates the object does not contribute to attenuating sound for frequencies at 250 Hz, 500 Hz, 1000 Hz, and 2000 Hz range; an NRC of 1 indicates an average attenuation of sound per unit area that's equal to the average attenuation and transmittance of sound found in a reverberant room that meets the ASTM C423 standard for construction, size, shape, sound diffusion, and background noise, and decay rate for frequencies between 100 Hz and 5000 Hz. The NRC is highly dependant on the type of mounting,, which, if not specified, is usually a Type A mounting (ABPMA mounting #4) where the material is placed directly on the floor, wall, or ceiling.

Sound-absorbing coating material and preparation method thereof

ActiveCN102533016AImprove sound absorptionNon-combustibleCoatingsNoise reduction coefficientGlass fiber

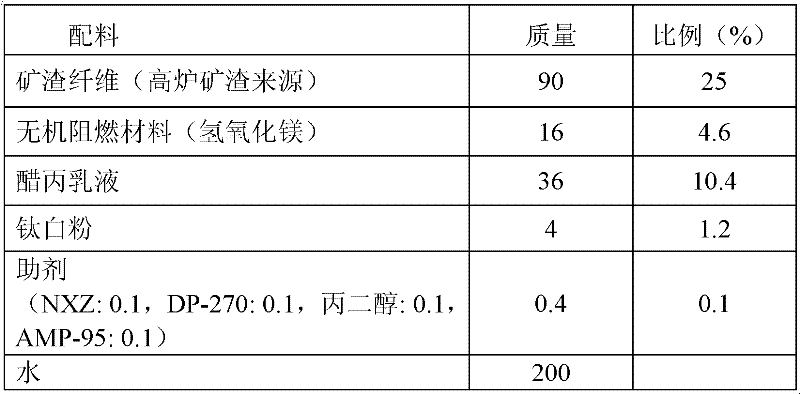

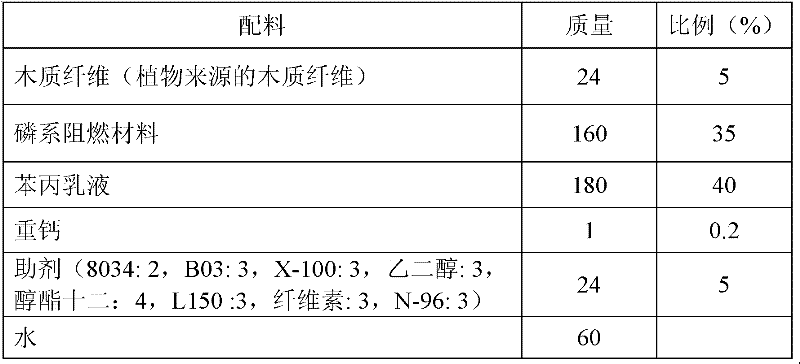

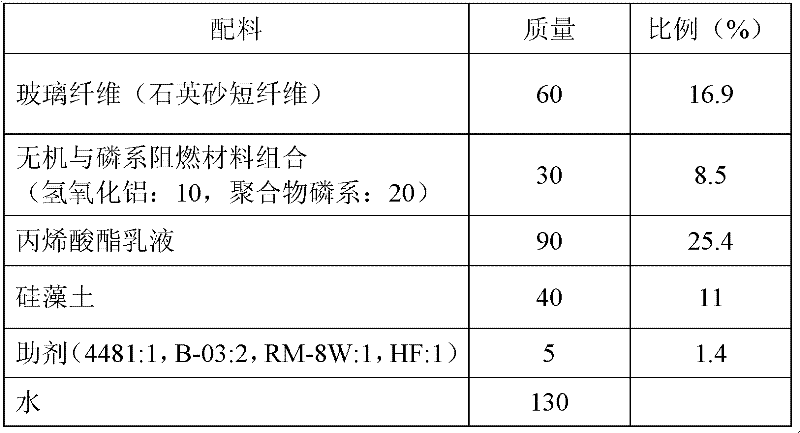

The invention discloses a sound-absorbing coating material, wherein every 100 parts by mass of coating contains 5-50 parts by mass of sound-absorbing function materials, 0.1-35 parts by mass of flame retardant materials, 10-40 parts by mass of binding materials, and the balance of an inorganic filling, an assistant and water in a common coating. The sound-absorbing function materials are selected from one or composite of some of materials such as slag fibers, mineral fibers, glass fibers and wood fibers, with fiber structures, and the sound-absorbing function materials are subjected to waterproof modification treatment. According to the invention, NRC (Noise Reduction Coefficient) of the coating material is tested to be more than 0.4 by using a standing wave tube method, and the sound-absorbing coating material has a good sound-absorbing denoising performance, excellent flame resistance and low heat conductivity coefficient, can be used for reducing the energy consumption of a building, is an environmental-friendly functional sound-absorbing coating material integrated with functions of sound absorption, flame resistance and decoration, and can be used on the surface of the building.

Owner:CHINA BUILDING MATERIALS ACAD

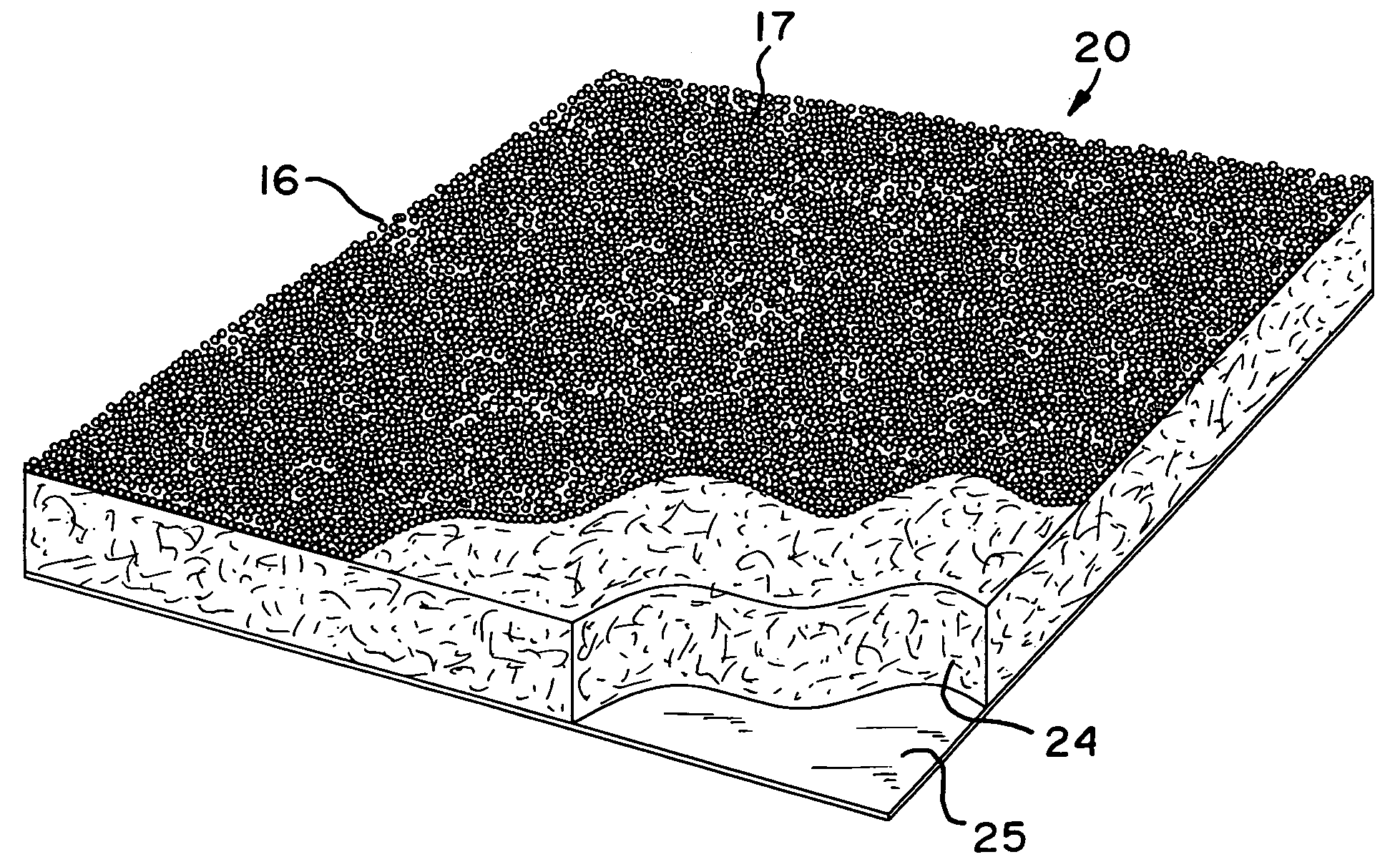

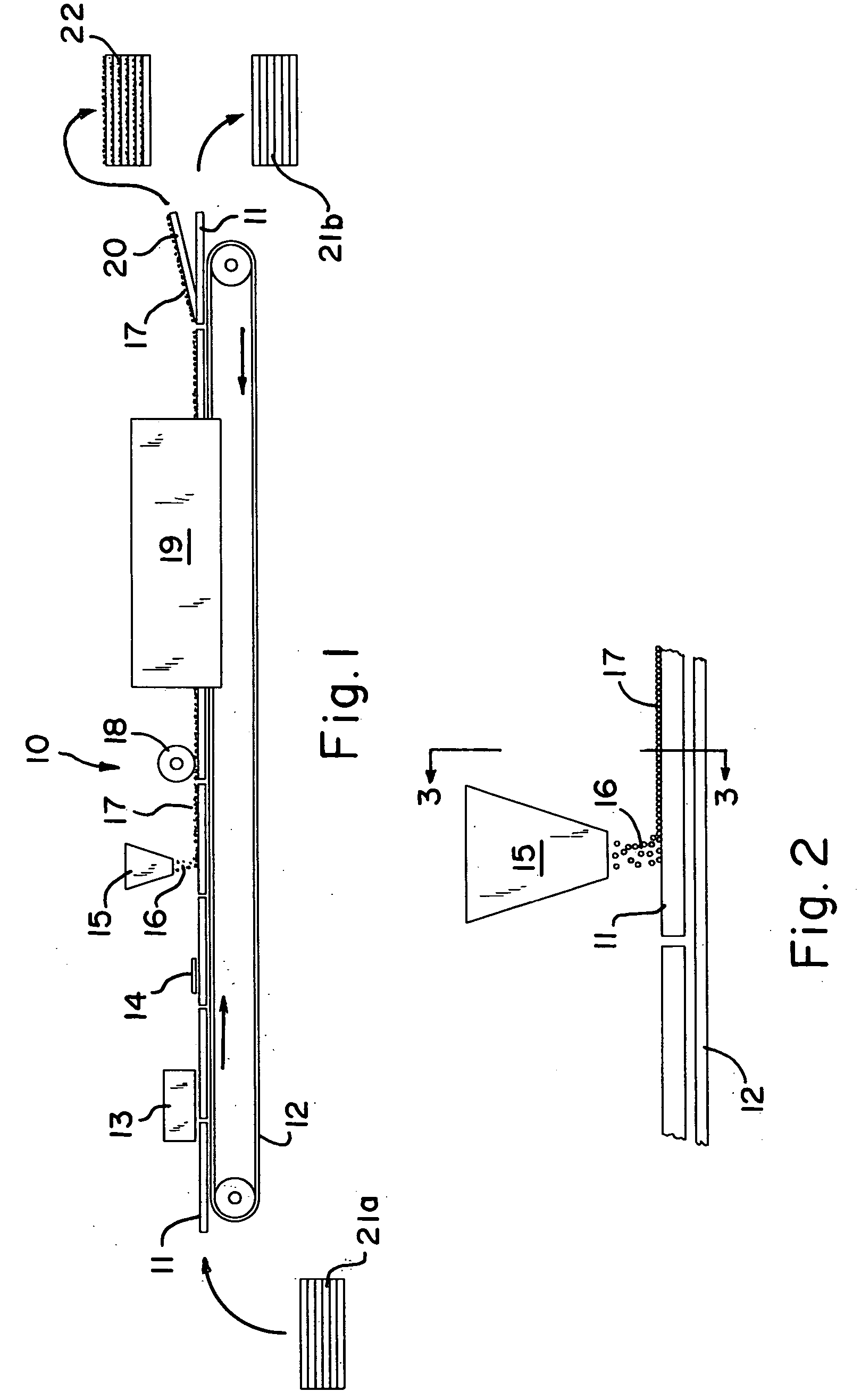

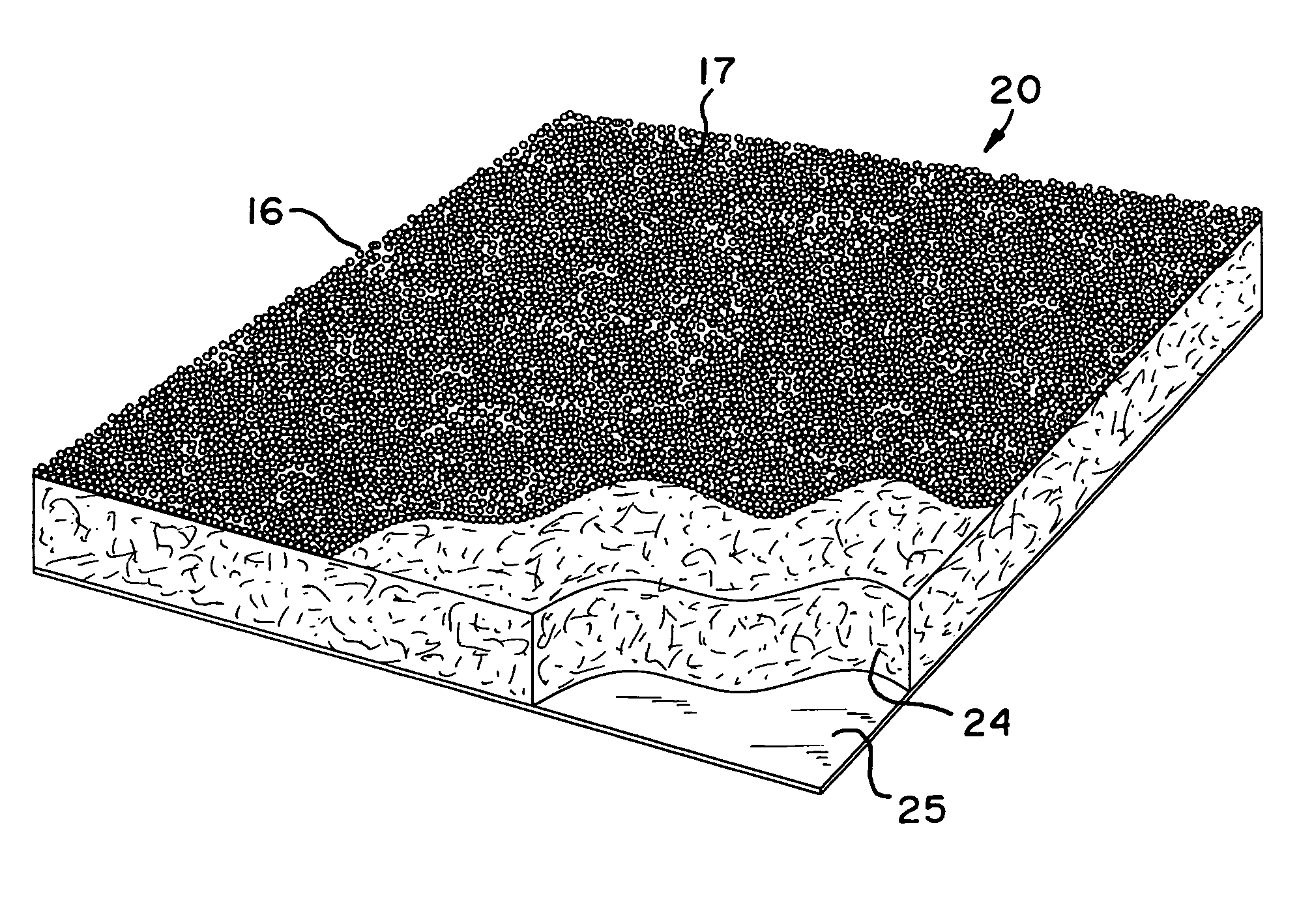

Abuse-resistant cast acoustical ceiling tile having an excellent sound absorption value

An abuse-resistant, cast acoustical ceiling tile having improved impact resistance and excellent sound absorption values. The ceiling tiles have aggregate particles applied to the surface of a wet pulp in the casting process and the particles are embedded in the pulp by compression with a roll and / or smooth plates. The aggregate particles have an average particle diameter of at least about 1,000 microns. The ceiling tiles have excellent sound absorption properties with a noise reduction coefficient (NRC) of at least about 0.50. Calcium carbonate is the preferred aggregate particle material.

Owner:USG INTERIORS INC

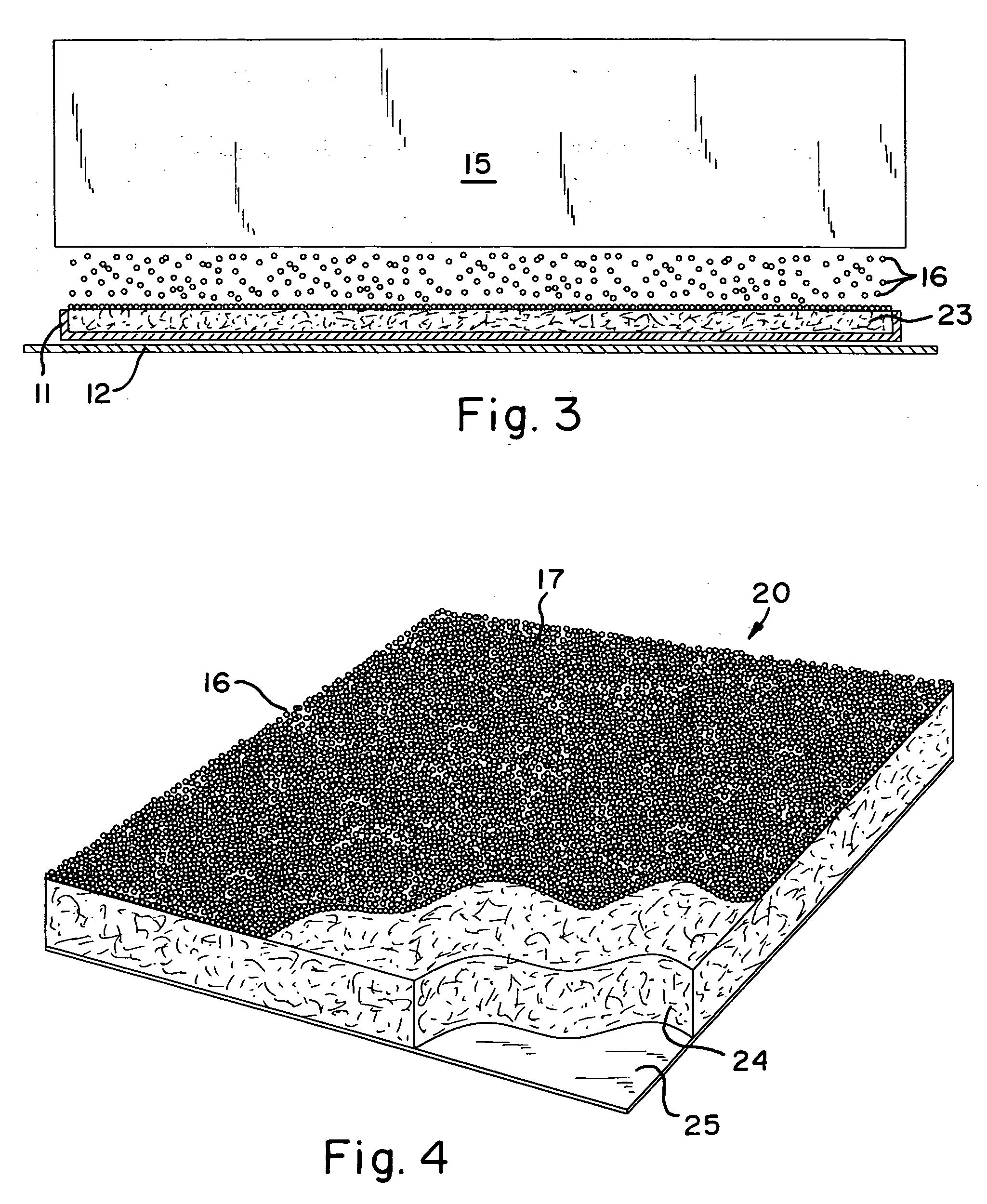

Three-dimensional porous framework-reinforced fiber sponge containing high-efficiency sound-absorbing material and preparation thereof

InactiveCN107116857AImproved dissipation capacityAct as a reflectionSynthetic resin layered productsCellulosic plastic layered productsNoise reduction coefficientFiber

The invention provides a three-dimensional porous framework-reinforced fiber sponge containing high-efficiency sound-absorbing material and preparation thereof. The three-dimensional porous framework-reinforced fiber sponge containing high-efficiency sound-absorbing material is characterized by comprising three-dimensional porous framework-reinforced fiber sponge and a microporous membrane compounded on the three-dimensional porous framework-reinforced fiber sponge. The sound-absorbing material is the high-efficiency sound-absorbing material obtained by introducing a three-dimensional porous framework with certain mechanical strength as a main body supporting reinforcing structure, putting the three-dimensional porous framework into flame retardant-containing fiber slurry, forming the slurry, drying a solvent, curing to obtain the reinforced fiber sponge with a reinforcing framework therein, and compounding the reinforced fiber sponge with the microporous membrane. The noise reduction coefficient (NRC) of the obtained sound-absorbing material is 0.34-0.59; and the sound-absorbing material shows relatively high sound-absorbing performance.

Owner:DONGHUA UNIV

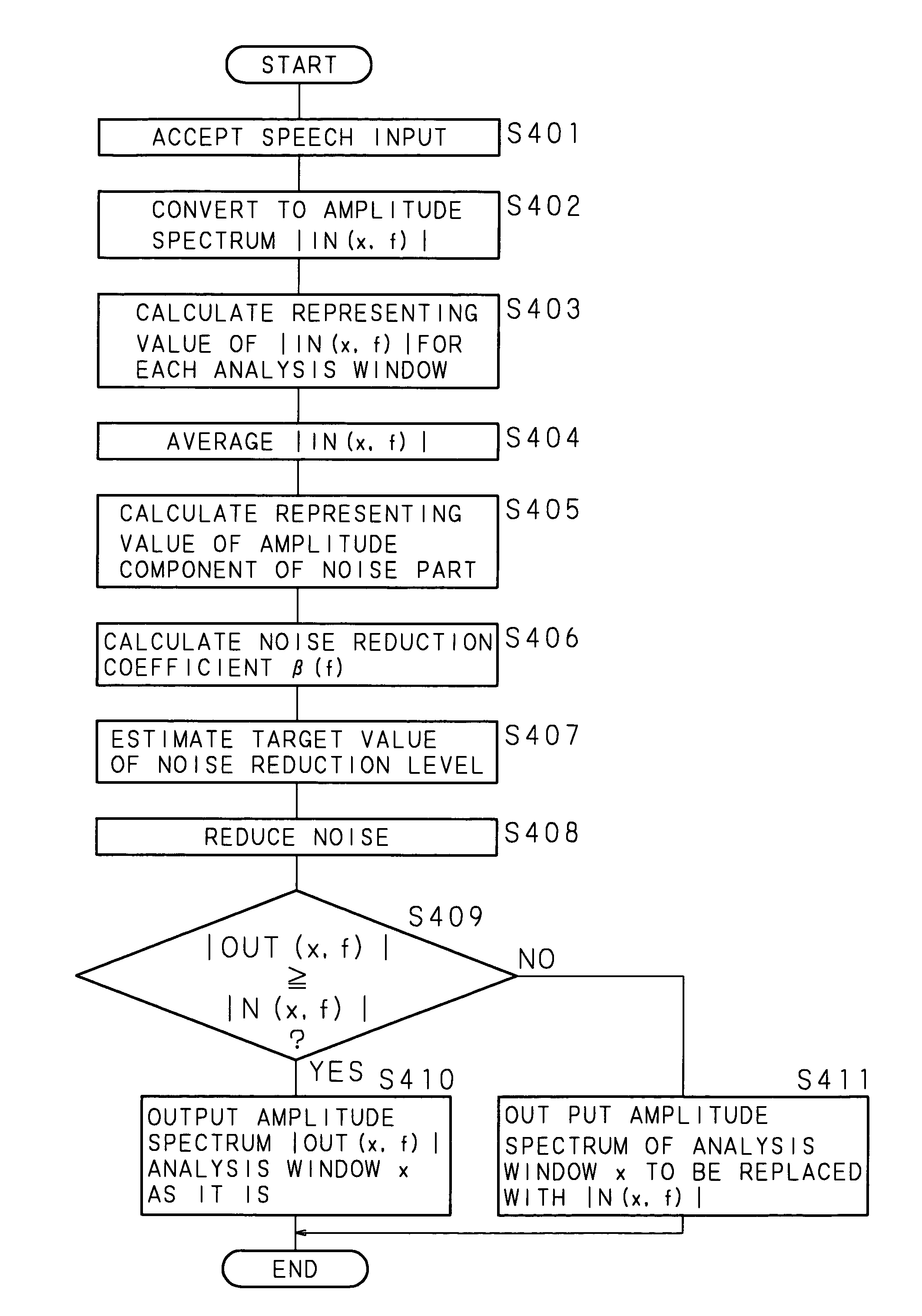

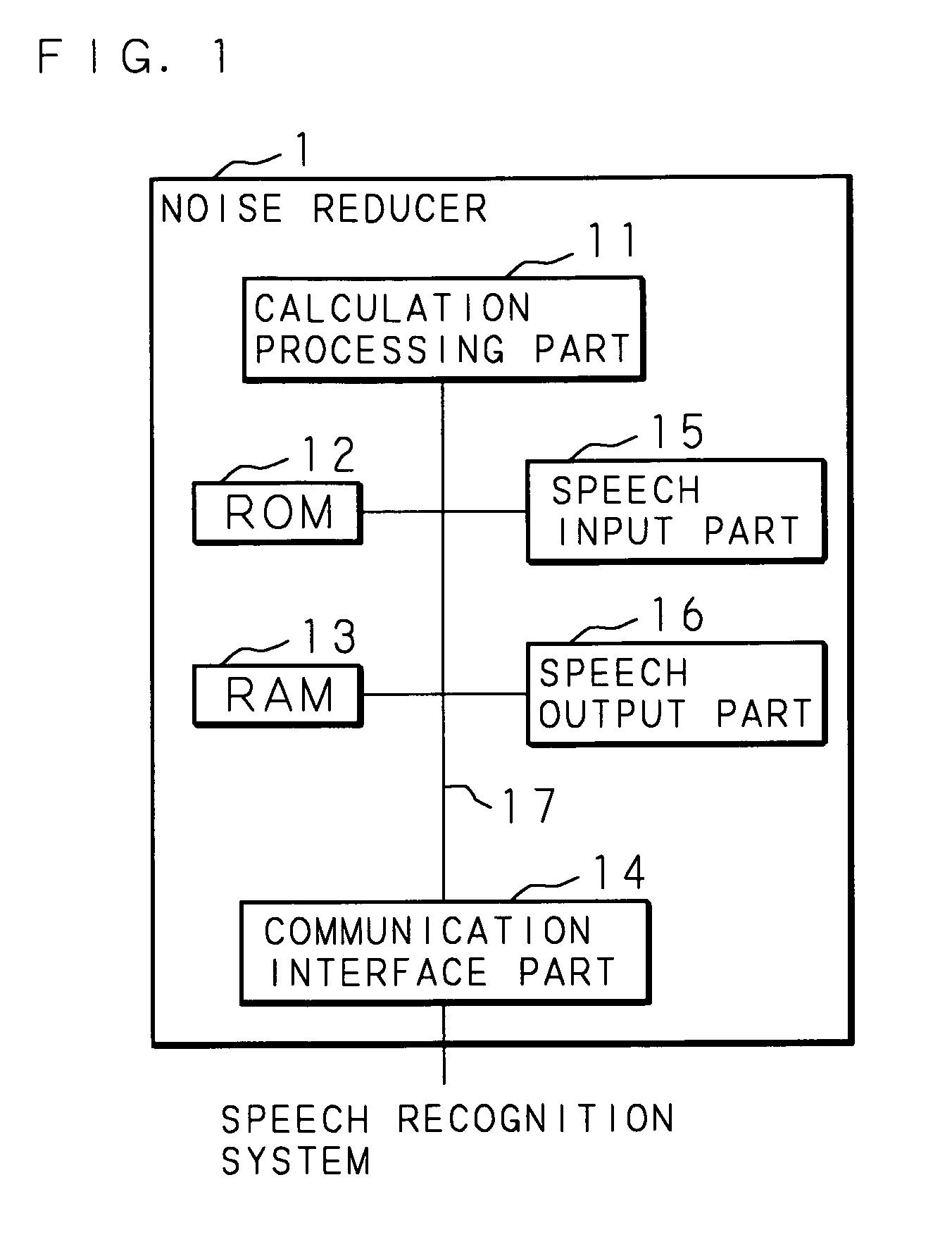

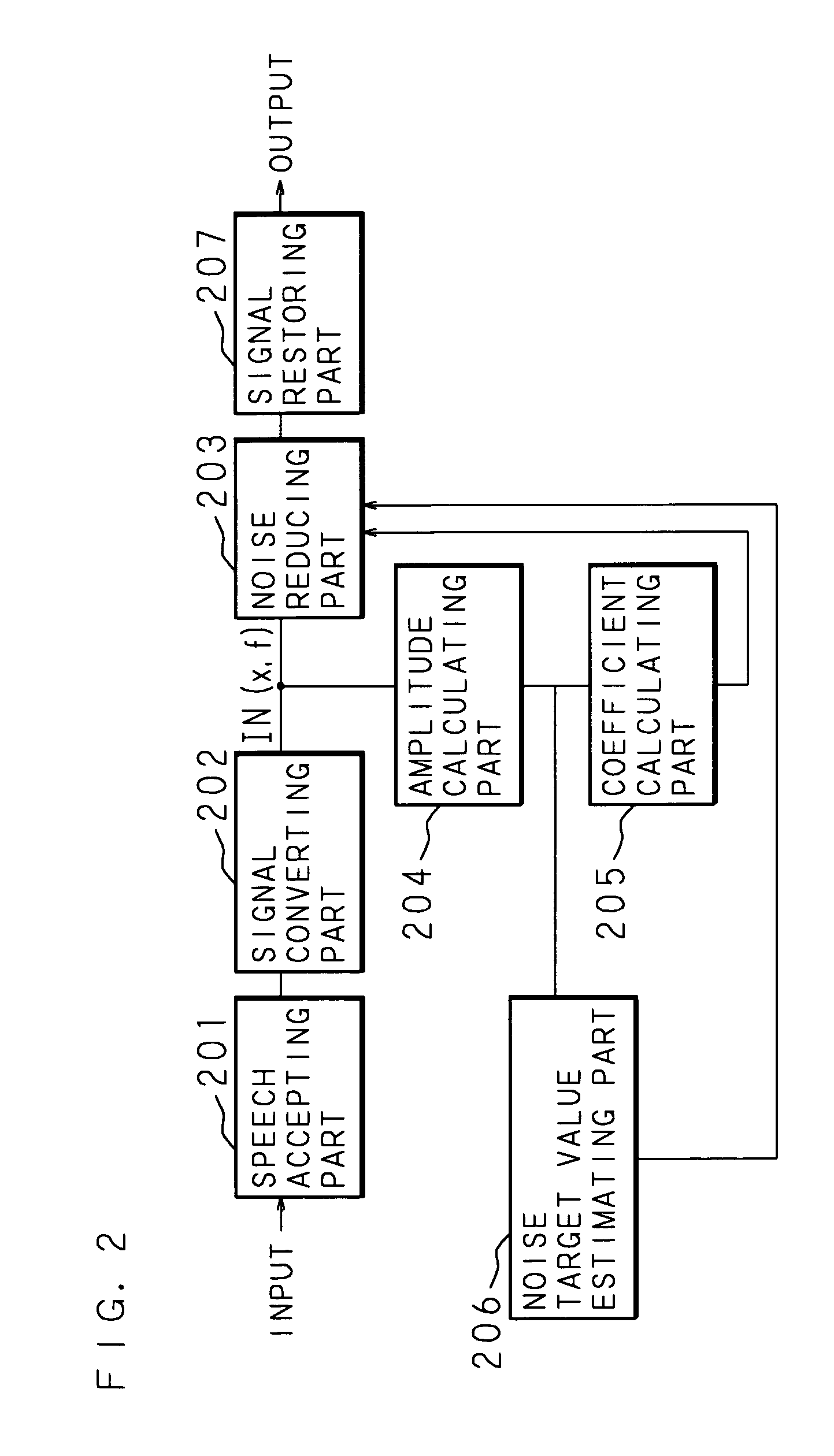

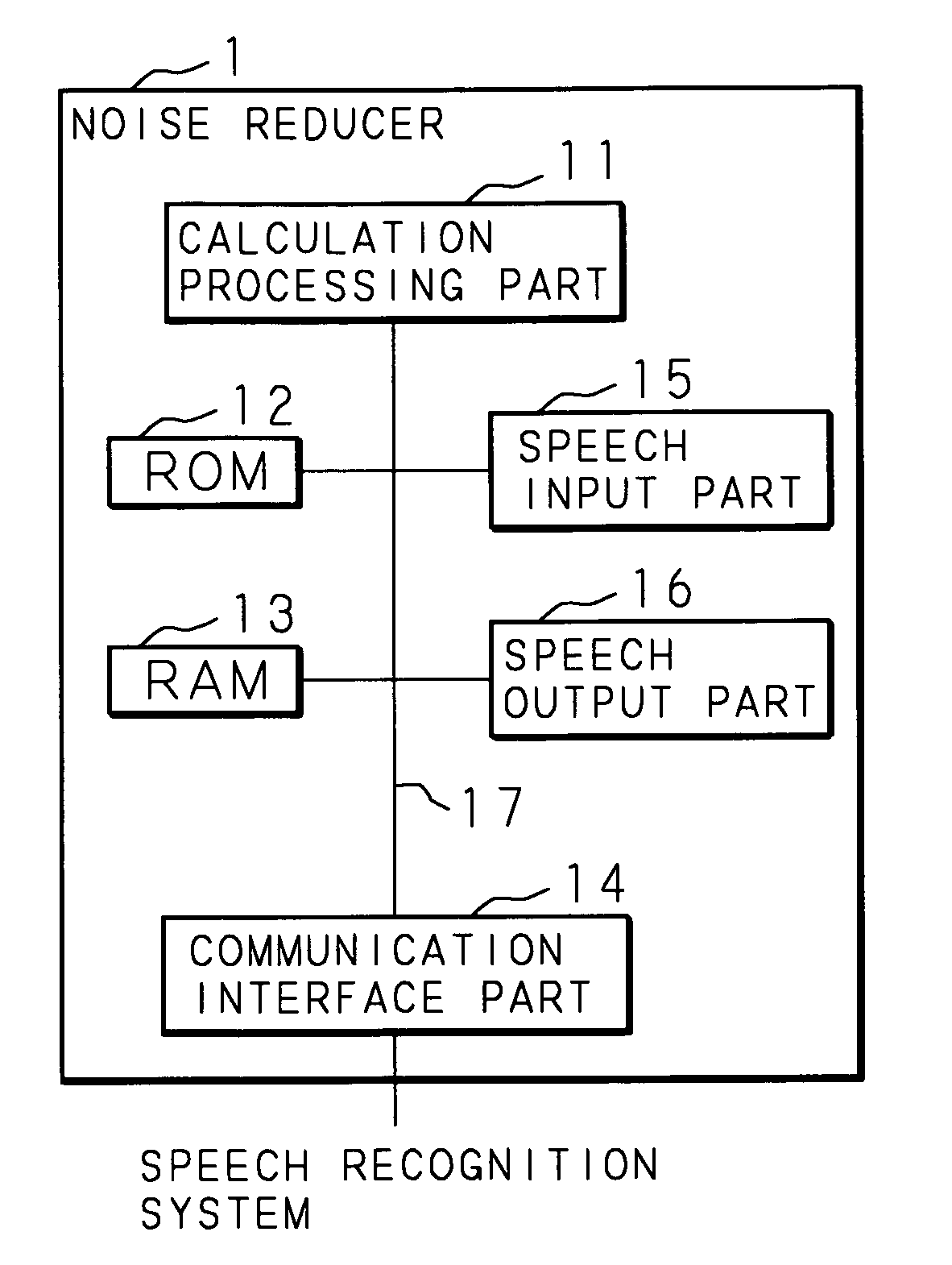

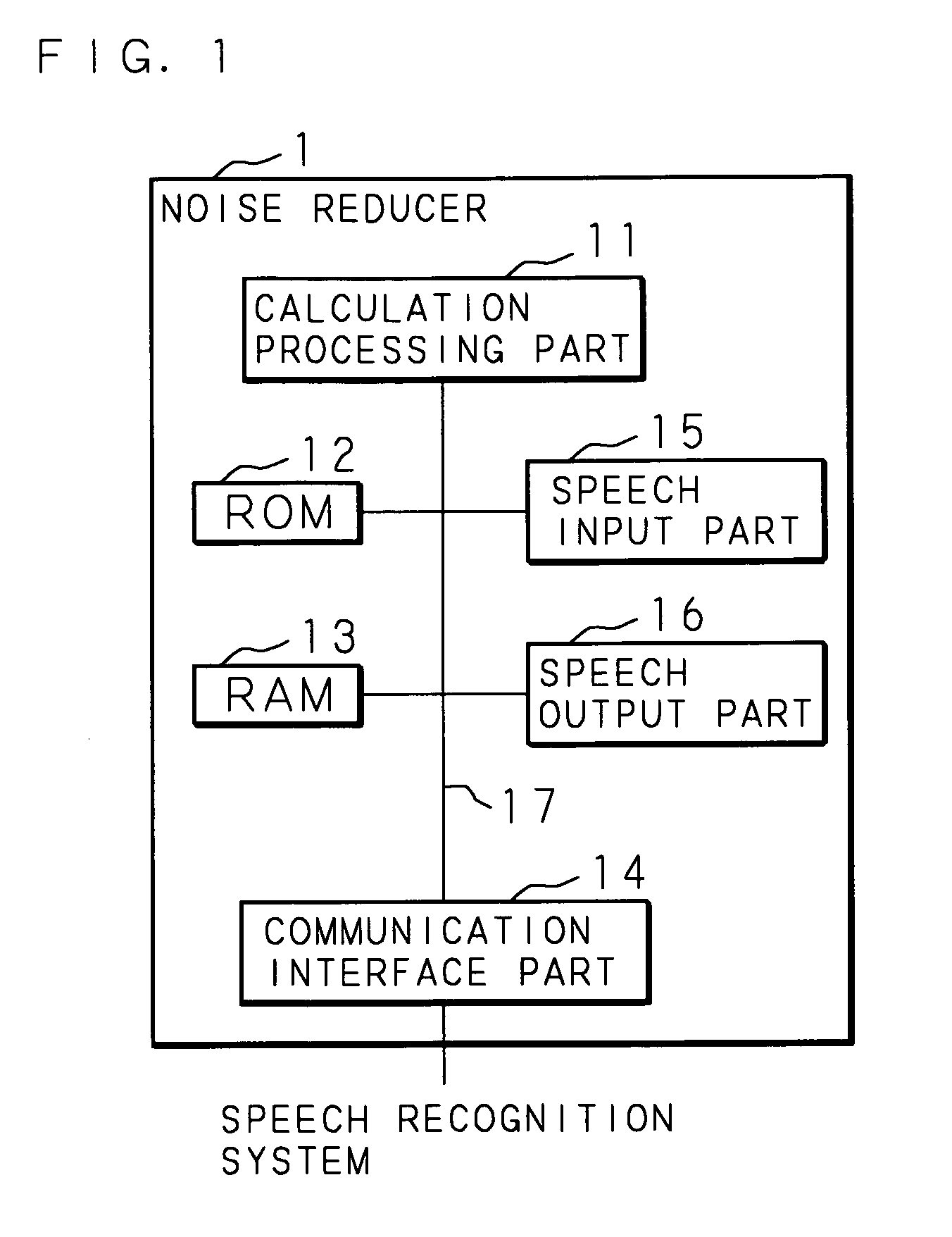

Noise reducer, noise reducing method, and recording medium

Owner:FUJITSU LTD

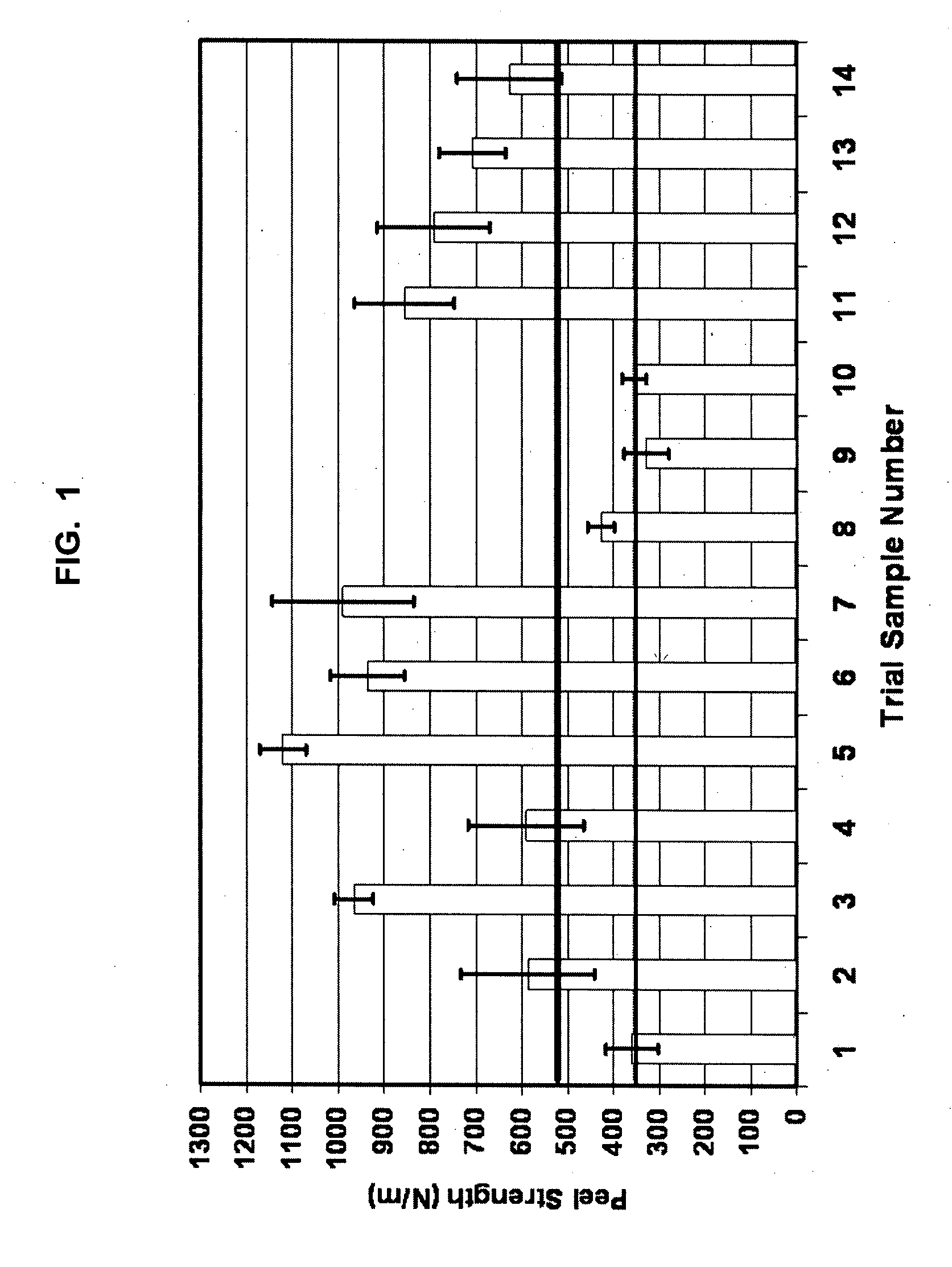

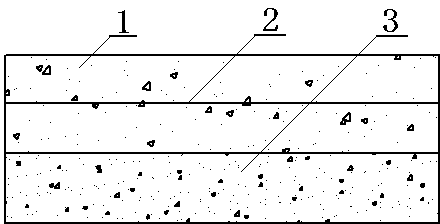

Moldable composite sheet with improved adhesion at elevated service temperatures

InactiveUS20080032094A1Improved thermal adhesive characteristicImprove adhesionThin material handlingMetal layered productsThermoplasticMetal forming

A moldable composite sheet having improved adhesion characteristics, particularly at elevated service temperatures, as well as improved sound absorption and attenuation of transmitted sound intensities. In one aspect, the composite sheet may be a porous fiber-reinforced thermoplastic comprising discontinuous reinforcing fibers and having an adhesive skin layer covering. Generally, the-composite sheet may have a void content or porosity from about 5% to about 95% by volume of the sheet, an areal weight between about 400 g / m2 to about 4000 g / m2 and a fiber content from about 20% to about 98% by weight. The composite sheet can be molded via low pressure processes, such as thermoforming, match metal molding on stops, vacuum forming and pressure forming, to produce durable automotive interior trim parts capable of withstanding service temperatures exceeding 100° C. for extended periods of time along with improved sound absorption capabilities exceeding a noise reduction coefficient (NRC) rating of 0.5.

Owner:AZDEL INC

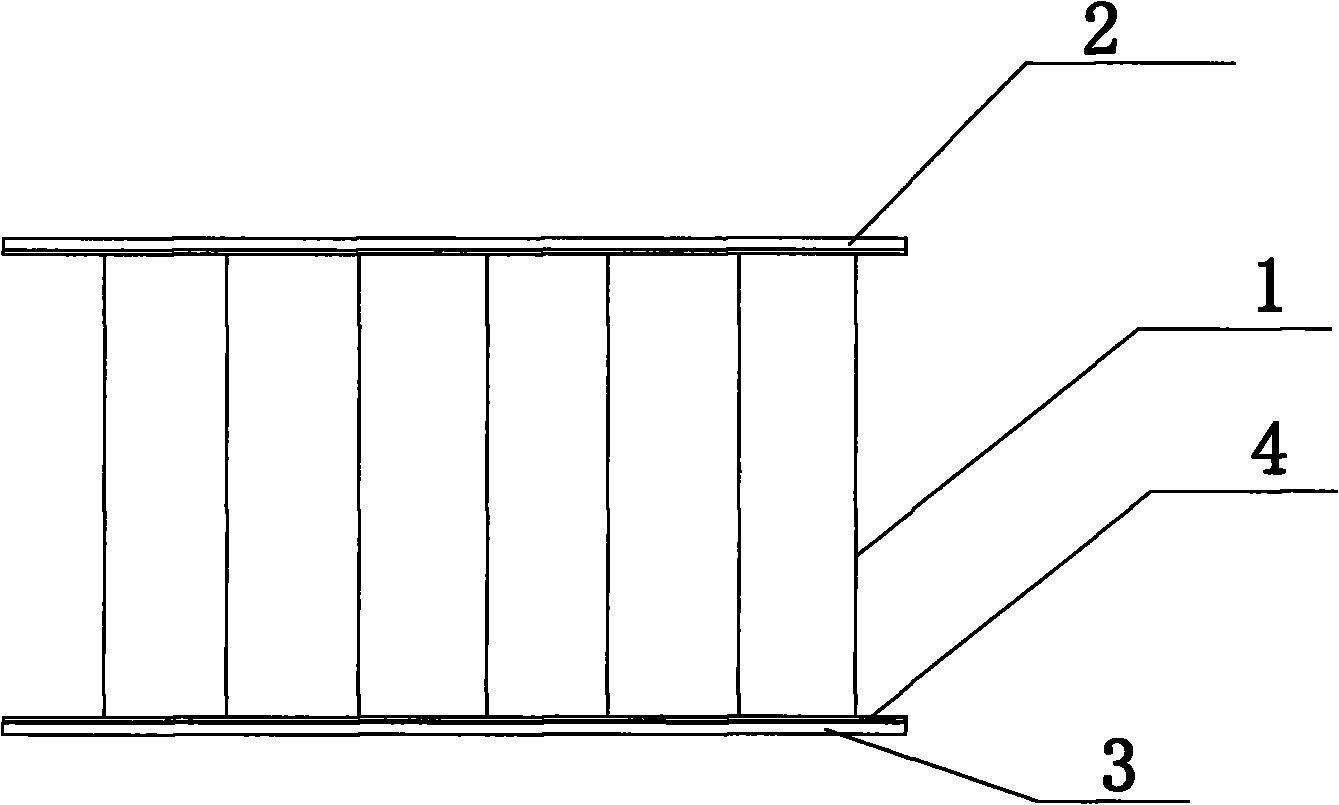

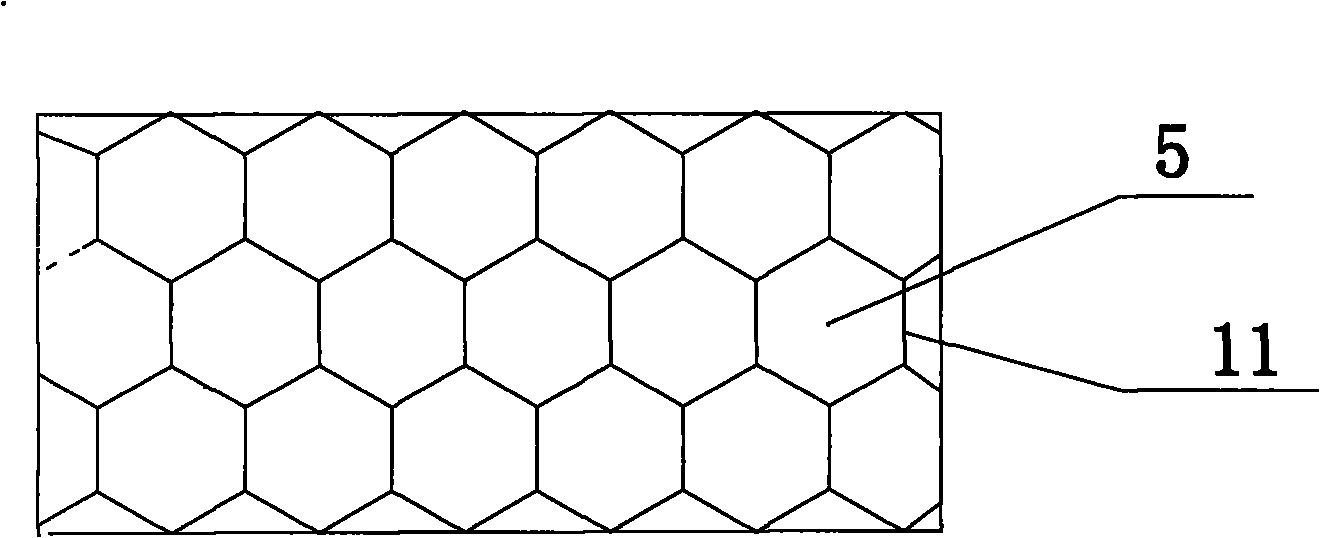

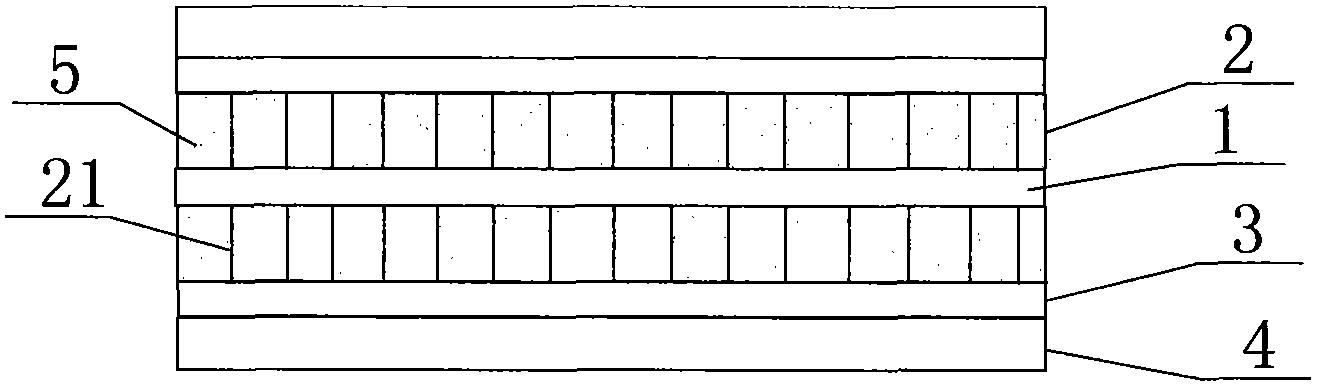

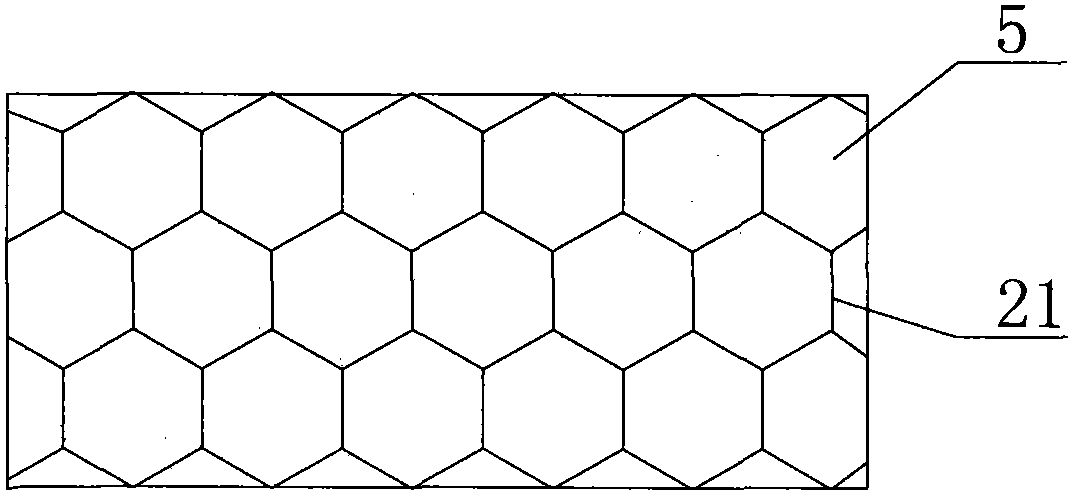

A kind of honeycomb sound-absorbing panel and its production process

InactiveCN102261139ATo achieve sound-absorbing effectHigh noise reduction factorSound proofingMetal layered productsNoise reduction coefficientPublic place

The invention discloses a honeycomb sound-absorbing panel and a production process thereof, which comprises a three-layer structure, the middle layer is a hexagonal honeycomb core, the upper surface of the hexagonal honeycomb core is provided with a supporting sheet; The invention fills the hexagonal honeycomb cavity with sound-absorbing materials such as filling the hexagonal honeycomb cavity, and the sound wave passes through the microporous aluminum plate and is absorbed by the sound-absorbing material in the hexagonal honeycomb core to achieve the sound-absorbing effect, and can be used for sound-absorbing ceilings and walls in public places. Such as the ceilings and walls of airport waiting halls, stadiums, conference halls and other places, the noise reduction coefficient is high, which can reach more than 0.8, and it can be used as a large-area wide-slab ceiling. It is beautiful, light in weight and no deformation.

Owner:青岛同力得塑料蜂巢有限公司

Acoustic absorption polymer foam having improved thermal insulating performance

InactiveUS7018700B2Increase contentButtonsLayered productsLow-density polyethyleneAcoustic absorption

Polymer foams having a good balance of high sound absorption, low thermal conductivity and generally low water absorption are disclosed which are obtainable by perforating (i.e., hole punching) a polymer foam having a moderately large cell size (1.5 mm to 4 mm) and an open content not greater than 40 percent to increase the open cell content of the foam by at least about 10 percent relative to the non-perforated foam, the polymer foam matrix preferably made of a thermoplastic foam, such as a low-density polyethylene (LDPE) resin, a high melt strength (HMS) polypropylene resin (PP), or a blend of an HMS PP resin and an LDPE resin, optionally containing a cell size enlarging agent such as glycerol monostearate, an antioxidant, carbon black and / or flame retardant additives, using a volatile organic compound, e.g. isobutane, as blowing agent. These foams are useful for applications in which a combination of acoustic absorption, thermal insulation and possibly low water absorption is needed, such as outdoor, motor vehicle and marine applications. They exhibit a noise reduction coefficient greater than 0.3, a thermal conductivity not greater than 90 mW / m° K measured at an average temperature of 10° C. according to DIM52616 and a low (less than 10, such as less than 1.5, percent by volume) water absorption when measured according to EN 12088 at a 50° C. temperature gradient for an exposure test period of 14 days.

Owner:SEALED AIR U S

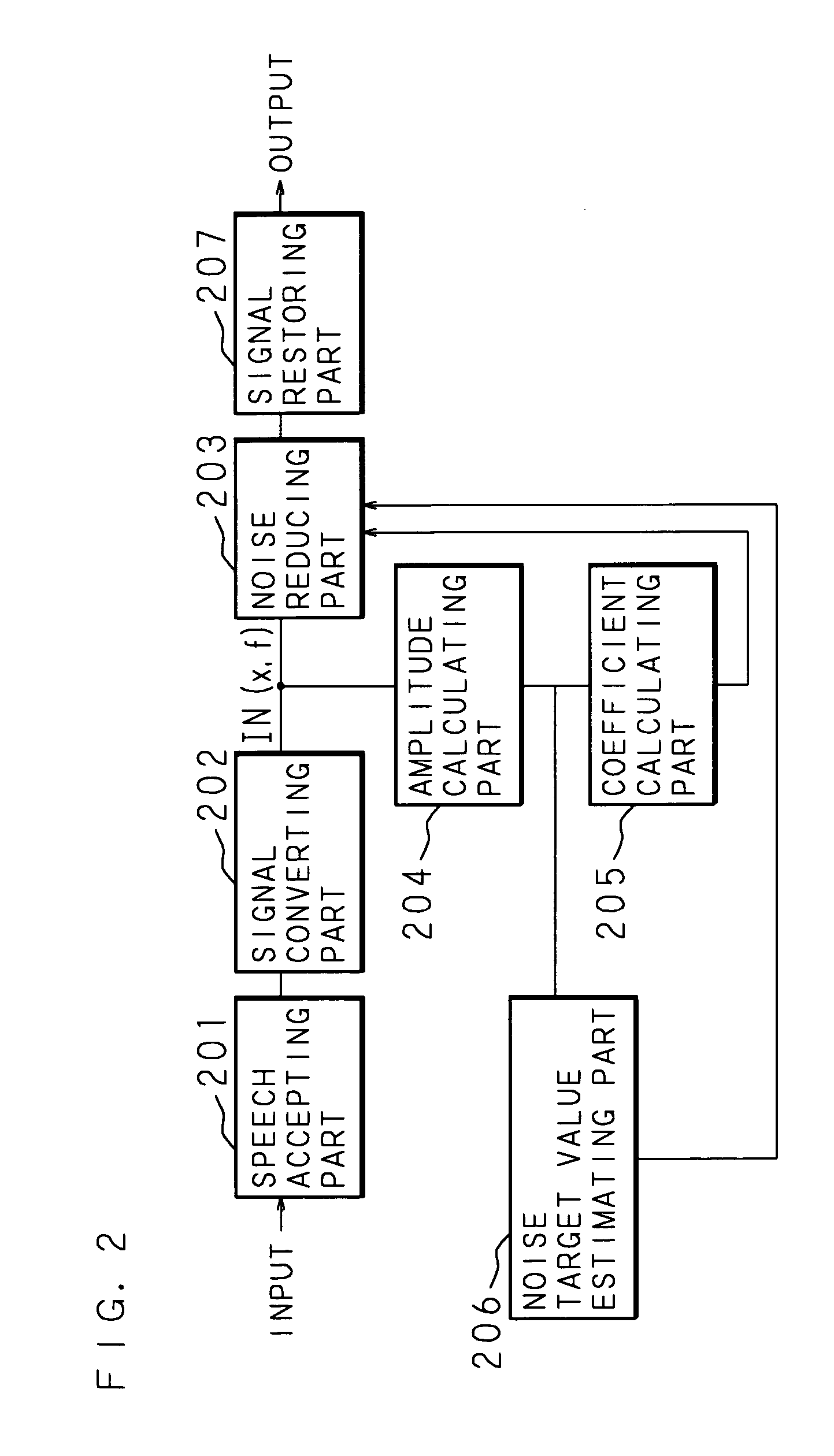

Noise reducer, noise reducing method, and recording medium

ActiveUS20070156399A1Reduce noisePreventing output distortionSpeech recognitionNoise reduction coefficientSignal on

Accepting the speech having the noise superimposed thereon and converting it into a signal on a time axis of the speech, an amplitude component of a speech for each predetermined frequency band of the converted signal on the frequency axis is calculated. Calculating a noise reduction coefficient, the noise component is reduced by multiplying the signal on the frequency axis of the original signal by the calculated noise reduction coefficient. By estimating the target value of the remaining noise for each frequency band, a signal on a frequency axis in which a signal corresponding to a frequency band of which target value estimated by the noise target value is larger than the value of the amplitude component of the signal on the frequency axis of which noise component is reduced is corrected to a signal corresponding to the target value is restored, into a signal on a time axis.

Owner:FUJITSU LTD

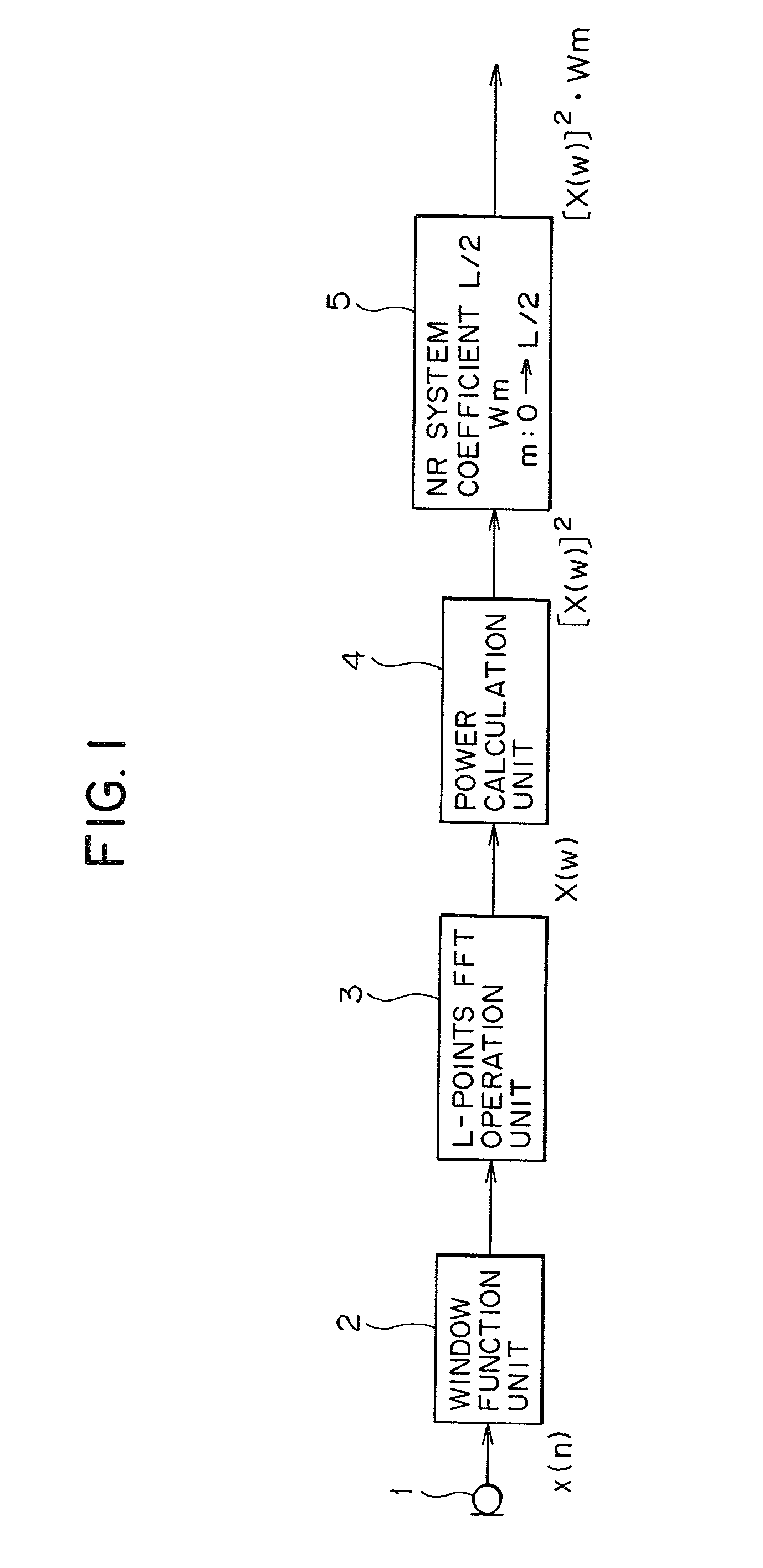

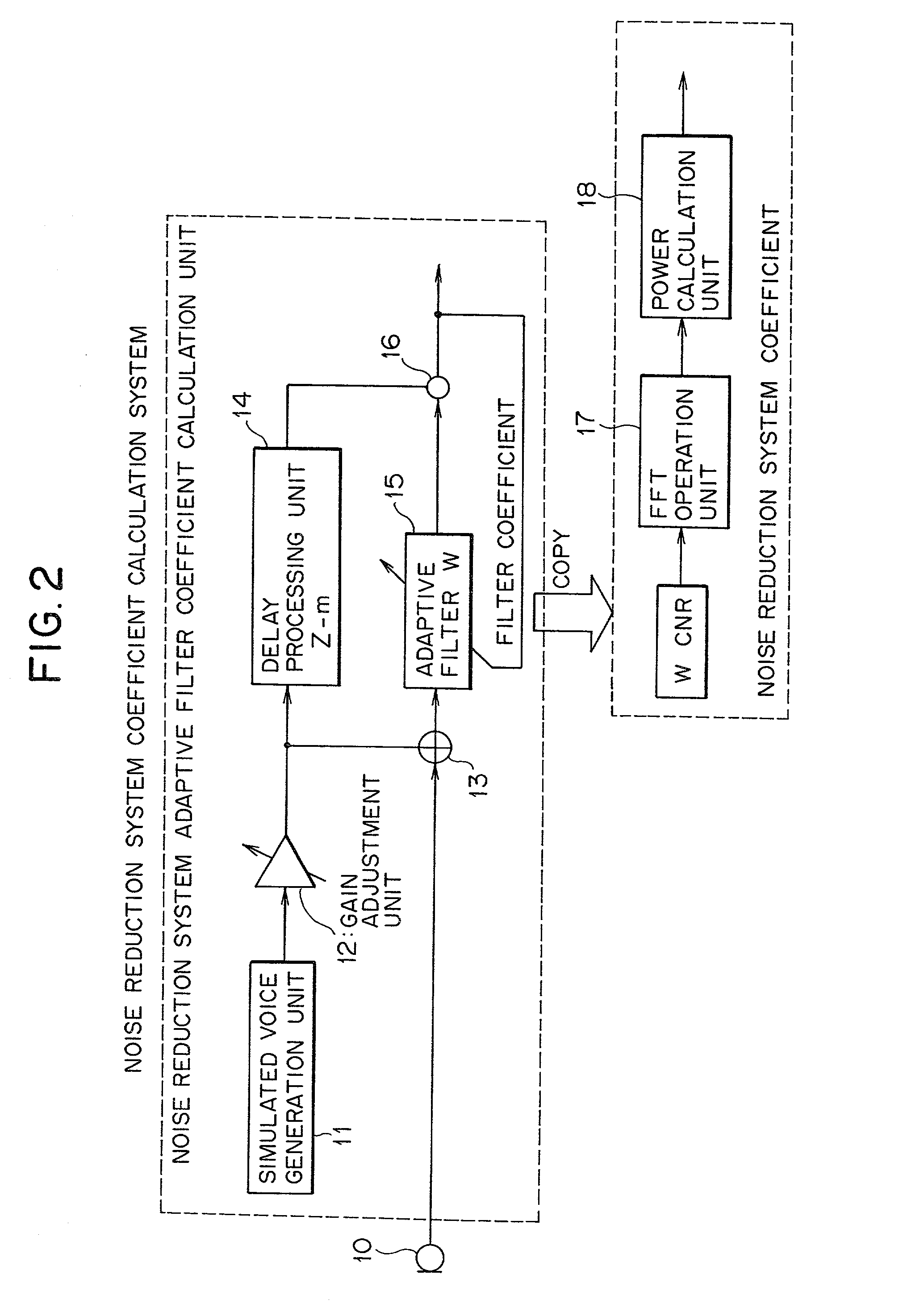

Voice feature extraction device

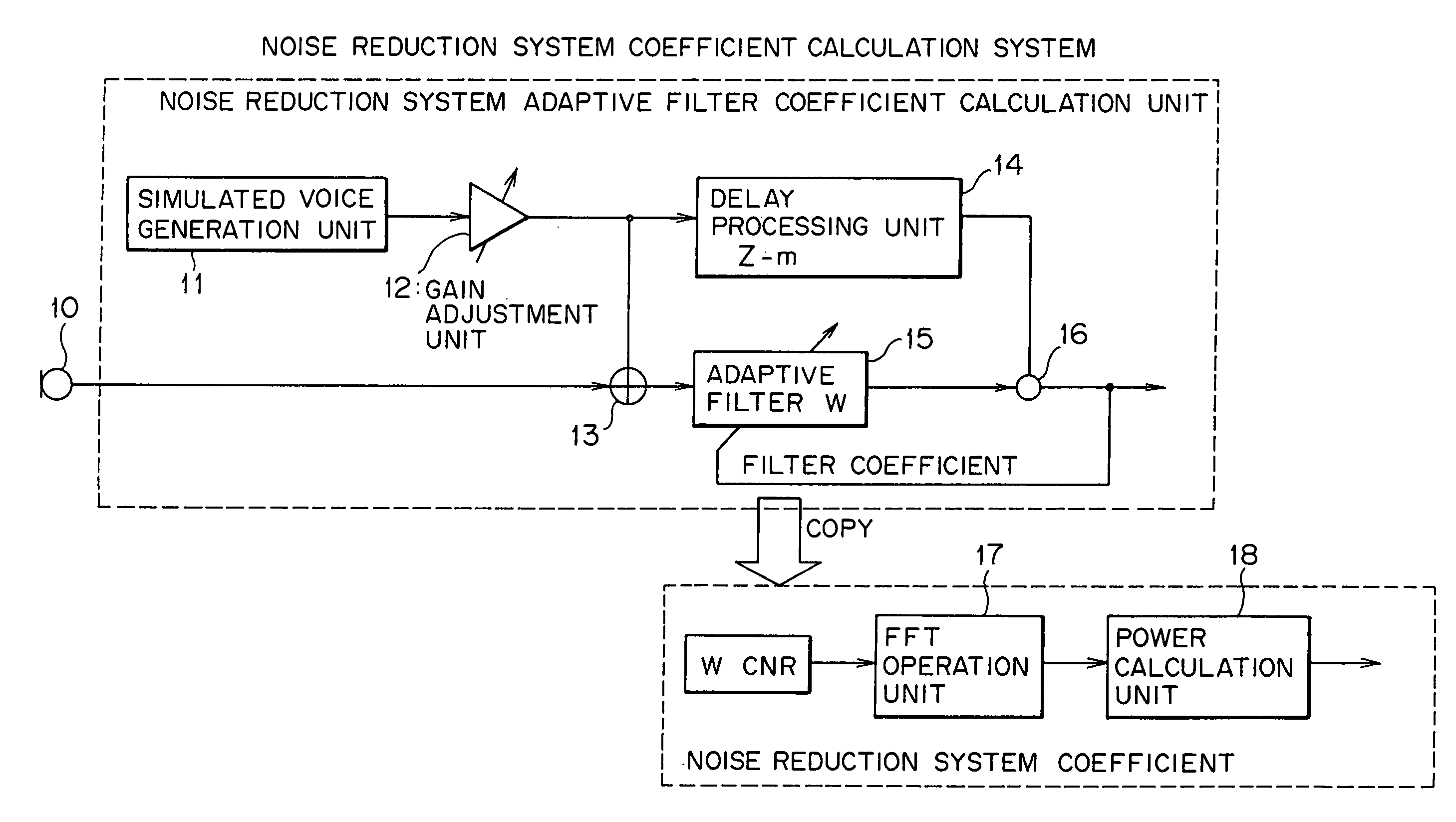

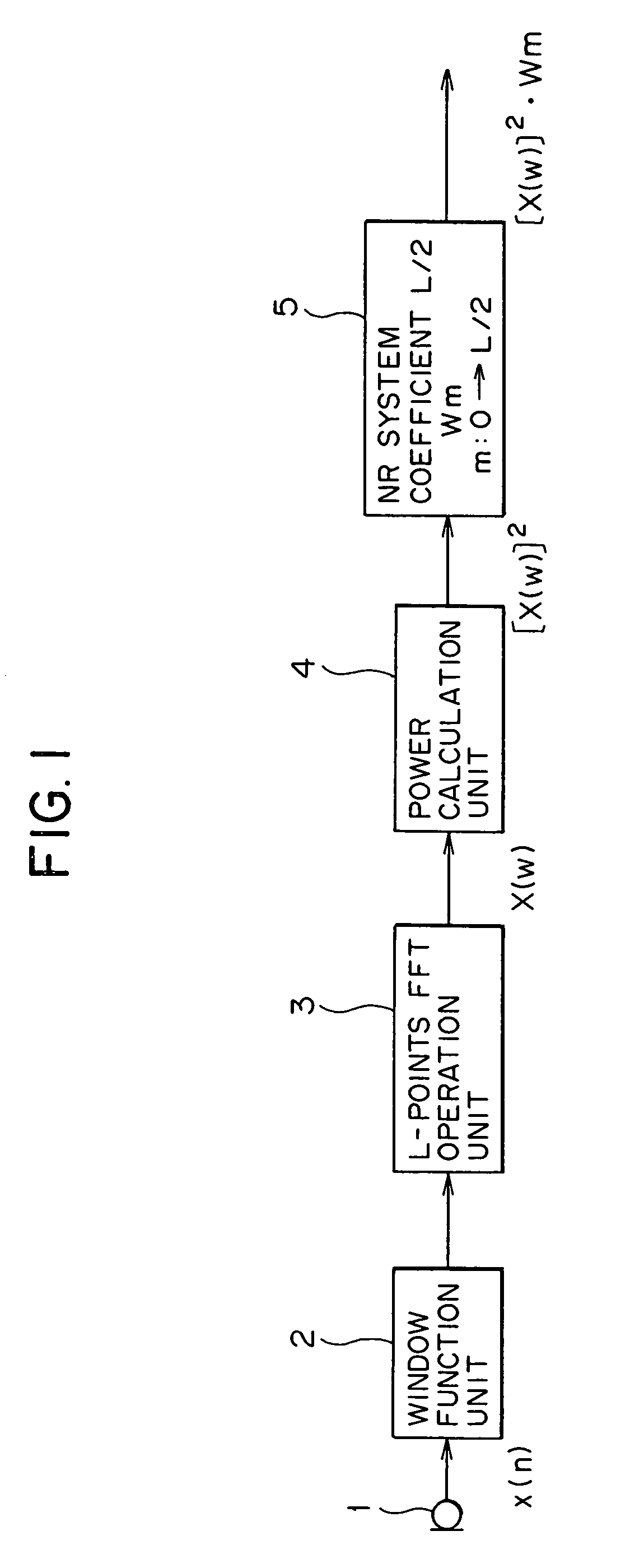

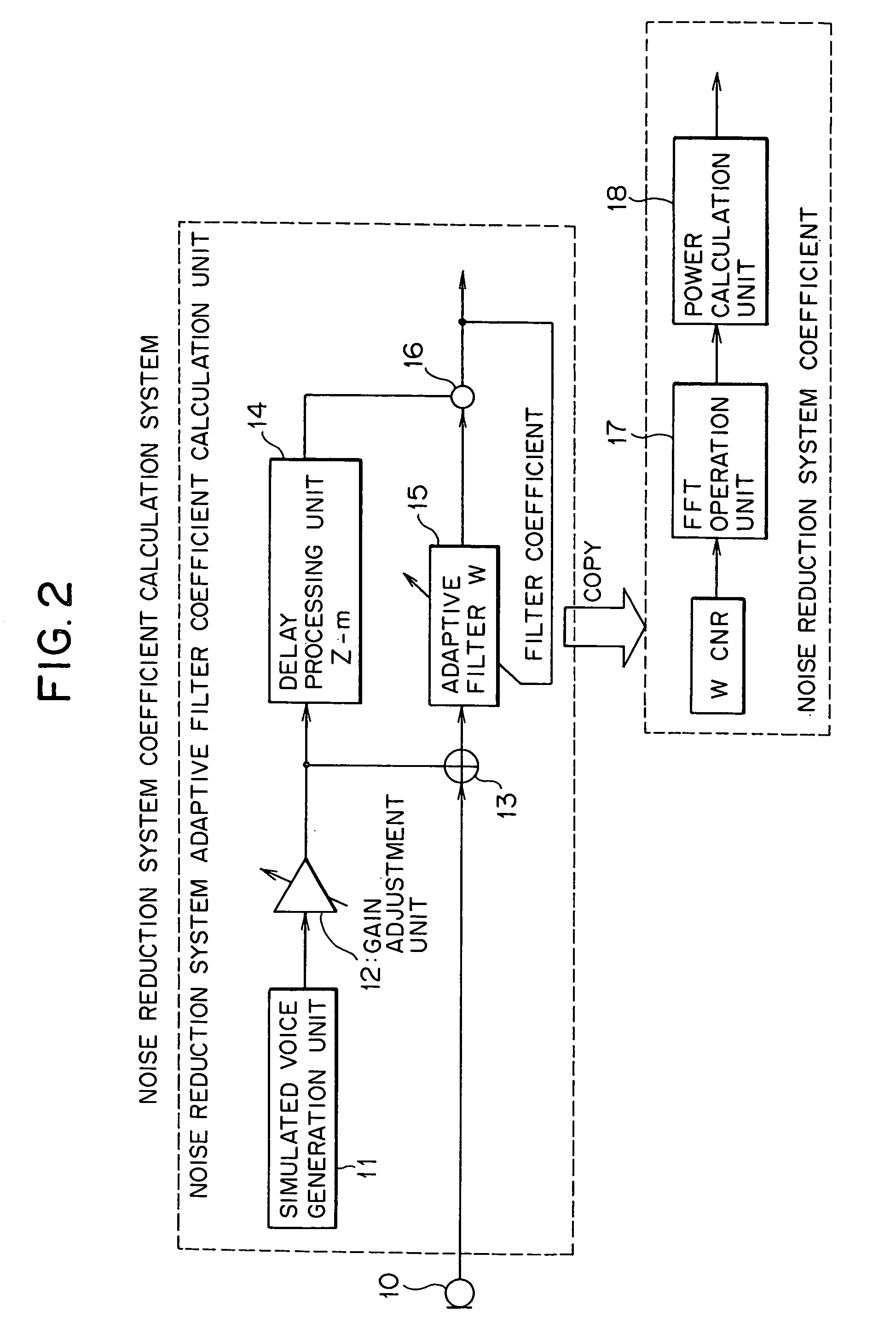

In a conventional device for extracting voice features accurately without being influenced by noises, such as a voice recognition device, usually an input voice signal is processed first by a noise reduction system having the tap length N, and the result is FFT-processed by L-points, and then the power spectrum vector is calculated; accordingly, a one time operation requires N multiplications and (N-1) summations. The voice feature extraction device according to the invention receives a voice signal including noises from a microphone, which is processed by a window function operation unit, and thereafter FFT-processed by an FFT operation unit by L-points. A power calculation unit calculates a power spectrum vector of the input voice signal. However, a noise reduction system determines in advance a filter coefficient of this system and processes the coefficient to calculate a noise reduction coefficient, and the power spectrum vector is processed by this noise reduction system. Thereby, the voice feature extraction device of the invention reduces the processing volume to 1 / (4N-2) in comparison to the conventional device, lightens the processing load of the processing unit, and increases the processing speed.

Owner:ALPINE ELECTRONICS INC

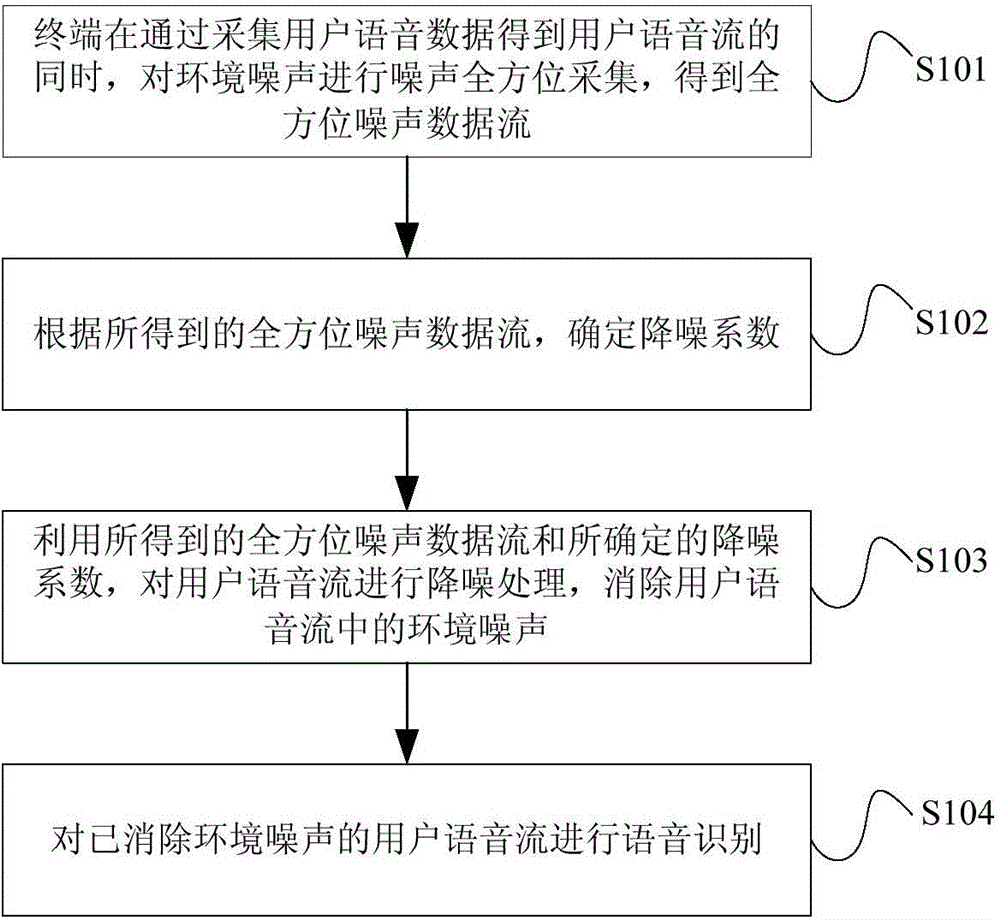

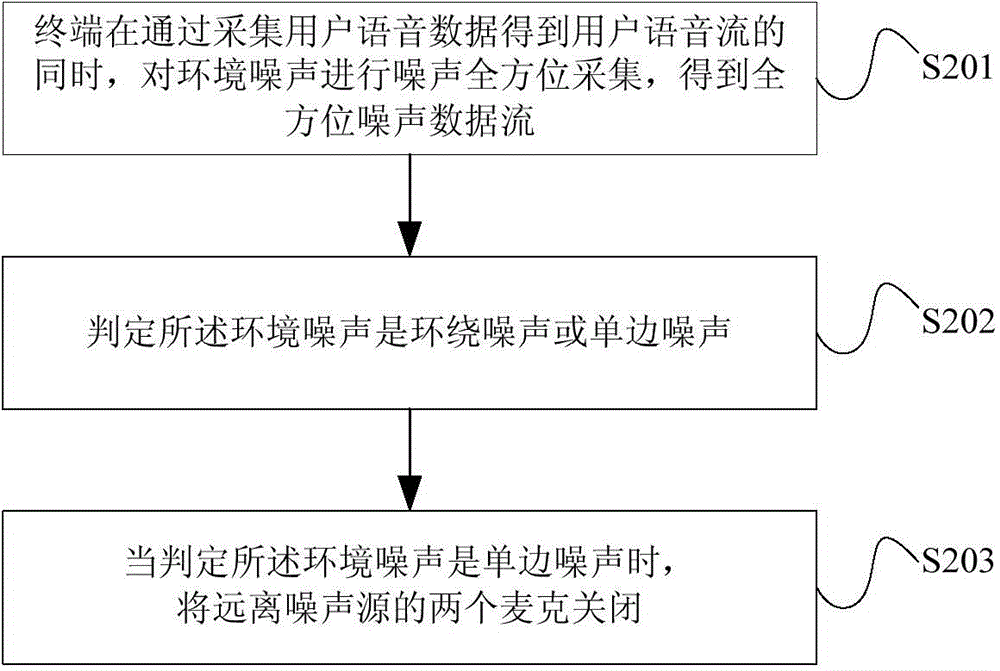

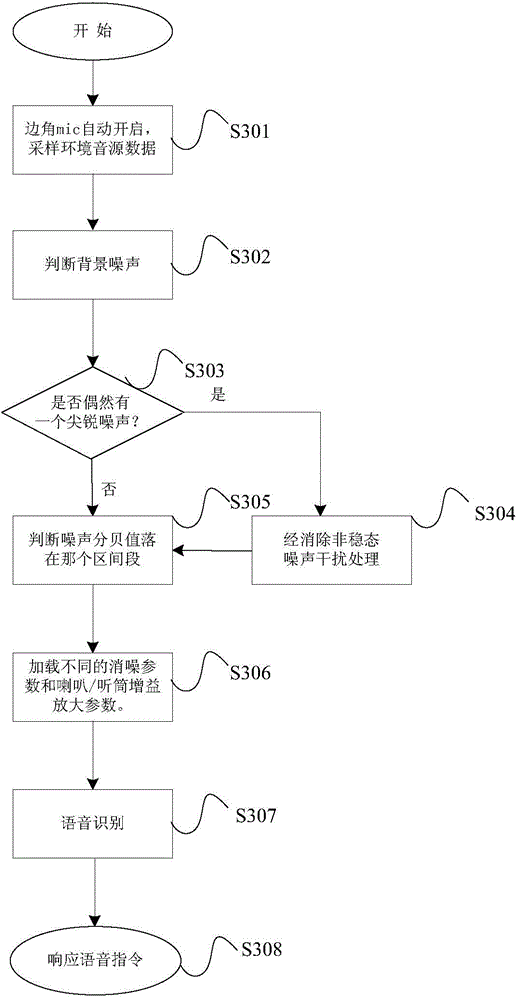

Method and device for adaptively adjusting voice recognition rate

InactiveCN105719644AIncrease success rateImprove efficiencySpeech recognitionNoise reduction coefficientEnvironmental noise

The invention discloses a method and device for adaptively adjusting the voice recognition rate, and the method comprises the steps: carrying out the omnibearing collection of environment noises when a terminal obtains a user voice flow through collecting the voice data of a user, and obtaining the omnibearing noise data flow; determining a noise reduction coefficient according to the obtained omnibearing noise data flow; carrying out the noise reduction of the user voice flow through the obtained omnibearing noise data flow and the noise reduction coefficient, and eliminating the environment noise in the user voice flow; and carrying out the voice recognition of the user voice flow with the environment noise being reduced. The method guarantees the higher voice recognition success rate in a high environment noise environment, and can automatically adjust the play sound quality according to the environment noise.

Owner:ZTE CORP

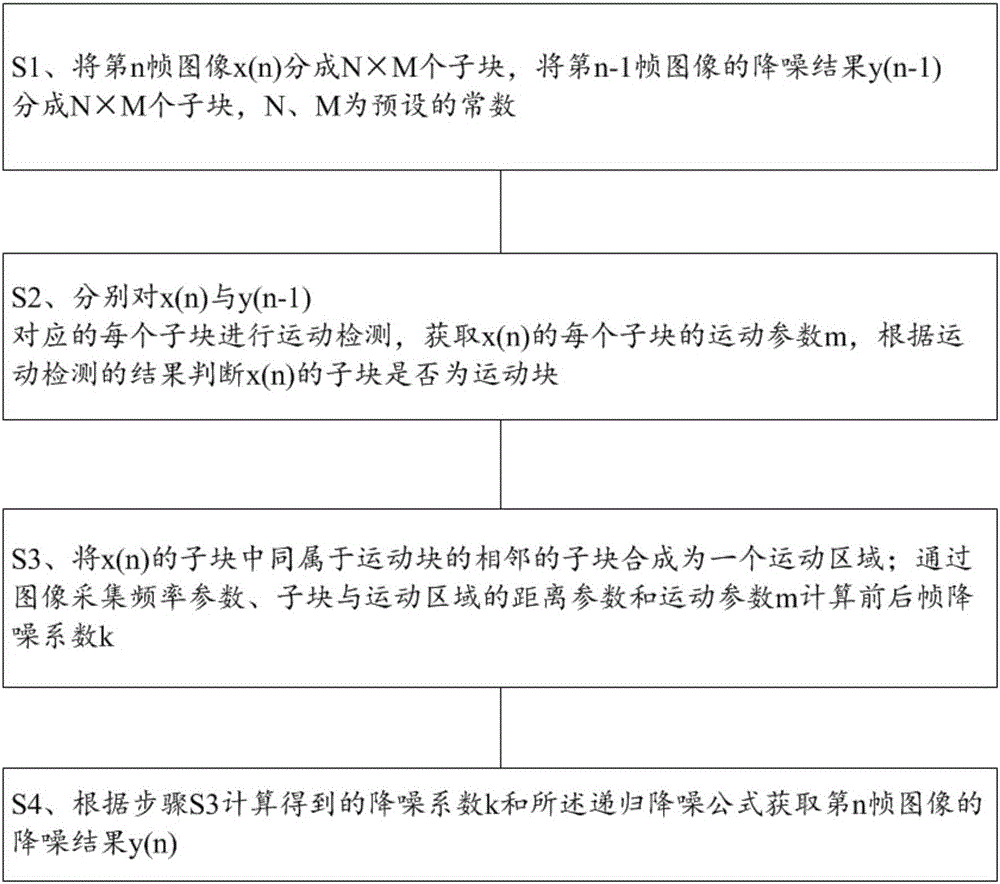

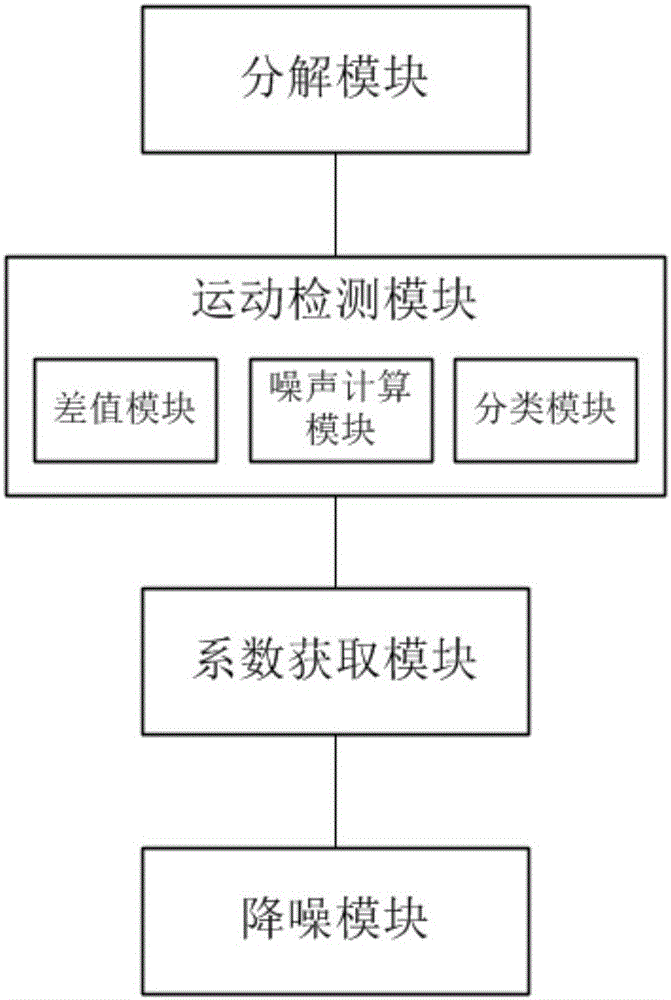

Image blocking adaptive recursion noise reduction method and device

ActiveCN107437238AReduce noise varianceDoes not reduce noise canceling effectImage enhancementPattern recognitionNoise reduction coefficient

The present invention discloses an image blocking adaptive recursion noise reduction method. The method comprises: uniformly dividing a current image and the noise reduction result of a preview frame into a plurality of subblocks, performing motion detection of each subblock, and obtaining the motion parameter of each subblock; combining adjacent subblocks belonging to motion blocks into one motion region; calculating the noise reduction coefficient k of the preview frame and next frames through the image collection frequency parameters and the distance parameters and the motion parameters m of the subblocks and the motion region; and obtaining the noise reduction result of an nth frame image x(n) according to the noise reduction coefficient and a recursion noise reduction formula obtained through calculation. The present invention further discloses an image blocking adaptive recursion noise reduction device. Noise reduction parameters are adaptively regulated according to the noise level, the motion condition and the frame frequency of each block after doing difference and a distance between the current block and the motion region to effectively eliminate the motion trailing phenomenon and reduce the noise difference between blocks while the noise reduction effect in a stationary region is not decreased.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

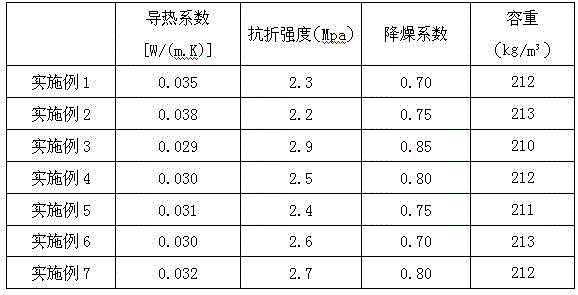

Solid waste foam concrete and preparation method thereof

The invention relates to a solid waste foam concrete and a preparation method thereof, belongs to the technical field of engineering materials, and provides a preparation method for a noise reductionfoam concrete. According to a cementitious material, solid waste material steel slag, slag powder and desulfurized gypsum are firstly adopted as main components, and though double synergy optimizationbetween of particle size and the activity of the steel slag, slag and desulfurized gypsum without adding cement clinker or alkali-activator, the absorption of a large proportion of industrial solid waste is achieved. The preparation method for the foam concrete can save the milling time, reduce the energy consumption and improve the production efficiency by adopting a step mixing grinding technology mixing the ball mill and the segment mill; pores in the concrete can be further communicated by adopting high-temperature wet curing, while high compressive strength is kept, a high noise reduction coefficient is obtained, so that the noise reduction coefficient NRC exceeds 0.6, and the compressive strength can reach 10MPa, the concrete can be used as a wall sound absorbing structural materialin a noise reduction project, and the problems that traditional foam concretes are not high in strength, and the pores are not communicated are solved.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +4

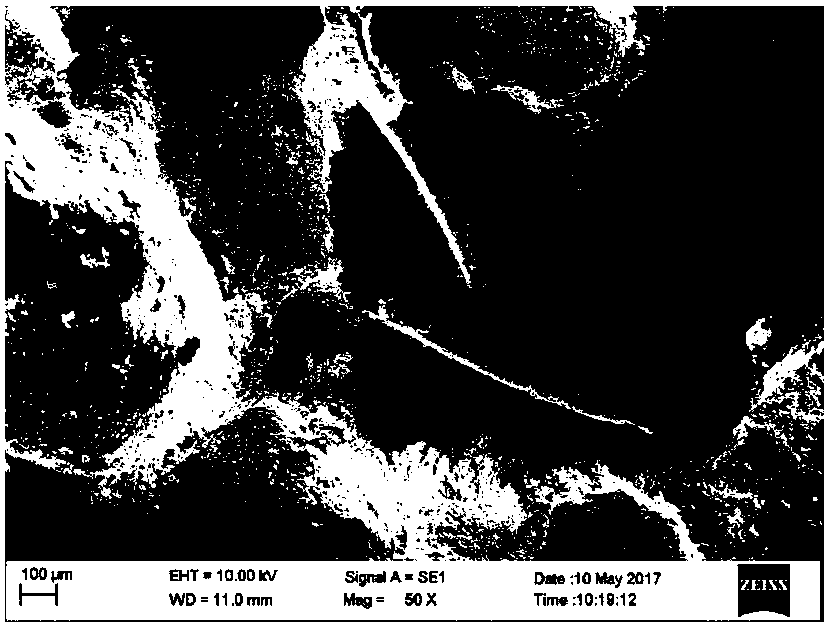

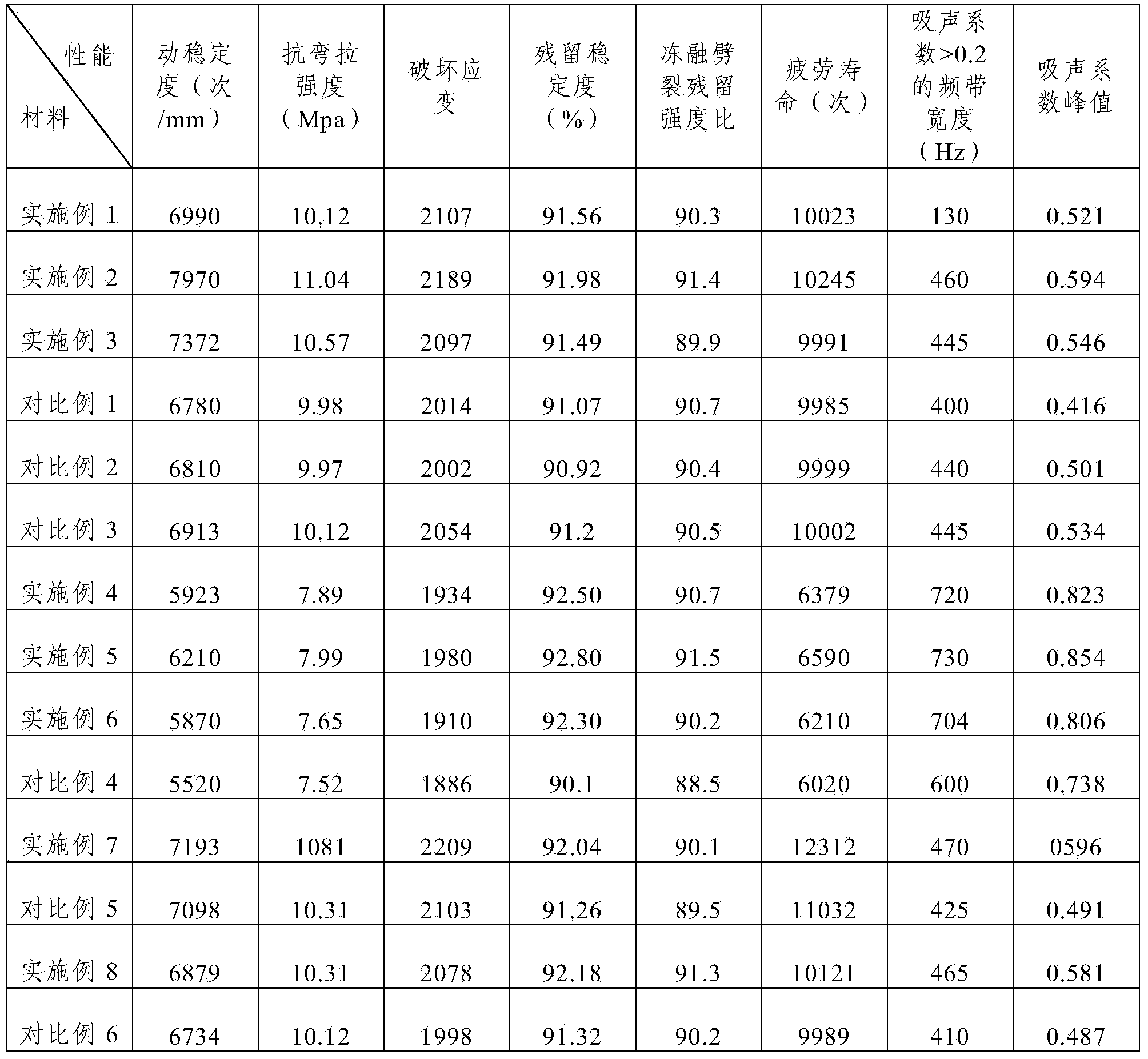

Compound modified asphalt concrete

InactiveCN104355569AEasy to prepareImprove flame retardant performanceNoise reduction coefficientSocial benefits

The invention provides compound modified asphalt concrete which is characterized by being prepared from the following raw materials in parts by weight: 100 parts of mineral aggregate, 3-7 parts of asphalt, 0.05-0.15 part of chlorinated polyethylene, 0.2-1.5 parts of aliphatic polyurethane resin, 0.075-1 part of serpentine, 0.15-1.5 parts of halloysite and 0.001-0.04 part of a coupling agent. The compound modified asphalt concrete provided by the invention is remarkably improved in noise reduction coefficient, has excellent pavement performance, is simple in preparation technology, has non-poisonous and harmless raw materials and has great social benefits for improving the pavement performance of asphalt and protecting the environment.

Owner:CHANGAN UNIV

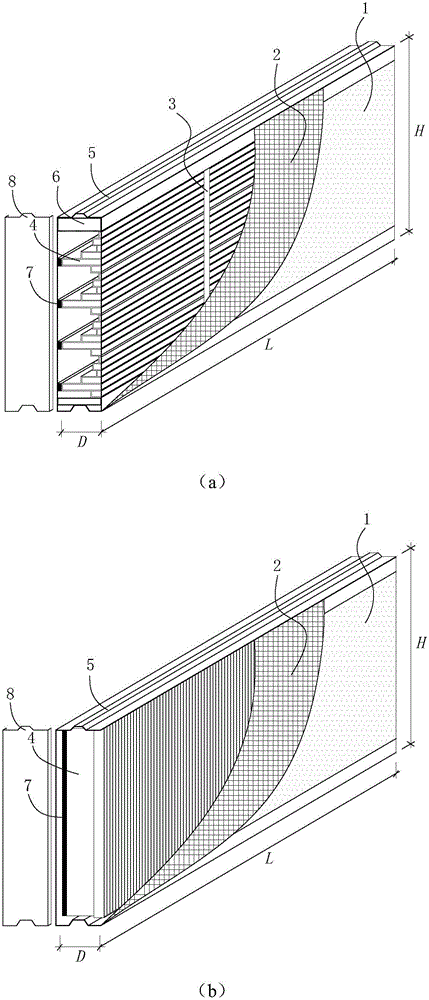

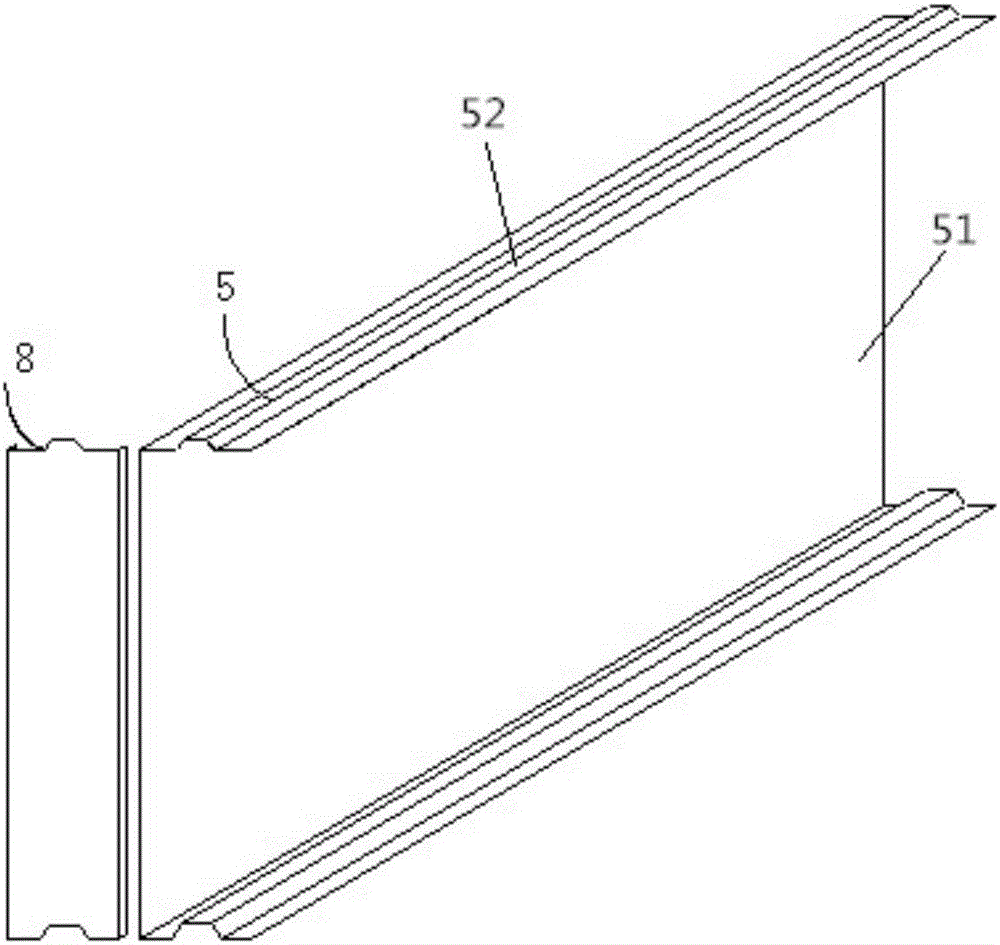

Sound barrier unit board based on wide band microperforated panel sound absorber and designing method thereof

InactiveCN106223222AIncrease widthSimple structureNoise reduction constructionEnvironmental noiseOctave

The invention discloses a sound barrier unit board based on a wide band microperforated panel sound absorber, and belongs to the technical field of environmental noise control. The sound barrier unit board comprises the sound absorber and a sound insulation backboard. The sound absorber comprises a microperforated panel and cavity sets with different depths. The sound insulation backboard comprises a back panel, an upper side panel and a lower side panel, and the left side and the right side of the sound insulation backboard are sealed with end sealing plates. The cavity sets with different depths are arranged on the back panel of the sound insulation backboard, and the opening sides of the cavity sets with different depths face the microperforated panel. The invention further discloses a designing method of the sound barrier unit board. The sound barrier unit board has the advantages of environment friendliness, simple structure, high strength, high weather resistance and the like. The noise reduction coefficient of the sound absorption unit board is not lower than 0.8. The sound barrier unit board has an excellent sound absorption property in a highway noise energy concentration frequency band, 1 / 3 octave center frequency random incidence sound absorption coefficients in the range from 125 Hz to 2500 Hz are all higher than 0.5, and the average value of 1 / 3 octave center frequency random incidence sound absorption coefficients in the range from 160 Hz to 2000 Hz is 0.85; and meanwhile the weight-counted sound insulation quantity Rw reaches 31 dB.

Owner:SOUTHEAST UNIV

Abuse-resistant cast acoustical ceiling tile having an excellent sound absorption value

Owner:USG INTERIORS INC

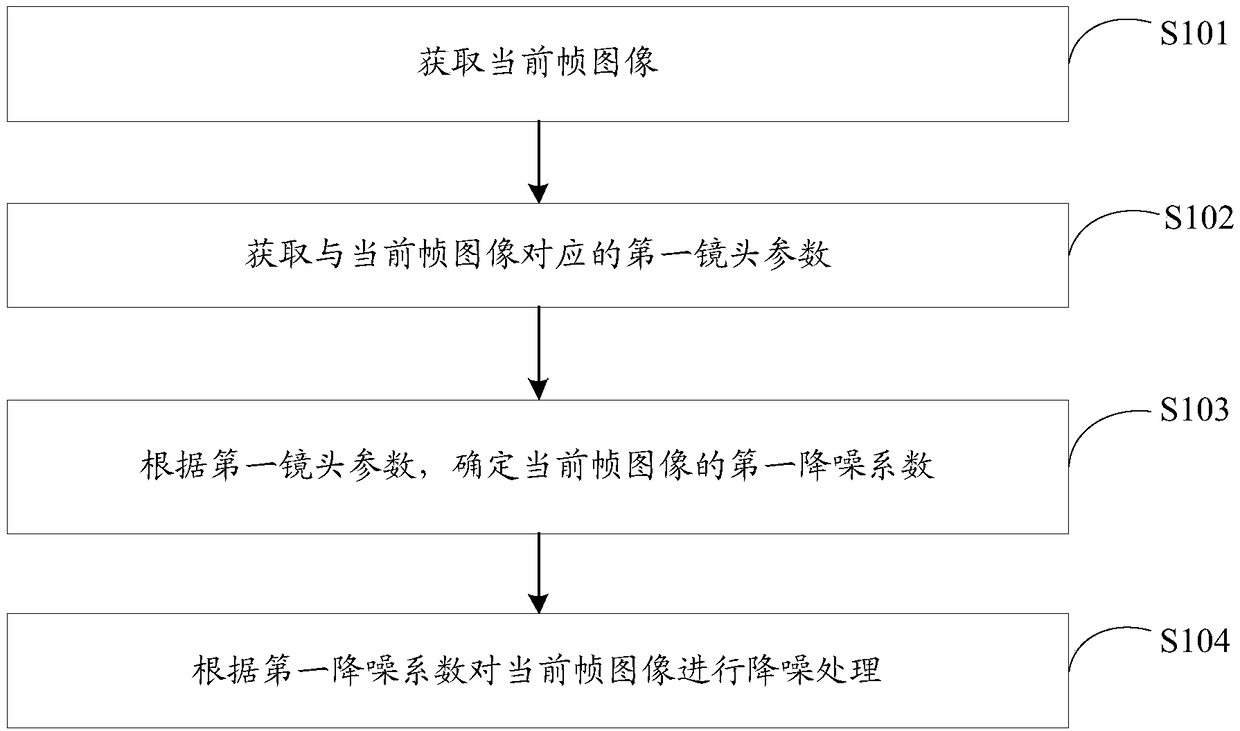

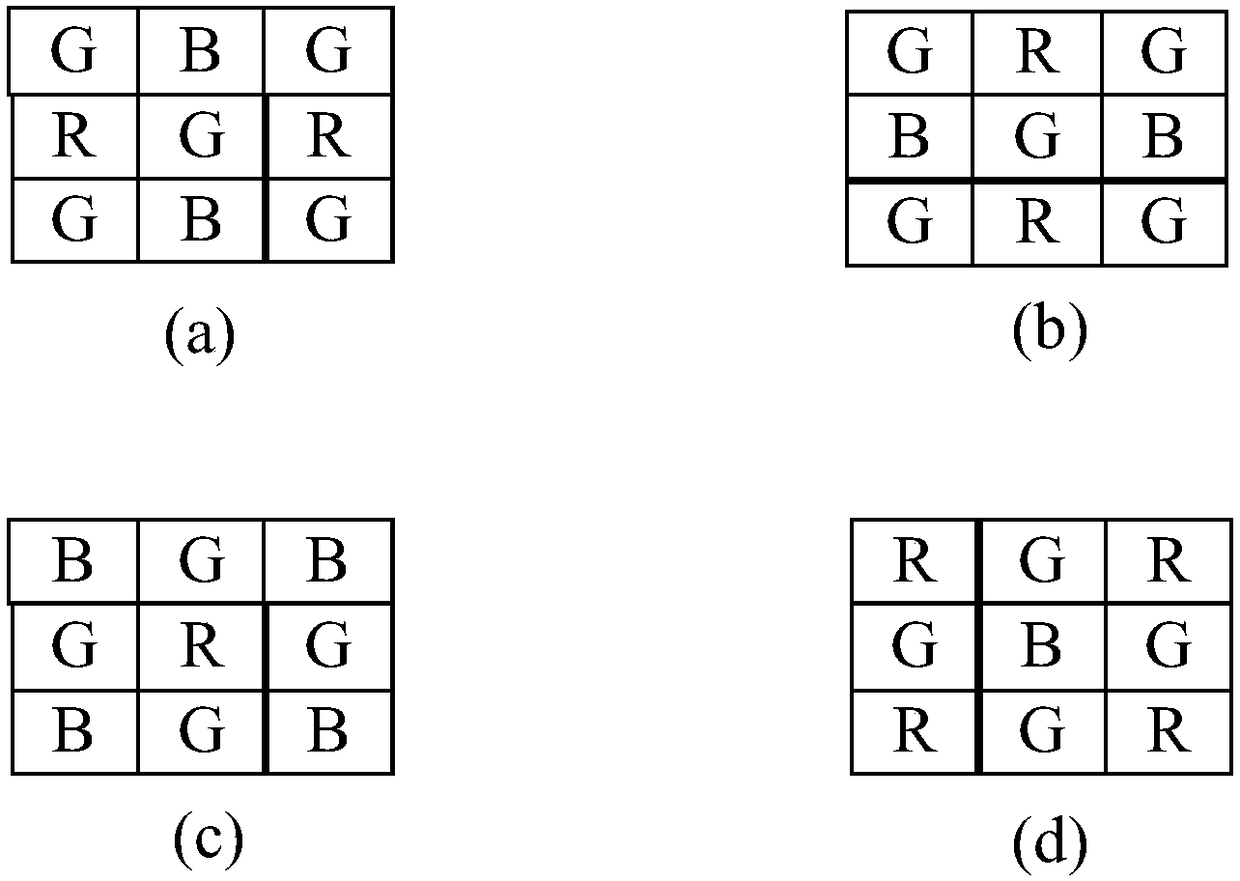

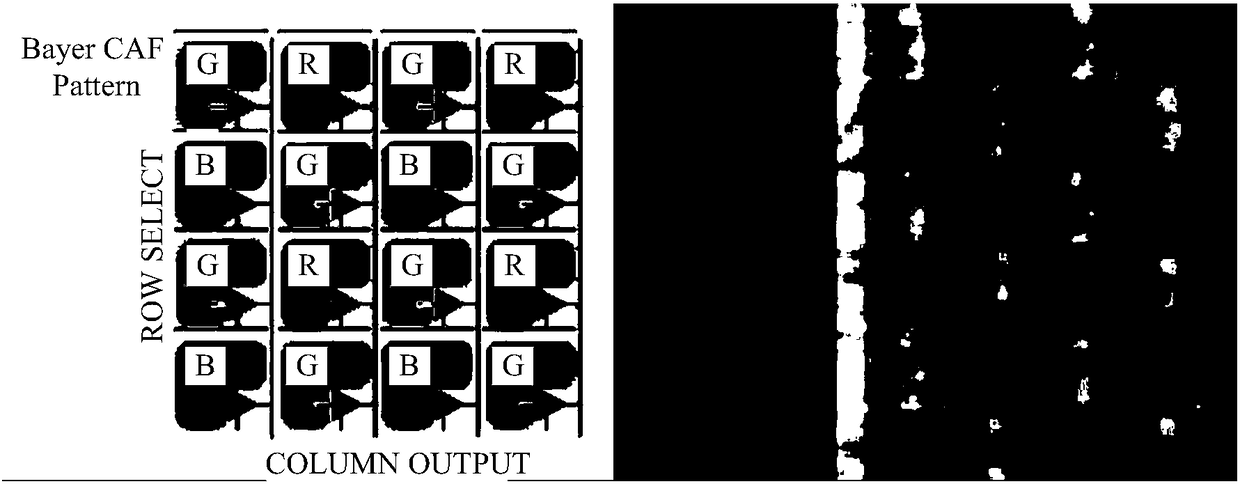

Image noise reduction method and terminal

InactiveCN108513043AImprove image qualityImage enhancementTelevision system detailsNoise reduction coefficientImage noise reduction

The embodiment of the invention discloses an image noise reduction method. The method comprises the following steps: acquiring the current frame image; acquiring a first lens parameter corresponding to the current frame image; determining a first noise reduction coefficient of the current frame image according to the first lens parameter; and performing noise reduction processing on the current frame image according to the first noise reduction coefficient. The embodiment of the invention further discloses a terminal at the same time.

Owner:ZTE CORP

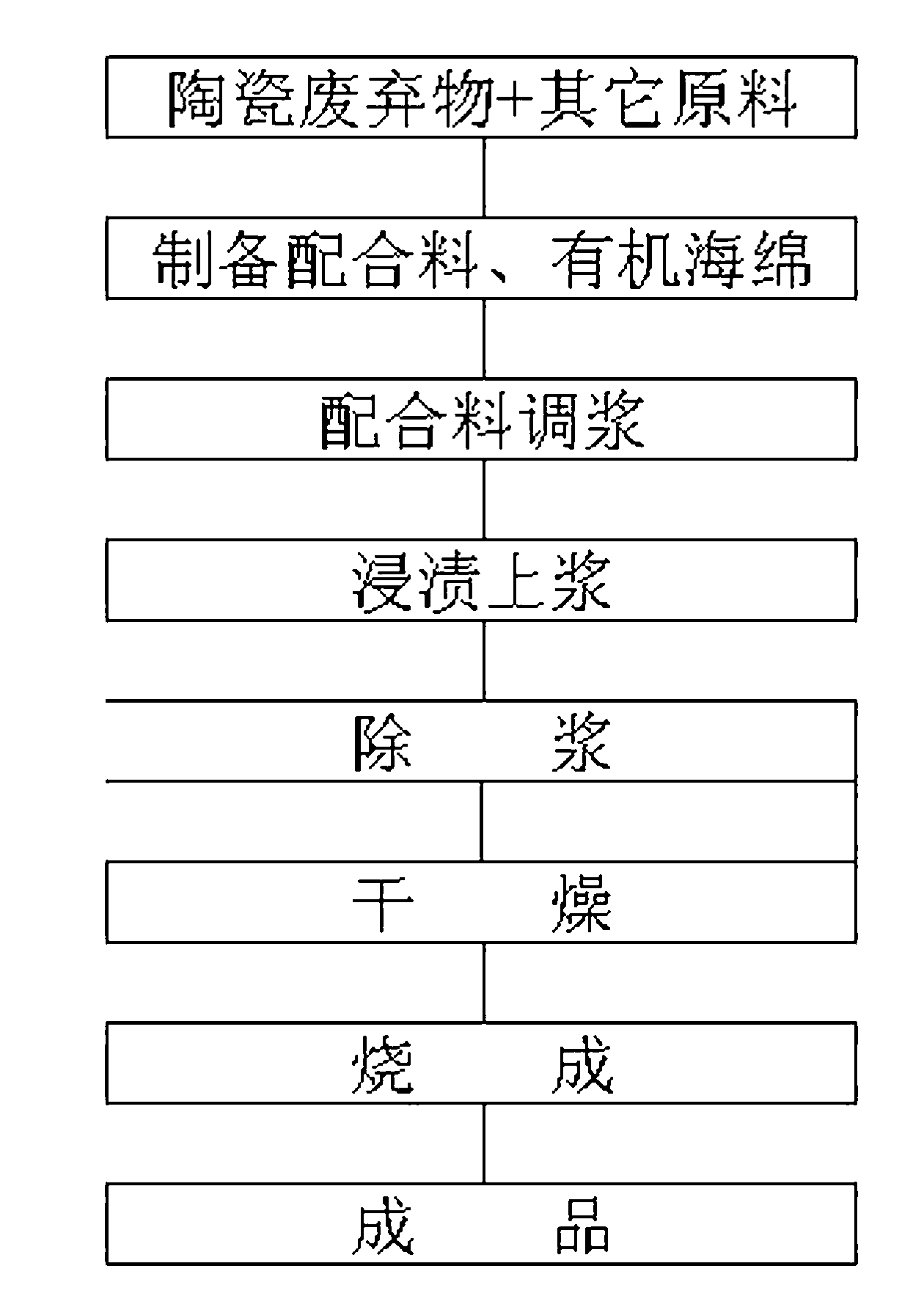

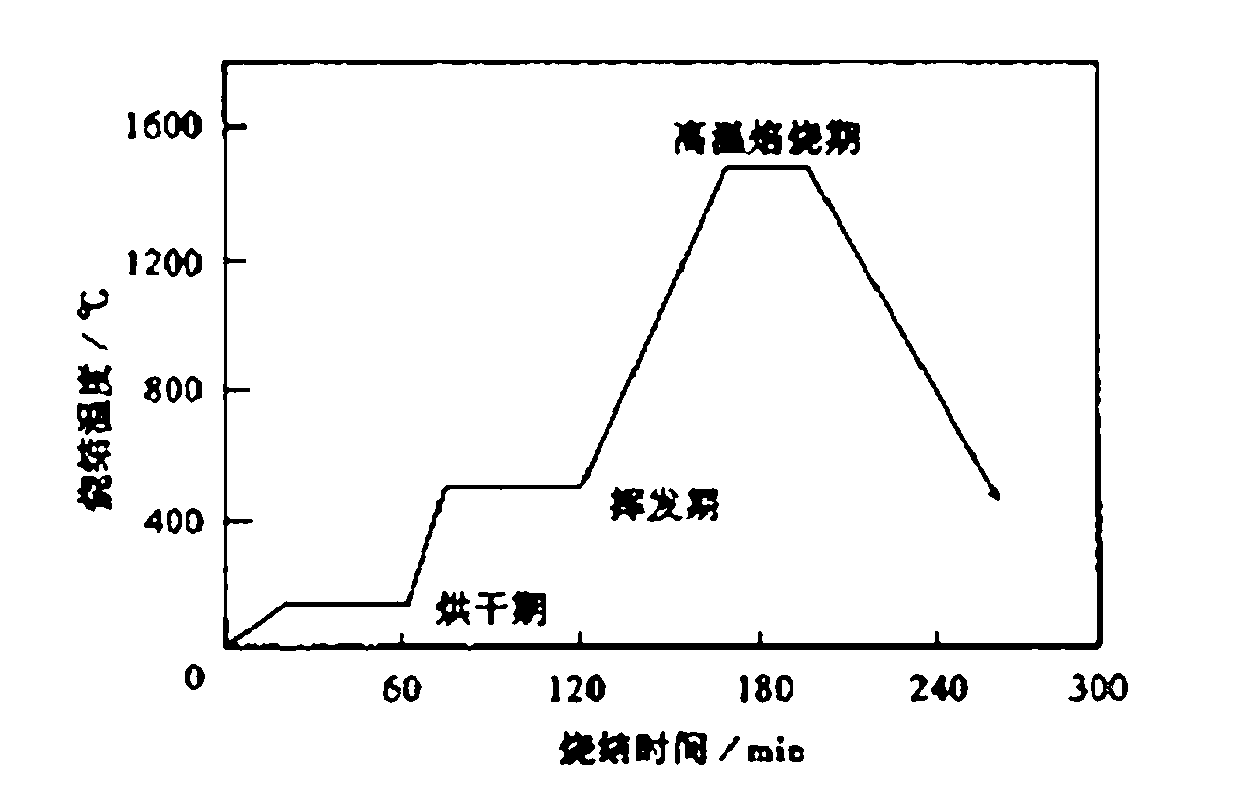

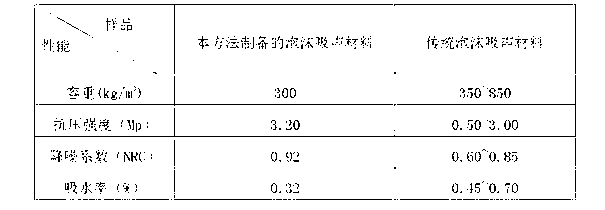

Foam sound absorption material produced by using ceramic waste and production method of foam sound absorption material

ActiveCN102936151AReduce manufacturing costLow costSolid waste disposalCeramicwareNoise barrierKaolin clay

The invention discloses a foam sound absorption material and a production method of the foam sound absorption material. A ceramic waste serves as a main raw material in production. The foam sound absorption material comprises, by weight, 55-85 parts of the ceramic waste, 15-30 parts of superfine kaoline, 0.2-0.6 part of a suspending agent and 0-6 parts of zirconium oxide. An organic precursor-dipping high-temperature sintering process is used for producing the foam sound absorption material, the disadvantages that a convention sound absorption material is low in noise reduction coefficient, short is service life and easy to deliquesce and produce secondary pollution are overcome, the material is light in weight, acid-resisting, alkali-resisting, fire-proof and high temperature-resisting and can be used in noise-elimination noise barriers in urban streets, railways, subways, construction sites, central air-conditioner rooms and the like, and also can be used in public places such as hospitals, libraries, convention centers, exhibition halls, lecture halls, music halls, movie theaters, gymnasiums, commercial buildings, public houses, hotels and office buildings. The waste serves as the production raw material, the production cost is reduced, the dumped amount of the ceramic waste is reduced at the same time, environmental pollution is controlled, and the resourcization recycling utilization of the waste is achieved.

Owner:张金青

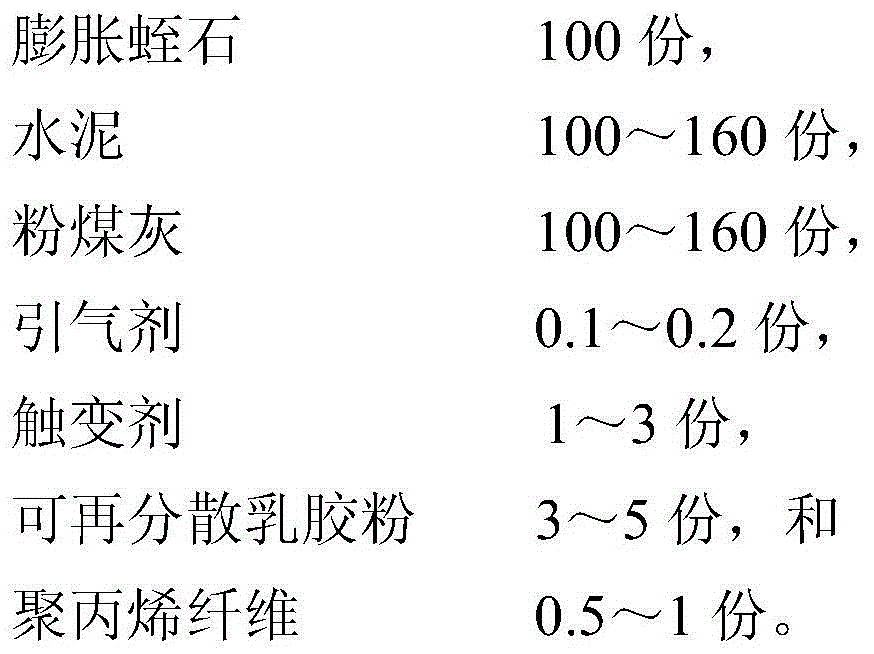

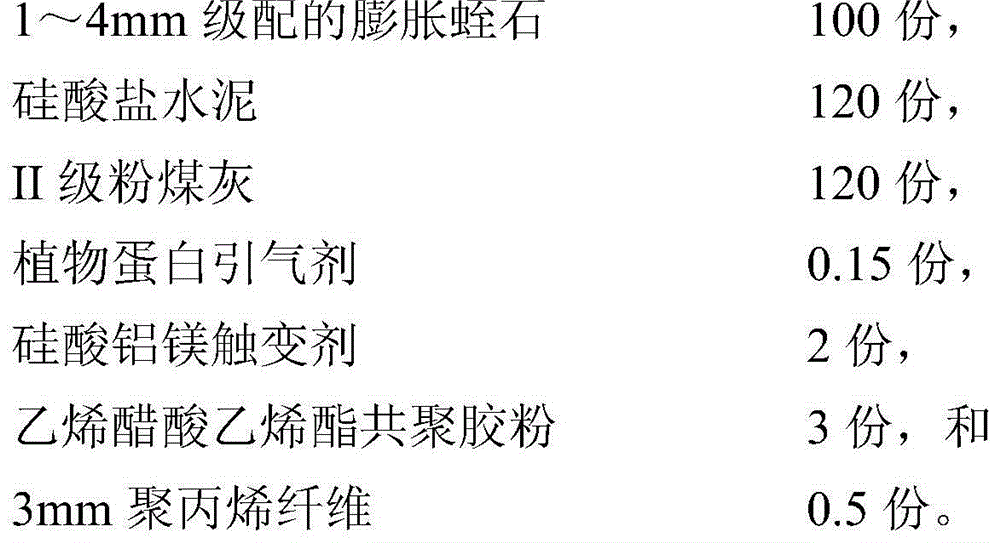

Cement-base sound-absorbing material for tunnel wall surfaces and preparation method thereof

The invention belongs to the technical field of cement-base sound-absorbing materials, and relates to a cement-base sound-absorbing material for tunnel wall surfaces and a preparation method thereof. The cement-base sound-absorbing material for tunnel wall surfaces comprises the following raw materials in parts by mass: 100 parts of expanded vermiculite, 100-160 parts of cement, 100-160 parts of fly ash, 0.1-0.2 part of air entraining agent, 1-3 parts of thixotropic agent, 3-5 parts of redispersible latex powder and 0.5-1 part of polypropylene fiber. The cement-base sound-absorbing material for tunnel wall surfaces can be prepared into a dry mixture, and is environment-friendly. The cement-base sound-absorbing material for tunnel wall surfaces can be mixed with water on site and sprayed on the tunnel wall surface, and thus, is convenient for construction. The cement-base sound-absorbing material for tunnel wall surfaces is mainly composed of expanded vermiculite and foaming cement with excellent fire resistance, and thus, has favorable fire resistance; and the combustion performance can reach Grade A. The noise reduction coefficient (NRC) is greater than or equal to 0.60, and the cement-base sound-absorbing material for tunnel wall surfaces has favorable sound absorptivity. The material can form a hard sound-absorbing material, and has the advantages of disturbance resistance and favorable weather resistance.

Owner:CHINA JINGYE ENG TECH CO LTD +2

Audio signal processing method and device, terminal equipment and storage medium

PendingCN111986693AAccurate estimateReduce residual noiseSpeech analysisTime domainNoise reduction coefficient

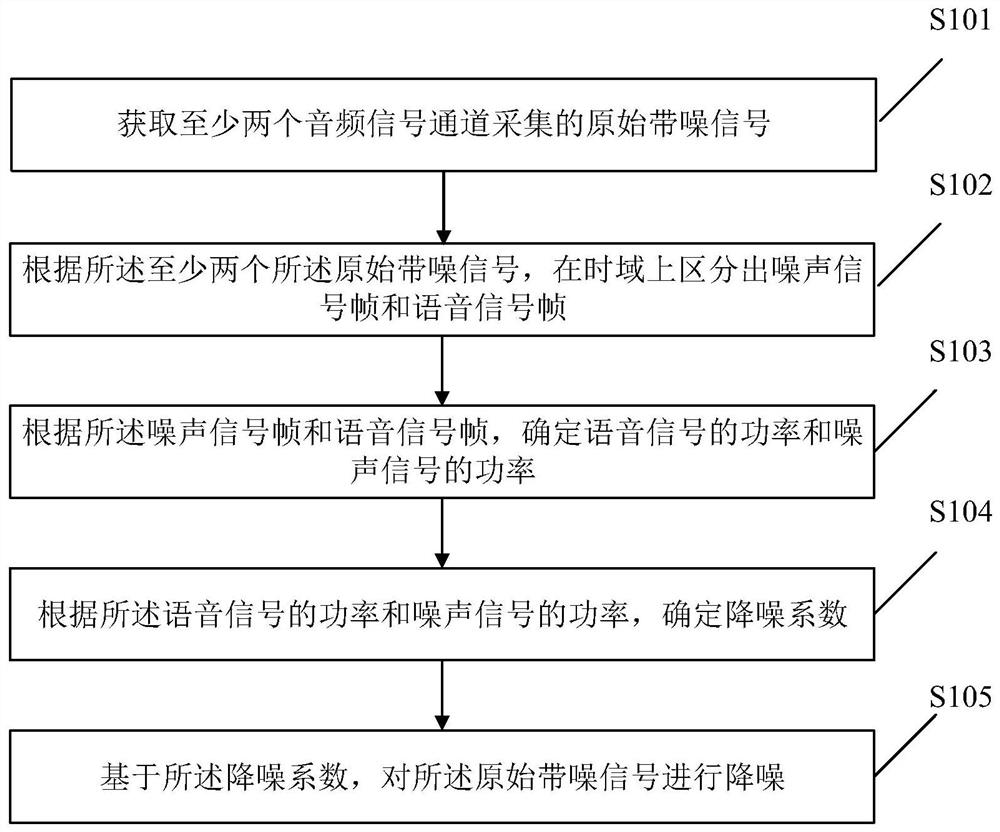

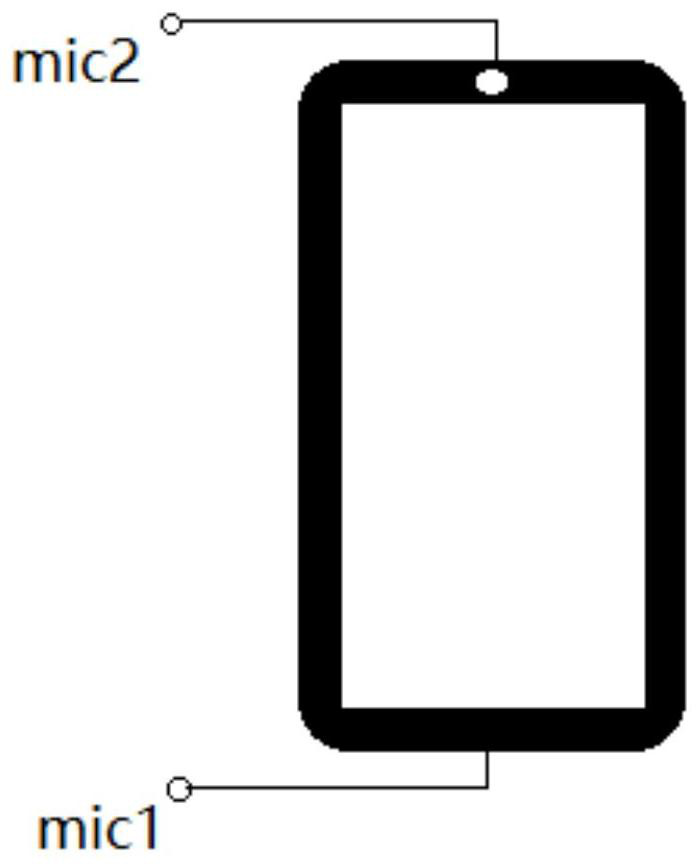

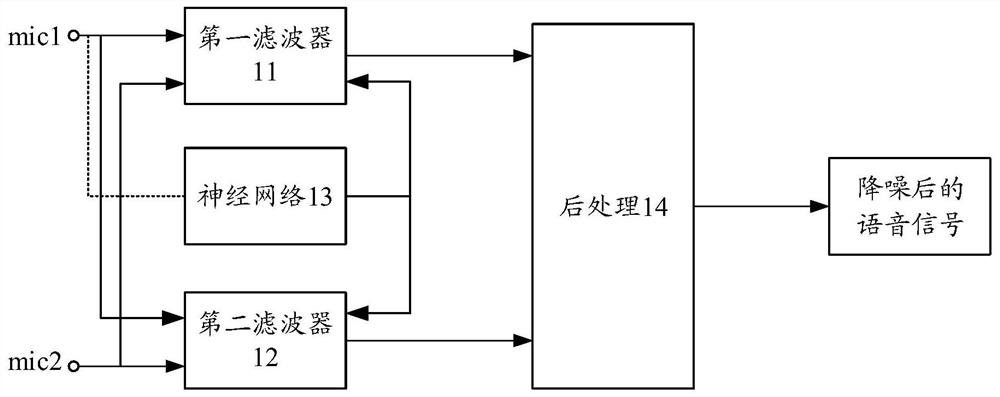

The invention relates to an audio signal processing method and device, terminal equipment and a storage medium. The method comprises the following steps: acquiring original noise signals acquired by at least two audio signal channels; distinguishing a noise signal frame and a voice signal frame in a time domain according to the at least two original noisy signals, wherein the voice signal frame comprises a voice signal and a noise signal which are superposed in a time domain; the noise signal frame comprises noise generated when the voice signal is silent; determining the power of the voice signal and the power of the noise signal according to the noise signal frame and the voice signal frame; determining a noise reduction coefficient according to the power of the voice signal and the power of the noise signal; and based on the noise reduction coefficient, performing noise reduction on the original noise signals.

Owner:BEIJING XIAOMI PINECONE ELECTRONICS CO LTD

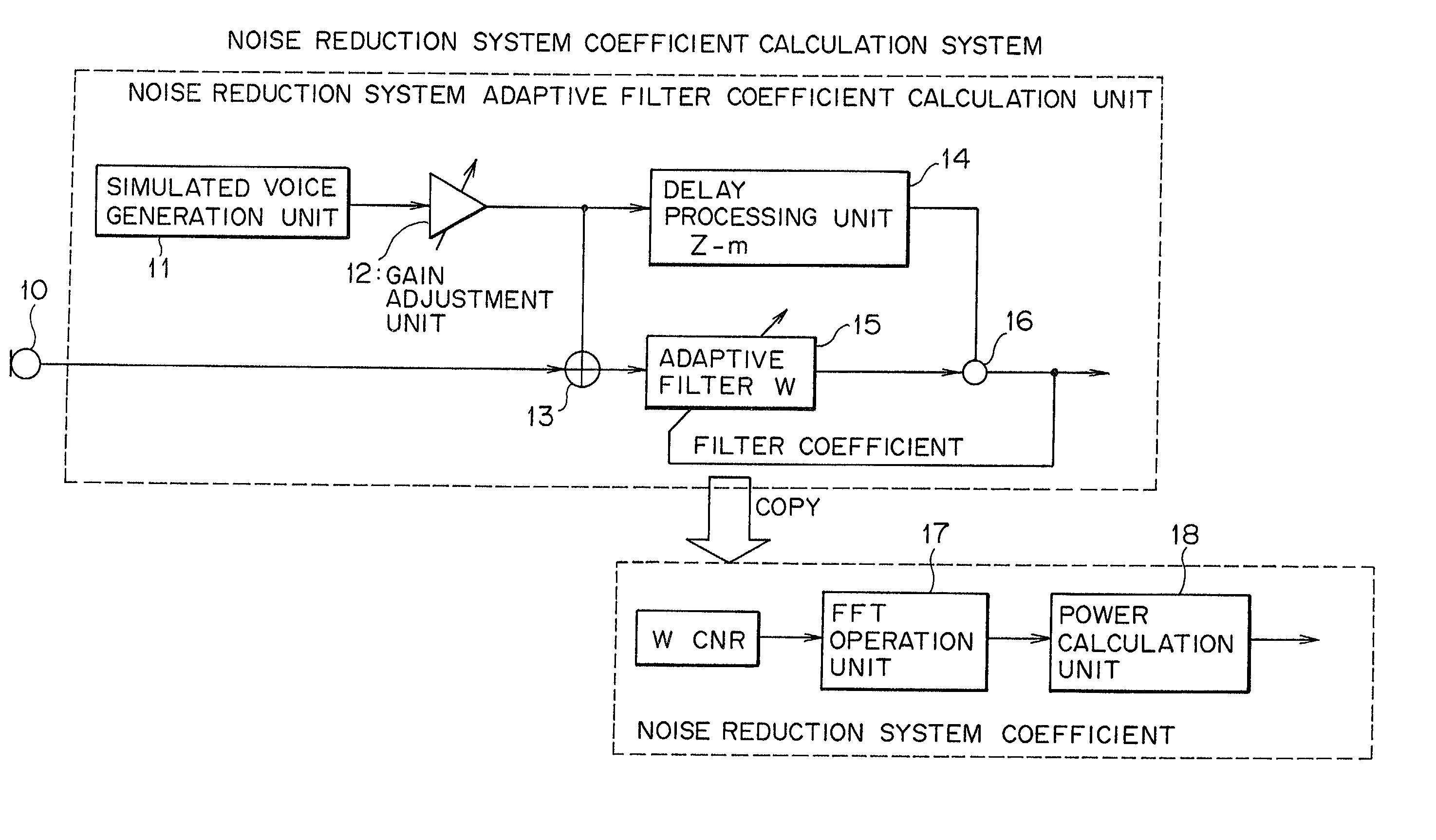

Voice feature extraction device

InactiveUS6959277B2Two-way loud-speaking telephone systemsSpeech recognitionNoise reduction coefficientFeature extraction

In a conventional device for extracting voice features accurately without being influenced by noises, such as a voice recognition device, usually an input voice signal is processed first by a noise reduction system having the tap length N, and the result is FFT-processed by L-points, and then the power spectrum vector is calculated; accordingly, a one time operation requires N multiplications and (N−1) summations. The voice feature extraction device according to the invention receives a voice signal including noises from a microphone, which is processed by a window function operation unit, and thereafter FFT-processed by an FFT operation unit by L-points. A power calculation unit calculates a power spectrum vector of the input voice signal. However, a noise reduction system determines in advance a filter coefficient of this system and processes the coefficient to calculate a noise reduction coefficient, and the power spectrum vector is processed by this noise reduction system. Thereby, the voice feature extraction device of the invention reduces the processing volume to 1 / (4N−2) in comparison to the conventional device, lightens the processing load of the processing unit, and increases the processing speed.

Owner:ALPINE ELECTRONICS INC

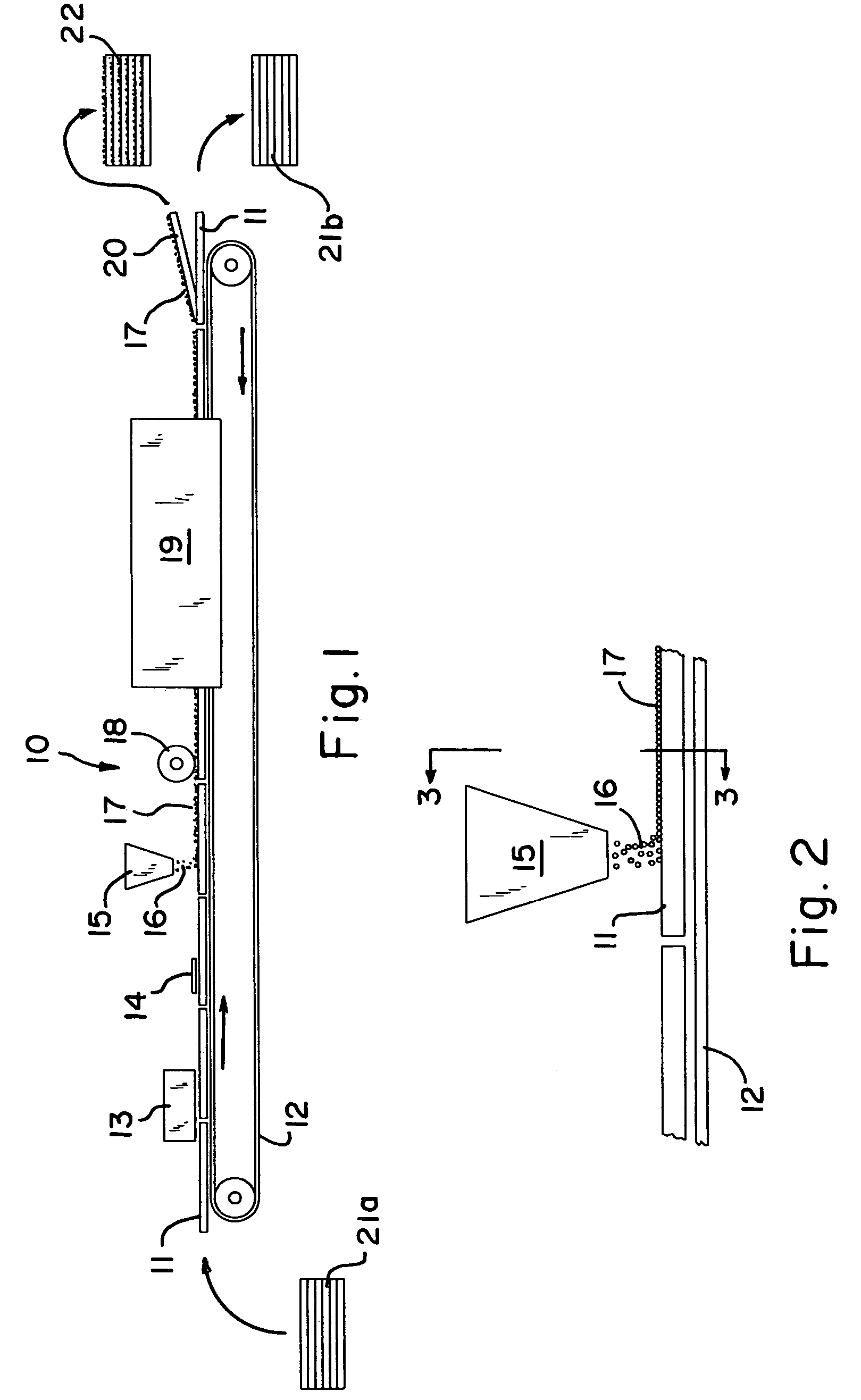

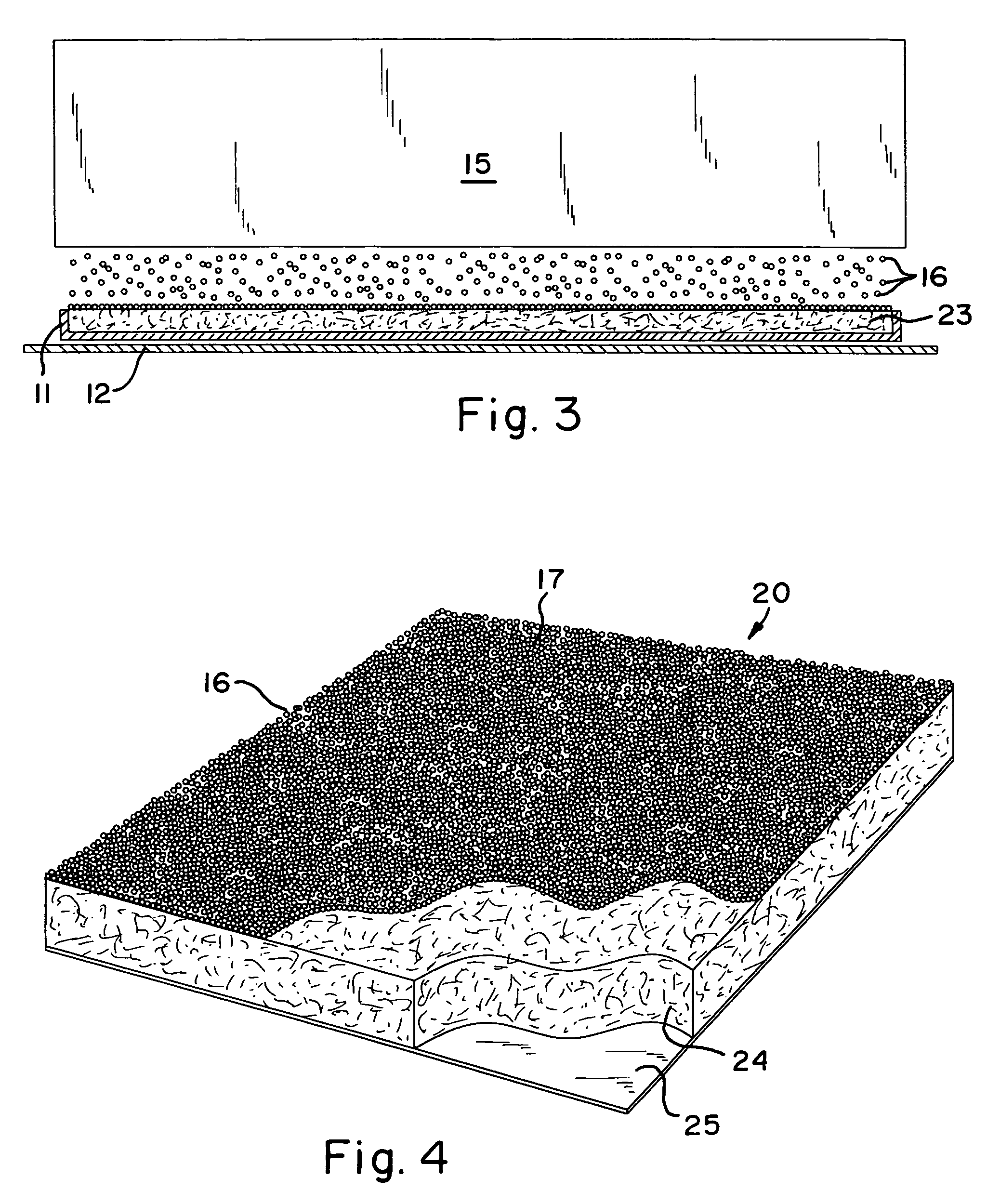

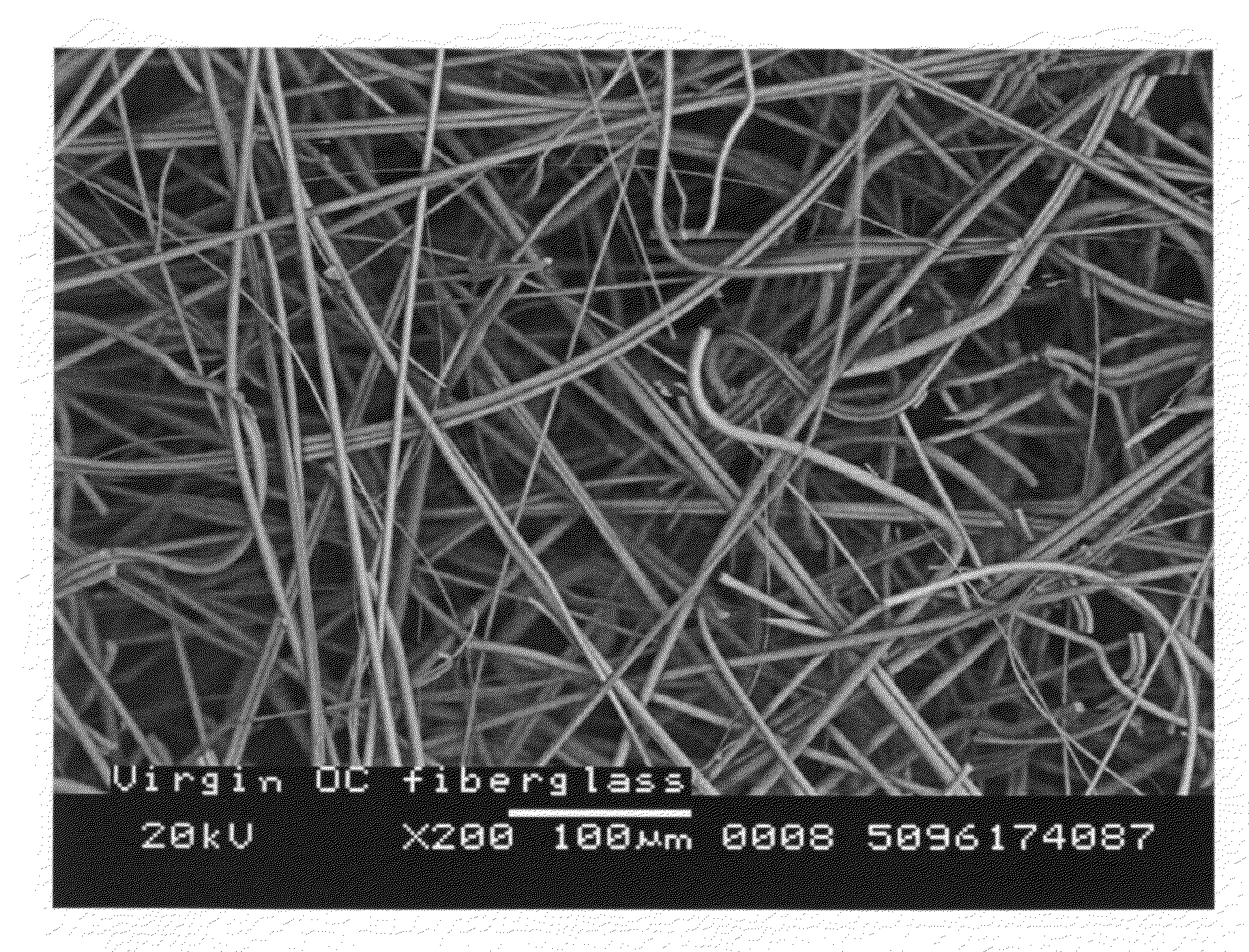

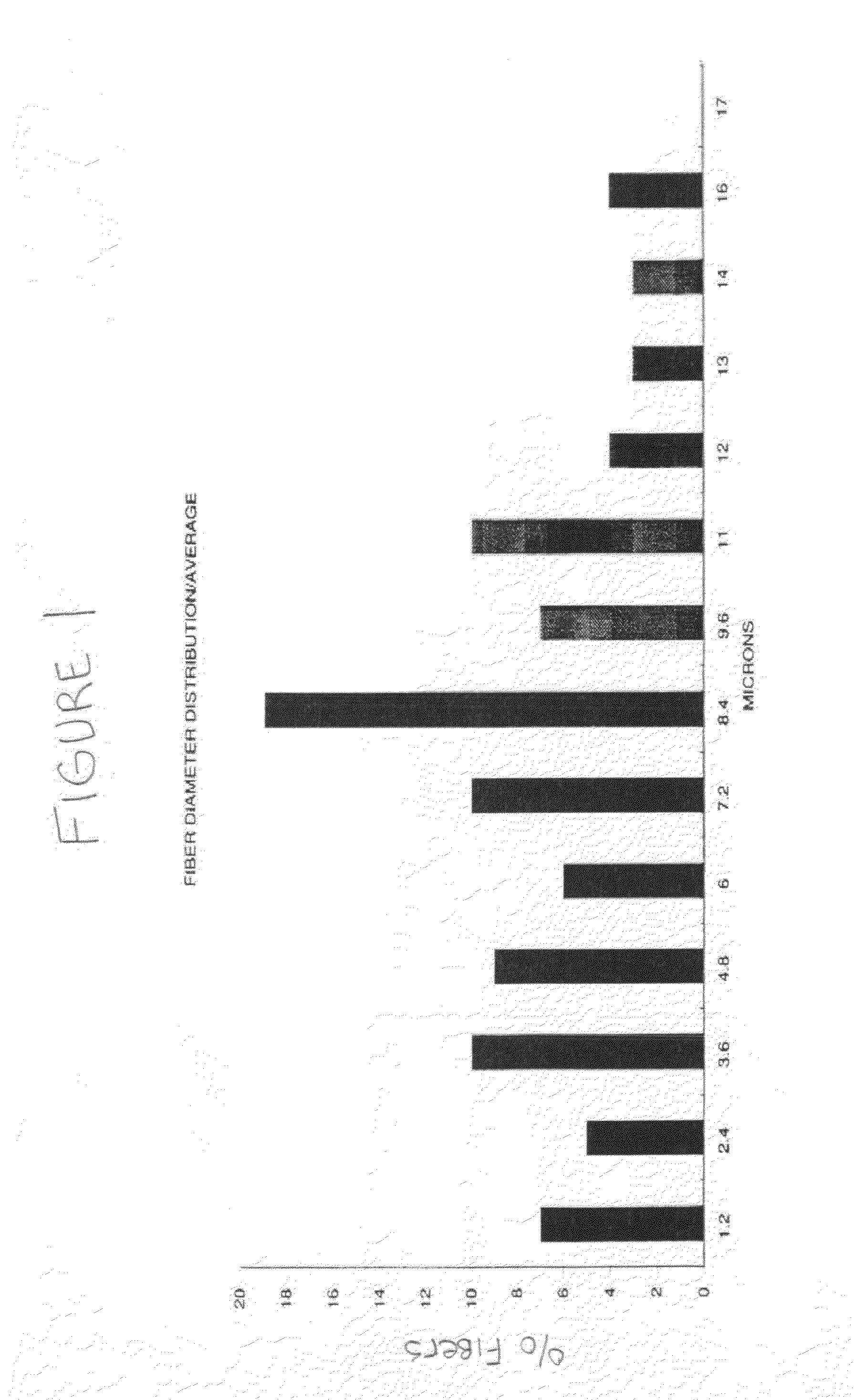

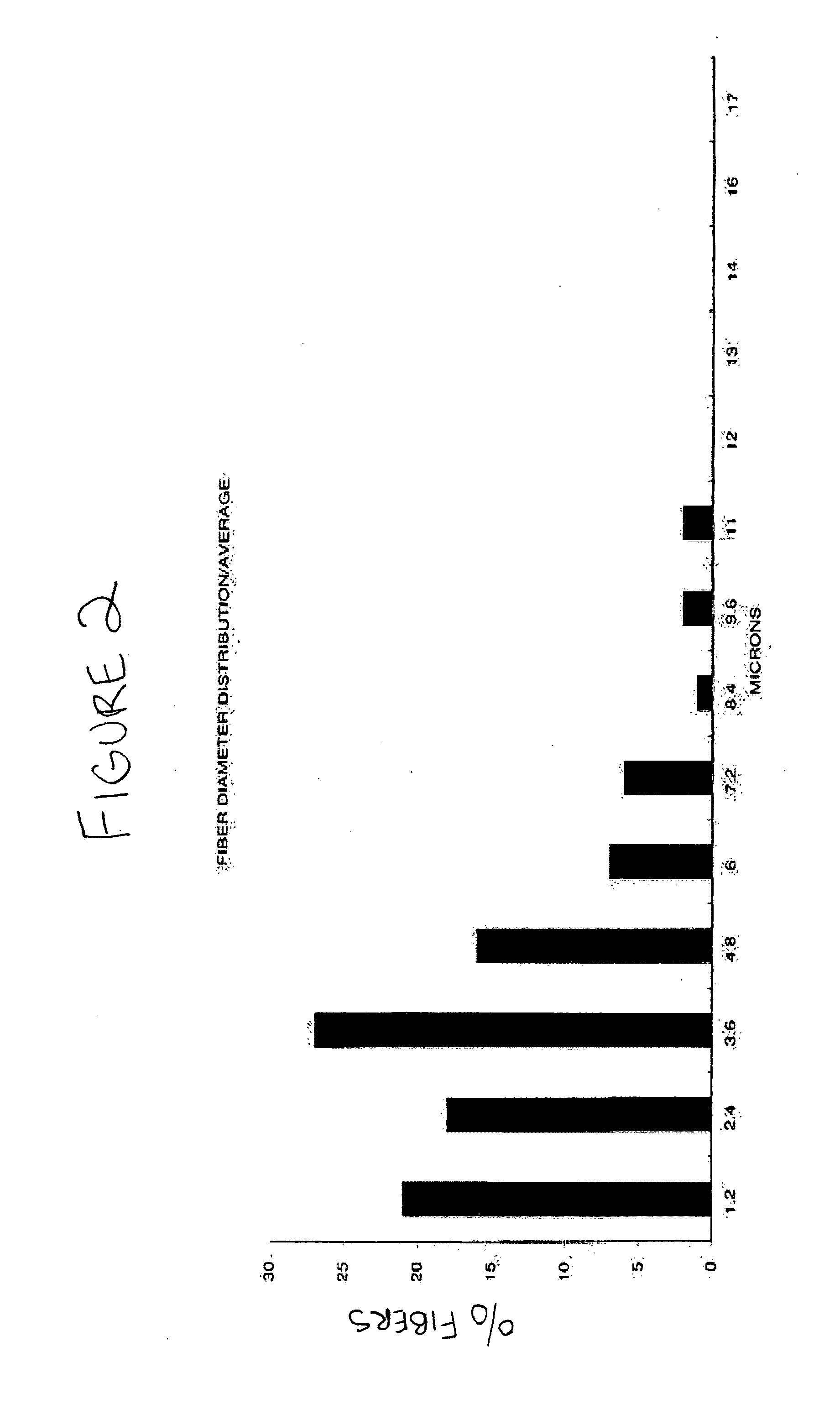

Highly acoustical, wet-formed substrate

ActiveUS20090056898A1High porosityHigh strengthFibreboardConstruction materialWater dispersibleCellulose fiber

This invention is an acoustic fiber-based substrate composed primarily of insulation-type spun fibers or blends of such fibers and wheel spun fibers. The fibers are bound with a water-dispersible latex binder, or an agri-binder such as starch in conjunction with cellulose fiber. The insulation-type spun fibers can be first quality virgin, post-industrial waste-stream or post-consumer waste stream fiber. The substrate is wet-formed from a very dilute aqueous dispersion of ingredients onto a mesh forming screen, as on a Fourdrinier paper machine. By virtue of the insulation-type spun fiber dimensions, morphology and orientation: very low density wet-mats can be formed from a sufficiently dilute suspension. With respect to other wet-formed substrates, the invention is much lower in density and more highly porous, and, thus, the substrate is highly absorbing, exhibiting noise reduction coefficients, NRC values of about 0.80 or greater. Such NRC values have only been achieved with dry-formed, or air-laid processes in which the fiber are bound with formaldehyde emitting reactive resins.

Owner:AWI LICENSING

Sound absorption and insulation sheet material and preparation method thereof

The invention provides a sound absorption and insulation sheet material and a preparation method thereof. The sound absorption and insulation sheet material is composed of, by weight, 50 to 80 parts of cement, 20 to 30 parts of pottery sand, 30 to 40 parts of waste haycite, 6 to 10 parts of silica sol, 5 to 8 parts of starch, 3 to 5 parts of a water repellent, 1 to 8 parts of carbon fiber, 1 to 3 parts of a foaming agent, and 7 to 15 parts of water. The preparation method is simple; operation is convenient; rive sand can be replaced with pottery sand; broken stone can be replaced with waste haycite; a large amount of solid waste in urban garbage can be used; the preparation method is beneficial for changing wastes into valuables, realizing resource cyclic utilization, reducing mineral mining and consumption, and protecting the environment; and the obtained sound absorption and insulation sheet material is high in noise reduction coefficient, and possesses excellent thermal insulation properties.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Cement-based railway sound barrier absorbing material and preparation method thereof

The invention belongs to the field of building materials, particularly discloses a cement-based railway sound barrier absorbing material and a preparation method thereof and is intended to solve the problem that existing railway sound barrier materials are unable to meet the requirements provided in Technical Requirements and Test Methods for Acoustic Elements of Railway Sound Barrier (TB / T 3122-2010). The cement-based railway sound barrier absorbing material is prepared from, by weight, 100 parts of cement, 180-250 parts of mineral residue particles, 0-40 parts of expanded perlite particles, 45-55 parts of water, 2-4 parts of a water reducer, 0-2 parts of a foaming agent, and 0-0.4 part of fibers. The cement-based railway sound barrier absorbing material has good sound-absorbing property and has acoustic properties that meet the requirement in Technical Requirements and Test Methods for Acoustic Elements of Railway Sound Barrier (TB / T 3122-2010) that denoising coefficient is not less than 0.70 when train operation velocity is 200 km / h and above.

Owner:POWERCHINA CHENGDU ENG

Cement-based perlite composite sound barrier

InactiveCN102849995AStable chemical propertiesNo pollution in the processNoise reduction constructionNoise reduction coefficientSound barrier

The invention discloses a cement-based perlite composite sound barrier, applied to noise prevention and control engineering for railway and urban rail transit projects. The sound barrier comprises a perlite layer and a ceramisite concrete layer. The perlite layer comprises perlite, glue, cement, water and sand at weight ratio of 1:(0.048-0.052):(1.8-2.2):(3.8-4.2):(2.7-3.3). The ceramisite concrete layer comprises ceramisite, cement, water and sand at weight ratio of 2:(1.8-2.2):(3.8-4.2):(2.7-3.3). The invention utilizes cementing force of cement itself to bond the perlite layer and ceramisite concrete layer, and utilizes self porosity of perlite to realize noise reduction effect, with noise reduction coefficient of above 0.65, and sound insulation amount of above 27 dB. The sound barrier has the advantages of good sound absorbability, high bending and impact strength, good freeze-thaw resistance, and stable material chemical stability.

Owner:郭云驰

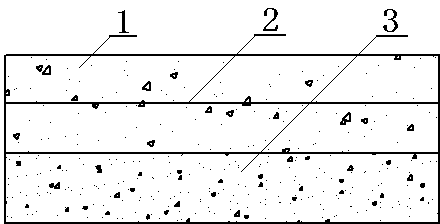

Sound absorption heat-insulation plate

InactiveCN102839762AReduce weightTo achieve sound-absorbing effectSynthetic resin layered productsHeat proofingNoise reduction coefficientPolyester

The invention discloses a sound absorption heat-insulation plate, which comprises seven layers of structures, wherein the middle layer is a layer of metal plate, wherein the upper surface and the lower surface of the metal layer are respectively provided with a sound absorption heat-insulation layer, the upper surface and the lower surface of the sound absorption heat-insulation layer are respectively provided with non-woven fabric layers, and the upper surface and the lower surface of the non-woven fabric layer are respectively provided with polyester glass fiber plates. The sound absorption heat-insulation layer adopts hexagonal honeycomb cores made of PVC (polyvinyl chloride), sound absorption materials such as rock wool or perlite are filled in the hexagonal honeycomb cores, sound waves pass through the non-woven fabric layer and are absorbed by the sound absorption materials in the hexagonal honeycomb cores, the sound absorption effect is reached, the sound absorption heat-insulation plate can be used for sound absorption suspended ceilings and wall surfaces of public places, such as airport terminals, stadiums and conference halls, the noise reduction coefficient is high and can reach more than 0.8, the sound absorption heat-insulation plate can be used for manufacturing the large-area wide plate suspended ceiling, the appearance is attractive, the weight is light, the deformation is avoided, and the popularization is convenient.

Owner:青岛同力得塑料蜂巢有限公司

Cement-based sawdust composite noise barrier

InactiveCN102852098AStable chemical propertiesTo achieve the purpose of noise reductionNoise reduction constructionRailway tracksNoise reduction coefficientNoise barrier

The invention discloses a cement-based sawdust composite noise barrier mainly applicable to noise preventing projects of railways and urban light railway projects. The cement-based sawdust composite noise barrier comprises a sawdust layer and a concrete layer. The sawdust layer is made by mixing sawdust particles, glue, cement, water and yellow sands according to a weight proportion of 1:0.048-0.052:1.8-2.2:4.5-5.5:2.7-3.3. Bonding force of cement gum is used to bond the sawdust layer and the concrete layer. Pores of the sawdust layer are used to absorb noise energy for consumption, and accordingly noise reduction is achieved, noise reduction coefficient reaches more than 0.7, and noise insulation factor reaches 25dB. The cement-based sawdust composite noise barrier is fine in noise absorption, fracture-resistant, high in impact strength, fine in freezing and thawing resistance, stable in material chemical properties, humidity-resistant, anticorrosion, mildew-resistant, nonflammable, pollution-free, easy to transport, convenient to mount and maintain and the like.

Owner:郭云驰

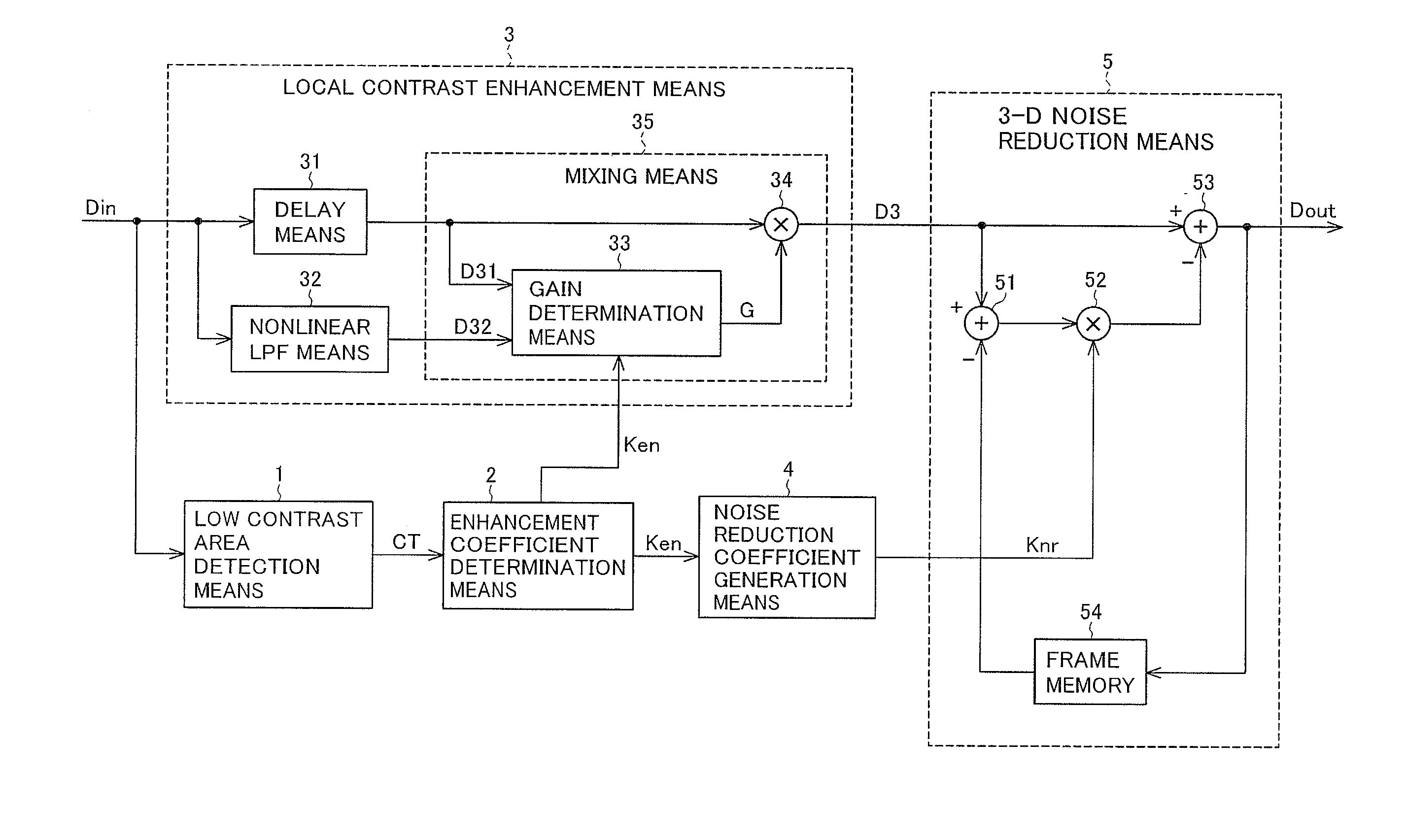

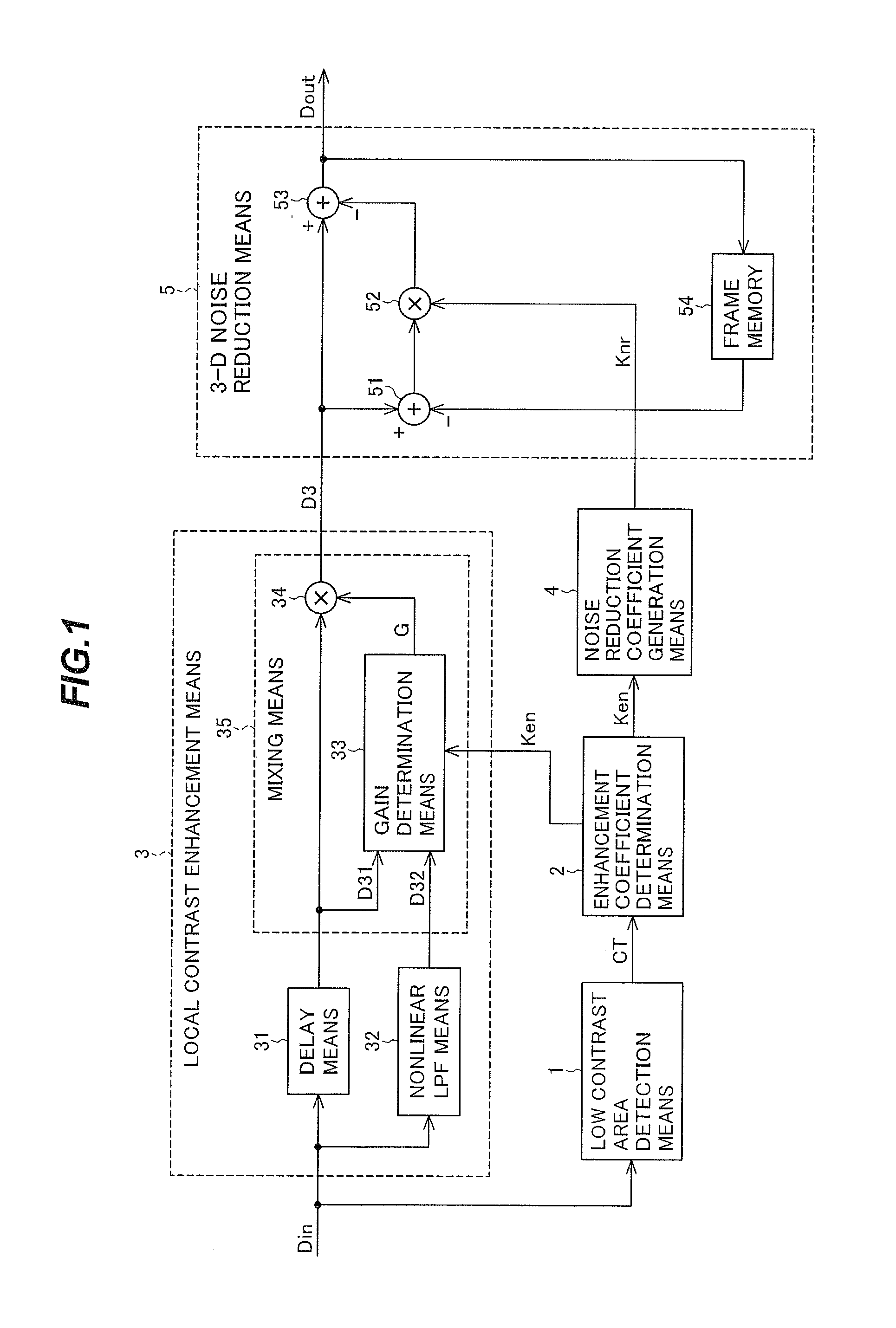

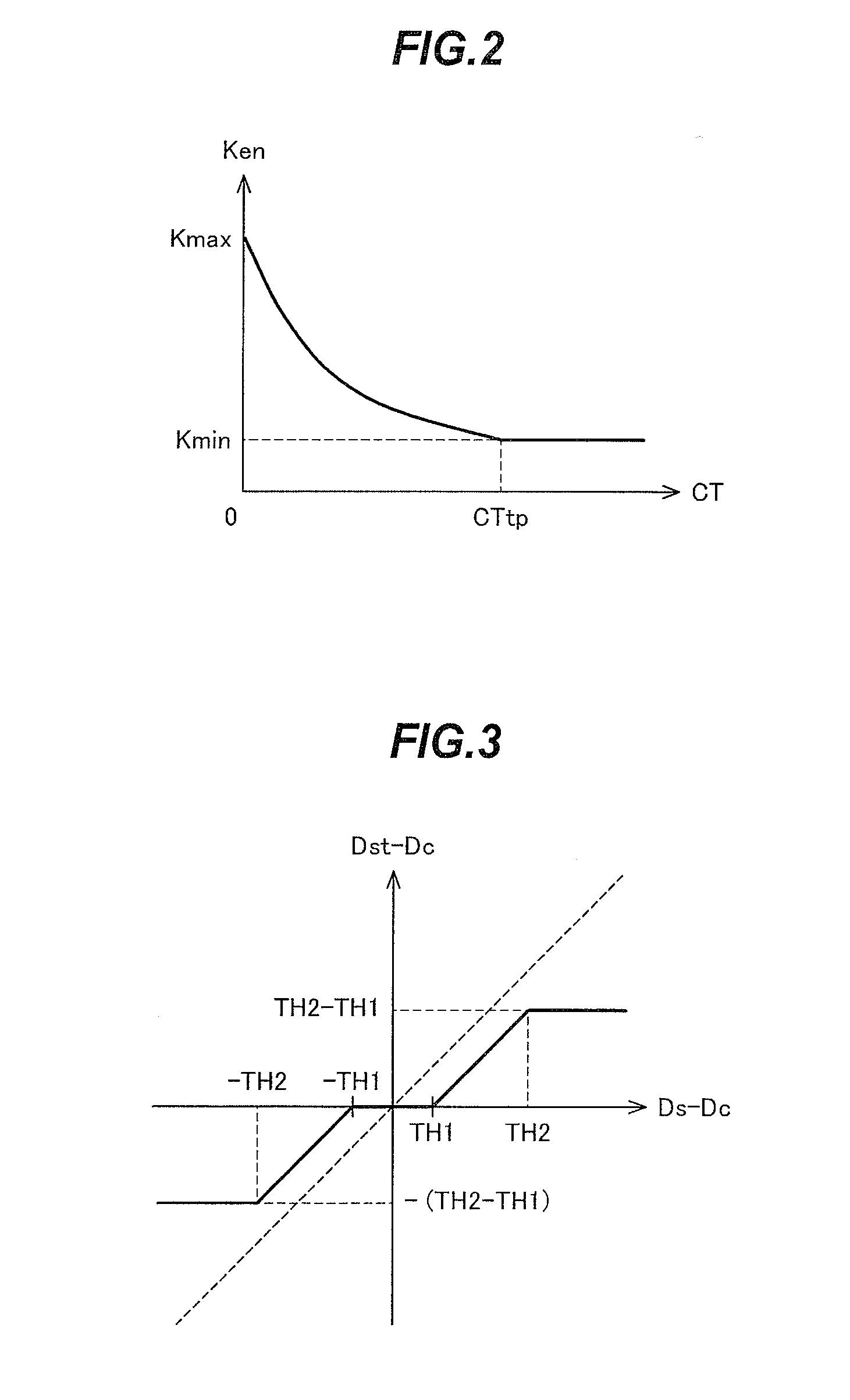

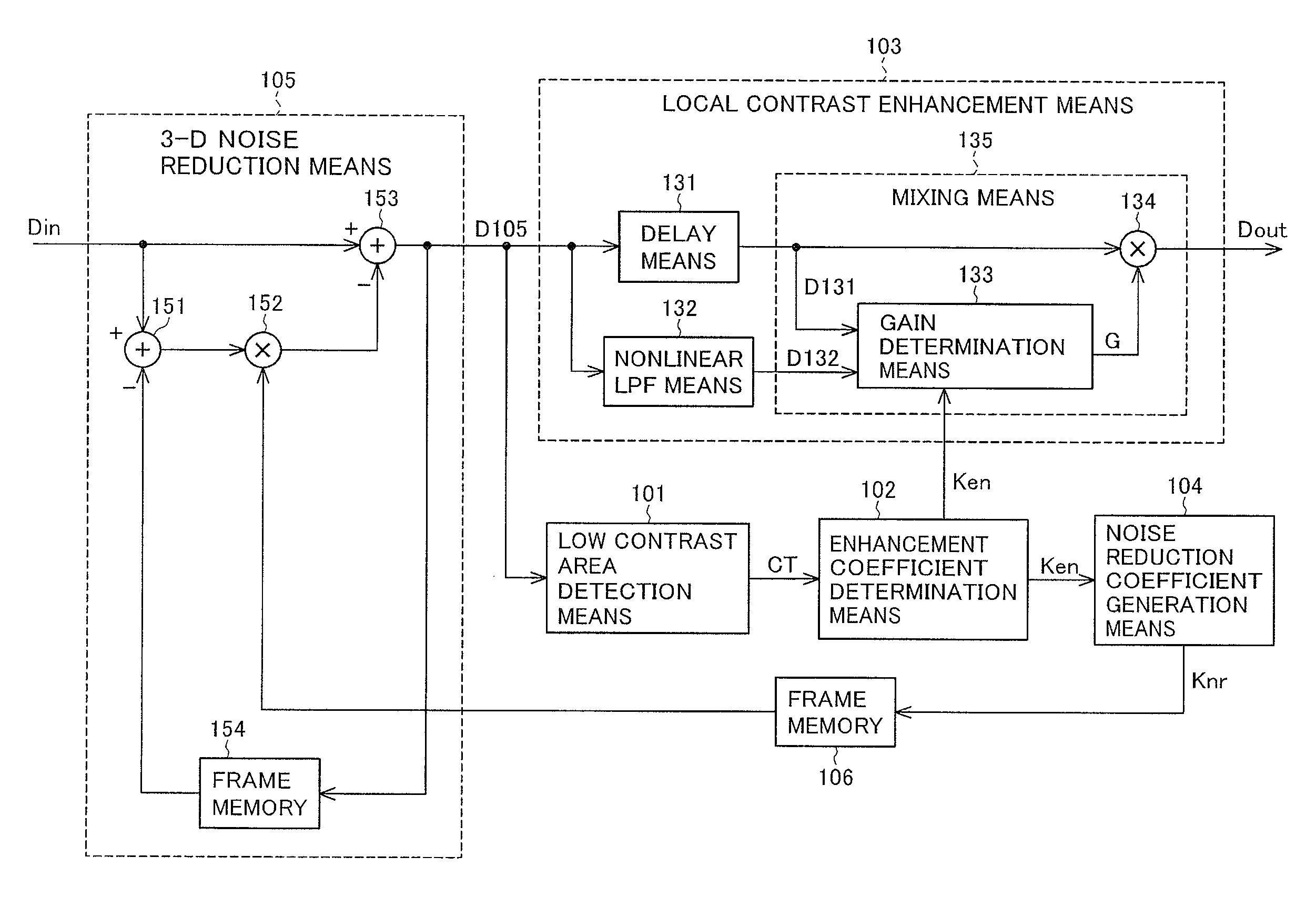

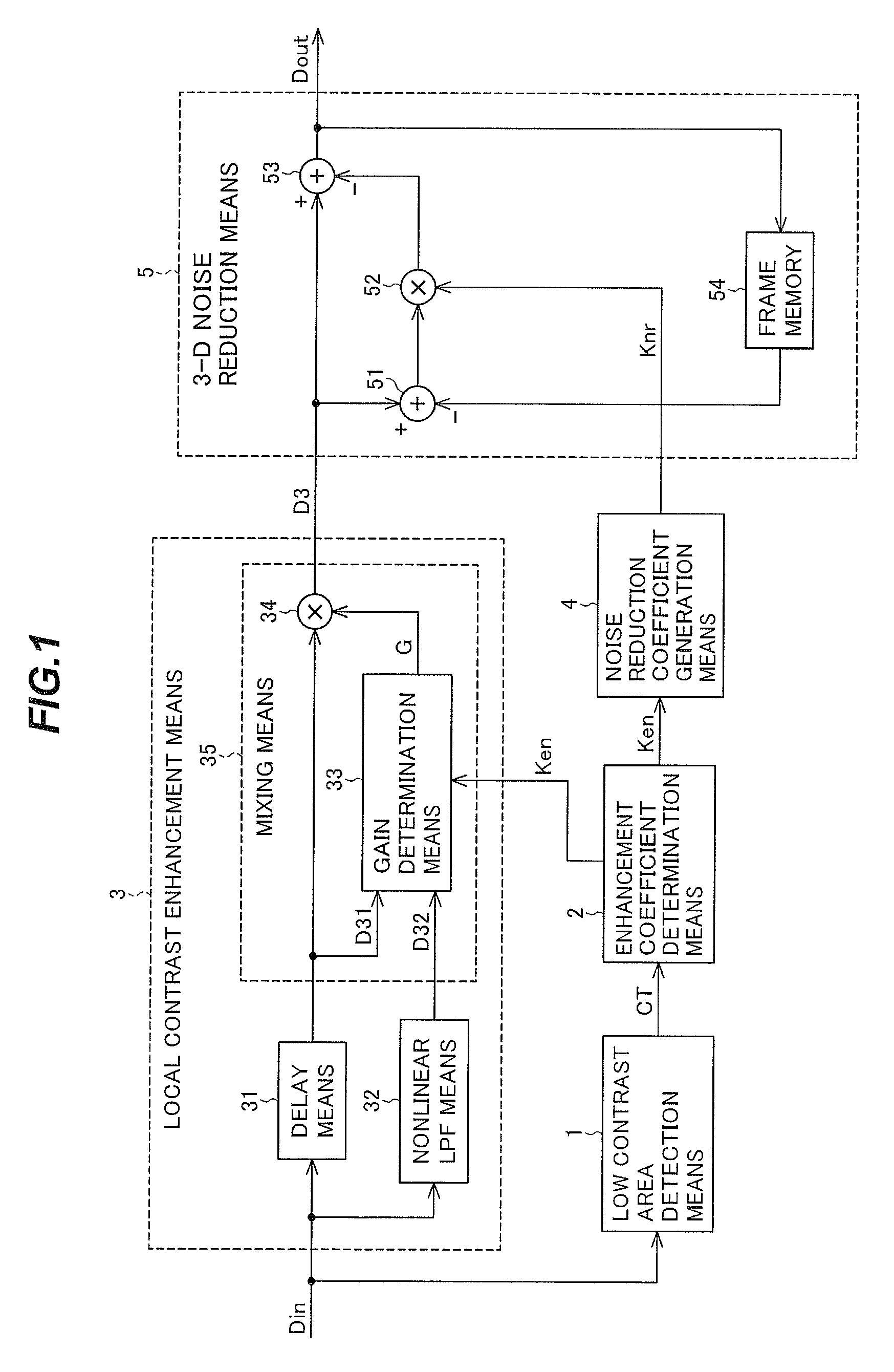

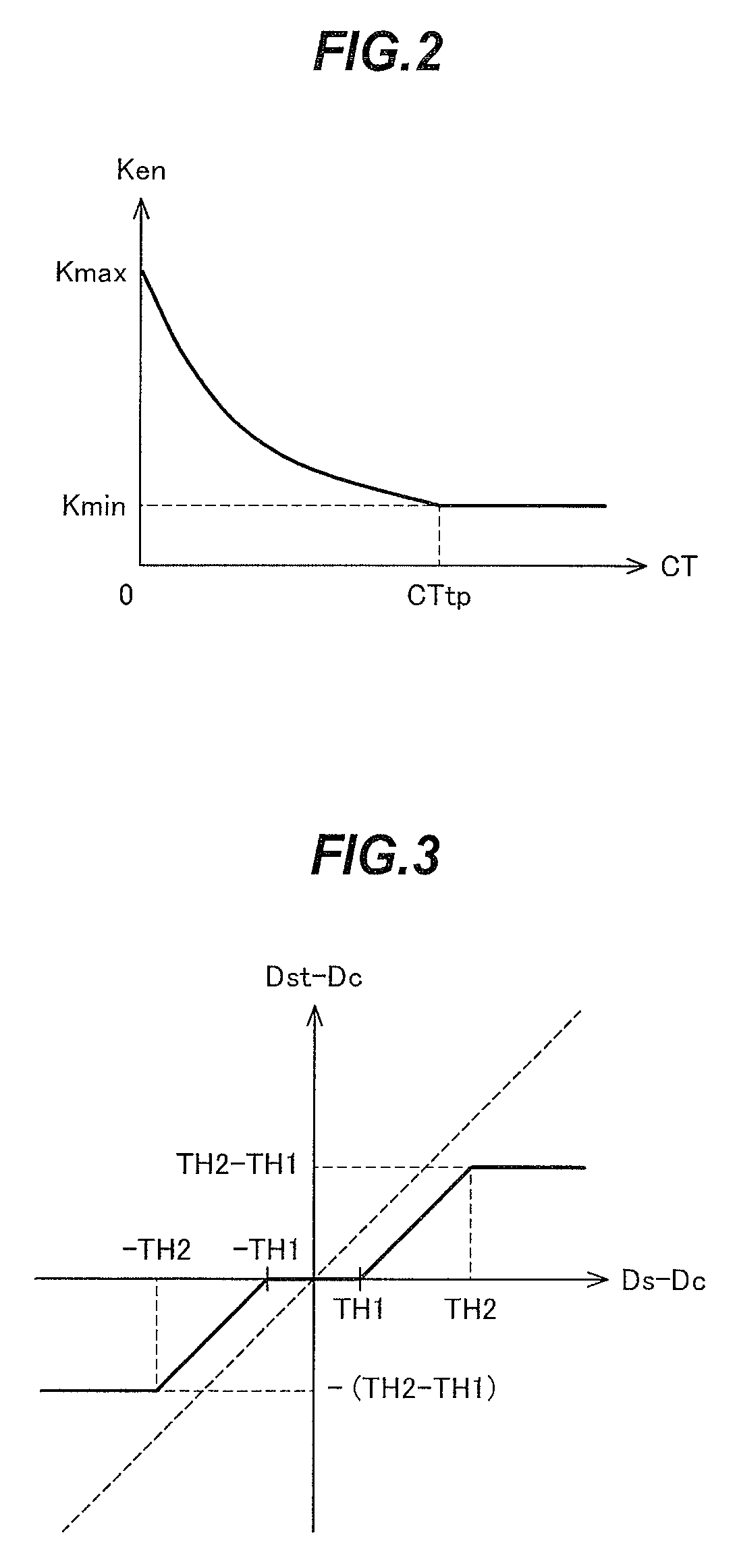

Image processing device and method

InactiveUS20130336596A1Reduce noiseImprove local contrastImage enhancementTelevision system detailsNoise reduction coefficientIntermediate image

For each pixel in an image (Din), a contrast correlation value (CT) is detected for peripheral areas centered around the pixel to be corrected (1), a contrast enhancement coefficient (Ken) is determined in accordance with the contrast correlation value (CT) (2), and in accordance with the enhancement coefficient (Ken), local contrast is enhanced for each pixel and an intermediate image (D3) is generated (3). When performing noise reduction (5) by smoothing the intermediate image (D3) in the time direction, the degree of noise reduction is controlled in accordance with a noise reduction coefficient (Knr) that is large where the enhancement coefficient (Ken) is large. With respect to a low-contrast image such as one captured under fog, haze or other poor weather conditions, the contrast in areas having reduced contrast is appropriately improved, and the noise that is enhanced in conjunction with contrast improvement is reduced, enabling a high quality image to be obtained.

Owner:MITSUBISHI ELECTRIC CORP

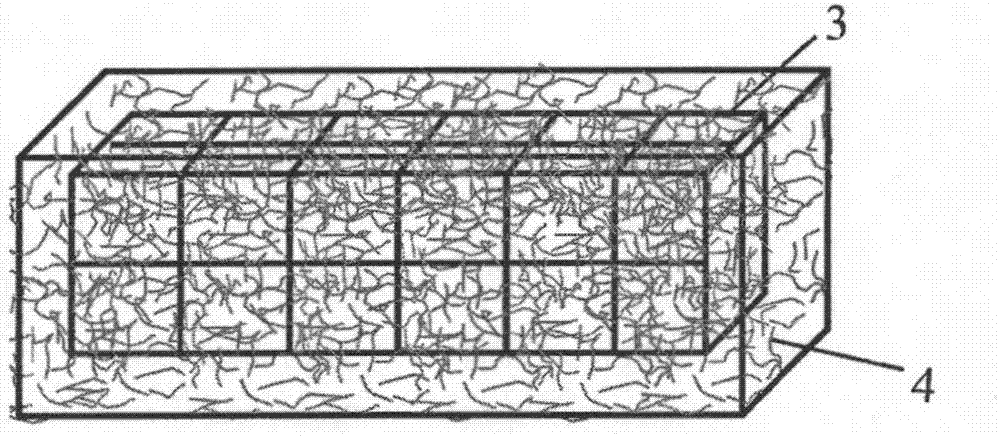

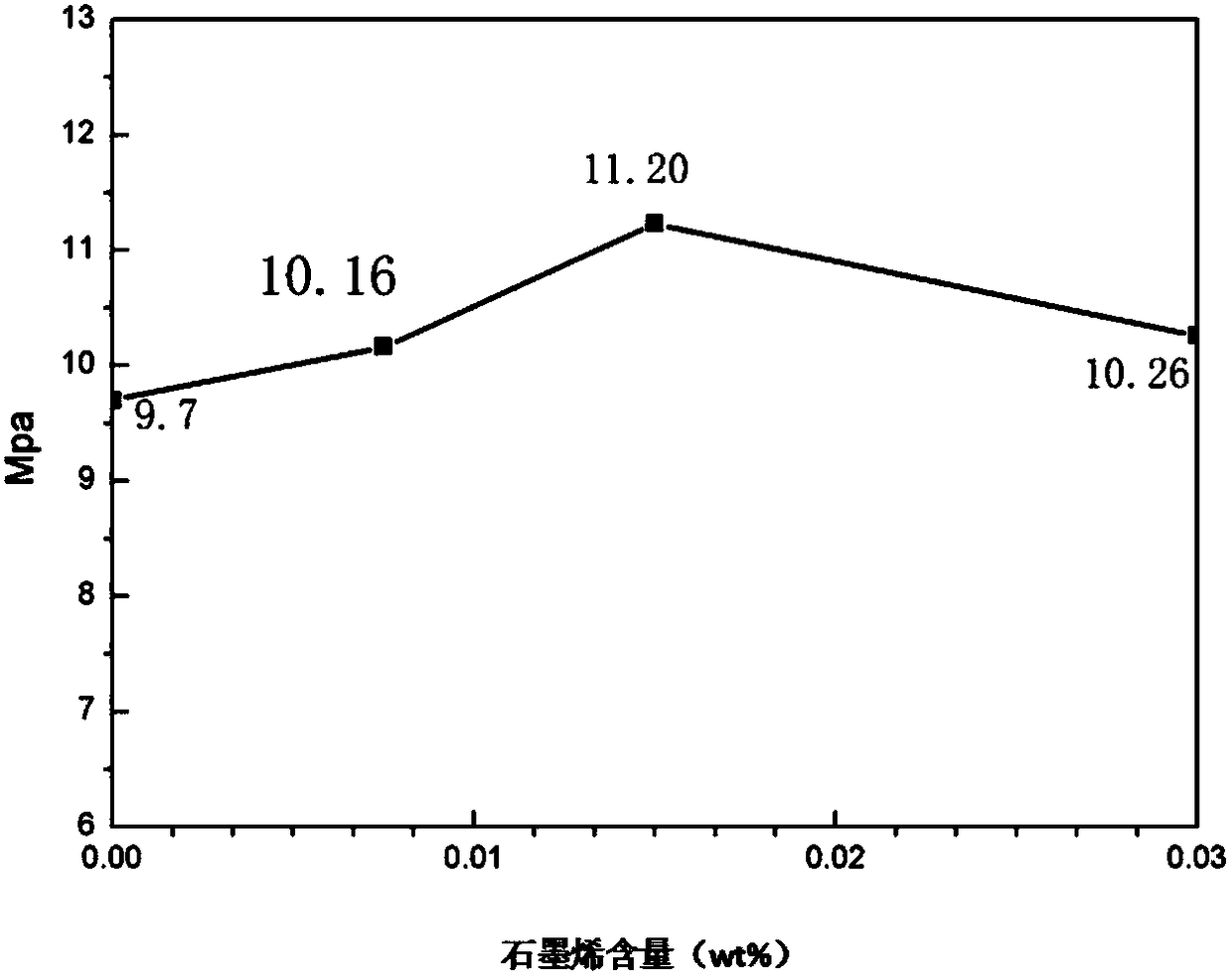

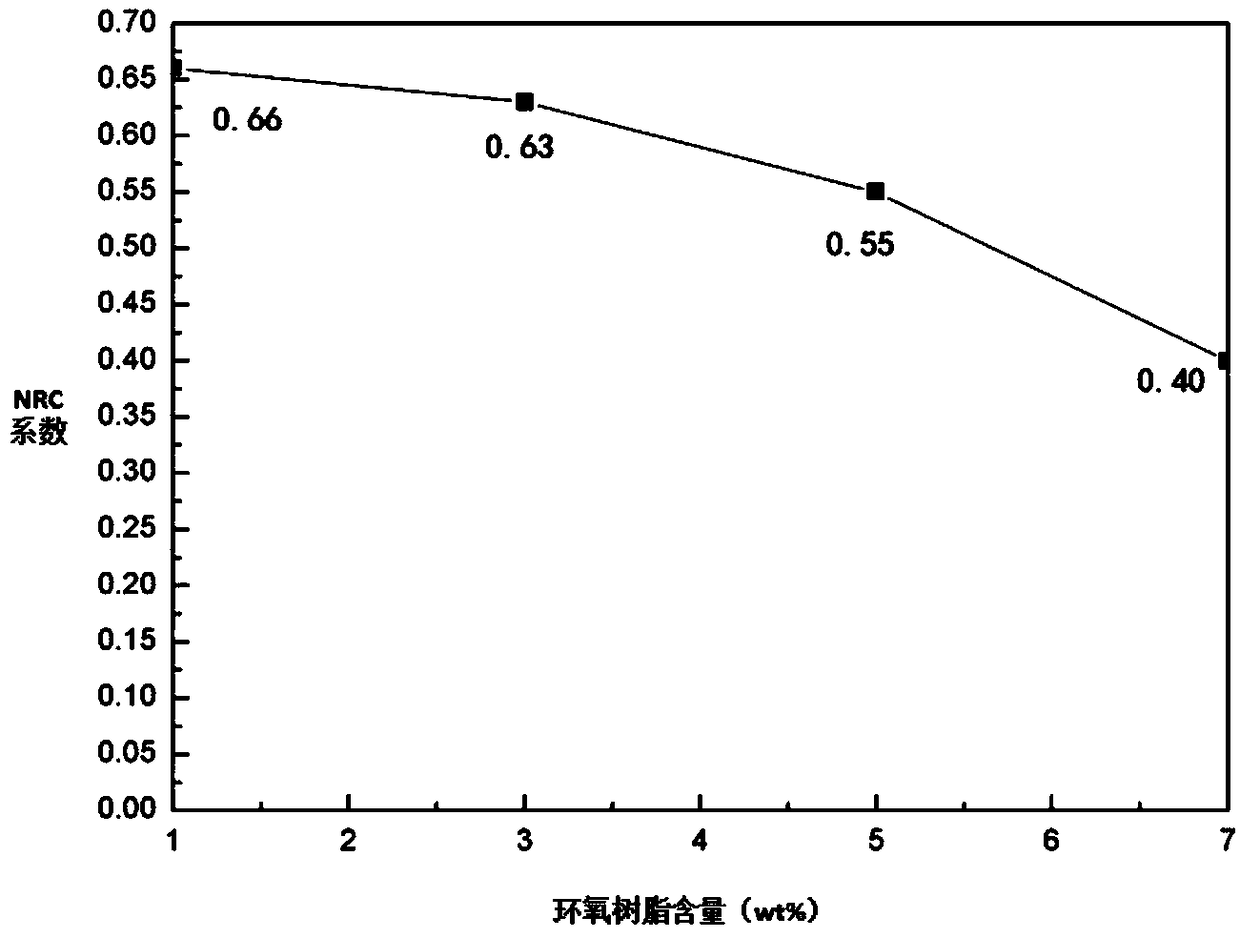

Polymeric microparticle acoustic panel and production method thereof

The invention discloses a polymeric microparticle acoustic panel. The polymeric microparticle acoustic panel comprises raw materials in percentage by mass as follows: 89%-98.5% of aggregate, 1.4%-10.7% of an adhesive, 0.003%-0.03% of graphene and 0.003%-0.3% of silane. According to a preparation method, the adhesive, graphene and silane are mixed, sufficiently stirred for 5-10 min, ultrasonicallyirradiated and stirred for 5-30 min, and then the aggregate is added and stirred uniformly, and a mixture is obtained; a layer of mixture is laid in a mold, gridding cloth is added, the mold is fullypaved, pressing molding is performed, and the graphene reinforced polymeric microparticle acoustic panel is obtained. A graphene sheet layer in the polymeric microparticle acoustic panel is stably dispersed in the adhesive, oxygen-containing functional groups on graphene or graphene oxide participate in a curing reaction of the adhesive, and strength of the polymeric microparticle acoustic panel is improved; by reasonable selection of the adhesive quantity, strength of the acoustic panel is guaranteed, the polymeric microparticle acoustic panel contains a large quantity of communicated micropores inside, NRC (noise reduction coefficient) of the polymeric microparticle acoustic panel is guaranteed, and sound absorbing effect of the polymeric microparticle acoustic panel is improved.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

Image processing device and method

InactiveUS9153015B2Reduce noiseImprove local contrastImage enhancementTelevision system detailsNoise reduction coefficientIntermediate image

For each pixel in an image (Din), a contrast correlation value (CT) is detected for peripheral areas centered around the pixel to be corrected (1), a contrast enhancement coefficient (Ken) is determined in accordance with the contrast correlation value (CT) (2), and in accordance with the enhancement coefficient (Ken), local contrast is enhanced for each pixel and an intermediate image (D3) is generated (3). When performing noise reduction (5) by smoothing the intermediate image (D3) in the time direction, the degree of noise reduction is controlled in accordance with a noise reduction coefficient (Knr) that is large where the enhancement coefficient (Ken) is large. With respect to a low-contrast image such as one captured under fog, haze or other poor weather conditions, the contrast in areas having reduced contrast is appropriately improved, and the noise that is enhanced in conjunction with contrast improvement is reduced, enabling a high quality image to be obtained.

Owner:MITSUBISHI ELECTRIC CORP

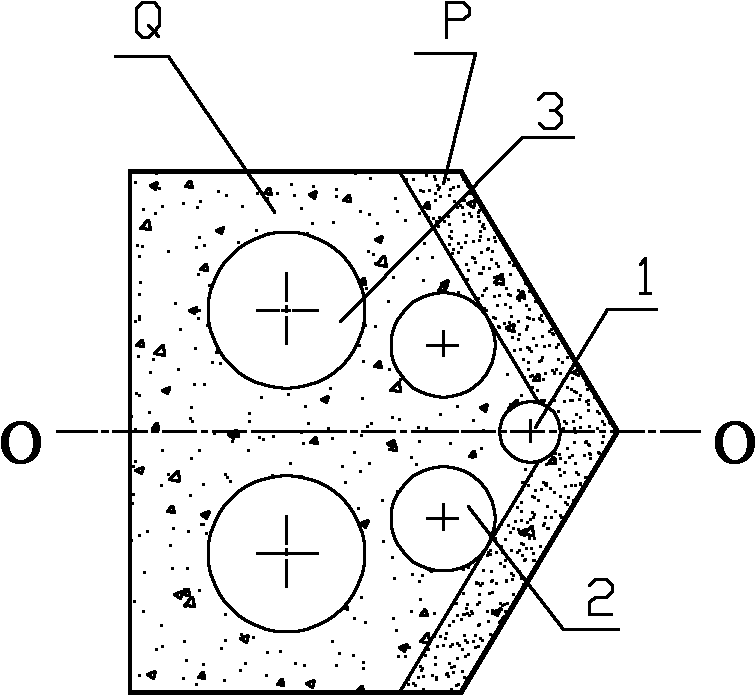

Wedge-shaped perlite resonance acoustical tile

ActiveCN102419971AImprove sound absorption performanceAvoid sound reflectionSound producing devicesNoise reduction coefficientAcoustic absorption

The invention relates to a wedge-shaped perlite resonance acoustical tile, which is mainly made of expanded perlite and cement and is characterized in that the surface of the acoustical tile, which faces the incident direction of acoustic waves, is wedge-shaped; and a closed air resonance cavity is constructed inside the acoustical tile. The acoustic absorption coefficient of the wedge-shaped perlite resonance acoustical tile disclosed by the invention is greater than 0.75 in the frequency range of 125-5000Hz, the noise reduction coefficient of the wedge-shaped perlite resonance acoustical tile reaches 0.93, and the wedge-shaped perlite resonance acoustical tile can be used for manufacturing high-efficiency acoustical barrier of railways and roads.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com