Wedge-shaped perlite resonance acoustical tile

A kind of resonance sound absorption and perlite technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of loud reflection, poor sound absorption performance, inconvenient transportation, etc., and achieve the effect of reducing sound wave reflection, improving sound absorption performance, and avoiding sound reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

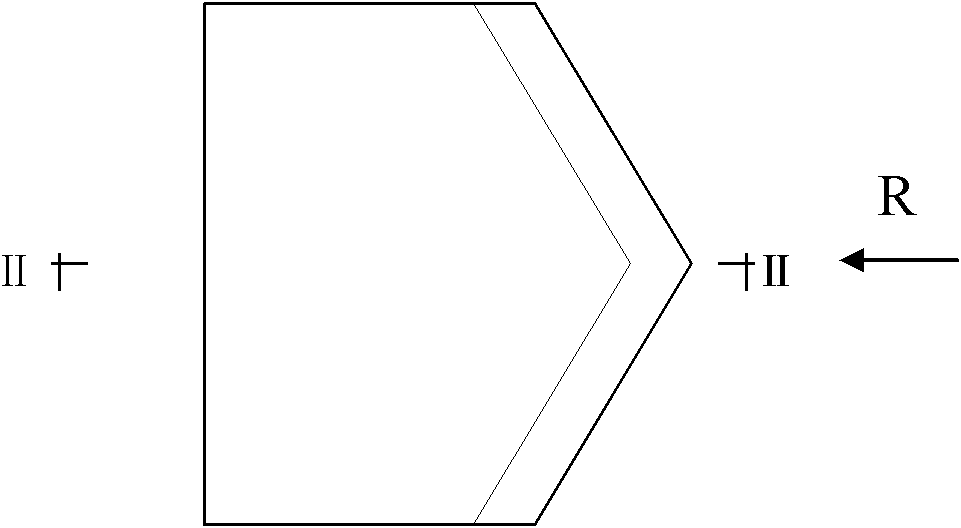

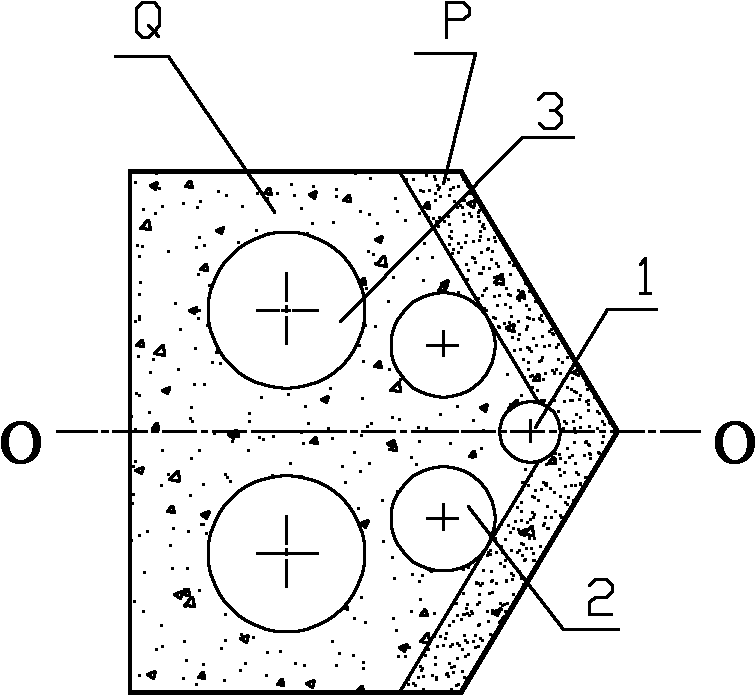

[0037] This embodiment relates to a perlite wedge resonant sound-absorbing brick, see Figure 1-4 , It is characterized in that the surface of the sound-absorbing brick facing the sound wave incident direction R is wedge-shaped (that is, triangular shape); a shape-closed air resonance cavity is built inside the sound-absorbing brick. The air resonant cavity is a spherical cavity, which is arranged according to the size of the volume, that is, the closer to the sound wave incident part, the smaller the volume.

[0038] The specific arrangement and size of the air resonance cavity are preferably as follows: a first spherical cavity 1 with a diameter of 25-45 mm is set near the center of the sharp corner, and then two 50-70 mm diameters are respectively arranged at symmetrical positions along the center line O-O. The second spherical cavity 2, followed by two third spherical cavities 3 with a diameter of 80-100 mm at symmetrical positions along the center line O-O.

[0039] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com