Performance testing method for wideband perforated plate

A test method and perforated plate technology, which can be applied to sound-producing instruments, use sonic/ultrasonic/infrasonic waves to analyze solids, instruments, etc., and can solve the problems of inability to change a single sound absorption peak, limitation, poor sound absorption effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

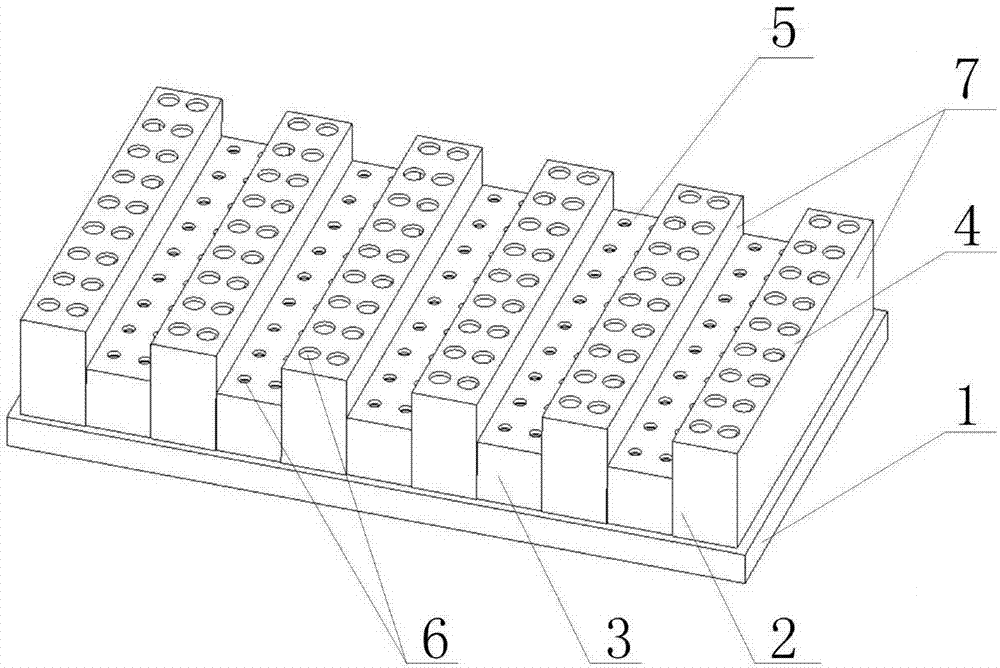

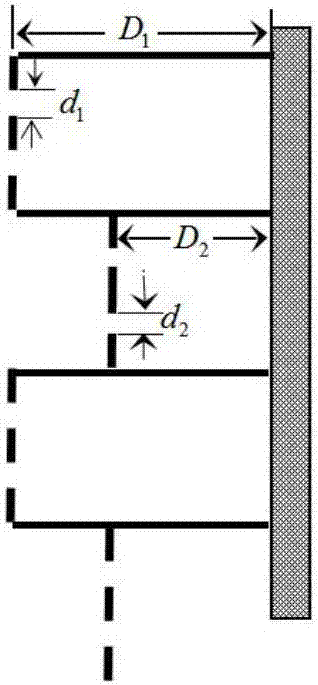

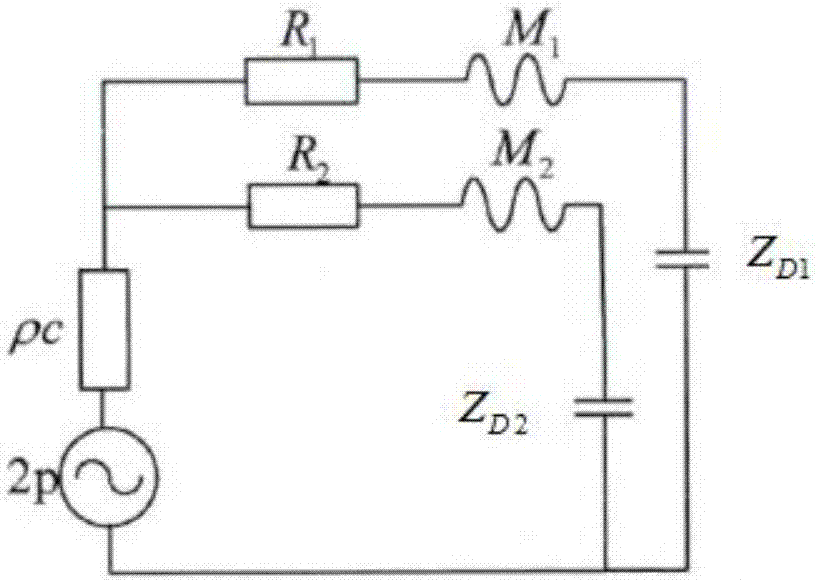

[0057] Embodiment 1 of the present invention: a wide-band perforated plate, including a back plate 1, a plurality of first cavity bodies 2 and a plurality of second cavity bodies 3 are arranged on the back plate 1, and each adjacent two first cavity bodies A second cavity body 3 is arranged between the cavity bodies 2, the first cavity body 2 includes an A hole plate 4, the second cavity body 3 includes a B hole plate 5, and the A hole plate 4 and the B hole plate 5 are both It is a sound-absorbing panel provided with a plurality of small holes 6, and the distance between the A hole plate 4 and the back plate 1 is greater than the distance between the B hole plate 5 and the back plate 1.

Embodiment 2

[0058] Embodiment 2 of the present invention: a broadband perforated plate, including a back plate 1, on which a plurality of first cavities 2 and a plurality of second cavities 3 are arranged, and each adjacent two first cavities A second cavity body 3 is arranged between the cavity bodies 2, the first cavity body 2 includes an A hole plate 4, the second cavity body 3 includes a B hole plate 5, and the A hole plate 4 and the B hole plate 5 are both It is a sound-absorbing panel provided with a plurality of small holes 6, and the distance between the A hole plate 4 and the back plate 1 is greater than the distance between the B hole plate 5 and the back plate 1. The first cavity body 2 further includes a partition 7 vertically connected to the backplane 1 . The aperture diameter of the small hole 6 provided on the A hole plate 4 is larger than the aperture diameter of the small hole 6 provided on the B hole plate 5 . The distance between two adjacent small holes 6 on the A ho...

Embodiment 3

[0059] Embodiment 3 of the present invention: a broadband perforated plate, including a back plate 1, on which a plurality of first cavities 2 and a plurality of second cavities 3 are arranged, and every two adjacent first cavities A second cavity body 3 is arranged between the cavity bodies 2, the first cavity body 2 includes an A hole plate 4, the second cavity body 3 includes a B hole plate 5, and the A hole plate 4 and the B hole plate 5 are both It is a sound-absorbing panel provided with a plurality of small holes 6, and the distance between the A hole plate 4 and the back plate 1 is greater than the distance between the B hole plate 5 and the back plate 1. The first cavity body 2 further includes a partition 7 vertically connected to the backplane 1 . The aperture diameter of the small hole 6 provided on the A hole plate 4 is smaller than the aperture diameter of the small hole 6 provided on the B hole plate 5 . The distance between two adjacent small holes 6 on the A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com