Polymeric microparticle acoustic panel and production method thereof

A technique of polymerizing particles and a production method, which is applied in the field of architectural decoration, noise-reducing sound-absorbing materials, and acoustic design. It can solve problems such as stress concentration and affecting the performance of composite materials, and achieve the effect of increasing strength and improving sound-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

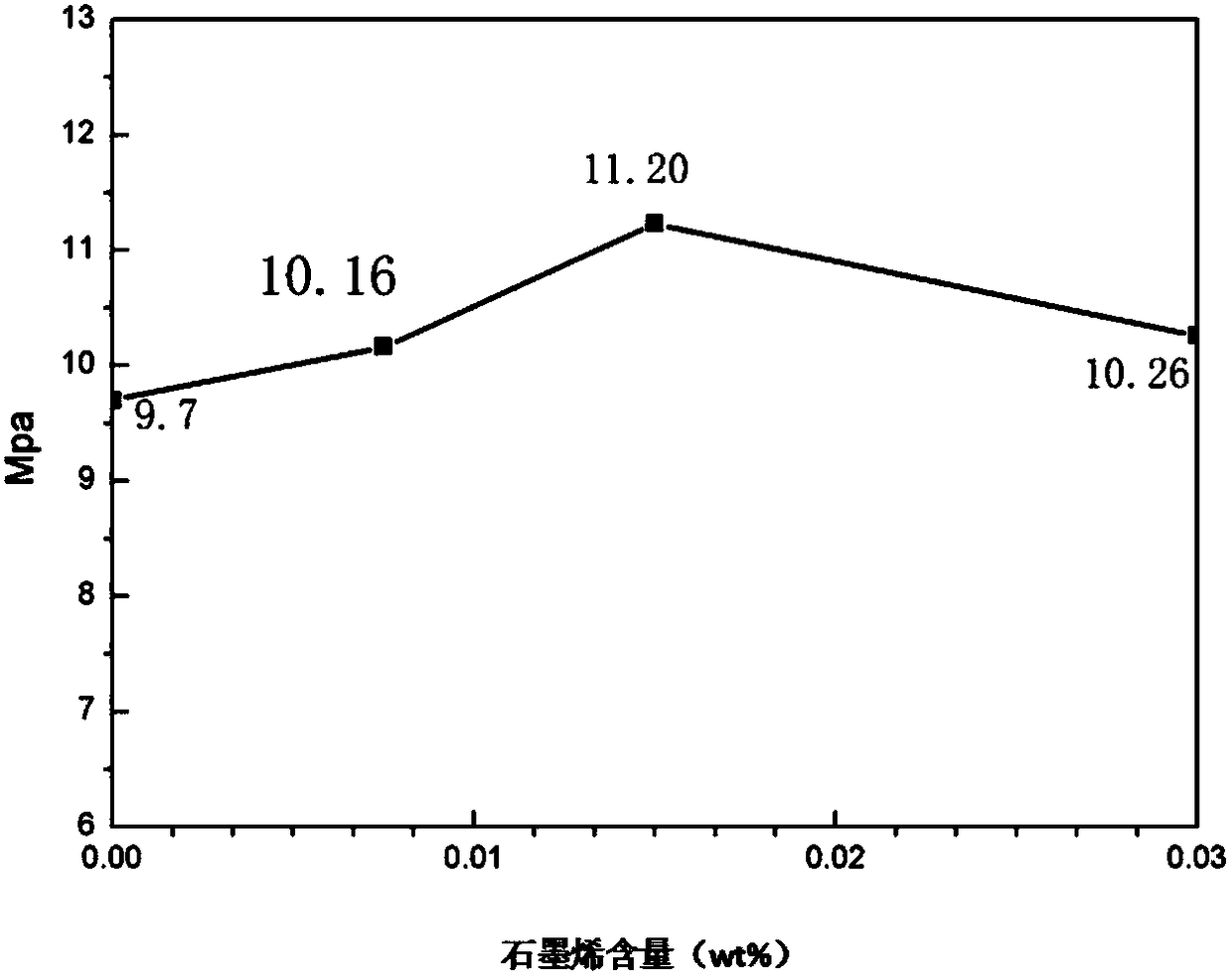

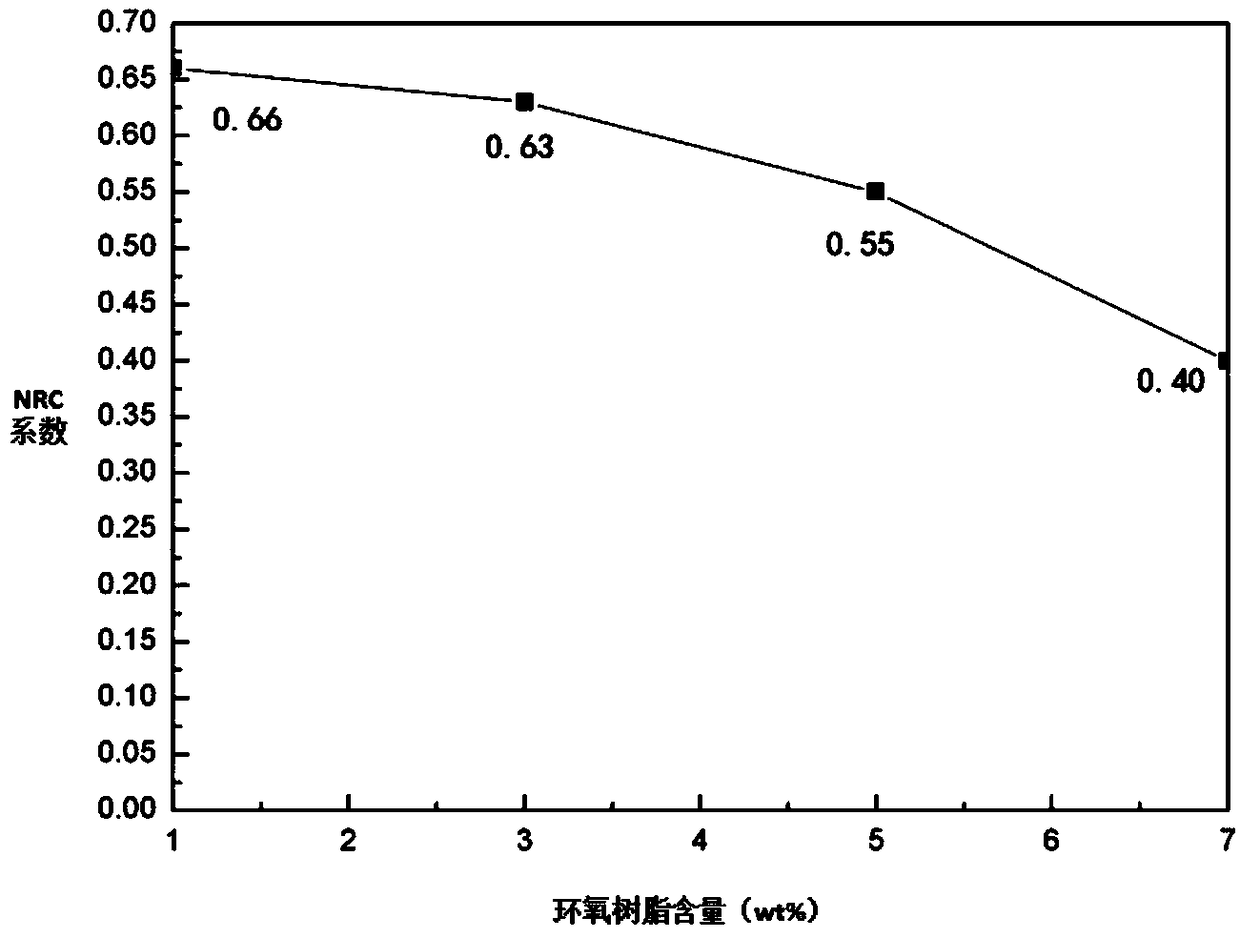

[0029] Select 98.04kg of 20-70 mesh machine-made sand, 1.95kg of polyurethane resin, 0.005kg of graphene, and 0.005kg of silane.

[0030] Mix the polyurethane resin, graphene dispersion and silane and stir thoroughly for 5 minutes, then irradiate with ultrasonic waves with a frequency of 50KHz and a power of 400w and stir for 5 minutes, then add machine-made sand and stir evenly to obtain a mixture; spread a layer of mixture in the mold Material, add grid cloth and then cover the mold, press molding to get graphene reinforced polymer particle sound-absorbing panel. Wherein the addition form of graphene is the graphene dispersion liquid that solid content is 2wt%, and dispersing solvent is ethanol.

Embodiment 2

[0032] Select 1.84kg of 20-40 mesh slag, 7.36kg of 40-70 mesh natural aeolian sand, 0.796kg of phenolic resin, 0.002kg of graphene, and 0.002kg of silane.

[0033] Mix the phenolic resin, graphene dispersion and silane and stir thoroughly for 10 minutes, then irradiate with ultrasonic waves with a frequency of 20KHz and a power of 100w and stir for 30 minutes, then add aeolian sand and slag and stir evenly to obtain a mixture; spread in the mold A layer of mixture, plus grid cloth to cover the mold, press molding to get the graphene reinforced polymer particle sound-absorbing panel. Wherein the addition form of graphene is that solid content is 1wt%, and dispersion solvent is N-methylpyrrolidone graphene dispersion liquid.

Embodiment 3

[0035] Select 5.76kg of 20-40 mesh manufactured sand, 3.84kg of 40-70 mesh natural aeolian sand, 0.398kg of furan resin, 0.001kg of graphene, and 0.001kg of silane.

[0036] Furan resin, graphene oxide dispersion and silane were mixed and then fully stirred for 8 minutes, then irradiated with ultrasonic waves with a frequency of 30KHz and a power of 300w and stirred for 15 minutes, then added machine-made sand and natural aeolian sand and stirred evenly to obtain a mixture; Spread a layer of mixed material in the mold, add mesh cloth to cover the mold, and press molding to obtain a graphene-reinforced polymer particle sound-absorbing panel. Wherein the graphene is added in the form of a graphene oxide dispersion with a solid content of 5 wt% and a dispersion solvent of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com