Foam sound absorption material produced by using ceramic waste and production method of foam sound absorption material

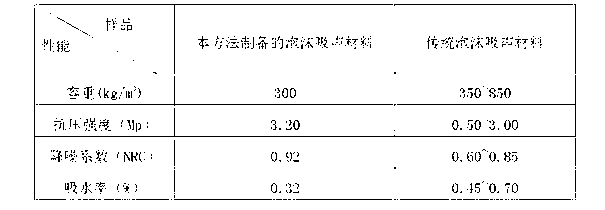

A technology of ceramic waste and sound-absorbing materials, which is applied in the field of sound-absorbing materials, can solve problems such as short service life, secondary pollution, and high production costs, and achieve the effects of reducing production costs, extending service life, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1, the foam sound-absorbing material produced by utilizing ceramic waste, its raw material composition is as follows by weight:

[0062] Ceramic waste: 70 parts;

[0063] Superfine kaolin: 29 parts;

[0064] Suspending agent: 0.3 parts;

[0065] Zirconia: : 0.7 copies;

Embodiment 2

[0066] Embodiment 2, the foam sound-absorbing material produced by utilizing ceramic waste, its raw material composition is as follows by weight:

[0067] Ceramic waste: 60 parts;

[0068] Superfine kaolin: 35 parts;

[0069] Suspending agent: 0.6 parts;

[0070] Zirconia: : 4.4 copies;

Embodiment 3

[0071] Embodiment 3, the foam sound-absorbing material produced by utilizing ceramic waste, its raw material composition is as follows by weight:

[0072] Ceramic waste: 80 parts;

[0073] Superfine kaolin: 18 parts;

[0074] Suspending agent: 0.4 parts;

[0075] Zirconia: : 1.6 copies;

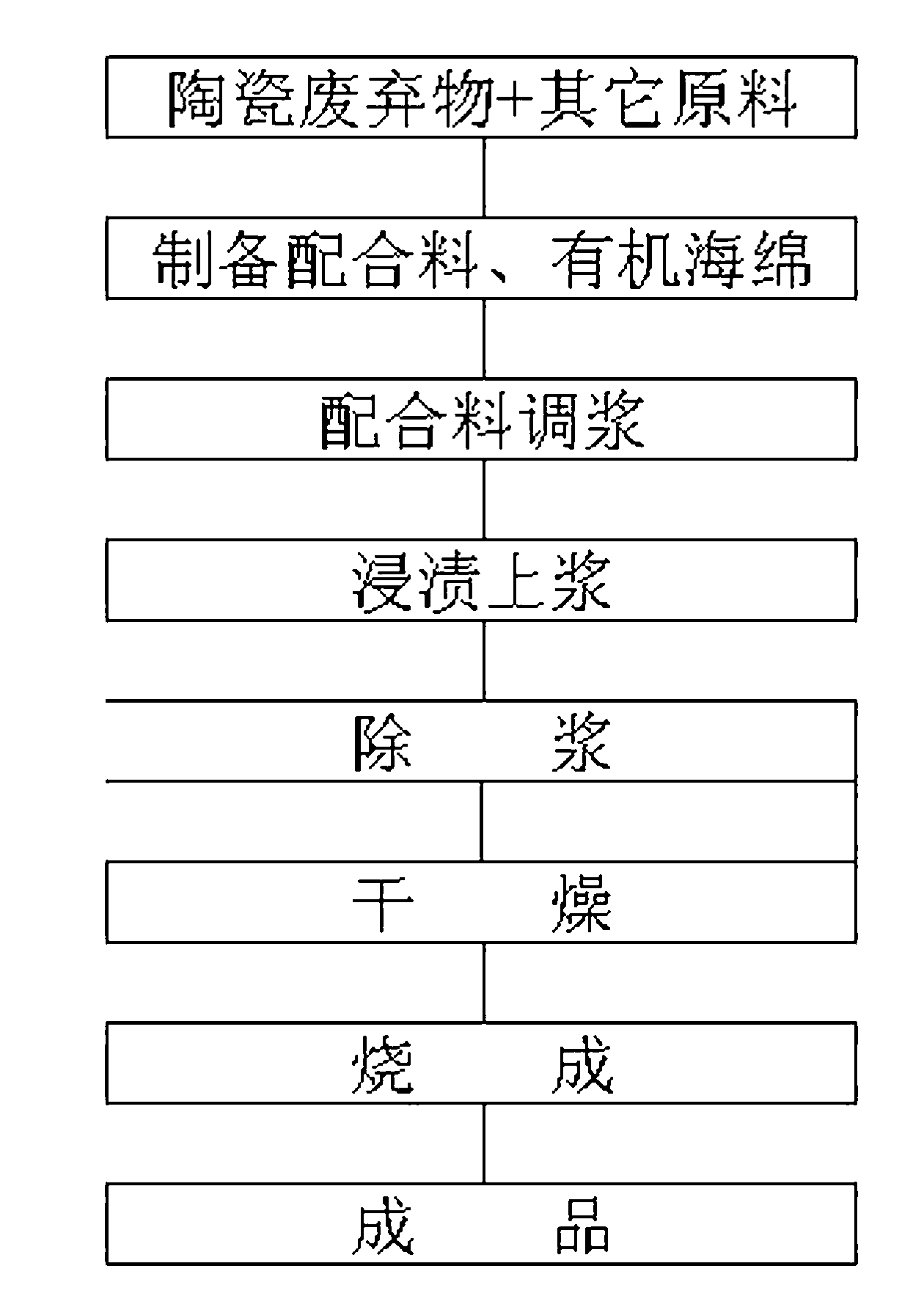

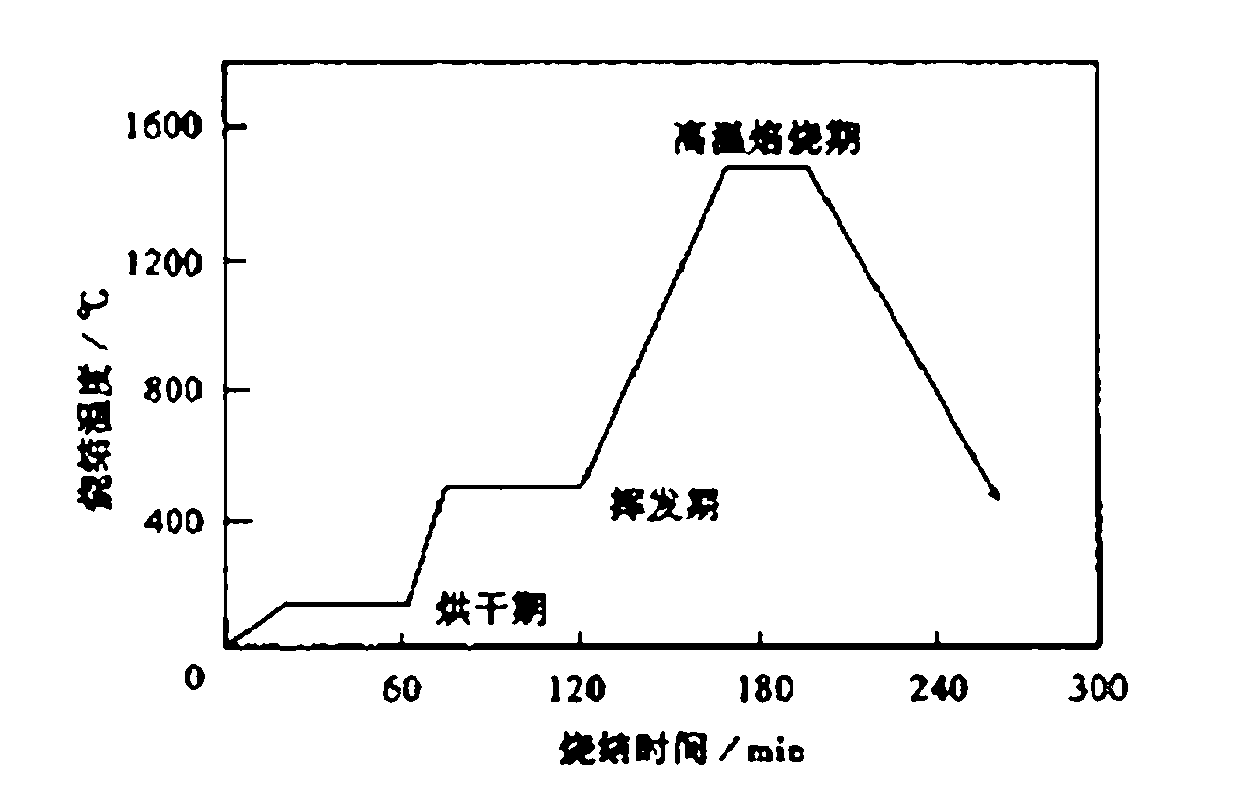

[0076] see figure 1 As shown, the preparation method of the foam sound-absorbing material produced by using ceramic waste is as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com