Three-dimensional porous framework-reinforced fiber sponge containing high-efficiency sound-absorbing material and preparation thereof

A three-dimensional porous, fiber-reinforced technology, applied in the field of sound-absorbing materials, can solve problems such as limitations, insufficient tensile properties and shear properties, and achieve the effects of enhanced dissipation, improved mechanical strength and resilience, and improved durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

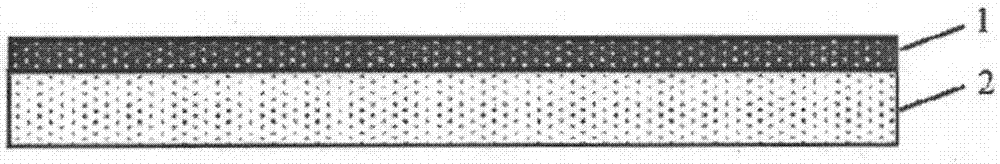

[0039] Such as figure 1 As shown, a three-dimensional porous frame-reinforced fiber sponge high-efficiency sound-absorbing material includes a three-dimensional porous frame-reinforced fiber sponge 2 and a microporous membrane 1 compounded on the three-dimensional porous frame-reinforced fiber sponge 2 .

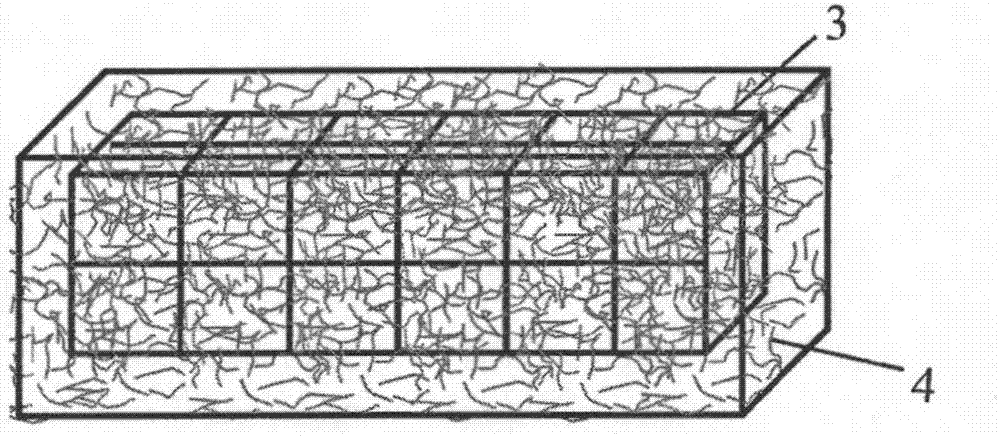

[0040] Such as figure 2 As shown, the three-dimensional porous frame-reinforced fiber sponge includes a three-dimensional porous frame 3 and fibers 4, and the three-dimensional porous frame is used as the main support reinforcement structure. By placing the three-dimensional porous frame in fiber slurry containing a flame retardant, the slurry is formed- Solvent drying-curing treatment obtained.

[0041] The preparation method of the three-dimensional porous frame reinforced fiber sponge high-efficiency sound-absorbing material is as follows:

[0042] The first step: disperse 10g of cotton fiber raw materials with an average diameter of 20 μm and an average aspect ratio o...

Embodiment 2

[0049] Such as figure 1 As shown, a three-dimensional porous frame-reinforced fiber sponge high-efficiency sound-absorbing material includes a three-dimensional porous frame-reinforced fiber sponge 2 and a microporous membrane 1 compounded on the three-dimensional porous frame-reinforced fiber sponge 2 .

[0050] Such as figure 2 As shown, the three-dimensional porous frame-reinforced fiber sponge includes a three-dimensional porous frame 3 and fibers 4, and the three-dimensional porous frame is used as the main support reinforcement structure. By placing the three-dimensional porous frame in fiber slurry containing a flame retardant, the slurry is formed- Solvent drying-curing treatment obtained.

[0051] The preparation method of the three-dimensional porous frame reinforced fiber sponge high-efficiency sound-absorbing material is as follows:

[0052] The first step: Disperse 5g of silk fiber raw materials with an average diameter of 15μm and an average aspect ratio of 30...

Embodiment 3

[0059] Such as figure 1 As shown, a three-dimensional porous frame-reinforced fiber sponge high-efficiency sound-absorbing material includes a three-dimensional porous frame-reinforced fiber sponge 2 and a microporous membrane 1 compounded on the three-dimensional porous frame-reinforced fiber sponge 2 .

[0060] Such as figure 2 As shown, the three-dimensional porous frame-reinforced fiber sponge includes a three-dimensional porous frame 3 and fibers 4, and the three-dimensional porous frame is used as the main support reinforcement structure. By placing the three-dimensional porous frame in fiber slurry containing a flame retardant, the slurry is formed- Solvent drying-curing treatment obtained.

[0061] The preparation method of the three-dimensional porous frame reinforced fiber sponge high-efficiency sound-absorbing material is as follows:

[0062] Step 1: Disperse 3.6g of polyimide fiber raw materials with an average diameter of 10μm and an average aspect ratio of 50,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com