Patents

Literature

32results about How to "Uniform flame retardant performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant porous polymer film and preparation method thereof

InactiveCN101905555AUniform flame retardant performanceImprove securitySynthetic resin layered productsSecondary cellsPolymer scienceOrganic solvent

The invention provides a preparation method for a flame-retardant porous polymer film. The method comprises the following steps of: a, dissolving the polymer with an organic solvent and adding a pore-forming agent into the dissolved polymer to obtain emulsion; b, coating the emulsion on a matrix and carrying out drying or extraction treatment on the matrix to obtain a porous polymer-based film; and c, plating an aluminum hydroxide film on the surface of the porous polymer-based film and heating the obtained product to decompose the aluminum hydroxide on the surface of the matrix into aluminum oxide to obtain the flame-retardant porous polymer film. The invention also provides the flame-retardant porous polymer film prepared by the method and a battery containing the same. The flame-retardant porous polymer film prepared by the method of the invention has uniformly dispersed aluminum oxide, so that the obtained flame-retardant porous polymer film has uniform flame retardance and the use safety of the battery is improved.

Owner:TIANJIN ENERGIES

Environment-friendly antibacterial and deodorization wallpaper

ActiveCN104074101AAntibacterial and deodorantGood antibacterial and deodorant effectCovering/liningsSpecial paperAnti bacteriaAntibacterial agent

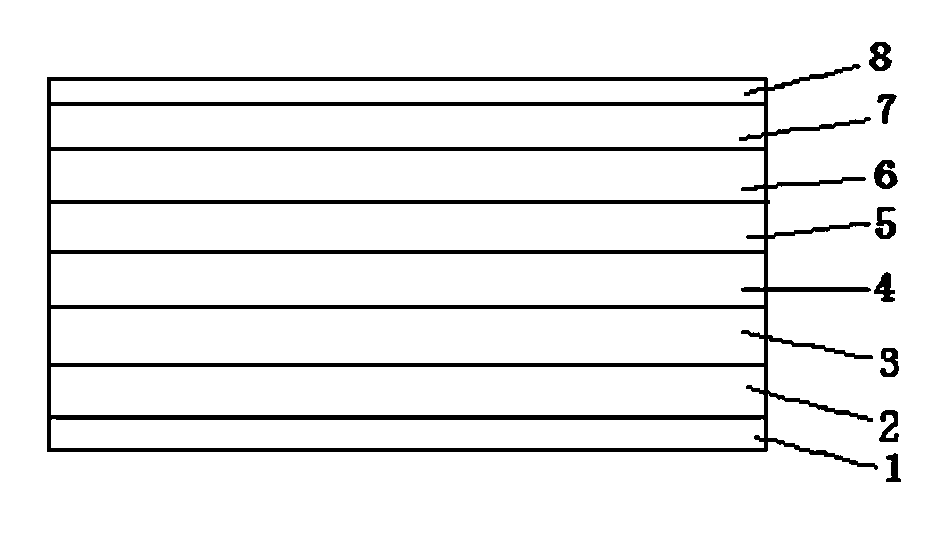

The invention provides environment-friendly antibacterial and deodorization wallpaper. The environment-friendly antibacterial and deodorization wallpaper comprises a base layer, wherein the back face of the base layer is provided with a waterproof coating; a coating layer is arranged on the base layer; an antibacterial layer is arranged on the coating layer; an adsorption deodorization layer is arranged on the antibacterial layer; a printing embossing layer is arranged on the adsorption deodorization layer and is coated with an antibacterial and deodorization compound layer; the antibacterial and deodorization compound layer is provided with a film coating layer. According to the wallpaper, the coating layer is provided with an antibacterial agent and a deodorization agent so that the wallpaper has antibacterial and deodorization properties; meanwhile, the adsorption deodorization layer, the antibacterial layer and the antibacterial and deodorization compound layer are further arranged so as to realize multiple protection, the antibacterial and deodorization properties of the wallpaper can be greatly improved and the performance of the wallpaper is excellent; overall, the wallpaper is environmental-friendly and multifunctional wallpaper.

Owner:TAICANG SANYI HEATING & CHILLING PROJECT CO LTD

Water-phase suspension granulation method for preparing gradient flame-retardant foamable polystyrene beads on basis of waste polystyrene materials and products of water-phase suspension granulation method

ActiveCN105566670AExcellent reflective infrared characteristicsRealize resource utilizationPolystyrene beadOil phase

The invention belongs to the field of high-value recycling of waste polystyrene foam materials, and particularly relates to a water-phase suspension granulation method for preparing gradient flame-retardant foamable polystyrene beads on the basis of waste polystyrene materials and products of the water-phase suspension granulation method. The water-phase suspension granulation method includes forming oil phases by inorganic-organic gradient cooperative flame-retardant heat-insulation systems, organic solvents and the waste polystyrene materials; forming water-phase dispersion media by surfactants, inorganic-organic synergistic suspension agents and deionized water; stably suspending and dispersing oil-phase liquid drop in the water-phase media under the actions of mechanical stirring by means of water-phase suspension granulation; heating and steaming out the organic solvents to cure gradient flame-retardant polystyrene beads; acquiring gradient flame-retardant polystyrene heat-insulation plates by means of pentane filling and foaming molding. The waster-phase suspension granulation method and the products have the advantages that waste polystyrene is used as a raw material, is recycled by the aid of physical processes and is used for preparing the gradient flame-retardant foamable polystyrene beads, accordingly, waste can be utilized, and the gradient flame-retardant performance and heat-insulation effects of the gradient flame-retardant foamable polystyrene beads can be improved; the organic solvents can be recycled, accordingly, the water-phase suspension granulation method and the products are environmental friendly, and industrial production can be facilitated.

Owner:WUHAN POLYTECHNIC UNIVERSITY

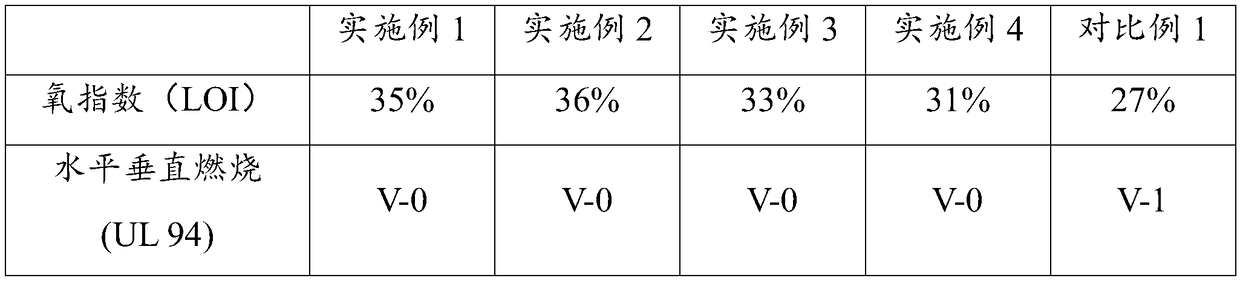

Special anti-flaming conductive polycarbonate material and preparation method thereof

InactiveCN103073870AUniform conductivityUniform flame retardant performanceElectronic componentPolycarbonate

The invention relates to a special anti-flaming conductive polycarbonate material and a preparation method thereof, and belongs to the technical field of anti-flaming conductive plastics. The formula of the special anti-flaming conductive polycarbonate material comprises the following components in parts by weight: 61 to 85 parts of polycarbonate, 5 to 15 parts of flame retardant, 6 to 20 parts of conductive auxiliary, 1 to 15 parts of flexibilizer, 0.1 to 0.5 part of dispersing auxiliary, 0.1 to 0.5 part of coupling agent and 0.1 to 0.5 part of heat stabilizer. The preparation method comprises the following steps: (1) preparing mixture in a mixing machine; (2) adding the mixture into an extruder to melt and plasticize the mixture by heating; (3) extruding, cooling and granulating to obtain the special material. The special anti-flaming conductive polycarbonate material prepared by the method has relatively good flame resistance, electrical conductivity and mechanical property, and can meet the requirement of the packing material of an electronic component.

Owner:田敬华

Flame-retardant reflective heat-insulating paint and preparation technique thereof

InactiveCN104910726ALarge thermal resistanceImprove reflectivityFireproof paintsReflecting/signal paintsHalogenButyl acetate

The invention discloses a flame-retardant reflective heat-insulating paint and a preparation technique thereof. The flame-retardant reflective heat-insulating paint comprises the following components in parts by weight: 25-35 parts of acrylic emulsion, 10-25 parts of butyl acetate, 5-15 parts of halogen-free flame retardant, 2-12 parts of heat-reflection heat-insulating powder, 10-20 parts of hollow microbead, 1-8 parts of coupling agent, 2-7 parts of leveling agent, 3-9 parts of film-forming assistant and 20-30 parts of deionized water. The flame-retardant reflective heat-insulating paint is free of halogens, and thus, is nontoxic and environment-friendly. The flame-retardant reflective heat-insulating paint has the advantages of high thermal resistance, high reflectivity and favorable radiant heat transfer performance, can simultaneously have the functions of heat insulation and flame retardancy, has more balanced flame retardancy and heat-insulating property, can implement better flame-retardant and heat-insulating effects, and is suitable for the field of decoration of dwelling houses, school buildings, hotel buildings and other buildings.

Owner:黎司华

Low-smoke halogen-free flame-retardant polypropylene material containing double hydroxide and preparation method thereof

ActiveCN104151699AImprove mechanical propertiesImprove flame retardant performanceAntioxidantMechanical property

The invention discloses a low-smoke halogen-free flame-retardant polypropylene material containing double hydroxide and a preparation method of the low-smoke halogen-free flame-retardant polypropylene material and belongs to the technical field of flame retardancy. The composite low-smoke halogen-free flame-retardant polypropylene material containing layered double hydroxide comprises 100 parts of polypropylene, 15-30 parts of modified ammonium polyphosphate, 20-40 parts of Mg-Al double hydroxide, 2-5 parts of silicon-containing compatilizer, 1-3 parts of liquid paraffin and 0.15-0.4 part of antioxidant. The invention further discloses a preparation method of the layered double hydroxide flame-retardant agent. The composite flame-retardant polypropylene material disclosed by the invention is free of halogen and has low smoke release when the composite flame-retardant polypropylene material is combusted. The composite flame-retardant polypropylene material has the advantages of good flame-retardant property and mechanical properties, simpleness in production process and low raw material cost and can be widely applicable to automotive and household appliance industries.

Owner:扬州润丰塑胶有限公司

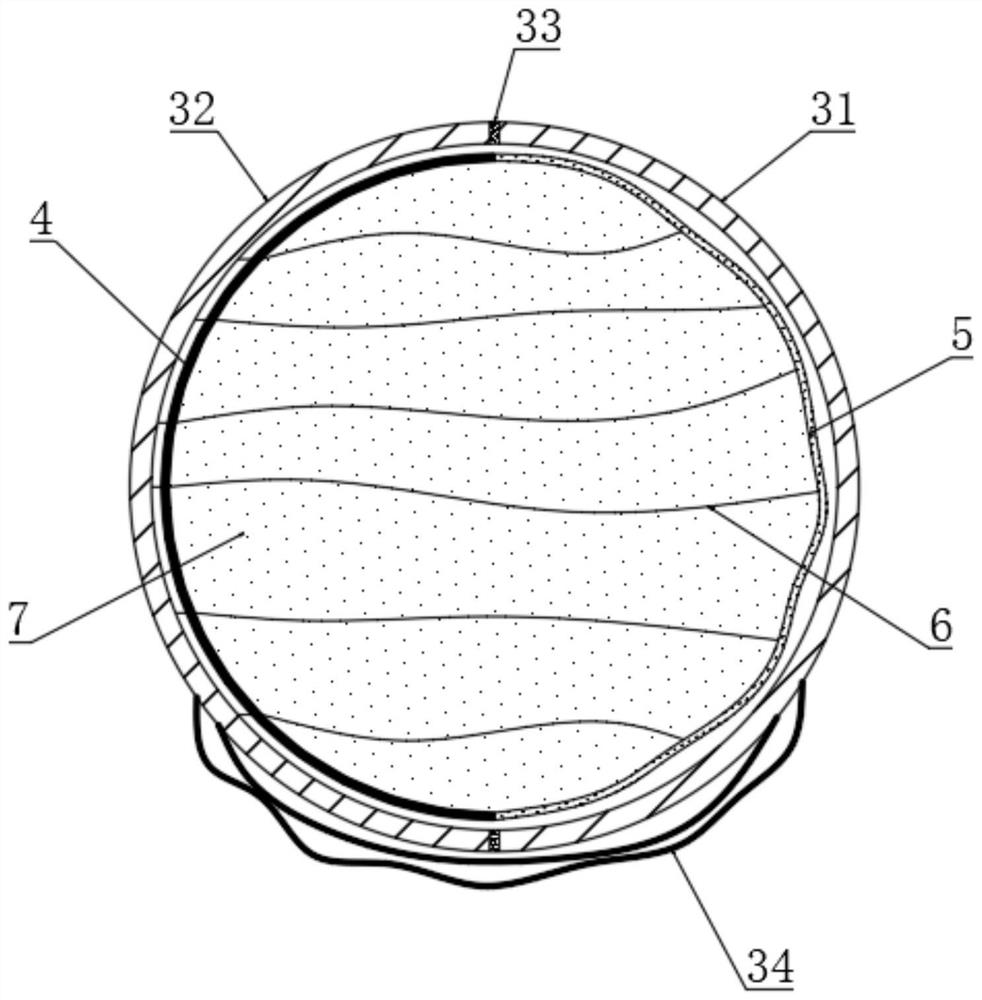

Fire-proof and flame-retardant tent

ActiveCN106863958AStrong flame retardant effectGood moisture resistanceSynthetic resin layered productsHeat resistant fibresChemistryPolyamide

The invention discloses a fire-proof and flame-retardant tent. The fire-proof and flame-retardant tent is technically characterized by comprising tent cloth, and mesh cloth and ground cloth which are connected to the tent cloth. The fire-proof and flame-retardant tent is characterized in that the tent cloth is made from the following components in parts by weight: 40 to 45 parts of dacron, 5 to 15 parts of glass fibers, 15 to 20 parts of polytetrafluoroethylene fibers, 5 to 15 parts of phosphorus flame retardant, 5 to 10 parts of organic silsesquioxane, 3 to 8 parts of metal chloride, and 3 to 8 parts of polyurethane; the mesh cloth is prepared from the following components in parts by weight: 40 to 45 parts of polyamide, 5 to 10 parts of spandex, 5-15 parts of phosphorus flame retardant, 5 to 10 parts of organic silsesquioxane, and 3 to 8 parts of metal chloride; the ground cloth is prepared from the following components in parts by weight: 40 to 45 parts of polyethylene (PE), 5 to 15 parts of ethylene-vinyl acetate (EVA), 5 to 10 parts of erucyl amide, 5 to 15 parts of phosphorus flame retardant, and 3 to 10 parts of antioxidant. The tent produced through the component setting has a good flame retardant effect, and long-lasting flame-retardant effect.

Owner:CIXI KINGTRA LEISURE PROD

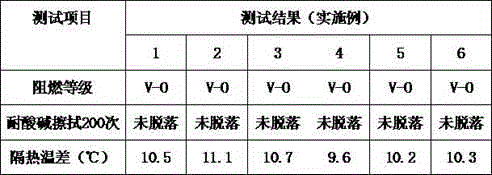

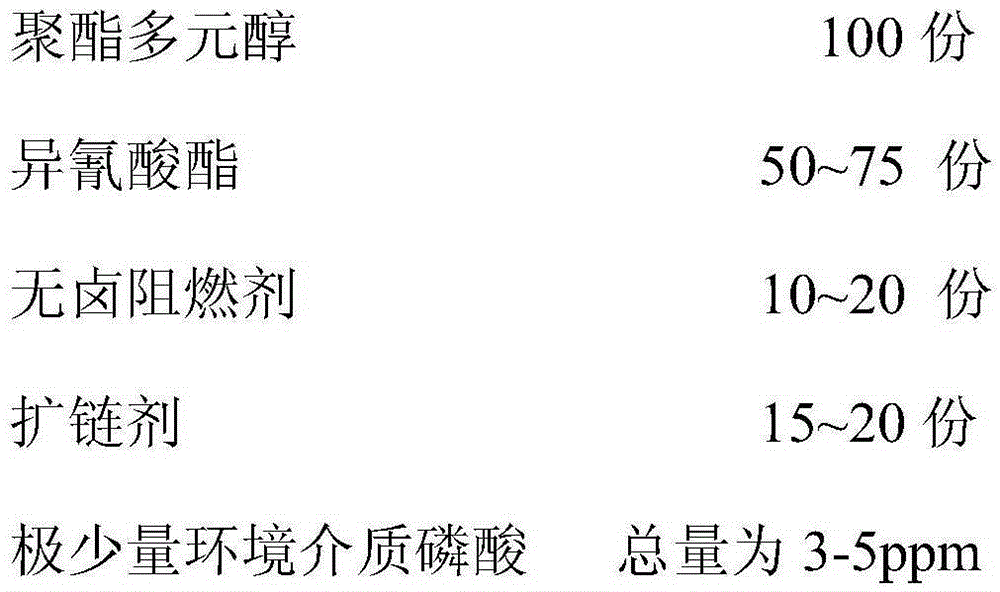

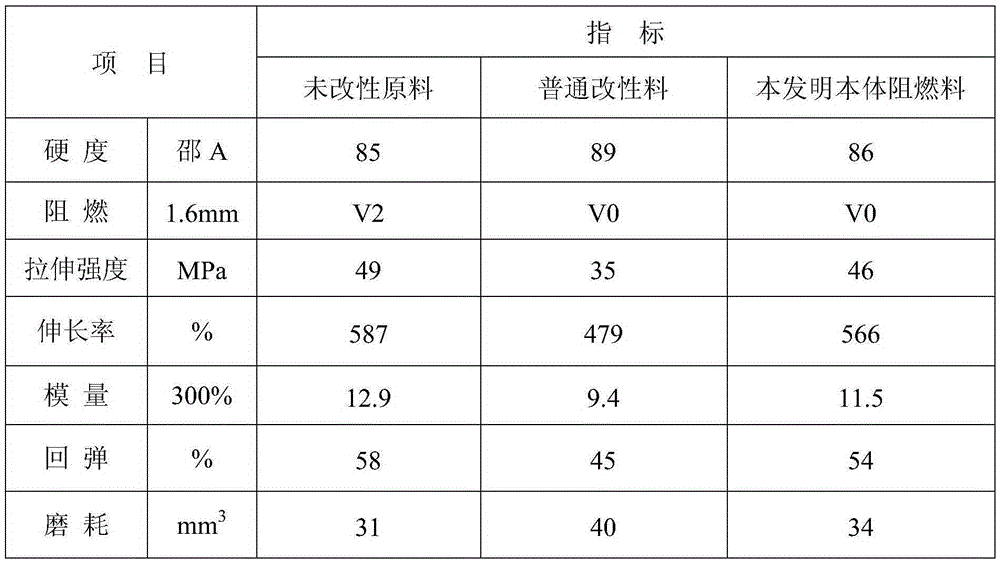

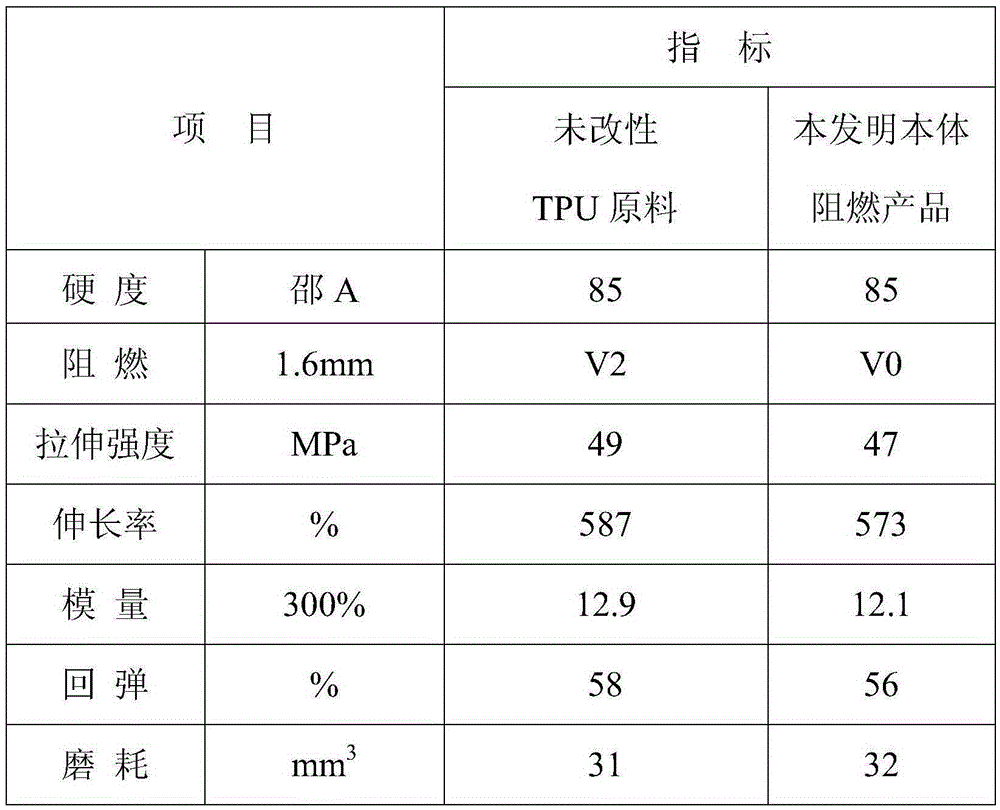

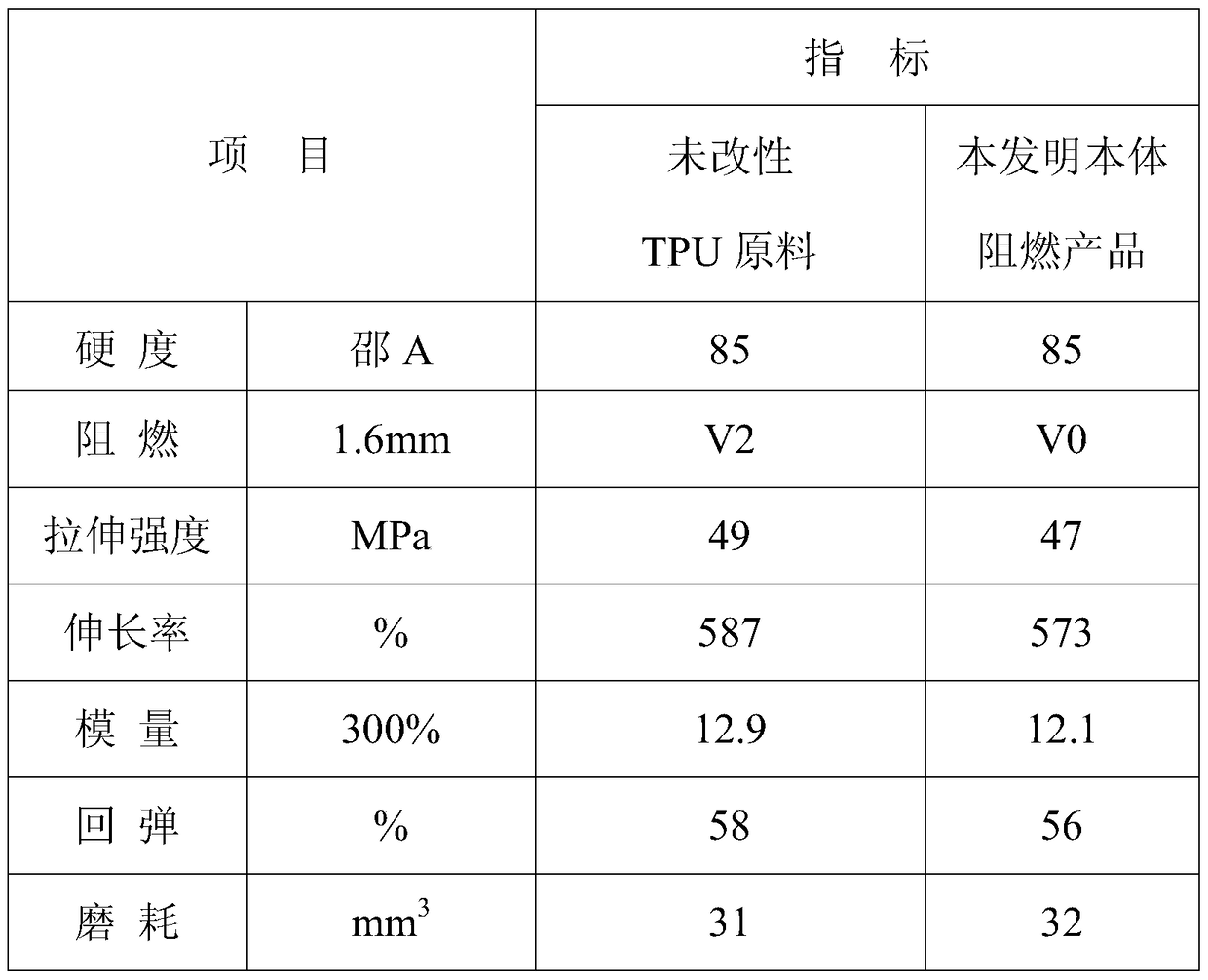

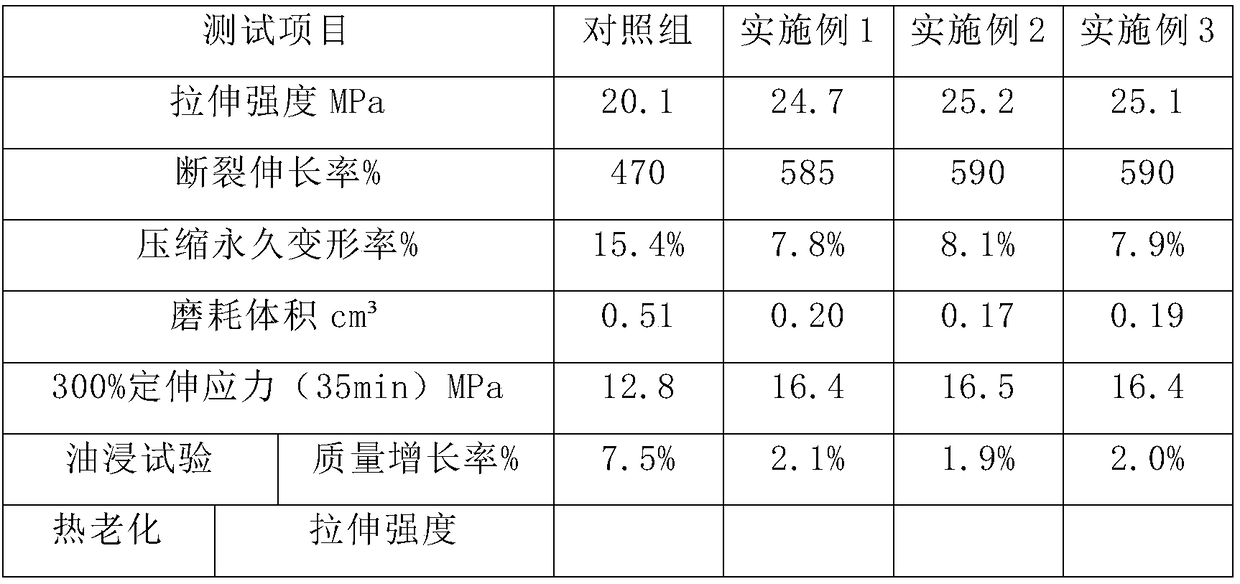

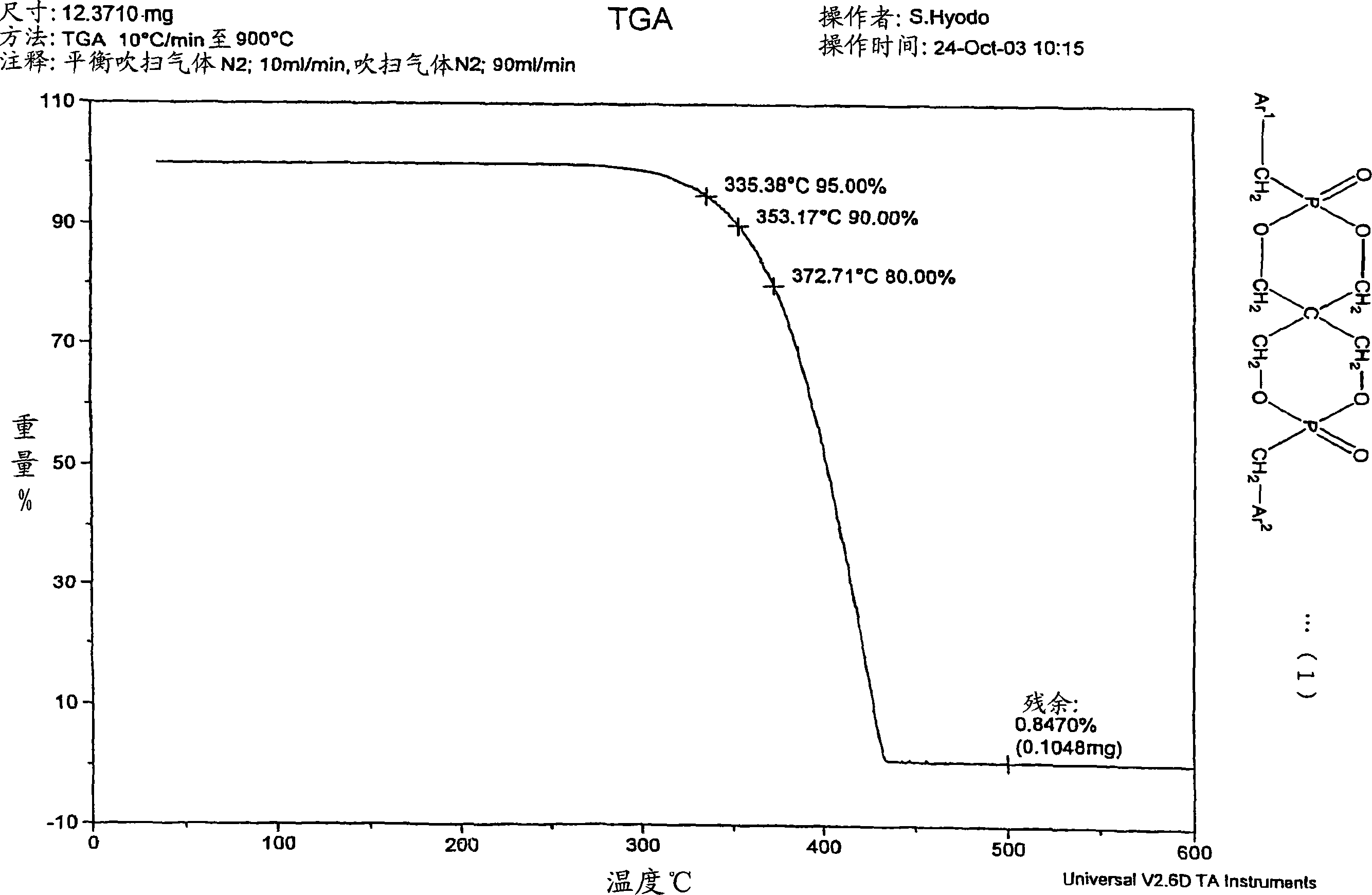

Body halogen-free flame retardant TPU modified material and preparing method thereof

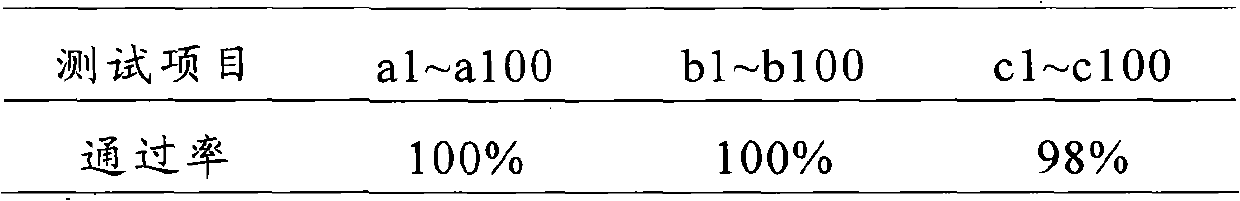

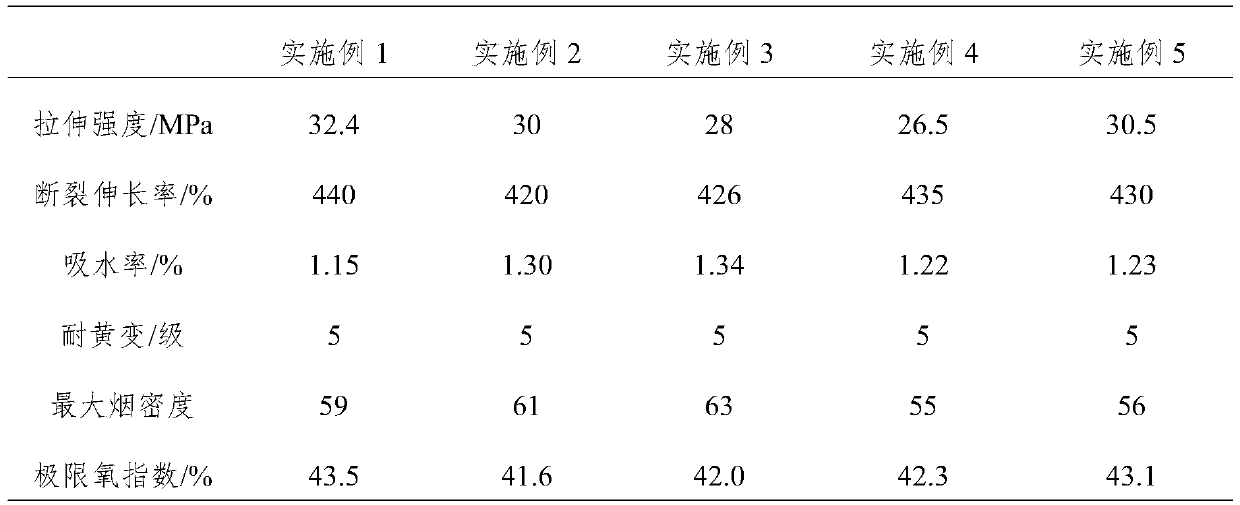

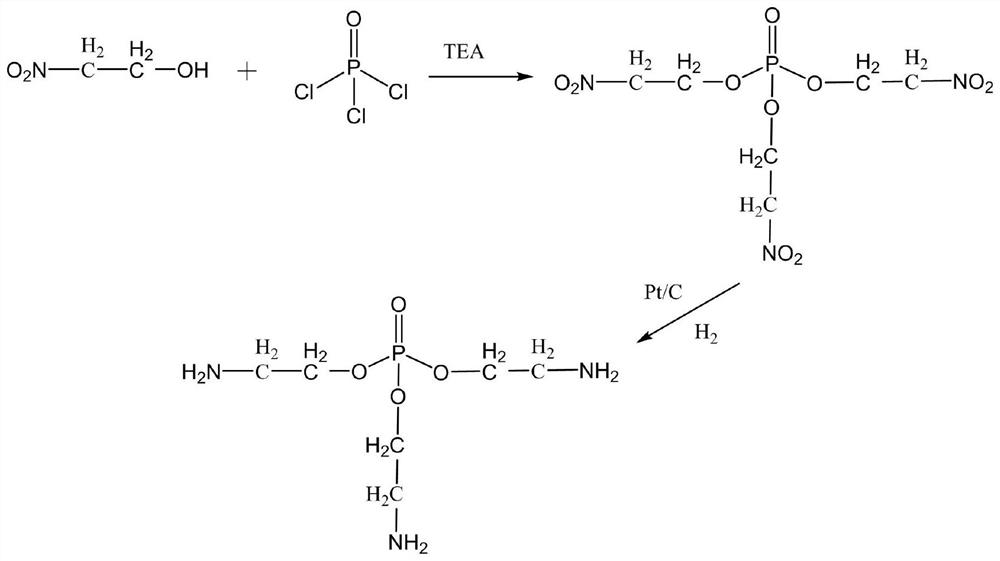

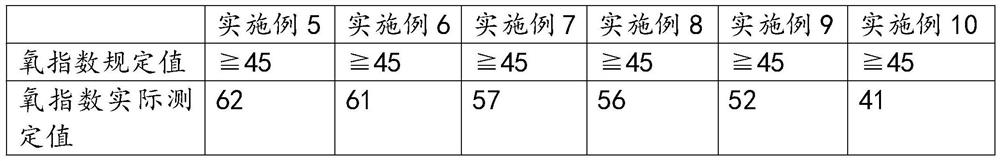

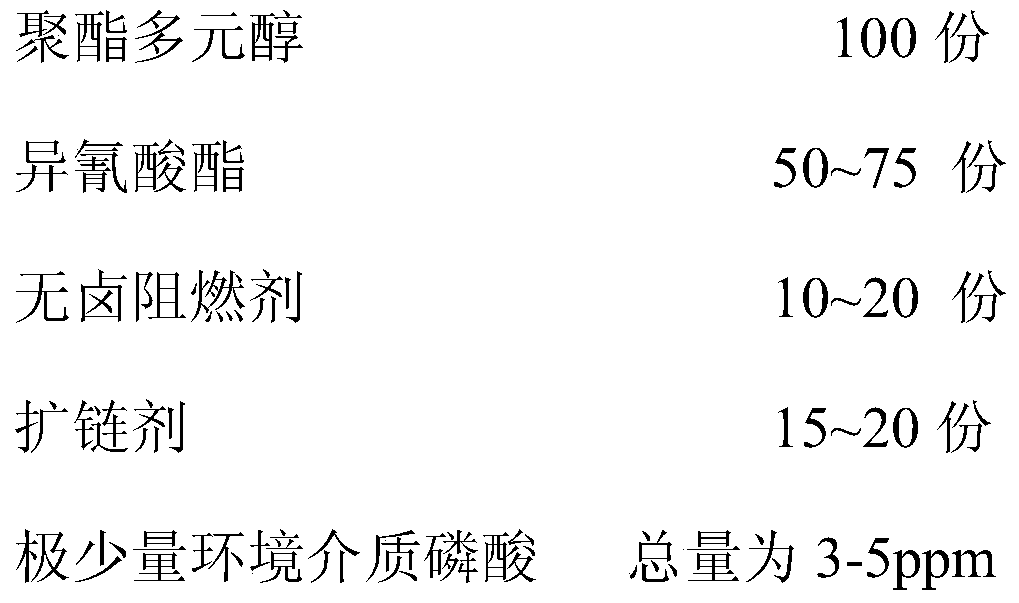

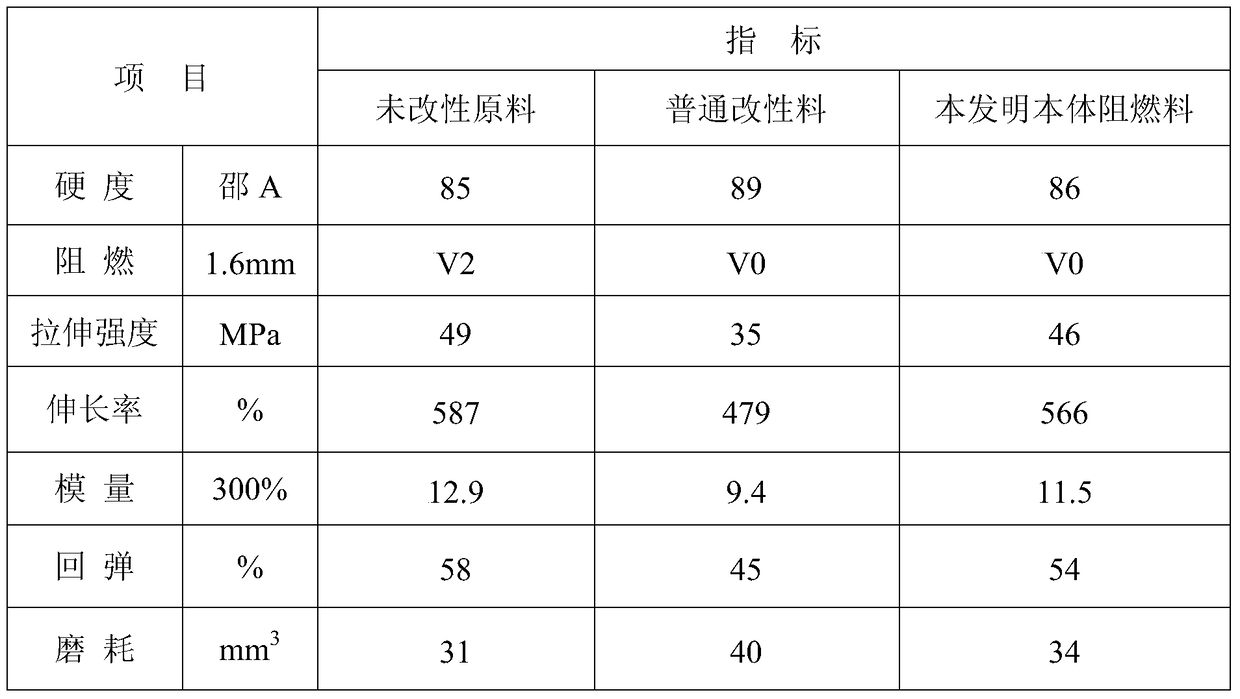

ActiveCN105254838AEvenly dispersedFlame retardant and all aspects of performance testing data are uniformPhosphoric acidIsocyanate

The invention discloses a body halogen-free flame retardant TPU modified material. The material is prepared from polyester polyol, isocyanate, halogen-free flame retardant, chain extender and a little amount of environmental medium phosphoric acid. Halogen-free flame retardancy of the synthesized TPU material is detected according to the vertical combustion testing standard and can meet the requirement of the UL 94 V0 level (1.6 mm), the flame retardant is dispersed more uniformly in the TPU material, detection data of flame retardancy and properties of all aspects are more uniform, and the problems that due to post-modification addition, dispersing is not uniform, and the flame retardant effect is instable are solved; in addition, compared with those of a pure raw material, stretching, the stretching rate, resilience and the modulus of the material are reduced only by about 12%, compared with that of a flame retardant modified material product sold in the market, all the properties are improved by over 20%, and the requirements of customers needing high-grade halogen-free flame retardancy in the aspect of TPU base materials can be met.

Owner:JINAN TAIXING FINE CHEM

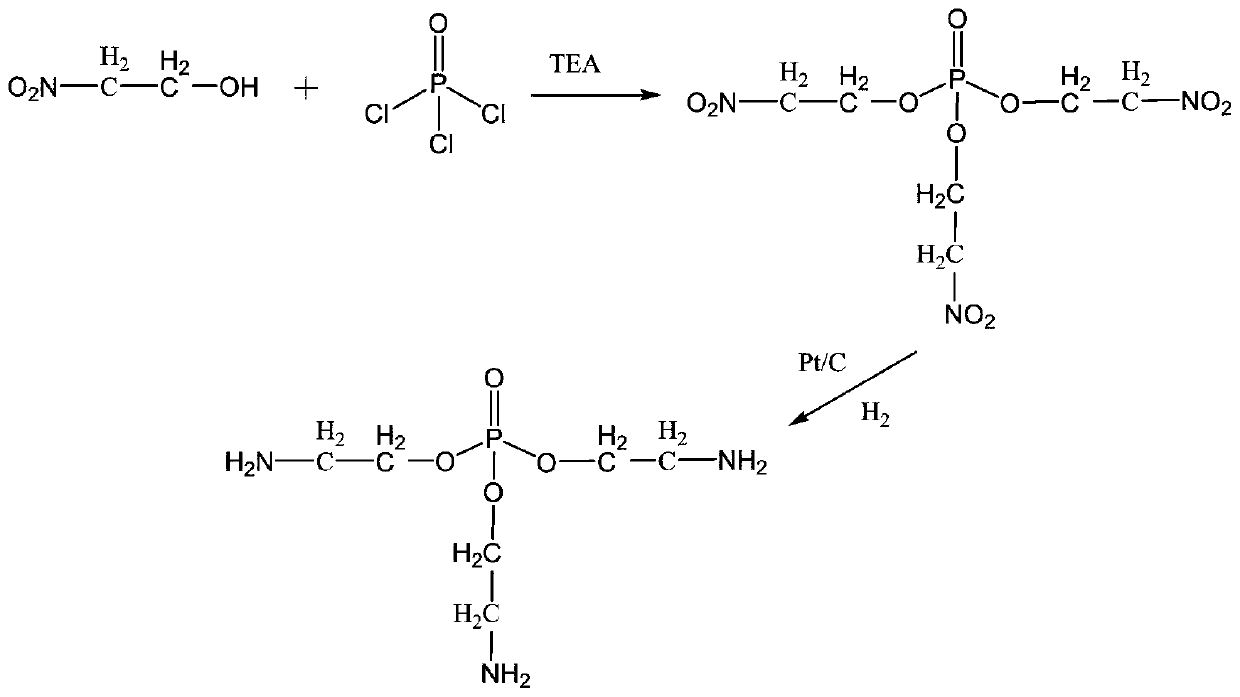

Preparation method of functional resin for synthetic leather production

InactiveCN110144034AGood weather resistance and hydrolysis resistanceGood strength and solvent resistanceIsocyanatePolyester

The invention relates to the technical field of resins, and specifically relates to a preparation method of a functional resin for synthetic leather production. The preparation method comprises following steps: step one, preparing hydrolysis resistant polyester polyol from aliphatic dibasic secondary alcohols, polybasic acids, and a catalyst; step two, preparing a component (A) from polyester polyol, a crosslinking agent, a chain extender, a reactive flame retardant, an enhancer, a foam stabilizer, a catalyst, a light / heat stabilizer, and water; step three, preparing a component (B) from isocyanate, polyester polyol, and a catalyst; and step four, fully mixing the component (A) and the component (B) according to a mass ratio of 3:1 to 1:3, evenly mixing, painting the mixture on release paper, placing the release paper in a baking oven, and curing the mixture at a temperature of 120 to 150 DEG C to obtain the functional resin. The prepared functional resin has the characteristics of good flame retardant property, corrosion resistance, hydrolysis resistance, and wear resistance.

Owner:福建成杰高分子材料有限公司

Diatomite modified composite environment-friendly coating and preparation method thereof

ActiveCN109943193AUniform flame retardant performanceGood dispersionFireproof paintsPolyurea/polyurethane coatingsDispersityCoprecipitation

The invention discloses a diatomite modified composite environment-friendly coating which is prepared from the following components in parts by weight: 52-58 parts of bisphenol A epoxy resin, 23-25 parts of a branched flame-retardant curing agent, 31-34 parts of polyurethane loaded diatomite material, 1-2 parts of a flatting agent, 3-5 parts of a dispersant and 100 parts of ethanol. The preparation method comprises the following steps: depositing an aluminum hydroxide flame-retardant material in duct structures of diatomite by a coprecipitation method; and then jointly foaming modified diatomite and polyurethane. As diatomite has relatively high dispersity and can be uniformly dispersed in polyurethane, the prepared material is uniform in flame-retardant performance, and the problem that the flame-retardant performance is further affected as a flame retardant which is directly added into a foaming process in the prior art is not uniformly dispersed while the prepared foamed material isfilled with the flame retardant to achieve the flame-retardant performance of the foamed material is solved.

Owner:广西弗士特资源综合利用有限公司

Modified PP flame-retardant material air-conditioner plastic suction thermal-insulation plate

InactiveCN108264685AImprove flame retardant performanceImprove mechanical propertiesLow-density polyethyleneThermal insulation

The invention discloses a modified PP flame-retardant material air-conditioner plastic suction thermal-insulation plate, which comprises, by weight, 50-70 parts of polypropylene, 30-50 parts of high-density polyethylene, 10-20 parts of a flame retardant, 0.3-1 part of an anti-aging agent, 2-5 parts of a synergist, and 0.5-1 part of a stabilizer, wherein the synergist is the compound of graphite, phosphoenolpyruvate and pyridoxal 5-phosphate, the stabilizer is sodium octyl phosphate, and the flame retardant is potassium hexatitanate crystal whisker. According to the present invention, the preparation is performed by mainly using polypropylene and high-density polyethylene as the basic materials, and potassium hexatitanate is added, such that the flame retardancy of the whole material can besubstantially improved; and the added synergist can provide good flame retardant performance, and can make the whole material can have good mechanical property in an annealed state for a long time.

Owner:WENZHOU XINTAI NEW MATERIALS CO LTD

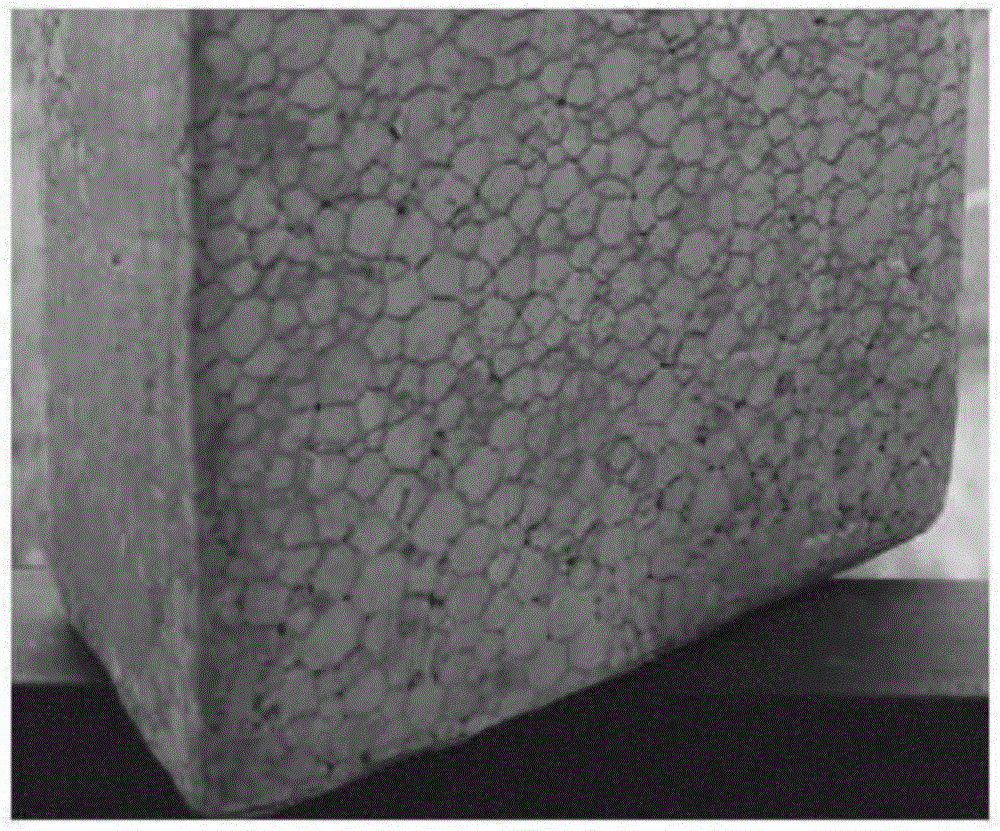

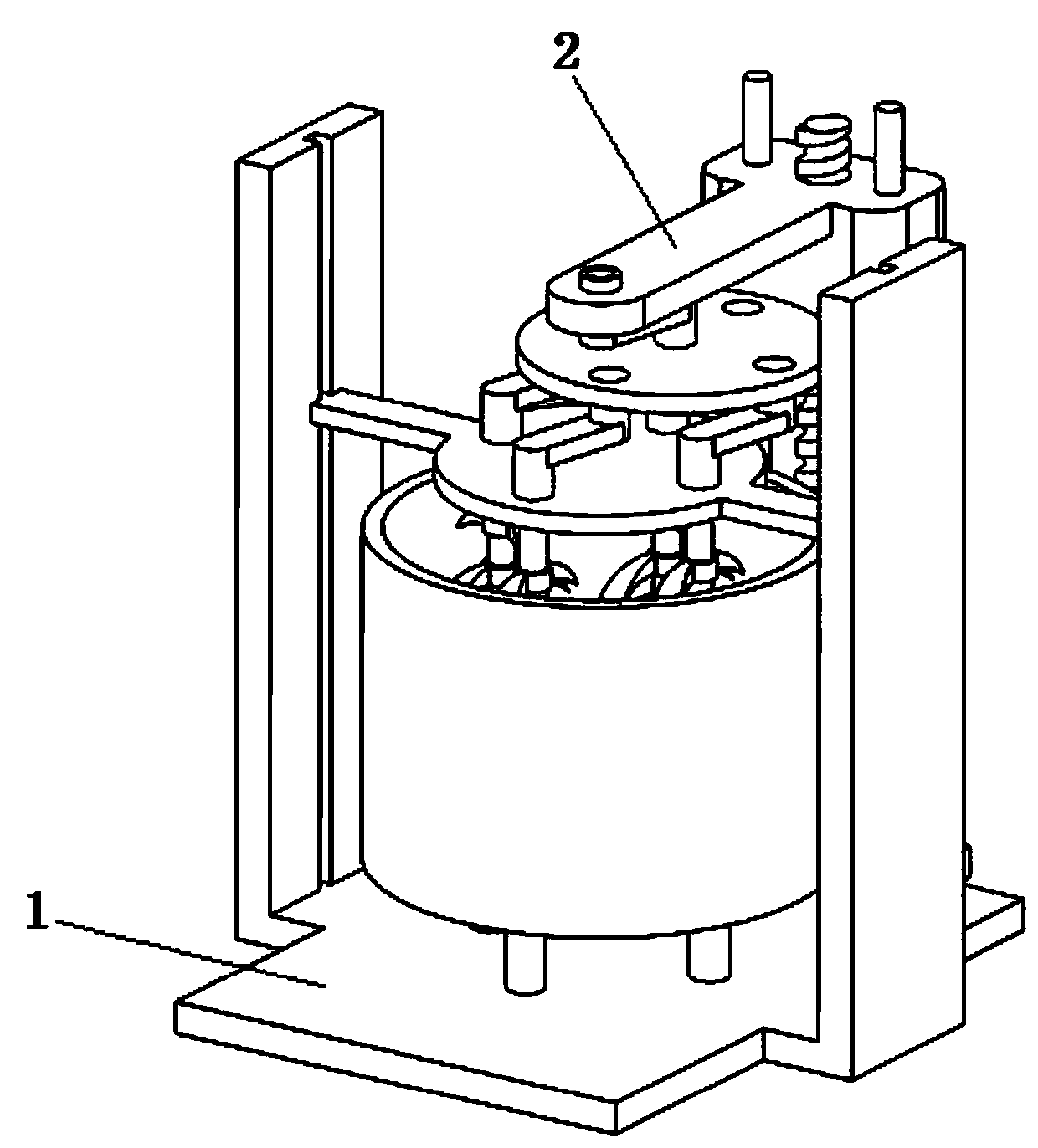

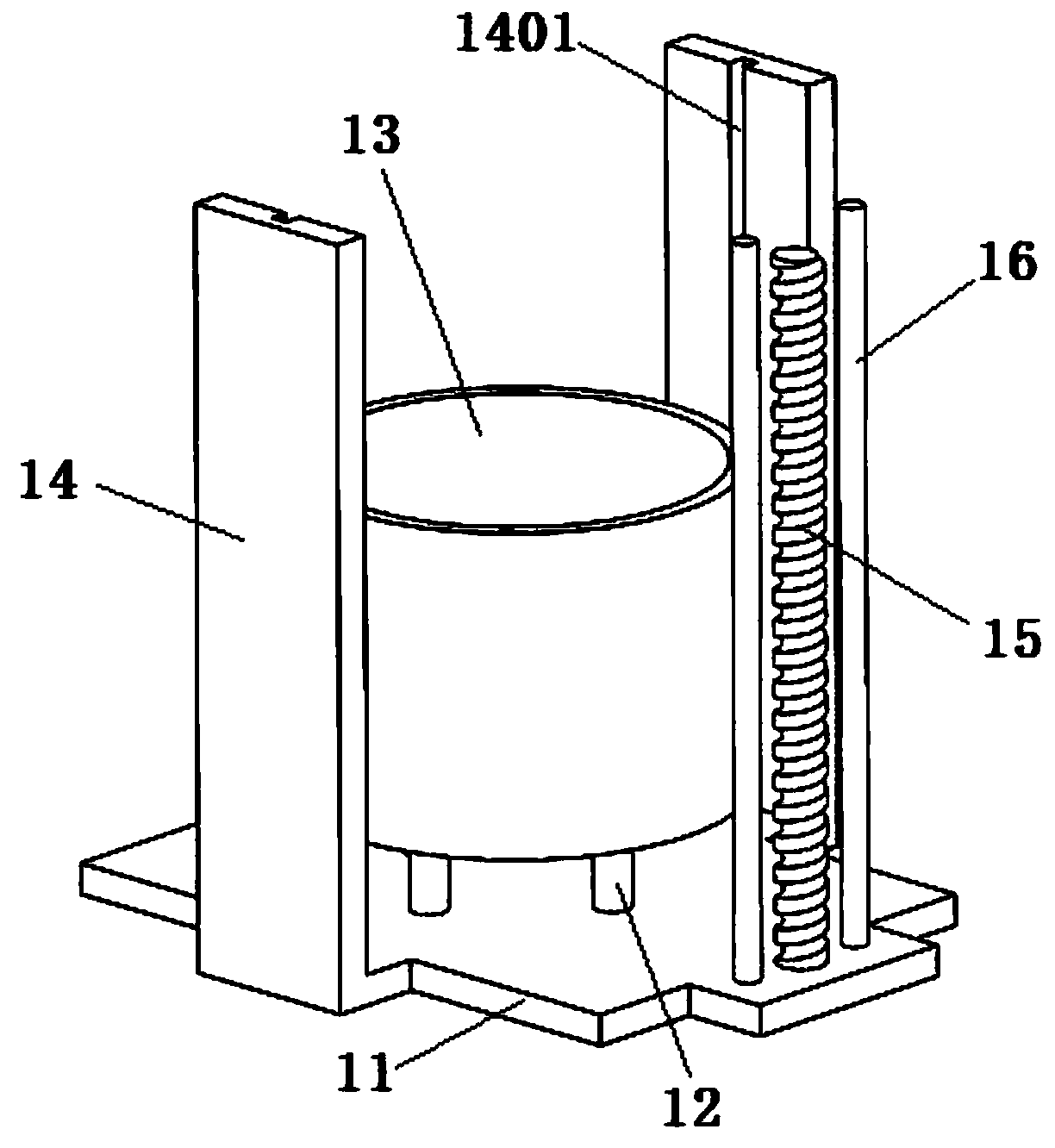

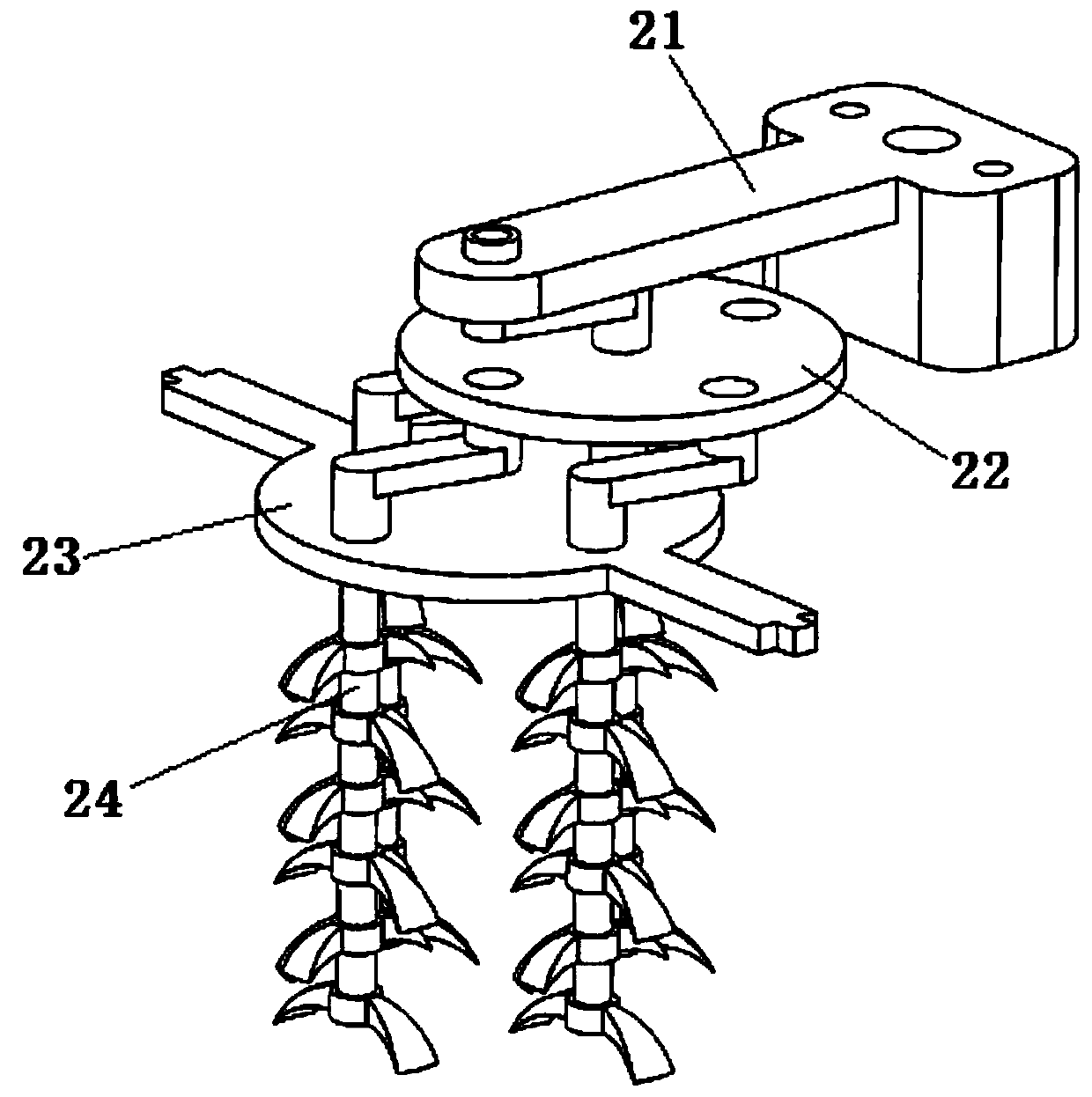

Light flame-retardant foamed plastic and preparation method thereof

The invention discloses a light flame-retardant foamed plastic which is prepared from the following raw materials in parts by weight: 80-90 parts of polyether polyol, 2-4 parts of a foaming agent, 0.8-1 part of a foaming aid, 0.2-0.3 part of a catalyst, 6-9 parts of modified expanded graphite and 40-50 parts of polymerized MDI. The invention further discloses a preparation method of the foamed plastic. In the preparation method, a specially-made plastic foaming device is adopted for carrying out foaming treatment on the raw materials. Polyurethane is used as a polymer matrix, water is used asa foaming agent, dodecanol is used as a foaming air, and a fine, dense and uniform foam structures are formed; due to the addition of the modified expanded graphite, the foamed material has flame retardant property; besides, the specially-made plastic foaming device is adopted for carrying out foaming treatment on the raw materials, more air is mixed into the raw materials while the raw materialsare fully stirred, a more excellent foaming effect is achieved, and the formed foamed plastic has the fine, dense and uniform foam structures.

Owner:安徽超星新材料科技有限公司

Preparation method of polyester flame-retardant non-woven fabric

InactiveCN109914103ASolve the problem of wet and greasyUniform flame retardant performanceFibre typesPolyesterChemistry

The invention relates to a preparation method of a polyester flame-retardant non-woven fabric, and belongs to the technical field of textiles. A self-produced polyester filament non-woven fabric is used as a raw material; after unwinding and cleaning treatment, the polyester filament non-woven fabric enters a liquid storage tank containing a liquid flame retardant for dipping, is discharged and extruded by a pressing roller, is subjected to far-infrared preheating treatment, and then is dried by a drying oven and wound, and the polyester flame-retardant non-woven fabric is obtained. The methodhas the advantages that by adding a certain amount of penetrant, the flame-retardant effect is uniform; by adjusting the proportion of the flame retardant in the fabric surface, the problem of damp and greasiness of the fabric surface is solved; by controlling the pH of the system, the flame-retardant effect of the flame retardant is improved.

Owner:JIANGXI NAT BRIDGE IND

High inflaming retarding abrasion resistance PP/ABS composite material and preparation method thereof

The invention relates to a PP / ABS composite material, and in particular relates to a high inflaming retarding abrasion resistance PP / ABS composite material and a preparation method thereof; the cashew nut shell oil friction powder is used for modifying PP for increasing the abrasion resistance performance, tin antimony oxide is used for modifying ABS, performance of the modified master batch is changed, modified PP, ABS master batch are mixed for preparing particles through crosslinking, expanded graphite micro powder is used for loading fire retardant triphenyl phosphate which can be evenly dispersed in the master batch, thus even and high effect flame retardant efficiency can be obtained; finished composite material prepared by the method effectively combines the advantages of the PP and ABS, has excellent inflaming retarding, abrasion resistance and anti-static electricity effect, and the market competitiveness is greatly improved.

Owner:WUHU ZHONGLI PARTS

Preparation method of PVC artificial leather resistant to high and low temperatures and low in VOC

The invention discloses a preparation method of PVC artificial leather resistant to high and low temperatures and low in VOC. A flame retardant zinc stannate is modified by sodium alginate, then graphene is dispersed into sodium alginate-based zinc stannate, and the flame retardant effect is uniform; reduced graphene oxide and sodium alginate-based zinc stannate have a good synergistic effect, and sodium alginate gives full play to a bridging effect between the flame retardant zinc stannate and a PVC matrix; N-beta-aminoethyl-gamma-aminopropyl methyl dimethoxy silane is used as a silane coupling agent to graft and crosslink the composite polyvinyl chloride, and amino groups in sodium alginate and amino groups in the coupling agent have a competitive relationship, so that the agglomeration phenomenon of the matrix is avoided, and the dispersity is ensured while the linkability is ensured; and the preparation method comprises the following steps of preparing flexible carbon fibers from bamboo fibers, and putting a polyvinyl chloride compound coupled by ethyl orthosilicate and silane into an alcohol / water solution to prepare silane-based sol impregnated flexible carbon fibers; and carrying out heat treatment under the protection of nitrogen, wherein the surface of the flexible carbon fiber is coated with a Si-C-O structure, so that the flexibility of the leather is improved.

Owner:南通中奥车用新材料有限公司

Halogen free flame retardant PVC material and preparation method thereof

InactiveCN110982014AUniform flame retardant performanceHigh capture functionPolymer scienceNano carbon

The invention discloses a halogen free flame retardant PVC material, which comprises following components in parts by weight: 78 to 86 parts of PVC, 5 to 7 parts of unsaturated chromatid, 0.6 to 0.8 part of unsaturated piperylhydrazine monomers, 2.3 to 2.5 parts of BPO, 0.9 to 1 part of a dispersant, and 0.5 to 0.6 part of nano calcium carbonate. Prepared unsaturated chromatids and PVC carry out free radical polymerization reactions directly; unsaturated chromatids are uniformly grafted onto the PVC molecular chains; at the same time, prepared unsaturated chromatids are rich in phosphate groups, after unsaturated chromatids are grafted to PVC molecules, the PVC molecular chains uniformly have a large amount of phosphate groups, thus the prepared PVC material has a uniform flame retardant performance; in the prior art, the flame retardant performance of a conventional PVC material is bad, normally, a flame retardant is added to enhance the flame retardant performance, due to the bad compatibility between an organic phosphor flame retardant and PVC, the flame retardant cannot be uniformly dispersed in the PVC material, the flame retardant performance of the PVC material is influenced, and the problems mentioned above are solved.

Owner:安徽瑞智福瑶环保科技有限公司

Antistatic knitted fabric

InactiveCN108162517ASimple structureImprove antistatic performanceWeft knittingSynthetic resin layered productsYarnFiber

The invention relates to the field of textiles, in particular to an antistatic knitted fabric. The antistatic knitted fabric comprises a surface layer fabric and an inner layer fabric, wherein the surface layer fabric and the inner layer fabric are mutually fitted and both have a preset thicknesses; a plurality of antistatic metal wires are woven in the surface layer fabric; and a plurality of flame-retardant fiber yarns are woven in the inner layer fabric. The invention has the advantages of simple structure, good antistatic property, good flame-retardant property and strong practicability.

Owner:WUHAN JUNXU IND CO LTD

Halogen-free flame-retardant epoxy resin and preparation method thereof

The invention discloses a halogen-free flame-retardant epoxy resin. The halogen-free flame-retardant epoxy resin is prepared from the following components in parts by weight: 100 to 150 parts of epoxyresin, 15 to 30 parts of a curing agent, 5 to 8 parts of a dispersant, 20 to 30 parts of hydroxylated multi-walled carbon nano-tubes and 5 to 10 parts of a halogen-free flame retardant. The halogen-free flame-retardant epoxy resin does not contain a halogen flame retardant; the flame retarding effect is good and uniform; the oxygen index can reach 30 percent or above.

Owner:SUZHOU SIRGEL RESINS SPECIALTIES CO LTD

Inflaming retarding fiberglass material plate layer for manufacturing expansion joints and preparing method and application of inflaming retarding fiberglass material plate layer

InactiveCN107999357AImprove toughnessAvoid crackingPipeline expansion-compensationCoatingsFiberGlass fiber

The invention provides an inflaming retarding fiberglass material plate layer for manufacturing expansion joints and a preparing method and application of the inflaming retarding fiberglass material plate layer, and belongs to the technical field of composite materials. A bottom coating comprises a curing agent, first solvent-free mixed resin and first fire retardant. A structure layer comprises glass fiber, carbon fiber, second solvent-free mixed resin and a curing agent. A face coating comprises a nano abrasion resisting material, a UV ultraviolet screening agent, an additive, accelerant, third solvent-free mixed resin, second fire retardant and a curing agent. According to the preparing method, the bottom coating is sprayed to the surface of a model firstly, the structure layer is sprayed to the face, away from the model, of the bottom coating, then, the face coating is sprayed to the face, away from the bottom coating, of the structure layer, and the plate layer is obtained. The plate layer has good tenacity, meanwhile, the mechanical performance and the heat resisting performance are not changed, the oxygen index is very high, the flame spreading speed is very low, and self-extinguishment performance is achieved; and abrasion resisting performance and inflaming retarding performance are achieved, strength is high, the inflaming retarding fiberglass material plate layer canbe used for preparing various expansion joints, and the requirements of users are met.

Owner:武汉博奇玉宇环保股份有限公司

Polylactic acid resin composition, method for producing polylactic acid resin composition, and polylactic acid resin molded article

InactiveCN102161818BSatisfactory mechanical strengthUniform flame retardant performancePolymer sciencePolymer chemistry

A polylactic acid resin composition contains a polylactic acid resin with an epoxy group and a flame retardant additive.

Owner:FUJIFILM BUSINESS INNOVATION CORP

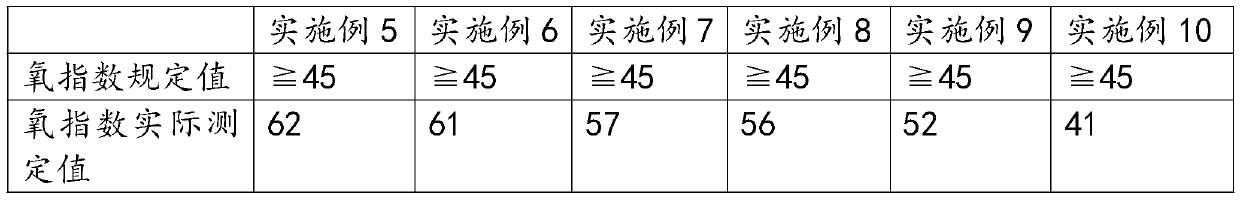

A kind of preparation method of microscopically dispersed zirconium phosphate synergistic flame retardant spandex

ActiveCN106283265BReduce risk of subsidenceHigh molecular weightFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentFilamentationLimiting oxygen index

The invention relates to a preparation method of zirconium phosphate (ZrP) synergistic flame retarding spandex with the microcosmical dispersion uniformity. The method comprises the following steps that 1, a prepolymer solution is prepared; 2, a mixed amine solution is prepared; 3, a polyurethane urea solution is prepared; 4, a polyurethane spinning solution is prepared; 5, the polyurethane spinning solution is subjected to spray spinning and stretching filamentation by means of a dry spinning system, and the zirconium phosphate synergistic flame retarding spandex with the microcosmical dispersion uniformity is obtained. According to the preparation method, the purpose of solving the problem that dispersion of a synergistic flame retardant ZrP in spandex is nonuniform is achieved, and the spandex prepared through the method has the advantages that contained ZrP has the microcosmical dispersion uniformity, the spinnability of the spinning solution is good, the synergistic flame retarding spandex reaches the national standard (the limit oxygen index (LOI) is higher than 28) of nonflammable materials, and the mechanical properties are excellent.

Owner:ZHEJIANG HUAFENG SPANDEX

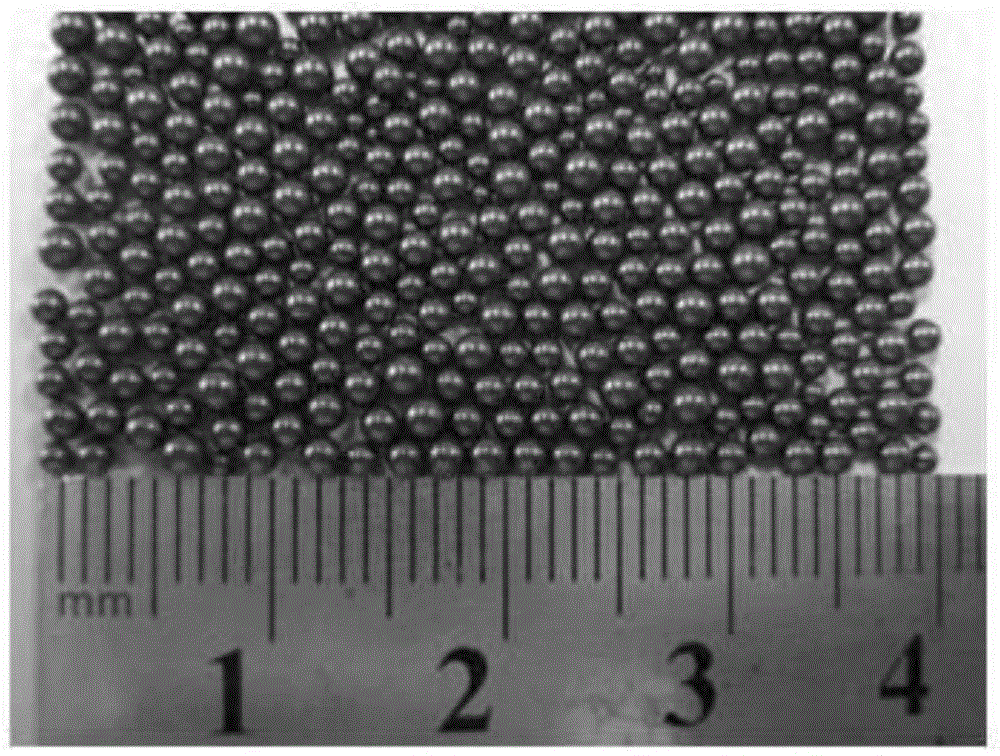

Aqueous phase suspension granulation method for preparing gradient flame-retardant expandable polystyrene beads based on waste polystyrene materials and its products

ActiveCN105566670BExcellent reflective infrared characteristicsRealize resource utilizationPolystyrene beadOil phase

The invention belongs to the field of high-value recovery and utilization of waste polystyrene foam materials, and specifically relates to an aqueous phase suspension granulation method for preparing gradient flame-retardant expandable polystyrene beads based on waste polystyrene materials and a product thereof. It uses an inorganic-organic gradient synergistic flame-retardant heat insulation system, organic solvents and waste polystyrene materials to form an oil phase, and uses surfactants, inorganic-organic synergistic suspending agents and deionized water to form a water phase dispersion medium. , water phase suspension granulation makes the oil phase droplets stably suspended and dispersed in the water phase medium, the organic solvent is evaporated by heating to realize the curing of gradient flame retardant polystyrene beads, and the gradient flame retardant is obtained by filling and foaming with pentane Polystyrene insulation board. The invention uses waste polystyrene as raw material, recovers and prepares gradient flame-retardant expandable polystyrene beads by physical method, utilizes waste, improves its gradient flame-retardant performance and heat insulation effect at the same time, organic solvent can be recycled, and is environmentally friendly. Friendly, easy to industrialize production.

Owner:WUHAN POLYTECHNIC UNIVERSITY

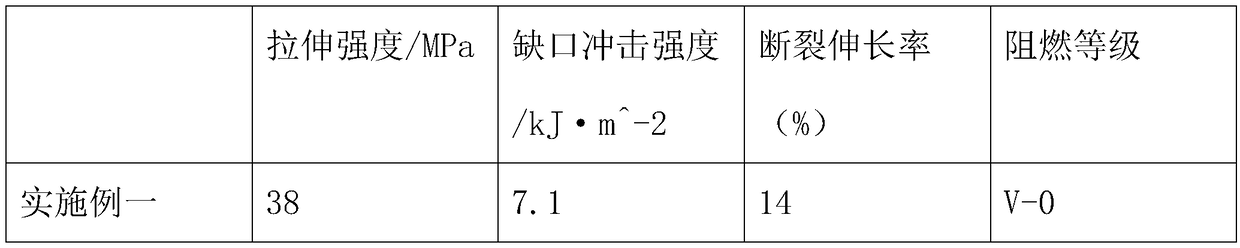

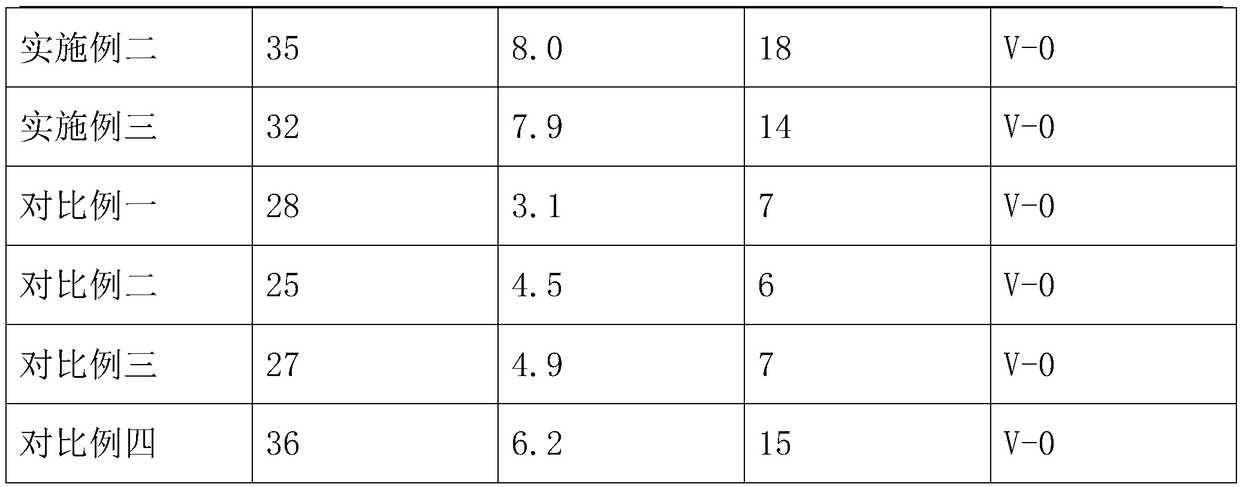

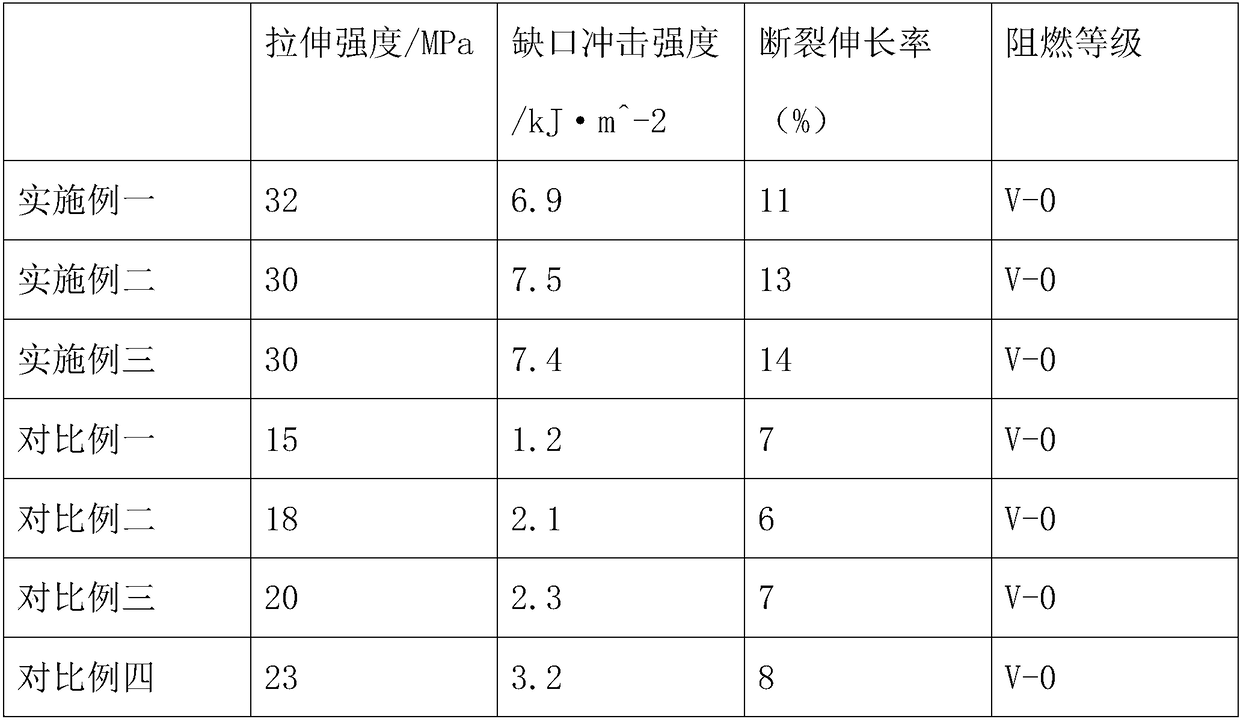

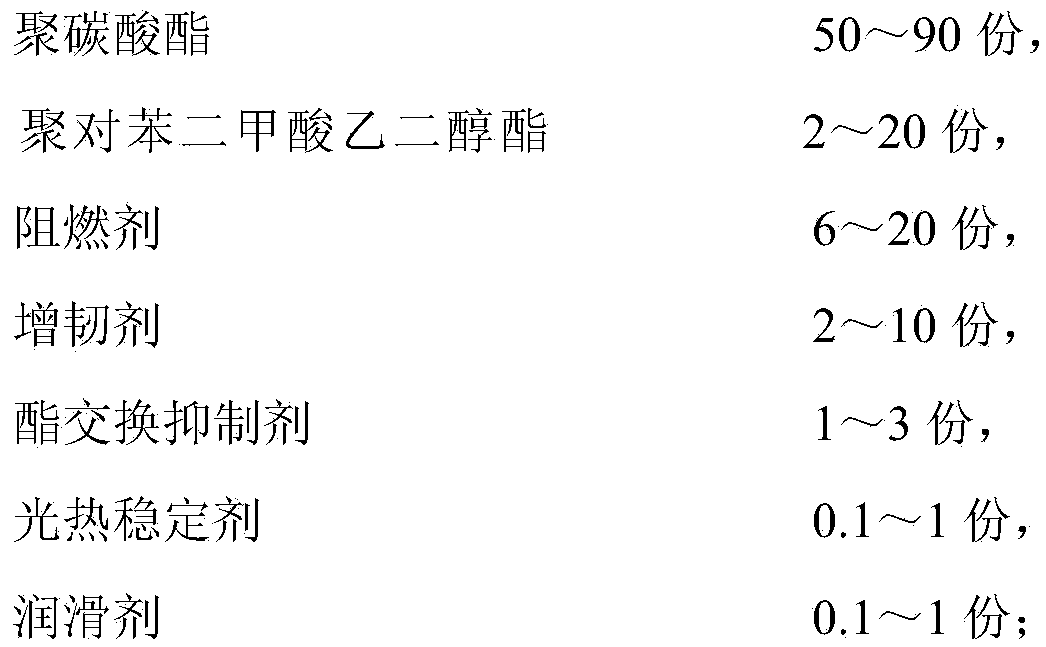

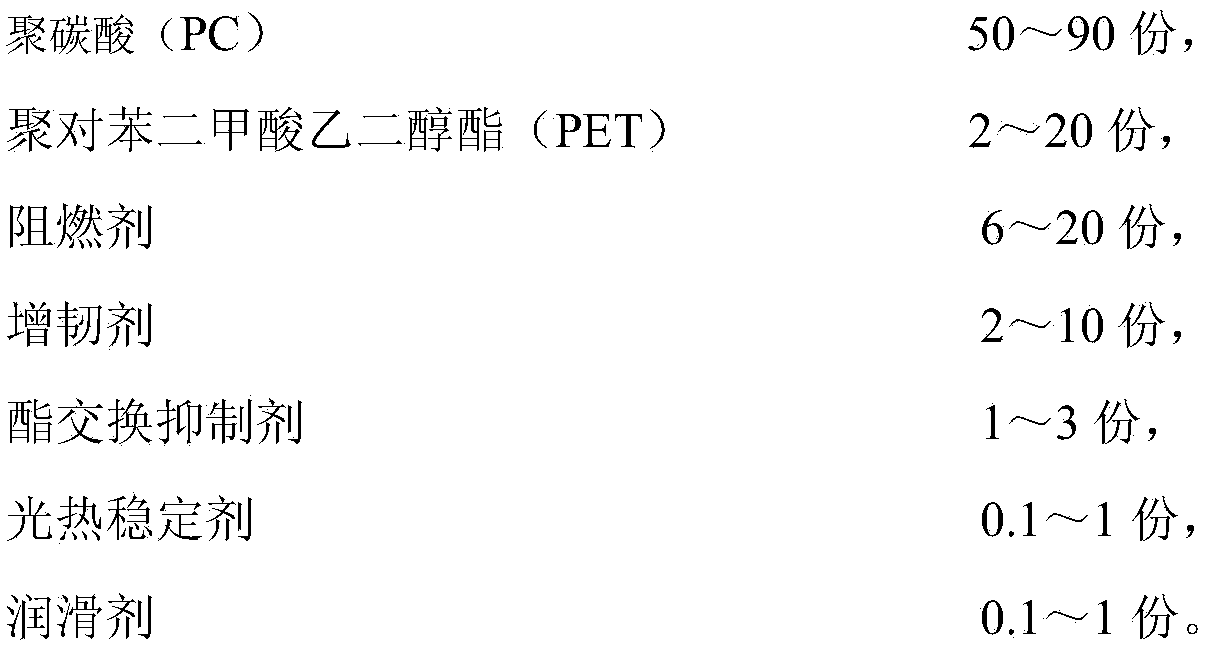

A high-performance flame-retardant pc/pet alloy material and its preparation method

The invention belongs to the technical field of polymer alloy materials, and relates to a PC / PET alloy material and a preparation method thereof. The material comprises the following components by weight: 50-90 parts of polycarbonate, 2-20 parts of polyethylene terephthalate, 6-20 parts of a flame retardant agent, 2-10 parts of a toughening agent, 1-3 parts of an ester exchange inhibitor, 0.1-1 part of a photo-thermal stabilizer and 0.1-1 part of a lubricant. The invention has advantages of simple and continuous process, high production efficiency and stable product quality; at the same time, the flame retardant system does not involve synergistic flame retardant such as antimonous oxide; the flame retardant properties, heater ignition temperature and tracking index of the alloy material gain balanced improvement; and the alloy material has characteristics of good mechanical properties, good appearance and good processing forming, and can be used for injection molding of a variety of electrical appliances and electrical and electronic products with high electrical performance requirements.

Owner:HEFEI GENIUS NEW MATERIALS

Composite environmental protection coating based on diatomite modification and preparation method thereof

ActiveCN109943193BUniform flame retardant performanceGood dispersionFireproof paintsPolyurea/polyurethane coatingsFirming agentBisphenol

The invention discloses a composite environmental protection coating based on diatomite modification, which comprises the following components in parts by weight: 52-58 parts of bisphenol A epoxy resin, 23-25 parts of branched flame retardant curing agent, polyurethane loaded Diatomite material 31-34 parts, leveling agent 1-2 parts, dispersant 3-5 parts, ethanol 100 parts. The aluminum hydroxide flame retardant material is deposited in the pore structure of diatomite by co-precipitation method, and then the modified diatomite is foamed together with polyurethane. Due to the high dispersion performance of diatomite, it can be uniform Dispersed in the polyurethane, so that the flame retardant performance of the prepared material is uniform, which solves the problem of adding a flame retardant in the foaming process in the prior art, so that the prepared foaming material is filled with a flame retardant, and realizes the flame retardant of the foaming material. Flame retardant properties, but directly adding flame retardants in the foaming process will cause uneven dispersion of flame retardants and affect its flame retardant properties.

Owner:广西弗士特资源综合利用有限公司

Low-smoke halogen-free flame-retardant polypropylene material containing double hydroxide and preparation method thereof

ActiveCN104151699BImprove mechanical propertiesImprove flame retardant performanceAntioxidantMechanical property

The invention discloses a low-smoke halogen-free flame-retardant polypropylene material containing double hydroxide and a preparation method of the low-smoke halogen-free flame-retardant polypropylene material and belongs to the technical field of flame retardancy. The composite low-smoke halogen-free flame-retardant polypropylene material containing layered double hydroxide comprises 100 parts of polypropylene, 15-30 parts of modified ammonium polyphosphate, 20-40 parts of Mg-Al double hydroxide, 2-5 parts of silicon-containing compatilizer, 1-3 parts of liquid paraffin and 0.15-0.4 part of antioxidant. The invention further discloses a preparation method of the layered double hydroxide flame-retardant agent. The composite flame-retardant polypropylene material disclosed by the invention is free of halogen and has low smoke release when the composite flame-retardant polypropylene material is combusted. The composite flame-retardant polypropylene material has the advantages of good flame-retardant property and mechanical properties, simpleness in production process and low raw material cost and can be widely applicable to automotive and household appliance industries.

Owner:扬州润丰塑胶有限公司

A kind of bulk halogen-free flame-retardant TPU modified material and preparation method thereof

The invention discloses a body halogen-free flame retardant TPU modified material. The material is prepared from polyester polyol, isocyanate, halogen-free flame retardant, chain extender and a little amount of environmental medium phosphoric acid. Halogen-free flame retardancy of the synthesized TPU material is detected according to the vertical combustion testing standard and can meet the requirement of the UL 94 V0 level (1.6 mm), the flame retardant is dispersed more uniformly in the TPU material, detection data of flame retardancy and properties of all aspects are more uniform, and the problems that due to post-modification addition, dispersing is not uniform, and the flame retardant effect is instable are solved; in addition, compared with those of a pure raw material, stretching, the stretching rate, resilience and the modulus of the material are reduced only by about 12%, compared with that of a flame retardant modified material product sold in the market, all the properties are improved by over 20%, and the requirements of customers needing high-grade halogen-free flame retardancy in the aspect of TPU base materials can be met.

Owner:JINAN TAIXING FINE CHEM

Anti-cracking and anti-ageing sealing rubber strip for glass doors and windows

InactiveCN108948543AUniform flame retardant performanceUniform mechanical strengthRubber layered productsCarbon blackWoven fabric

The invention relates to the technical field of door and window processing and in particular relates to an anti-cracking and anti-ageing sealing rubber strip for glass doors and windows. The sealing rubber strip is prepared from a stacked filling core composed of a net-shaped non-woven fabric and an outer-layer covered rubber material; the non-woven fabric and a rubber sheet are compounded in a stacking and hot pressing manner; and the rubber sheet is prepared from the following material components: nitrile butadiene rubber, natural rubber, ethylene propylene diene monomer, light calcium carbonate, a reinforcing agent, a coupling agent, an anti-ageing agent, a catalytic crosslinking agent and an activating agent, wherein the reinforcing agent is MT carbon black; the anti-ageing agent is one of an anti-ageing agent RD, an anti-ageing agent D and an anti-ageing agent 264; and the activating agent is nano zinc dioxide. The sealing rubber strip provided by the invention has strong elasticity and good sealing effect and has prominent corrosion resistance and anti-ageing performance; and the sealing rubber strip has good toughness and is unlikely to crack.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

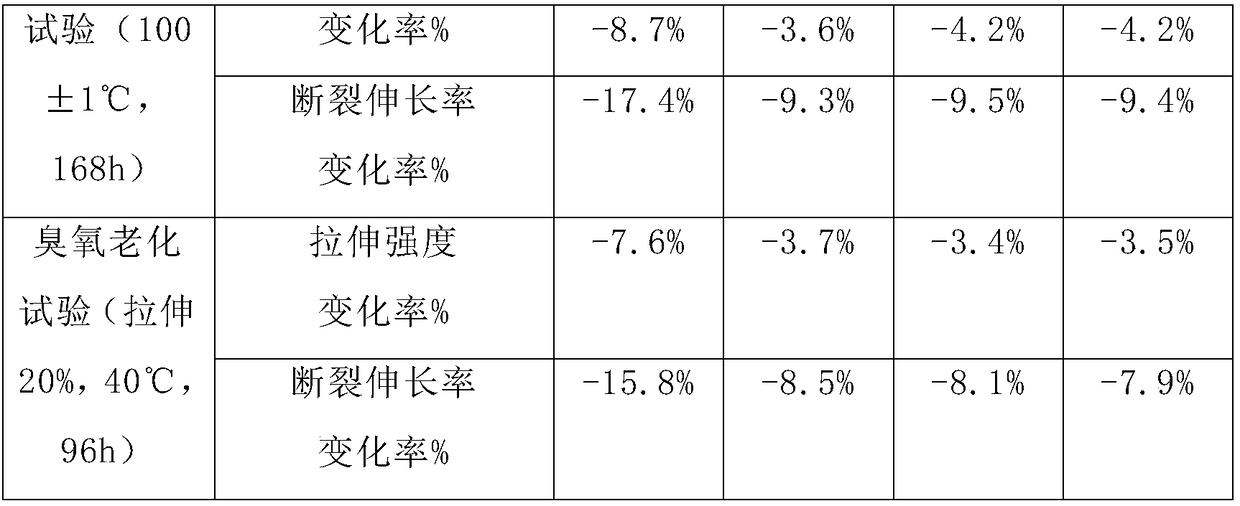

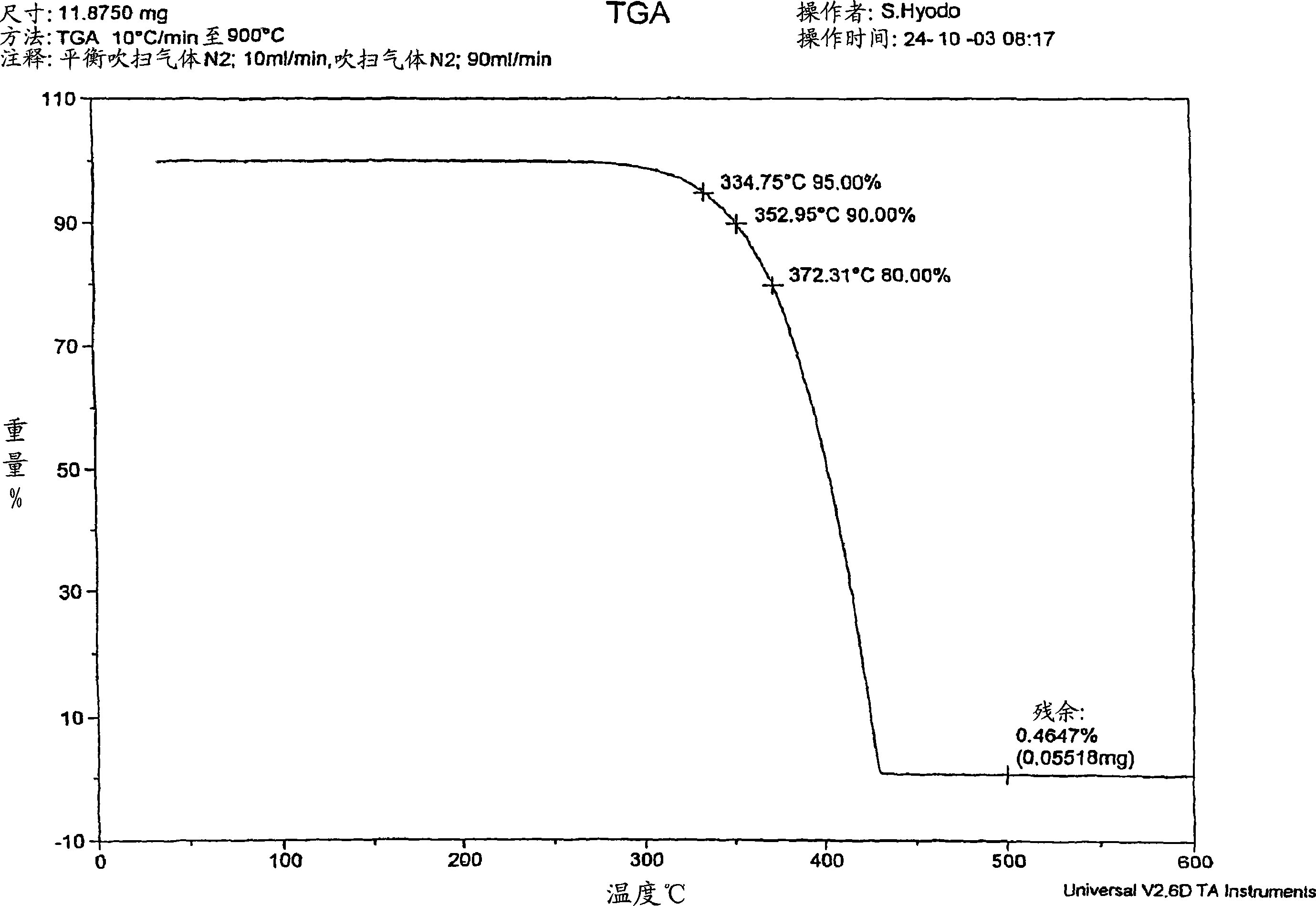

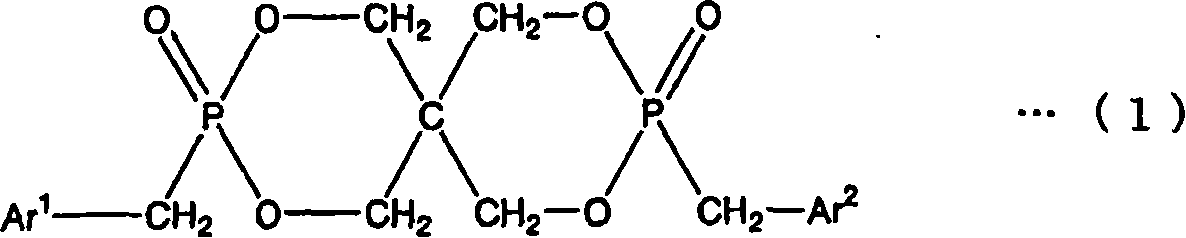

Fire-retardancy styrene resin composition and its forming product

InactiveCN1910230ANo thermal agingGood lookingGroup 5/15 element organic compoundsPolymer scienceEther

A styrene resin composition which is excellent in thermal stability, hue, flowability, and heat resistance and further has flame retardancy; and a molded article formed therefrom which has an excellent appearance. The resin composition comprises (A) 100 parts by weight of a styrene resin (ingredient (A)), (B) 0 to 100 parts by weight of a polyphenylene ether resin (ingredient (B)), and (C) 1 to 100 parts by weight of an organophosphorus compound represented by the following formula (1), and is characterized in that the organophosphorus compound (ingredient (C)) satisfies the following requirements: (i) the amount of the residue left after heating at 500 DEG C is 10% by weight or less, (ii) the HPLC purity is 90% or higher, and (iii) the acid value is 0.5 mg-KOH / g or lower. In the formula, Ar<1> and Ar<2> may be the same or different and each represents optionally substituted phenyl.

Owner:TEIJIN KASEK KK

A kind of red phosphorus micropowder aqueous suspension flame retardant and its preparation method and application

Disclosed are a flame retardant of red phosphorus micro powder in aqueous suspension and manufacturing method thereof. The manufacturing method comprises the steps of: adding a wetting and dispersing agent and an appropriate amount of water into red phosphorus micro powder and performing a grinding operation; adding water into the wet ground red phosphorus micro powder to perform a dispersing operation; and adding an anti-settling agent into the dispersion of red phosphorus micro powder and dispersing the same continuously until uniform to obtain a flame retardant of red phosphorus micro powder in aqueous suspension, wherein the red phosphorus content is 20-60%, and the viscosity is 10-500 cp, usually 10-100 cp. The aqueous suspension has good flowability and thixotropy, and the flame-retardant effect thereof on a material treated thereby is good and uniform; meanwhile, the suspension has good stability, low odor, and a wide variety of applications in polymers, paints, coatings and fabrics requiring flame retardance.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

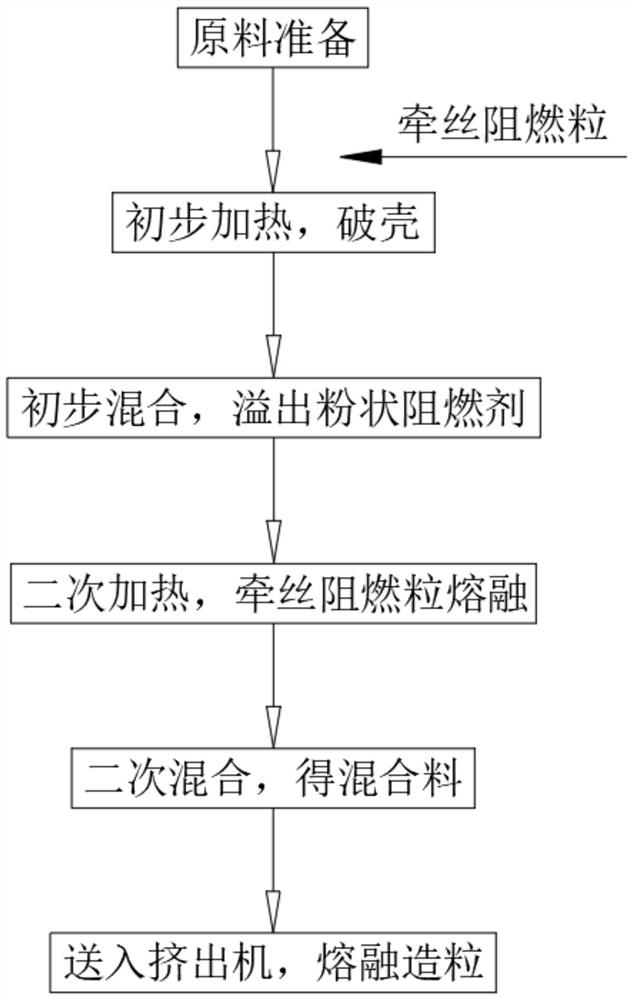

Preparation process of flame-retardant color master batch

The invention discloses a preparation process of flame-retardant color master batches, and belongs to the field of flame-retardant color master batches, granular wire-drawing flame-retardant particles are prepared by coating a powdery flame retardant, and when the granular wire-drawing flame-retardant particles are mixed with raw materials, not only can the dust problem caused by the flame retardant be effectively avoided and the environmental safety problem be improved, but also the flame-retardant flame-retardant particles can be used for preparing flame-retardant flame-retardant particles. In the mixing process of the wire-drawing flame-retardant particles and the raw materials, the shell-broken wire-drawing flame-retardant particles can be driven by the stirring force of the stirrer to move in the raw materials, and the flame retardant in the wire-drawing flame-retardant particles is extruded under pressure in the moving process and is dispersed in all areas in the raw materials in a multi-point manner; the flame retardant is uniformly diffused in a small range in a nearby area, and the uniform dispersion difficulty of the flame retardant can be greatly reduced and the uniformity of the flame retardant property of the color master batch can be improved in a manner of mixing the whole body and the local part.

Owner:湖南省升阳新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com