Flame-retardant reflective heat-insulating paint and preparation technique thereof

A reflective thermal insulation coating, flame retardant technology, applied in reflective/signal coatings, fire retardant coatings, coatings, etc. Balanced performance of combustion and heat insulation, good flame retardant and heat insulation effect, and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

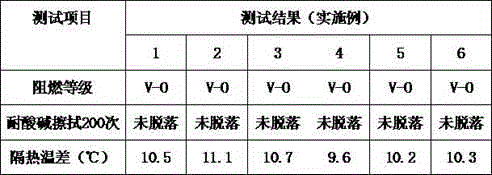

Examples

Embodiment 1

[0027] The flame-retardant reflective heat-insulating coating of the present invention comprises the following components in parts by weight: 35 parts of acrylic emulsion, 10 parts of butyl acetate, 5 parts of aluminum hydroxide, 12 parts of heat-reflective heat-insulating powder, hollow glass microspheres 20 parts, 1 part of silane coupling agent, 2 parts of leveling agent, 9 parts of glycol ether, 30 parts of deionized water.

Embodiment 2

[0029] The flame-retardant reflective heat-insulating coating of the present invention comprises the following components in parts by weight: 25 parts of acrylic acid emulsion, 25 parts of butyl acetate, 15 parts of magnesium hydroxide, 2 parts of heat-reflective heat-insulating powder, hollow ceramic microspheres 10 parts, 1 part of aluminate coupling agent, 7 parts of leveling agent, 3 parts of ethylene glycol butyl ether, 20 parts of deionized water.

Embodiment 3

[0031] The flame-retardant reflective heat-insulating coating of the present invention comprises the following components in parts by weight: 30 parts of acrylic emulsion, 17 parts of butyl acetate, 10 parts of antimony trioxide, 7 parts of heat-reflecting heat-insulating powder, hollow glass micro 15 parts of beads, 5 parts of titanate coupling agent, 4 parts of leveling agent, 6 parts of alcohol ester twelve, 25 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com