Patents

Literature

35results about How to "Good radiation heat transfer effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

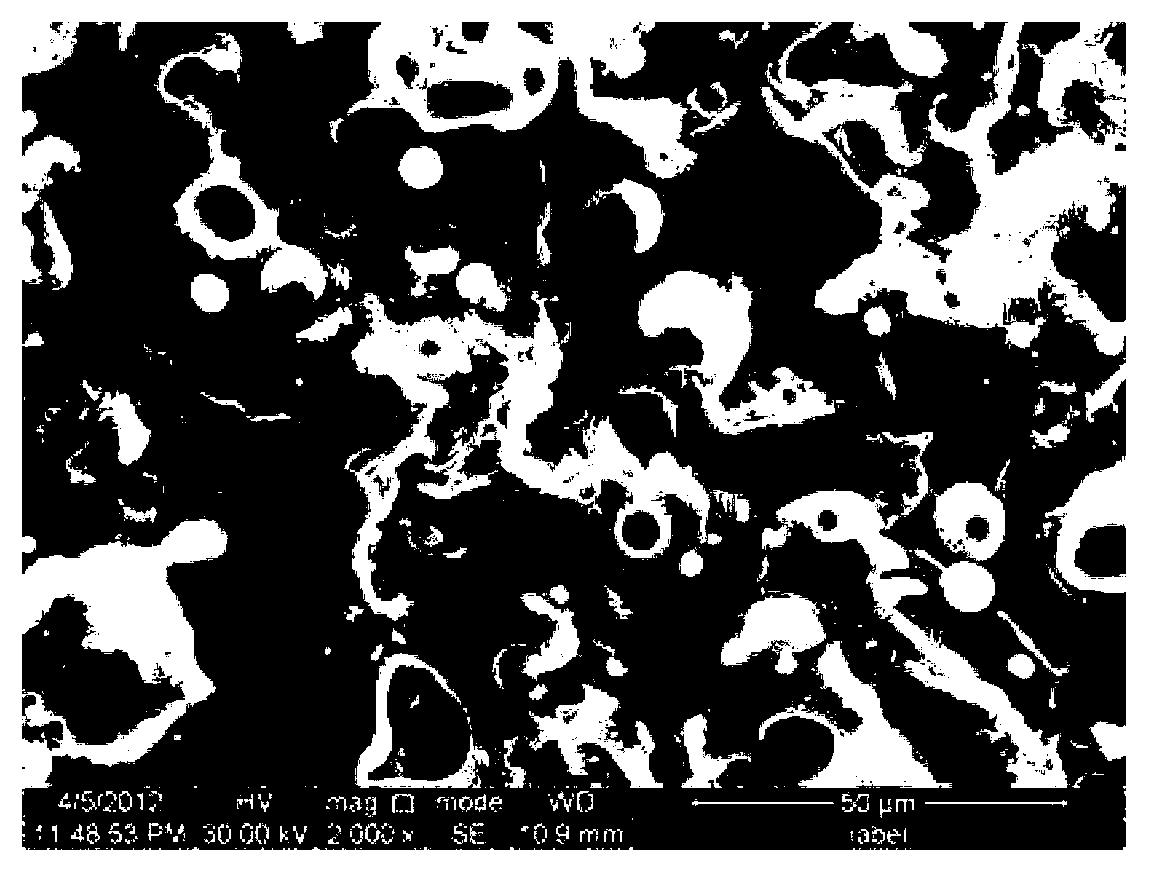

High-temperature-resisting heat-insulation coating as well as preparation method and application thereof

ActiveCN103725074AEasy to use in constructionPlay the role of saving energy and reducing consumptionReflecting/signal paintsPetroleumEnergy consumption

The invention relates to the field of functional coatings and particularly relates to a high-temperature-resisting heat-insulation coating and a preparation method thereof. The high-temperature-resisting heat-insulation coating is composed of the following raw materials in percentage by mass: 10%-40% of high-reflection paint with a shell-core structure, 10%-40% of heat-insulation powder with the shell-core structure, 1%-5% of a toughening agent, 10%-50% of a high-temperature bonding agent, 1%-10% of a coating auxiliary agent, and the balance of water. The preparation method comprises the following steps: mixing, dispersing and grinding raw materials; carrying out homogenization to enable an average grain diameter to be 325-400 meshes; and filtering and packaging to obtain a finished product. The high-temperature-resisting heat-insulation coating can be applied to high-temperature fields of industrial furnaces, industrial boilers, high-temperature steam pipelines, petroleum cracking equipment, engine parts, high-temperature smelting, sintering furnaces and the like, and can be used under a higher temperature for long time; the energy consumption can be saved and the service life of the furnaces is prolonged.

Owner:武汉双虎涂料股份有限公司

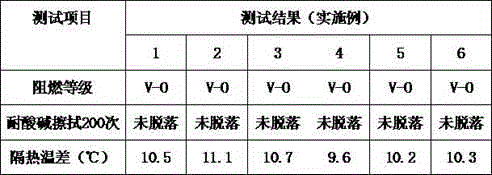

Waterborne heat-insulating flame-retardant multifunctional nano coating and preparation method thereof

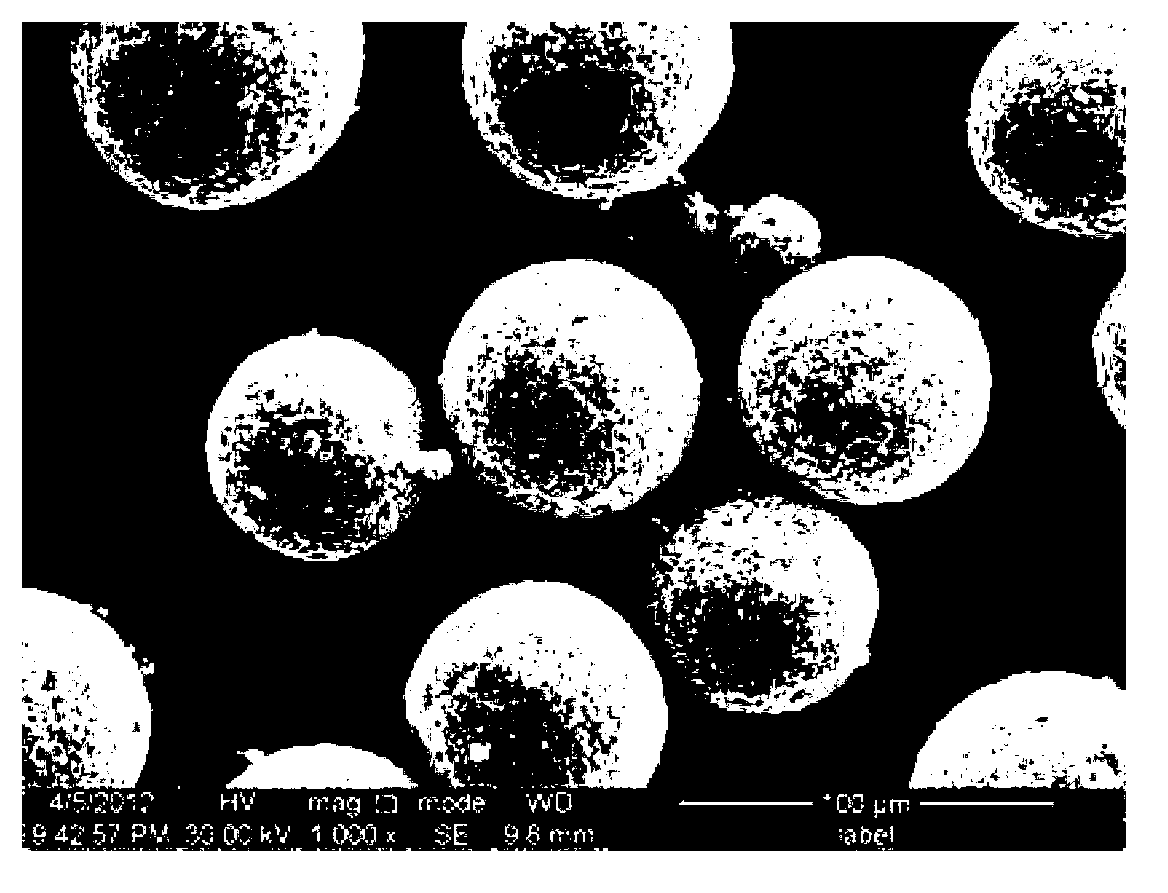

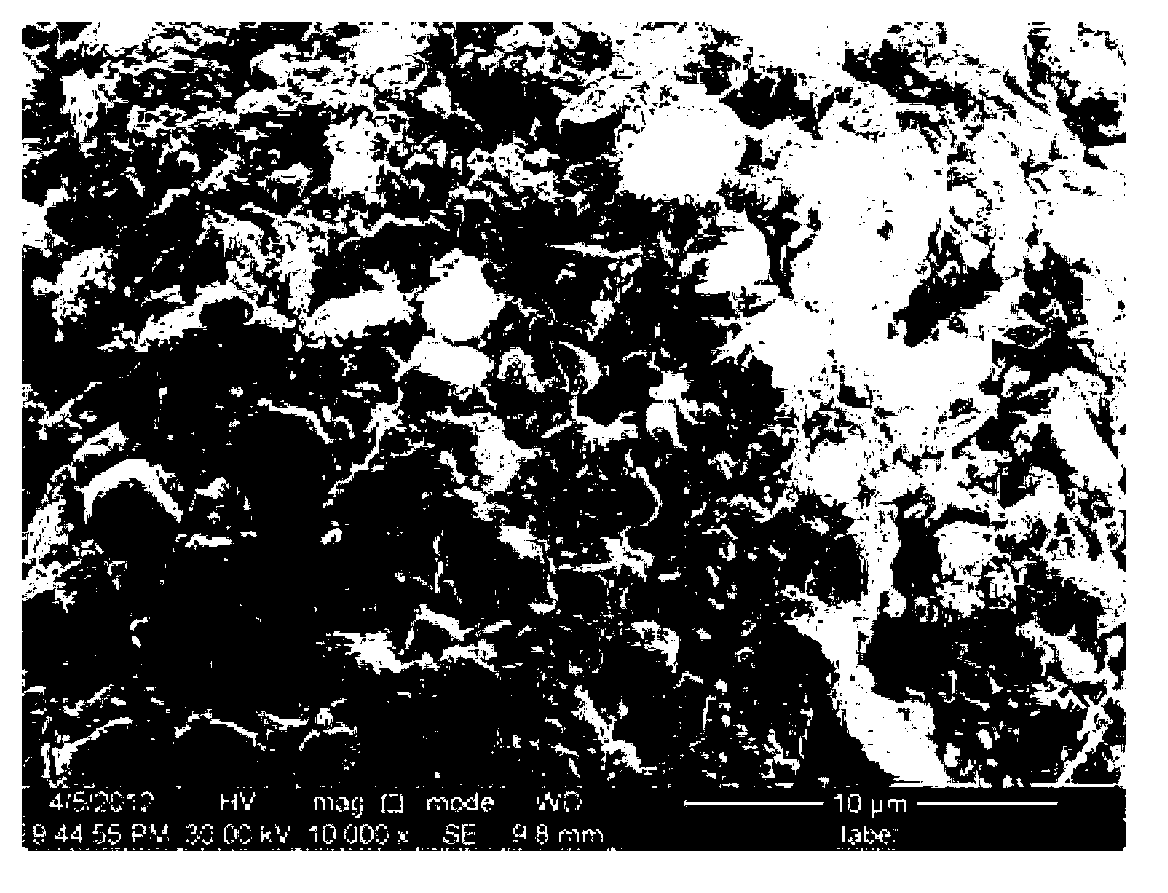

InactiveCN101824270AImprove performanceSimple preparation processFireproof paintsPolyurea/polyurethane coatingsTin dioxideMicrosphere

The invention relates to a waterborne heat-insulating flame-retardant multifunctional nano coating and a preparation method thereof. The coating consists of the following components in part by weight: 48 to 52 parts of waterborne resin and 30 to 50 parts of nano pigment fillers (nano titanium dioxide, nano titanium dioxide-coated hollow glass microspheres, nano titanium dioxide-coated hollow ceramic microspheres and nano antimony-doped tin dioxide (ATO) particles), size and auxiliary materials such as film-forming additive and coupling agent. The preparation method includes the steps that: the nano fillers and the size are first dipped into the waterborne resin, the auxiliary materials are then sequentially added and stirred, and thereby the heat-insulating flame-retardant multifunctional nano coating is obtained. The processing technique is simple, the component proportion is reasonable, and the prepared coating has the advantages of high heat resistance, high reflectivity, high radiative heat conductivity, certain fire resistance, high-efficient heat insulation, excellent mechanical and chemical properties, environment-friendliness, stain resistance, flame retardance and energy saving. The coating can be coated on outside facilities such as outer walls and building roofs.

Owner:长沙新凯化工有限公司

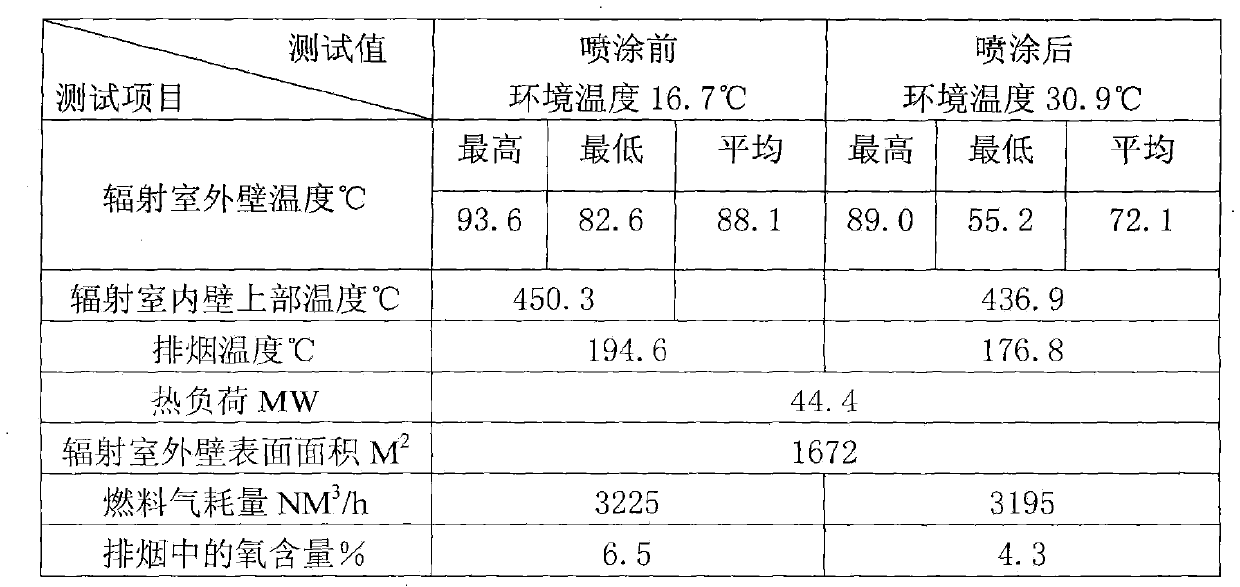

Thermal-radiating material and fire-resisting material using same

InactiveCN101973768AReduce heat lossHigh thermal efficiencyChemical industryHeat-exchange elementsHeat lossesHearth

The invention discloses a fire-resisting material using a thermal-radiating material, comprising a fire-resisting material body, wherein a furnace thermal-radiating element is arranged on the fire-resisting material body, and the thermal-radiating material is coated on the outer surfaces of the fire-resisting material body and the furnace thermal-radiating element. The invention also discloses a thermal-radiating material. Aiming at the defects of various traditional industrial heating furnaces, the thermal-radiating material is sprayed and arranged on the inner wall of a furnace to reduce the thermal loss of an industrial heating stove, thereby increasing heat efficiency and achievingthe purposes of saving energy and reducing emission.

Owner:BEIJING ENJI ENERGY SAVER TECH

Environmentally-friendly heat-insulating nanometer coating and preparation method thereof

InactiveCN102002320ASimple processing technologyThe group ratio is reasonableCoatingsEnvironmentally friendlyWetting

The invention relates to an environmentally-friendly heat-insulating nanometer coating and a preparation method thereof. The environmentally-friendly heat-insulating nanometer coating comprises the following components: nanometer pigment and filler slurry, synthetic waterborne resin, a film-forming aid, a coupling agent, an antifoaming agent, a leveling agent and a wetting agent. The preparation method of the environmentally-friendly heat-insulating nanometer coating comprises the following steps of: adding the nanometer pigment and filler slurry into the synthetic waterborne resin, sequentially adding the film-forming aid, the coupling agent, the antifoaming agent, the leveling agent and the wetting agent, and quickly stirring. The processing technology is simple, the components have a reasonable proportion, and the coating has high thermal resistance, reflectivity and radiative heat transfer performance.

Owner:长沙华润涂料有限公司

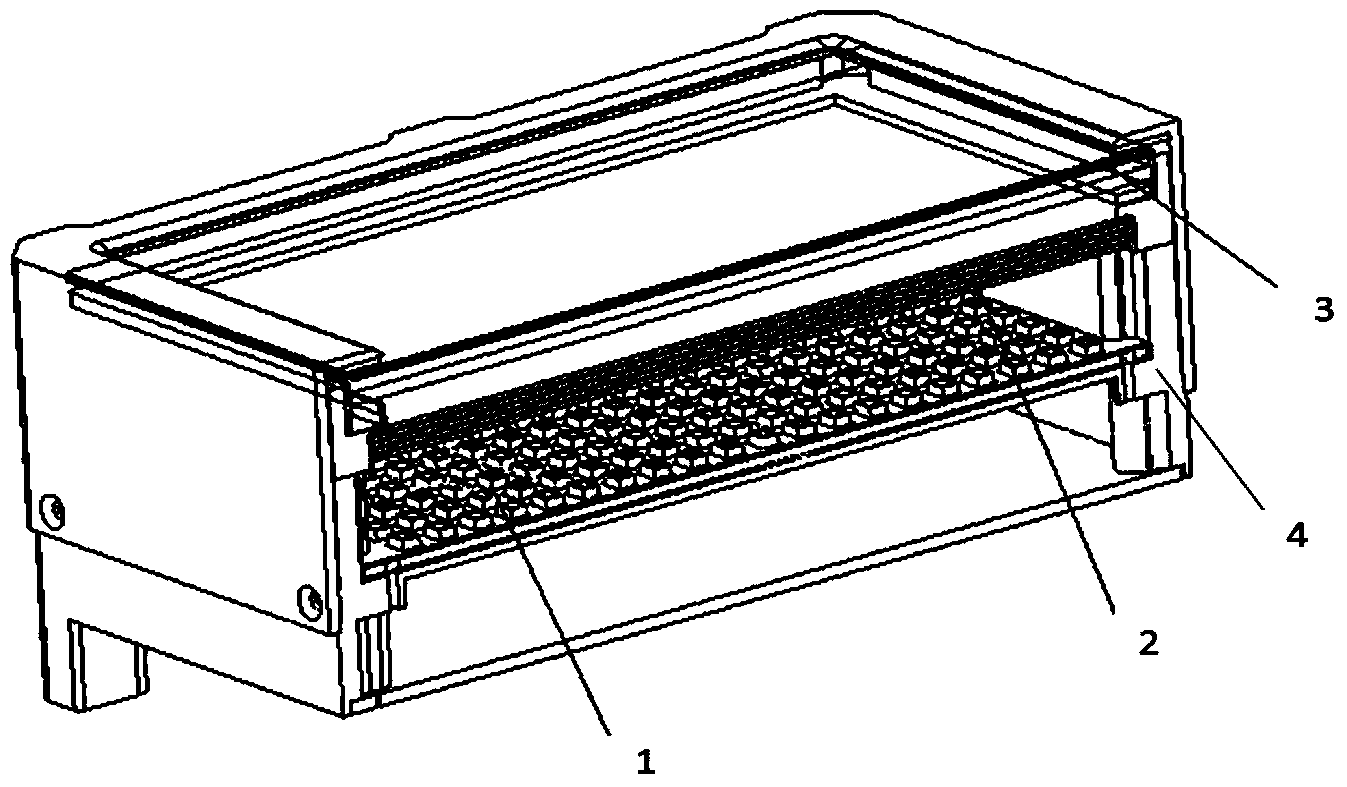

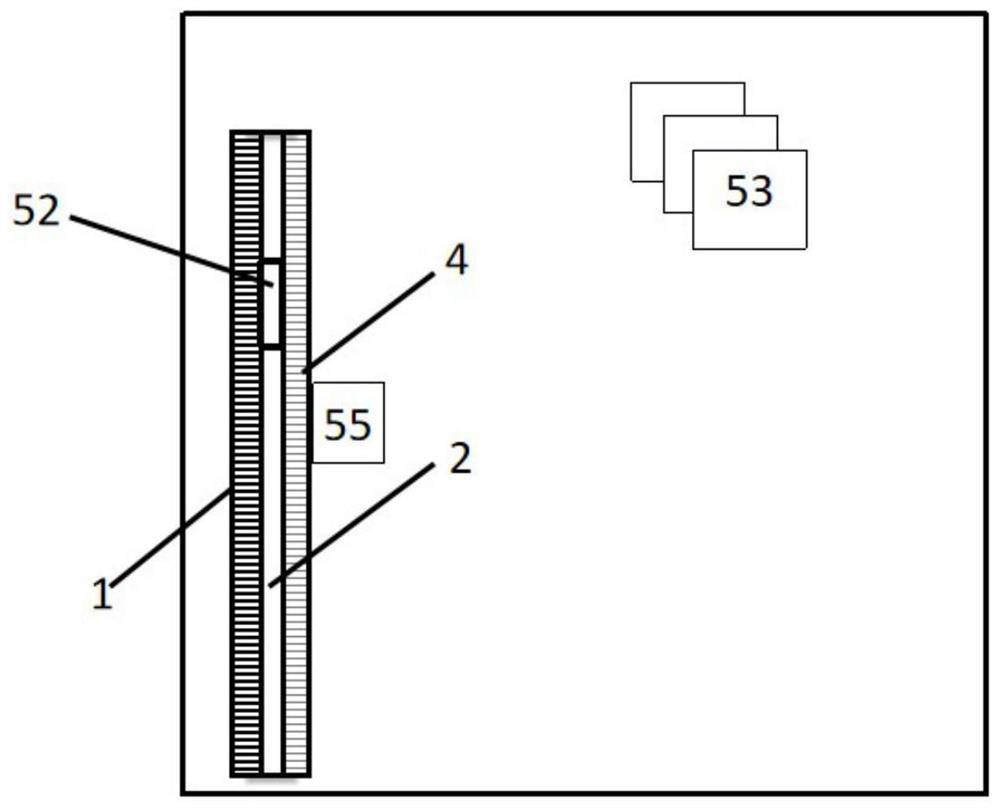

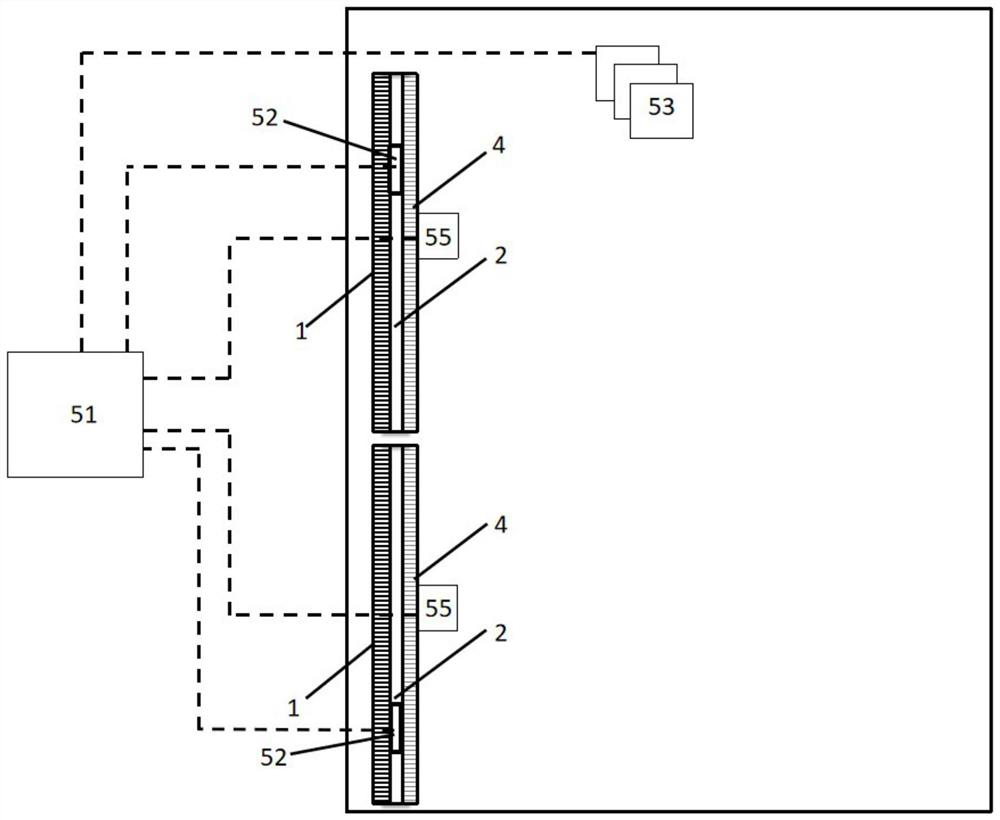

Efficient cooling LED backlight device

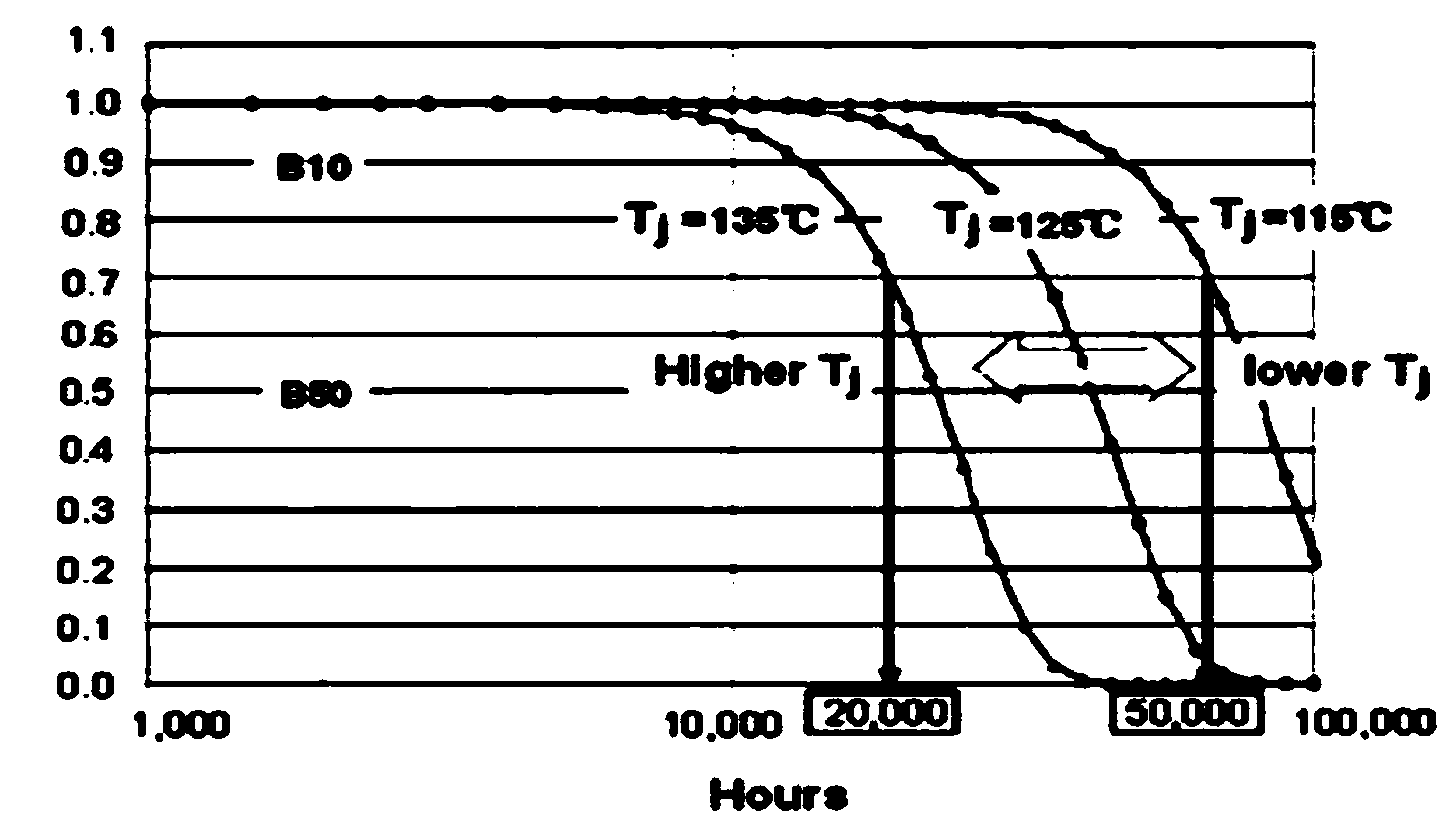

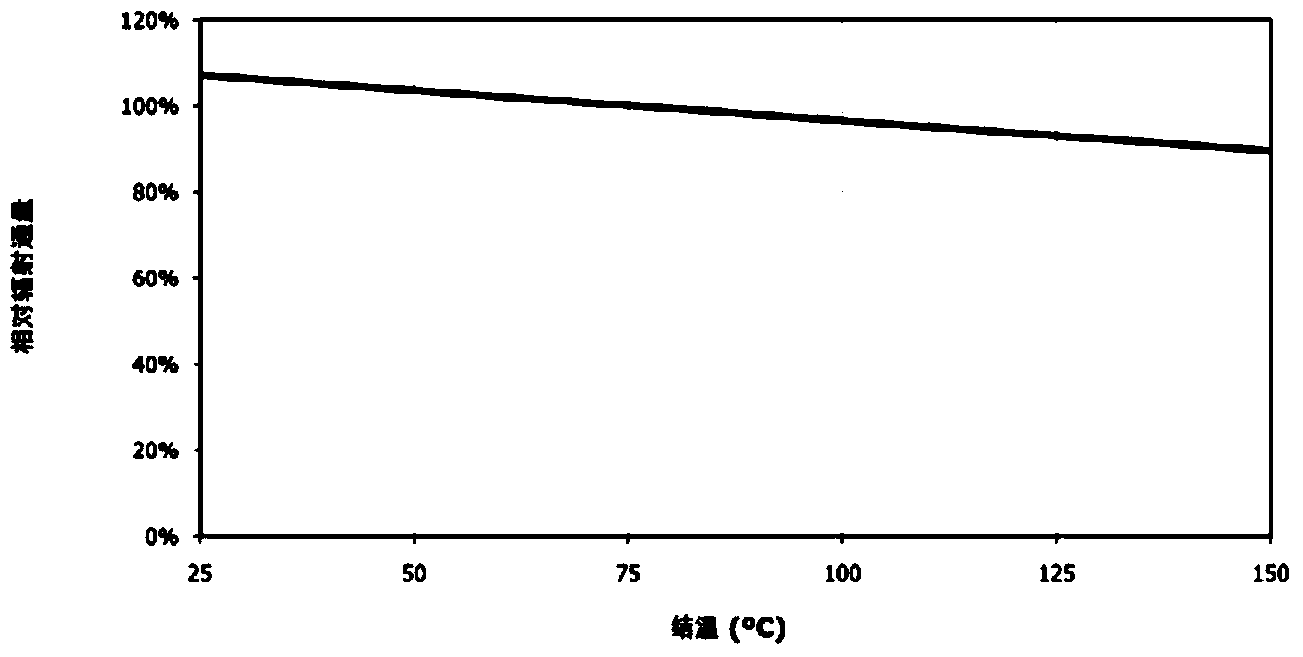

InactiveCN104267538AGood radiation heat transfer effectImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsHeat conductingJunction temperature

The invention discloses an efficient cooling LED backlight device. The efficient cooling LED backlight device comprises an LED lamp, a PCB lamp panel, a heat conducting material, a white reflective sheet and a backlight cavity structural part; holes corresponding to LED lamps on the PCB lamp panel in position are formed in the backlight cavity structural part and the white reflective sheet; the PCB lamp panel is mounted on the outer side of the bottom surface of the backlight cavity structural part; the LED lamps extends into the backlight cavity structural part through the holes; the efficient cooling LED backlight device further comprises a structural back panel, a graphene thin film and a thermal radiation enhancement material, wherein the structural back panel is arranged on the lower surface of the PCB lamp panel, the graphene thin film is arranged between the backlight cavity structural part and the PCB lamp panel and the thermal radiation enhancement material is formed on the outer wall of the backlight cavity structural part by coating. Compared with the prior art, the efficient cooling LED backlight device has the advantages of enhancing the radiative heat transfer capacity of the backlight structure, improving the heat dissipation capacity of the whole backlight system and reducing the junction temperatures of the LED lamps, and furthermore, improving the reliability of the LED backlight, prolonging the service life of the LED backlight and improving the luminous efficiency.

Owner:中航华东光电有限公司

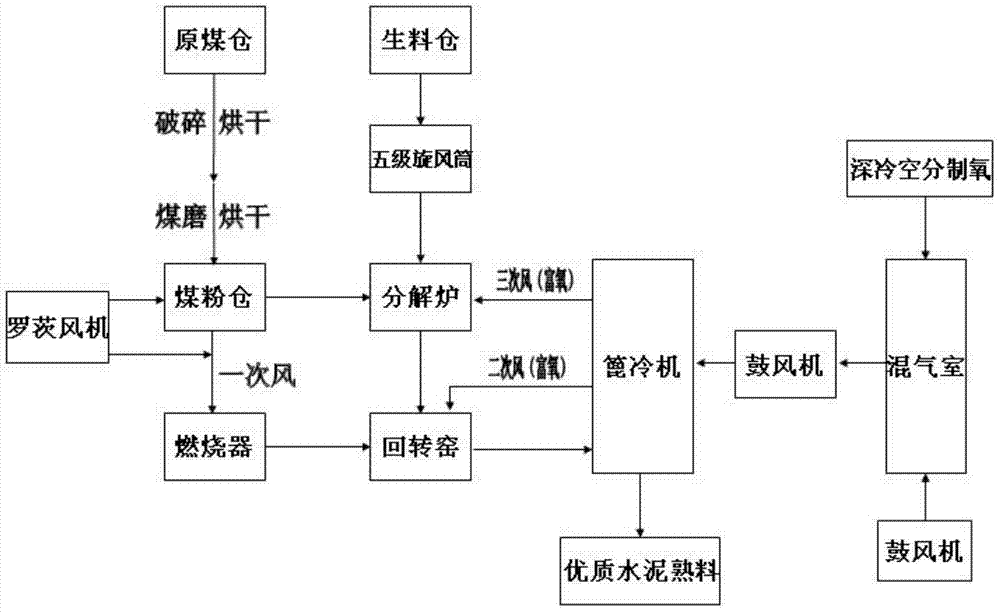

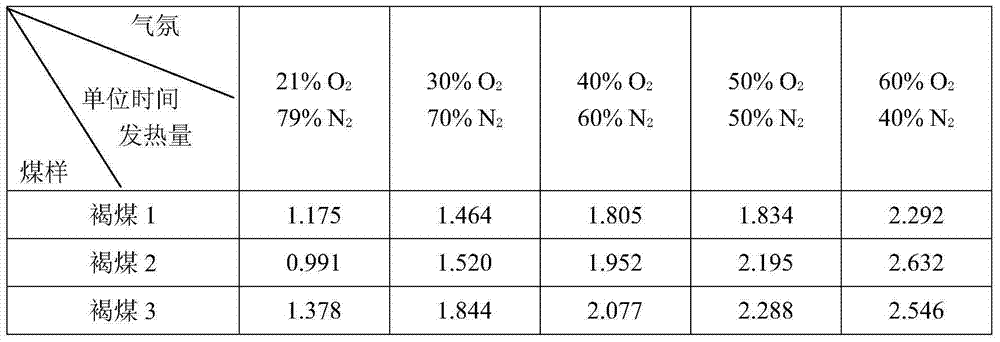

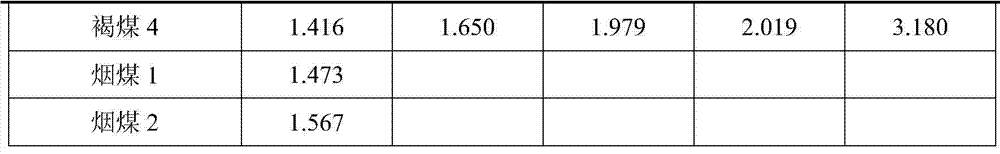

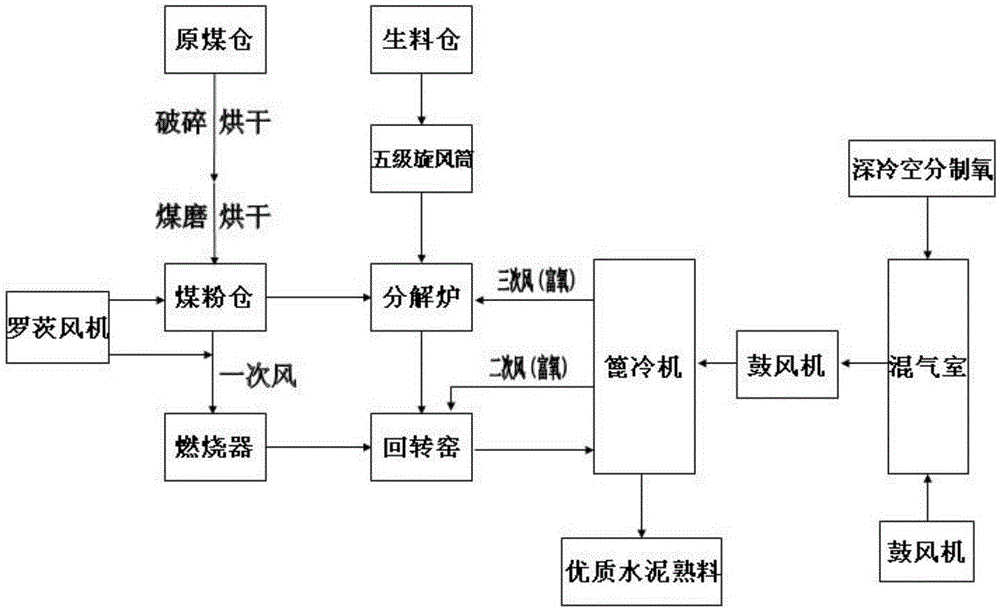

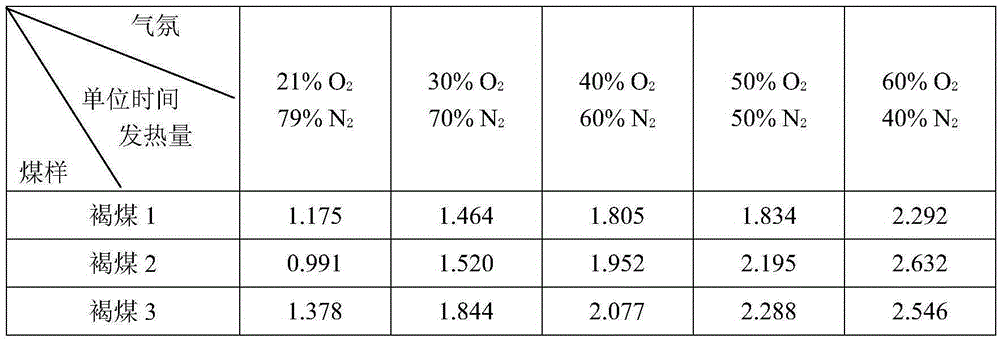

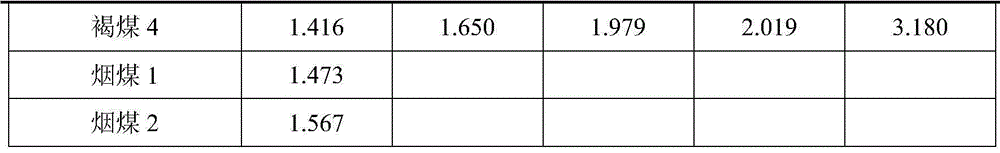

Production method of cement clinker by calcination with oxygen-rich reinforced lignite

ActiveCN103496863AIncrease burn rateStrong disturbing effectClinker productionSocial benefitsAir volume

The invention provides a production method of cement clinker by calcination with the combustion performance of oxygen-rich reinforced lignite. A combustor with four wind channels is adopted, wherein coal wind, cyclone wind and axial-flow wind serve as primary wind, the primary wind is air and the volume of the primary wind accounts for 8% total wind volume; center wind is also air and the volume of the center wind accounts for lower than 1% total wind volume; secondary wind and tertiary wind are oxygen-rich gas with oxygen concentration of 25-90%, and the temperature of a kiln head is controlled between 980 DEG C and 1020 DEG C when the secondary wind enters the kiln head. The combustion performance of the oxygen-rich reinforced lignite is applied to the calcinations of cement clinker, the limitation that at present lignite can not be used alone as a fuel during production of cement clinker is broken, and the production method has significant economical and social benefits.

Owner:INNER MONGOLIA UNIV OF TECH

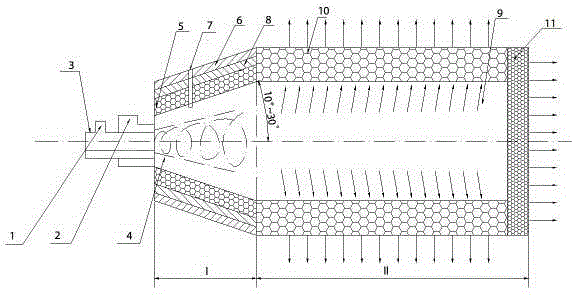

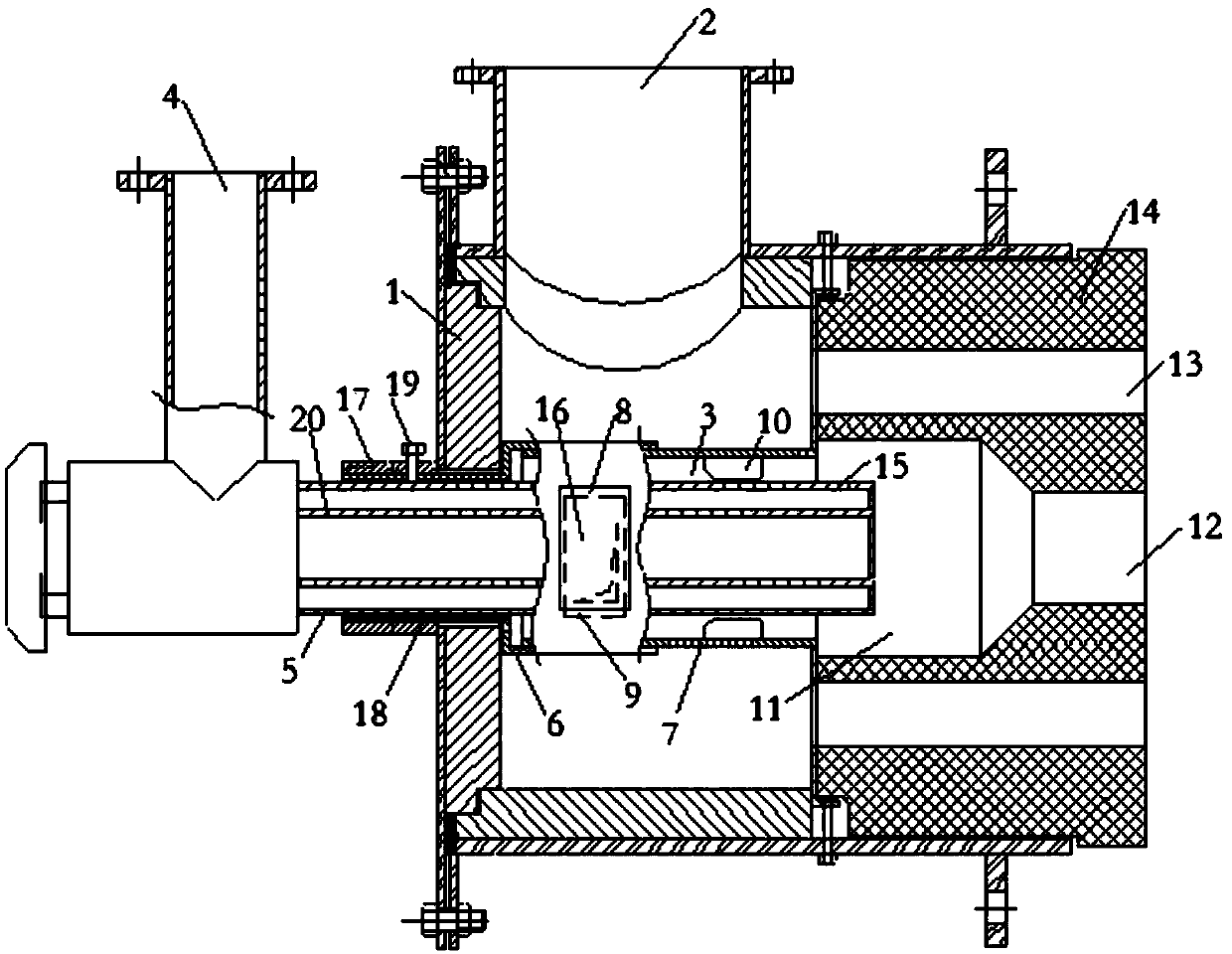

Cylindrical radiation porous medium heater capable of achieving diffusive combustion in cavity

InactiveCN104089287ALow lean burn limitImprove space utilizationHeat storage plantsGaseous fuel burnerCombustorPorous medium

A cylindrical radiation porous medium heater capable of achieving diffusive combustion in a cavity comprises a gas pipe, an air pipe, a rotational flow generator, the cavity, an electronic ignition device, first foam ceramics, second foam ceramics and third foam ceramics. Gas and air are electronically ignited after passing through the rotational flow generator, and the gas achieves rotational flow diffusive combustion in the conical cavity. The first foam ceramics are arranged around the cavity, thermal reflux is achieved through radiation heat transfer, the gas is preheated, and then flue gas enters in an airflow distribution area. The flue gas passes through the second foam ceramics and the third foam ceramics, part of heat of the flue gas is accumulated in the foam ceramics, and then the flue gas flows to a heating space. Due to the good radiation heat transfer performance of porous media, surrounding objects are quickly heated. Compared with a free flame burner, the radiation heat transfer performance can be greatly improved, heat transfer is more even, the concentration of fuel can be lower, and low heating value gas such as coal-mine gas and chemical waste gas can be combusted.

Owner:SHENYANG INST OF ENG

Alcohol-base fuel burner with radiant panel fuel nozzle

An alcohol-base fuel burner with radiant panel fuel nozzle comprises an air chamber, a mixed combustion chamber, an atomization injection pipe, wherein one end of the air chamber is opened, and the other end thereof is provided with an air inlet; the mixed combustion chamber is sleeved in the air chamber and is provided with air holes along the wall of the mixed combustion chamber; the center of the atomization injection pipe is a through hole, one end is provided with a radiant panel, the other end is installed on the soleplate of the mixed combustion chamber and is communicated with one end of a fuel supply pipe, and at least two fuel injection holes are uniformly distributed on the same cross section of the wall of the atomization injection pipe. The invention has high combustion efficiency, low energy consumption and less pollutant emission; compared with the existing technology, the discharge amount of CO and NOx is relatively reduced by 50% to 70%, and the heat efficiency reaches up to more than 40%. The burner is safe, environment-friendly, stable in combustion, high in combustion strength, easy and safe for combustion, good in fire adjustment, high-temperature and corrosion resistant, high impact resistant, mechanical impact resistant, low in thermal inertia and long in service life; and the burner is suitable for being applied to various special cookers in catering industry.

Owner:湖南中能力华新能源技术有限公司 +1

High-temperature far infrared radiation energy-saving composite coating and preparation method thereof

The invention discloses a high-temperature far infrared radiation energy-saving composite coating and a preparation method thereof, aiming at providing a composite coating with the advantages of stable structure, low production cost and little environment pollution. The high-temperature far infrared radiation energy-saving composite coating is technically characterized by comprising the followingcomponents in percent by weight: 25-30 percent of Baihou asbolite, 10-15 percent of Yinjiang kaolin, 5-7 percent of manganese oxide, 6-8 percent of ferric oxide, 4-6 percent of chromic oxide, 15-20 percent of Guodong mortar, 10-12 percent of aluminum oxide, 6-8 percent of zircon sand, 3-5 percent of titanium oxide and 1-3 percent of lanthanum oxide.. The preparation method comprises the steps of:1, crushing the Baihou asbolite and the Yinjiang kaolin, and screening; 2, respectively screening the aluminum oxide, the manganese oxide, the zircon sand, the ferric oxide, the titanium oxide and the chromic oxide; 3, respectively loading all screened components in a sagger and then entering a kiln for calcining; and 4, smashing and blending calcined block materials, grinding through a wet process ball grinder, and screening to obtain the composite coating. The invention belongs to the technical field of coating preparation.

Owner:广东宝丰陶瓷科技发展股份有限公司

Flame-retardant reflective heat-insulating paint and preparation technique thereof

InactiveCN104910726ALarge thermal resistanceImprove reflectivityFireproof paintsReflecting/signal paintsHalogenButyl acetate

The invention discloses a flame-retardant reflective heat-insulating paint and a preparation technique thereof. The flame-retardant reflective heat-insulating paint comprises the following components in parts by weight: 25-35 parts of acrylic emulsion, 10-25 parts of butyl acetate, 5-15 parts of halogen-free flame retardant, 2-12 parts of heat-reflection heat-insulating powder, 10-20 parts of hollow microbead, 1-8 parts of coupling agent, 2-7 parts of leveling agent, 3-9 parts of film-forming assistant and 20-30 parts of deionized water. The flame-retardant reflective heat-insulating paint is free of halogens, and thus, is nontoxic and environment-friendly. The flame-retardant reflective heat-insulating paint has the advantages of high thermal resistance, high reflectivity and favorable radiant heat transfer performance, can simultaneously have the functions of heat insulation and flame retardancy, has more balanced flame retardancy and heat-insulating property, can implement better flame-retardant and heat-insulating effects, and is suitable for the field of decoration of dwelling houses, school buildings, hotel buildings and other buildings.

Owner:黎司华

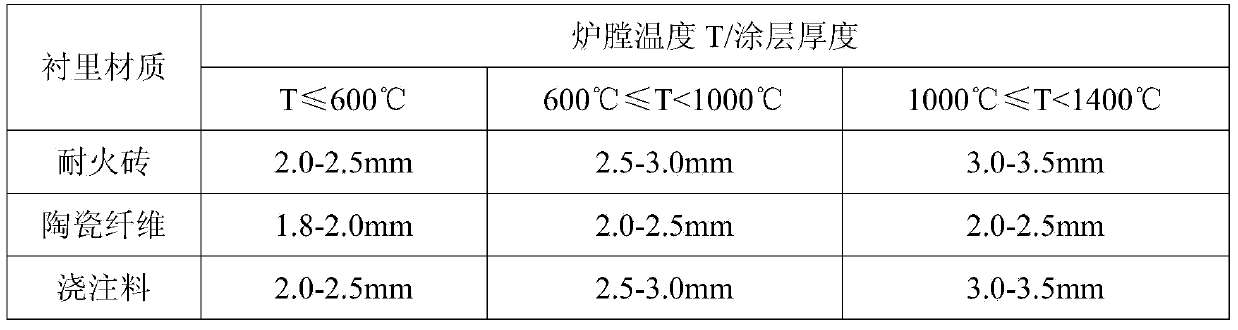

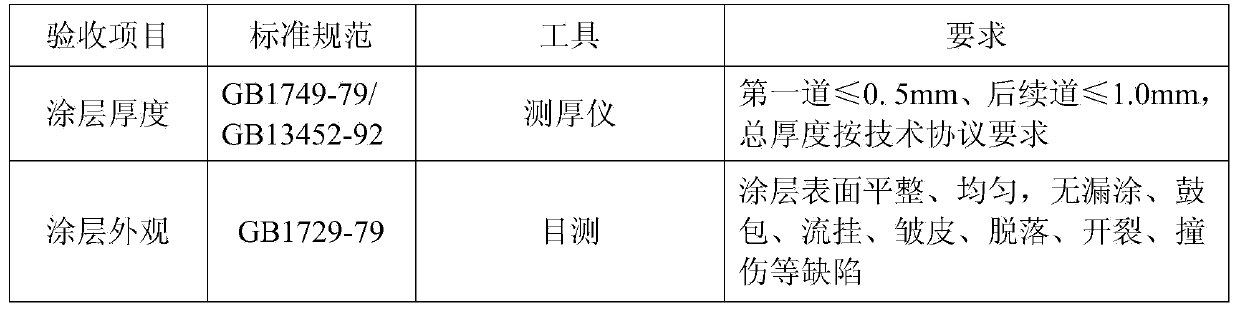

High-temperature-resistant anti-radiation inorganic coating construction method

InactiveCN104197718AExtended service lifeHigh thermal radiation coefficientLinings repairThermal radiationCoating

The invention discloses a high-temperature-resistant anti-radiation inorganic coating construction method. The method includes determining the total thickness of the construction coating according to different liner materials and hearth temperatures, performing multiple coating constructions, sintering at the temperature of 500 to 700 DEG C, and forming a high-temperature-resistant anti-radiation inorganic coating. According to the high-temperature-resistant anti-radiation inorganic coating, the heat radiation coefficient of the inner wall of a furnace liner can be increased effectively, the internal radiation heat transferring effect is enhanced greatly, the fine energy saving effect is provided, and the service life of the coating can be prolonged.

Owner:上海乐恒石油化工集团有限公司

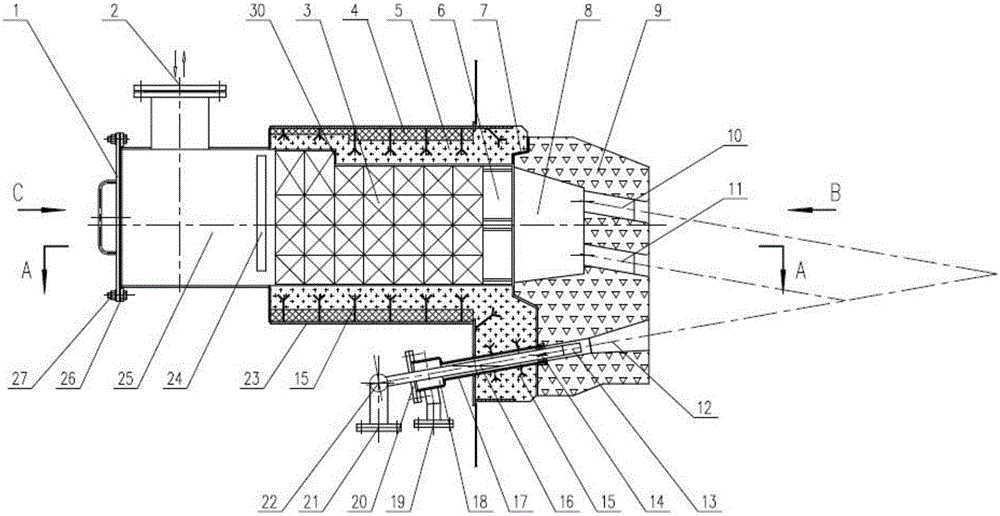

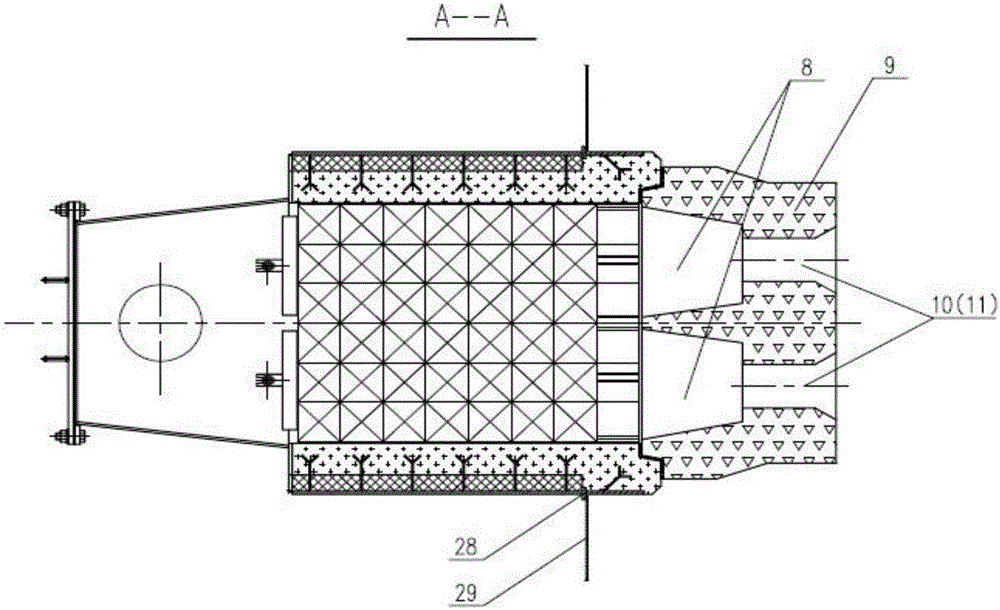

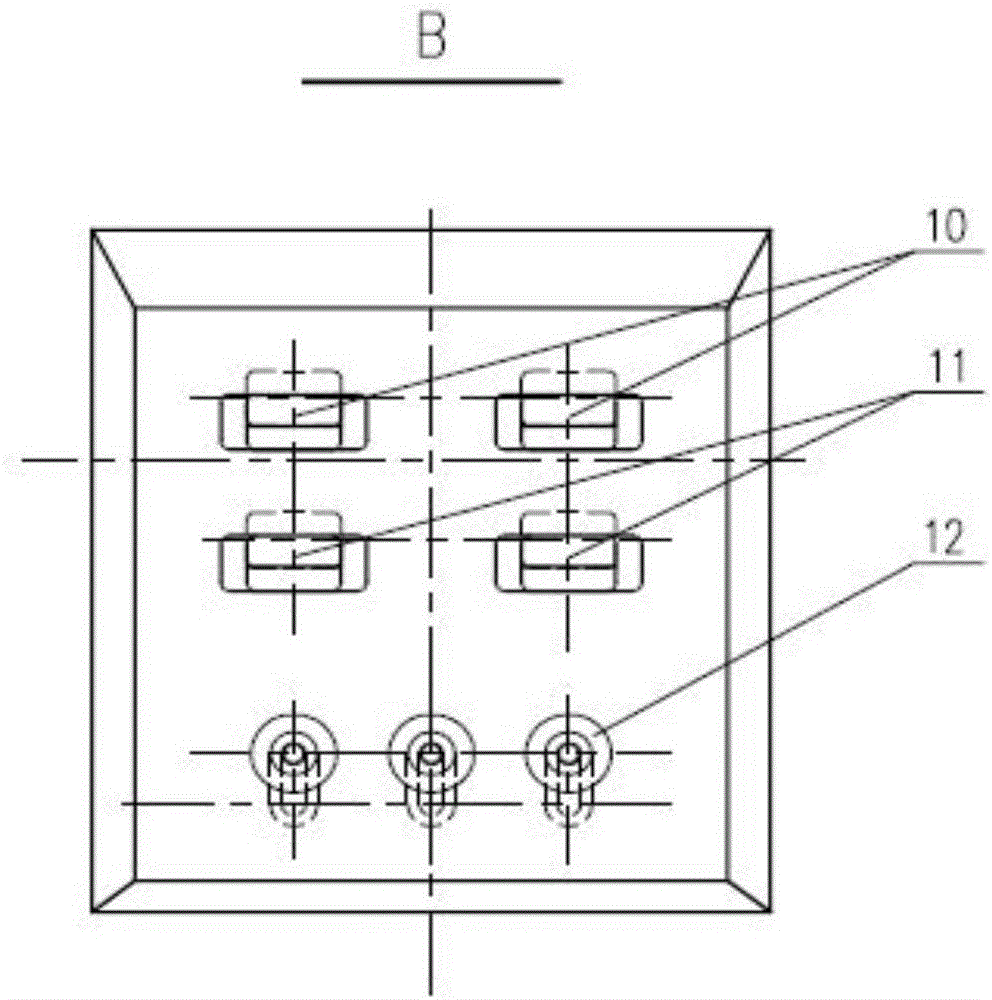

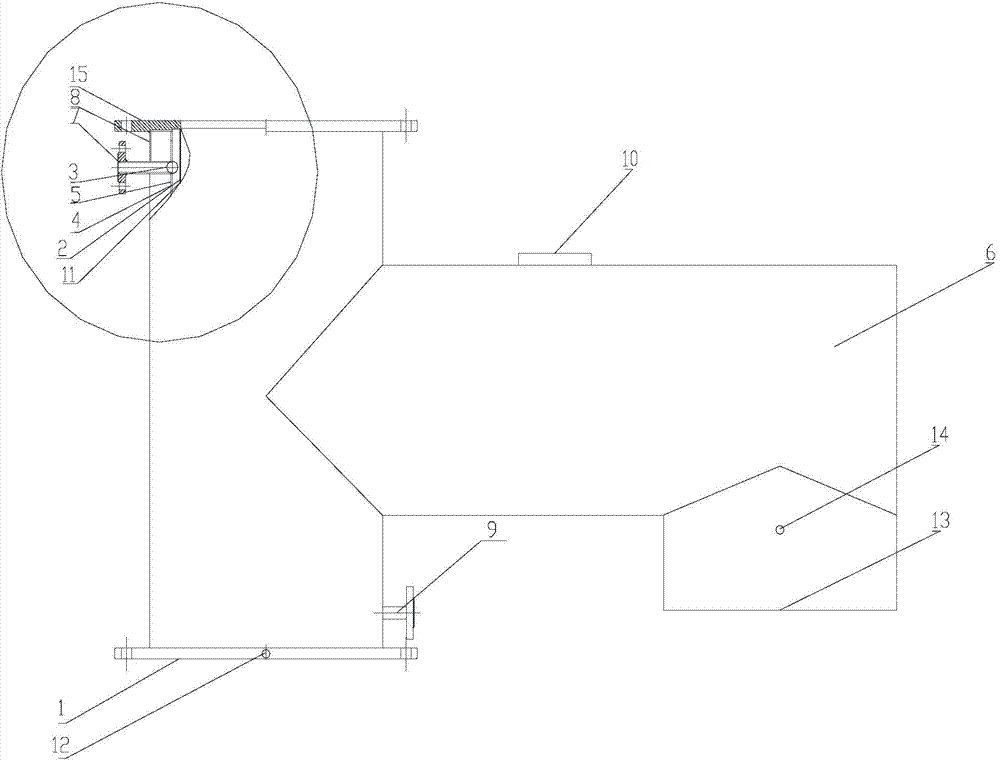

Multi-stage combustion energy-saving environment-friendly burner

PendingCN107435925AIncrease overall volumeReduce the temperatureGaseous fuel burnerThermodynamicsNitrogen oxides

The invention discloses a multi-stage combustion energy-saving environment-friendly burner, and belongs to the technical field of energy conservation and environmental protection. The burner comprises a burner overhaul cover plate, a combustion air inlet, a heat accumulator, a heat insulation material, a fire-resistant pouring material, a large-hole baffle brick, a high-temperature gas distribution chamber, a natural gas sprayer, a primary air spinning disk, an anchoring nail, a primary air inlet, a first connecting flange, a natural gas inlet, a grille plate, a second connecting flange, a bolt connector and a burner installation positioning plate, the burner overhaul cover plate is fixed on a low-temperature gas distribution chamber through the second connecting flange and the bolt connector, a steel pipe of the combustion air inlet is welded on the low-temperature gas distribution chamber, and the heat accumulator is mounted in a heat accumulation burner box. According to the burner, the advantages of air classifying combustion technique are sufficiently played, NOx generation is effectively restrained by the aid of oxygen-deficient combustion mechanism, and the discharge amount of pollutants such as nitrogen oxide is greatly reduced.

Owner:安徽皓沣环保科技有限公司

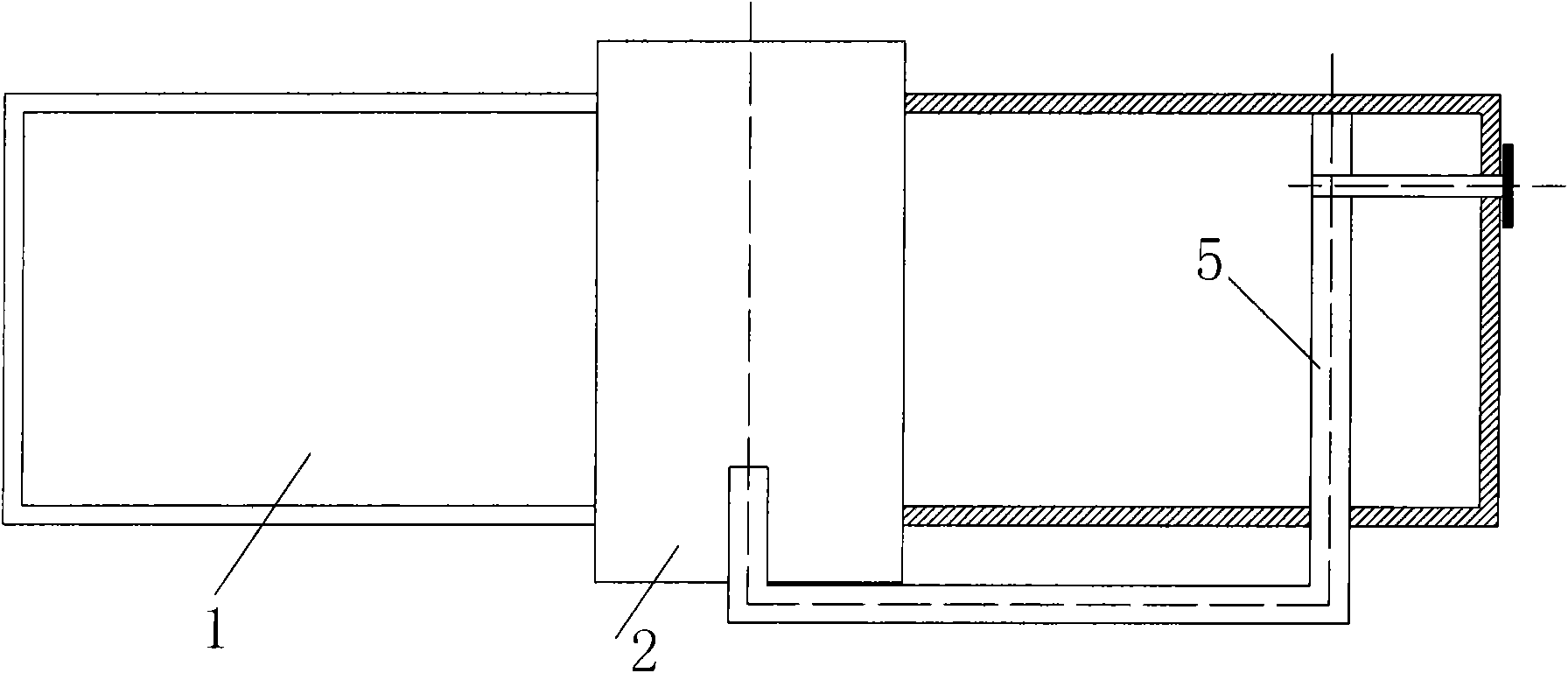

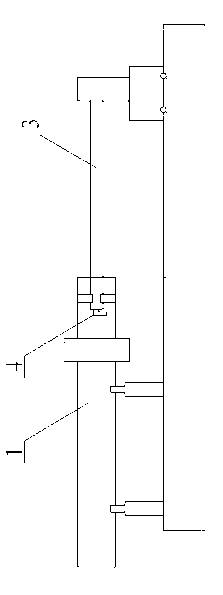

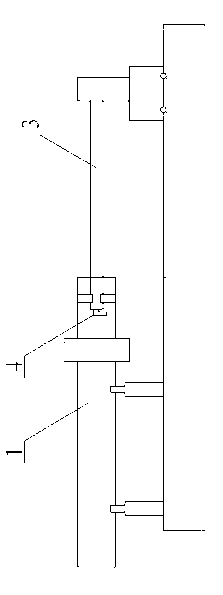

Coke oven three-way bridge pipeline heat exchanger device

InactiveCN104726110AIncrease profitPrevent high temperature corrosionStationary tubular conduit assembliesDistillation gas withdrawalEngineeringCoke oven

The invention relates to the field of heat exchangers and particularly relates to a coke oven three-way bridge pipeline heat exchanger device. The coke oven three-way bridge pipeline heat exchanger device comprises a vertical pipe section and a horizontal pipe section connected with the vertical pipe section, wherein a smoke inlet is formed in the lower end of the vertical pipe section and a coke cleaning hole is formed in the upper end; a smoke outlet is formed in the tail end of the horizontal pipe section, wherein the device is characterized in that a heat exchange tube sleeve is arranged inside the vertical pipe section, wherein the heat exchange tube sleeve comprises a heat exchange inner sleeve and a heat exchange outer sleeve; an inlet pipe hole connected with the heat exchange outer sleeve is formed in the upper part of the vertical pipe section, and an outer pipe hole connected with the heat exchange outer sleeve is formed in the other side of the lower part of the vertical pipe section; a guide plate flow is respectively arranged on each of the inlet pipe hole and the outlet pipe hole; and a heat insulating layer is arranged on the outer wall of the heat exchange outer sleeve, and a heat conduction coating is arranged on the inner wall of the heat exchange inner sleeve. By adopting the coke oven three-way bridge pipeline heat exchanger device, the raw coke oven gas afterheat is reused, the utilization rate is increased and the energy is saved.

Owner:常州江南冶金科技有限公司 +1

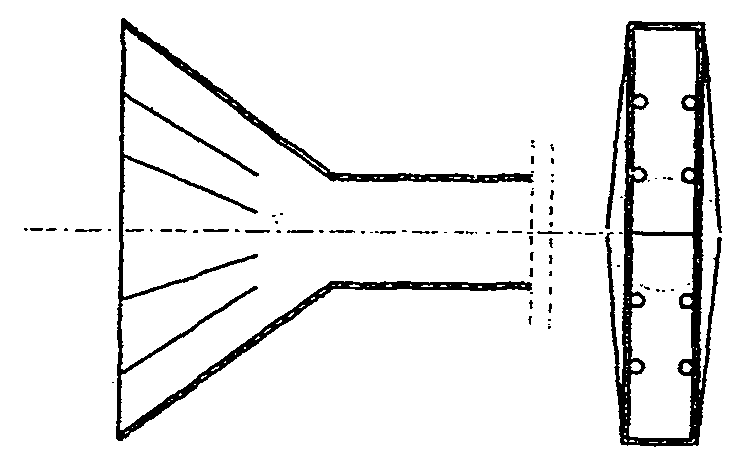

Biomass gas burner with adjustable flame length and using method thereof

InactiveCN109611843AAdvantages of the burnerEasy to operateAir/fuel supply for combustionNon-combustible gases/liquids supplyEngineeringFuel gas

The invention discloses a biomass gas burner with adjustable flame lengths. A mixing chamber is arranged in the center of inner burner blocks, a fuel gas source communicates with the left end of a fuel gas effuser through a fuel gas inlet pipe; the right end of the fuel gas effuser penetrates through a burner outer shell and extends into the mixing chamber; a fixed air cover sleeves the outer sideof the fuel gas effuser; a primary air channel is formed between the outer wall of the fuel gas effuser and the inner wall of the fixed air cover; a movable air cover is rotatably assembled on the outer side of the fixed air cover; a first air port and a second air port are correspondingly formed in overlapping parts of the fixed air cover and the movable air cover; the size of a opening formed by the first air port and the second air port is adjusted by a rotary movable air cover; one end of the primary air channel communicates with an air inlet pipe through the opening; the other end of theprimary air channel communicates with the mixing chamber; a secondary air channel is further arranged on the inner burner blocks; and the air inlet pipe communicates with a furnace chamber through the secondary air channel. According to the biomass gas burner with the adjustable flame lengths, air covers are used for adjusting a primary air flow rate, so the ratio of primary and secondary combustion air can be adjusted without disassembling a burner, and the operation is very convenient and simple.

Owner:NORTHEASTERN UNIV

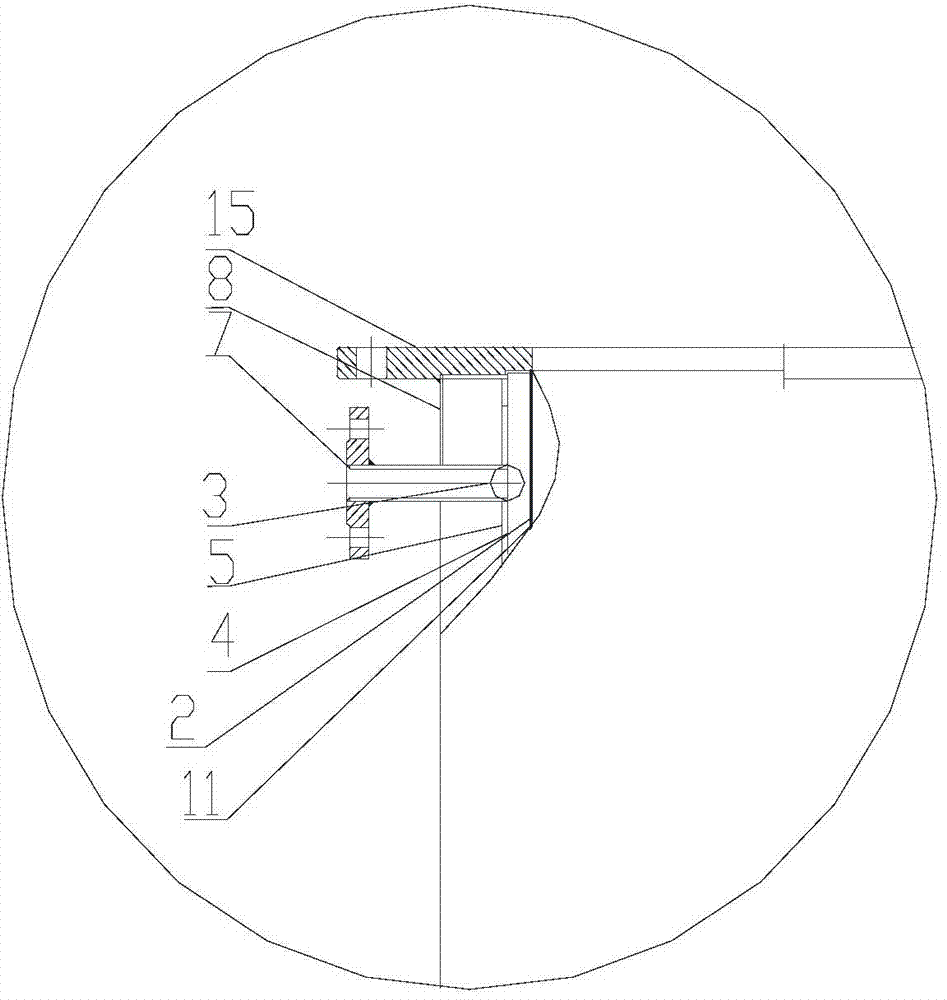

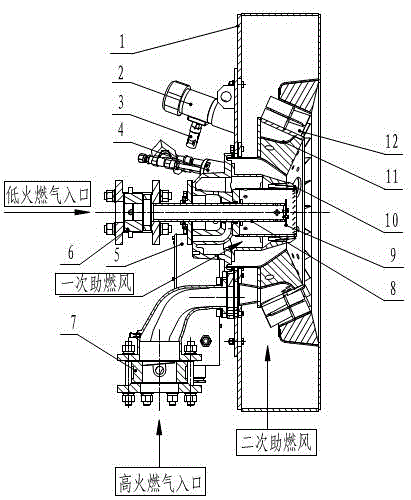

Gas burner

InactiveCN104482532AEasy to controlGood radiation heat transfer effectGaseous fuel burnerCyclonePetroleum

A gas burner comprises an air box, an igniter, a flame observing barrel, a flame monitor and a wiring box. A low-fire gas inlet is arranged on the air box and connected with a low-fire gas nozzle, a primary air cyclone is arranged on the outer side of the low-fire gas nozzle, a high-fire gas nozzle is arranged on the air box and connected with a high-fire gas nozzle, a secondary air cyclone is arranged on the outer side of the high-fire gas nozzle, the low-fire gas nozzle and the high-fire gas nozzle are of a concentric structure, the low-fire gas nozzle is connected with primary burning-assisting air, and the high-fire gas nozzle is connected with secondary burning-assisting air. Due to arrangement of the low-fire gas nozzle, adjusting ratio and adjusting accuracy of the burner are improved greatly, and oven gas needs of a gas oven can be met; the gas burner has the advantages of yellow bright burning flame and good radiation heat transfer effect and is free of backfire and flame lifting and suitable for natural gas, liquefied petroleum gas, coke oven gas, biomass gas, petroleum gas, chemical engineering tail gas and the like not lower than 3000kcal / m3 (standard) in burning heat value.

Owner:江西中船航海仪器有限公司

Preparation method of hexaaluminate high-emissivity thermal protection coating layer

InactiveCN102815927BSolve the impactGood radiation heat transfer effectMolten spray coatingThermal expansionSuperalloy

The invention provides a hexaaluminate high-emissivity thermal protection coating layer and a preparation method of the hexaaluminate high-emissivity thermal protection coating layer, and relates to a thermal protection coating layer and a preparation method of the thermal protection coating layer, aiming at solving the problem that the existing high-emissivity thermal protection coating layer is poor in thermal shock resistance, mismatched in thermal expansion and low in emissivity within a short-wave band. The thermal protection coating layer prepared by the invention has the chemical formula as shown in LaMg1-xMxAl11O19, wherein M is Mn, Fe, Co or Ni, x is larger than or equal to 0 and is less than or equal to 1. The preparation method comprises the following steps of: 1, preparing LaMg1-xMxAl11O19 feed material; 2, preparing a high-temperature alloy plate material base body; 3, preparing a NiCoCrAlYTa combination layer on the base body; and 4, preparing the LaMg1-xMxAl11O19 hexaaluminate high-emissivity thermal protection coating layer on the coating base body. The normal spectral emissivity of the thermal protection coating layer prepared by the invention is larger than 0.9 within the wave band of 7-14 mu m. The invention is suitable for the preparation of the metal material thermal protection coating layer.

Owner:HARBIN INST OF TECH

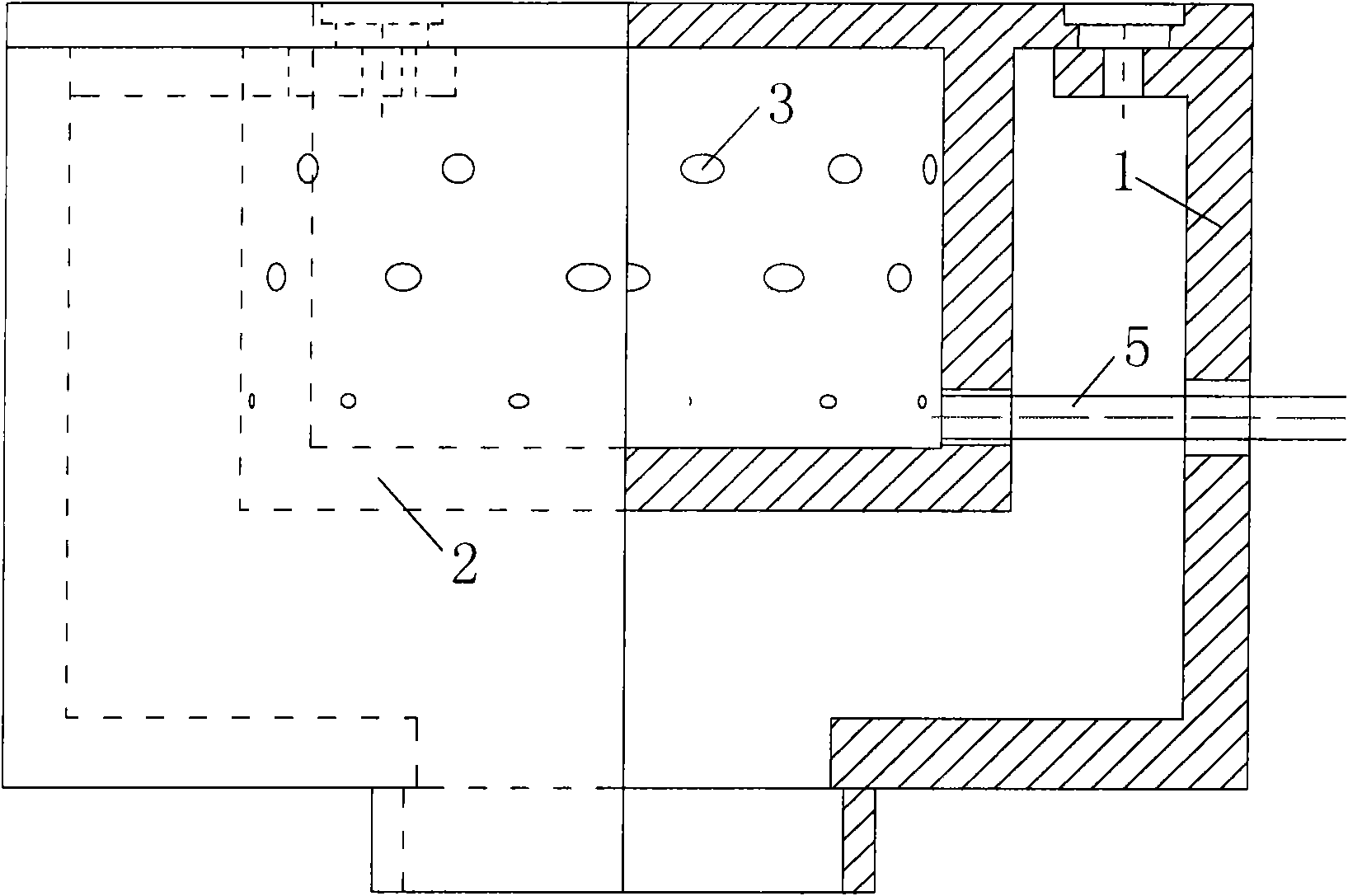

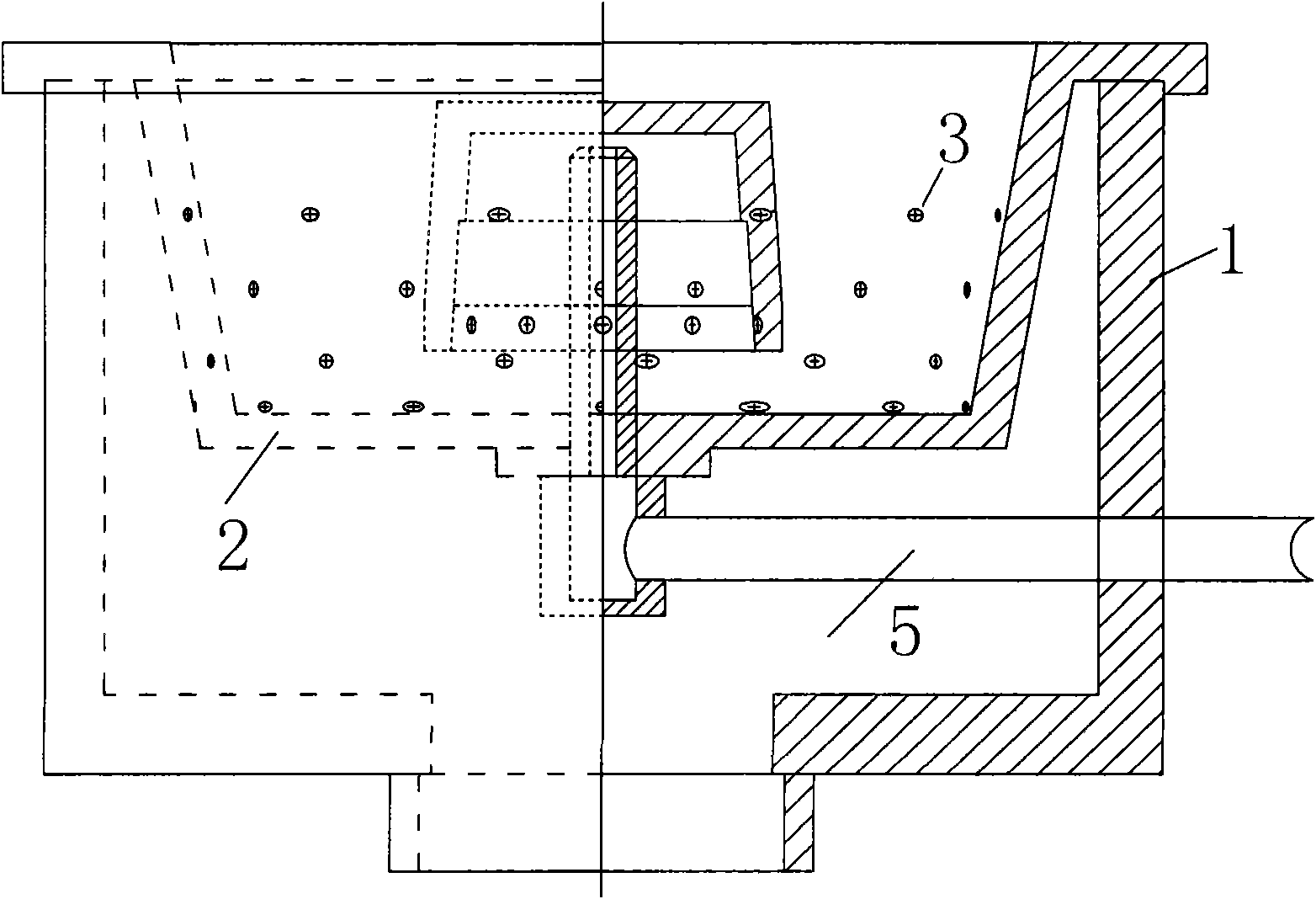

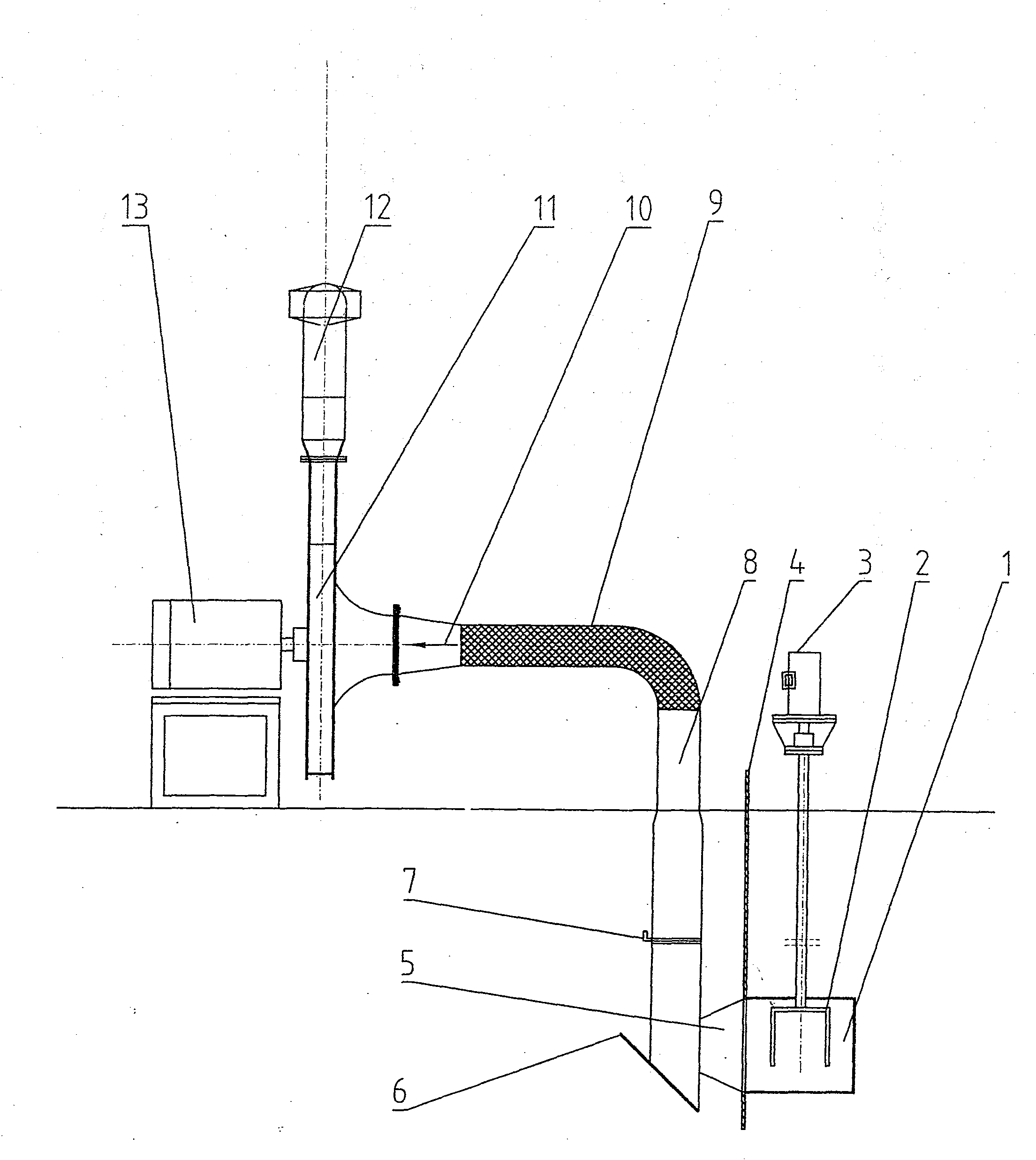

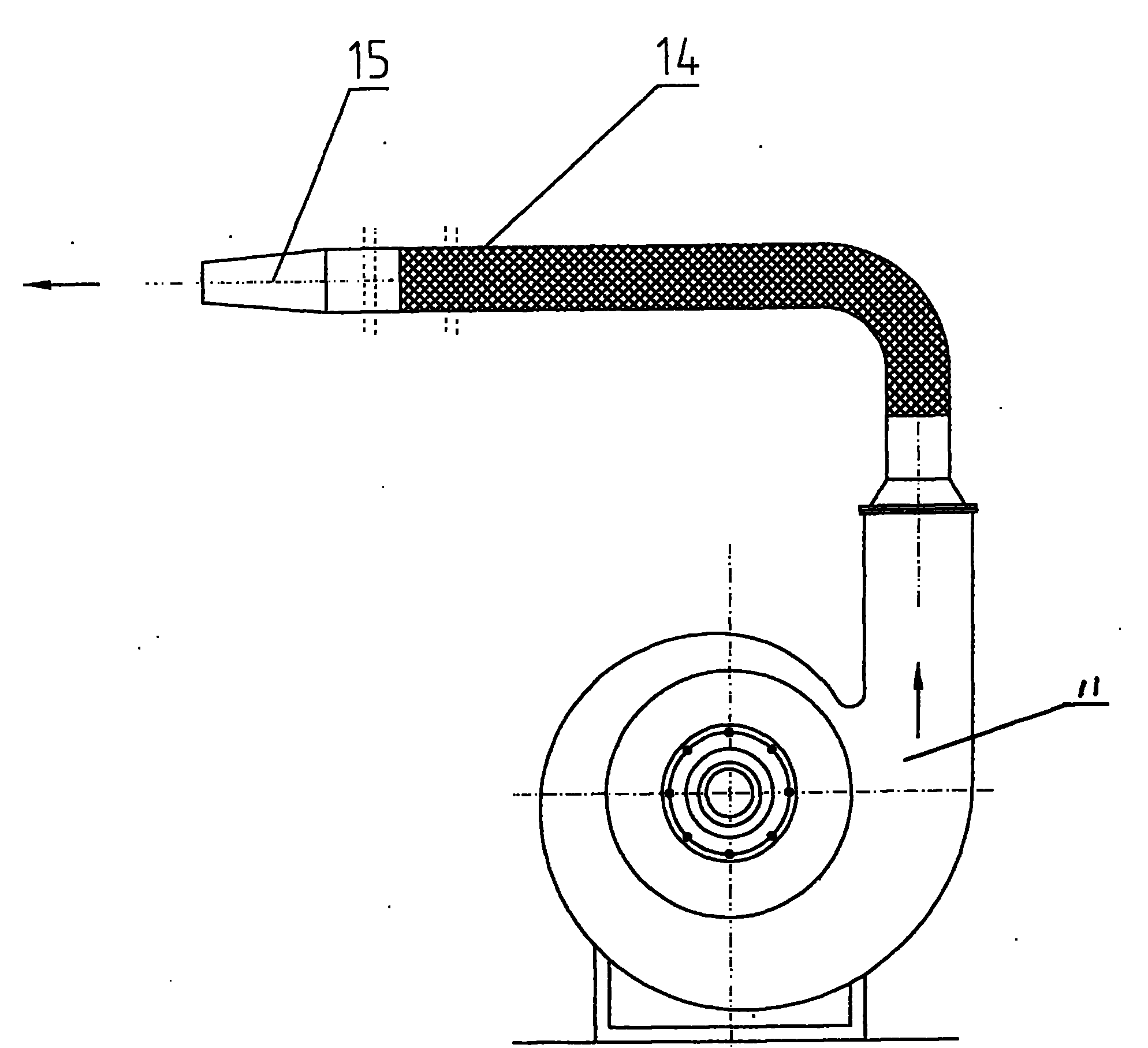

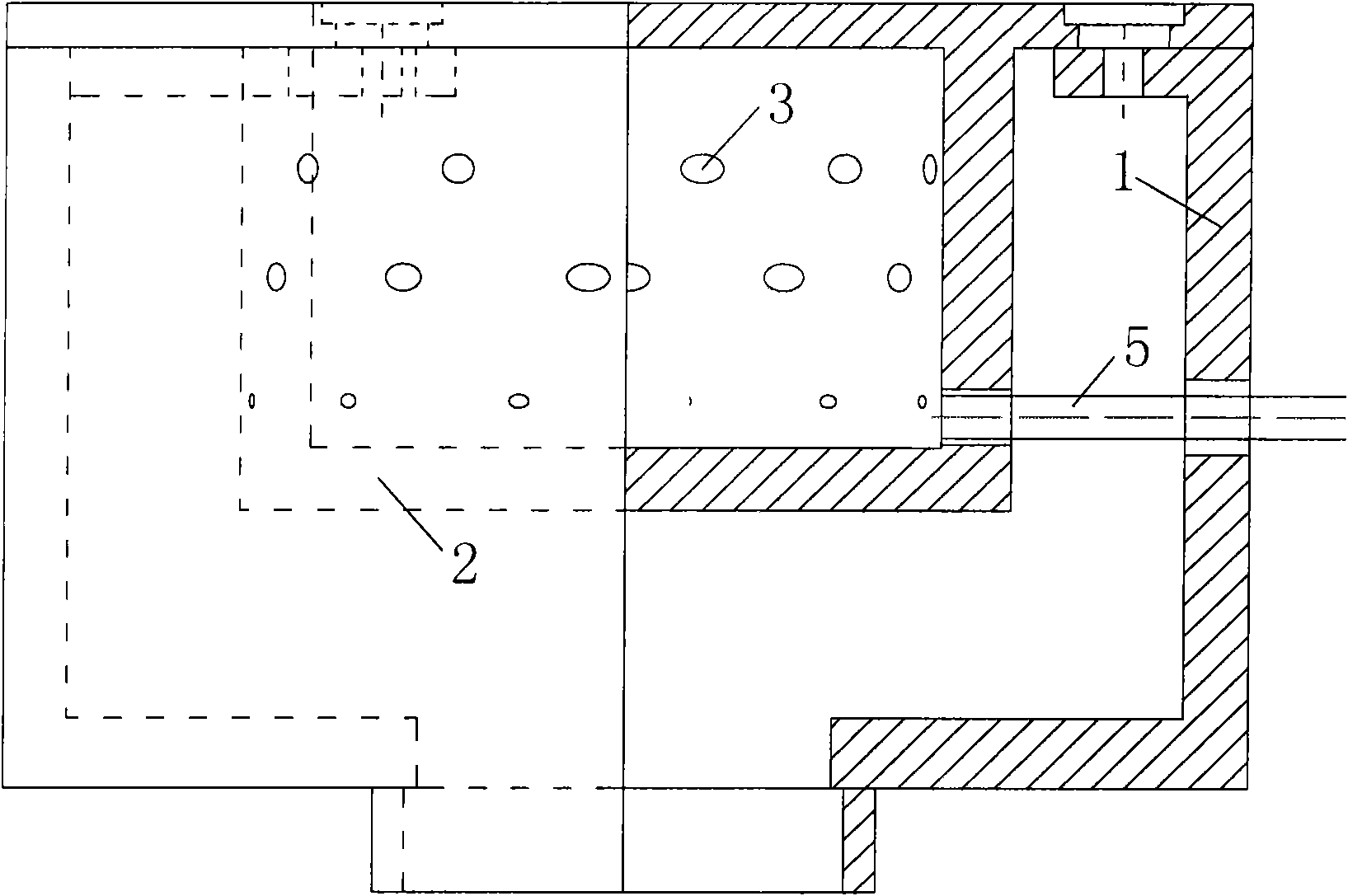

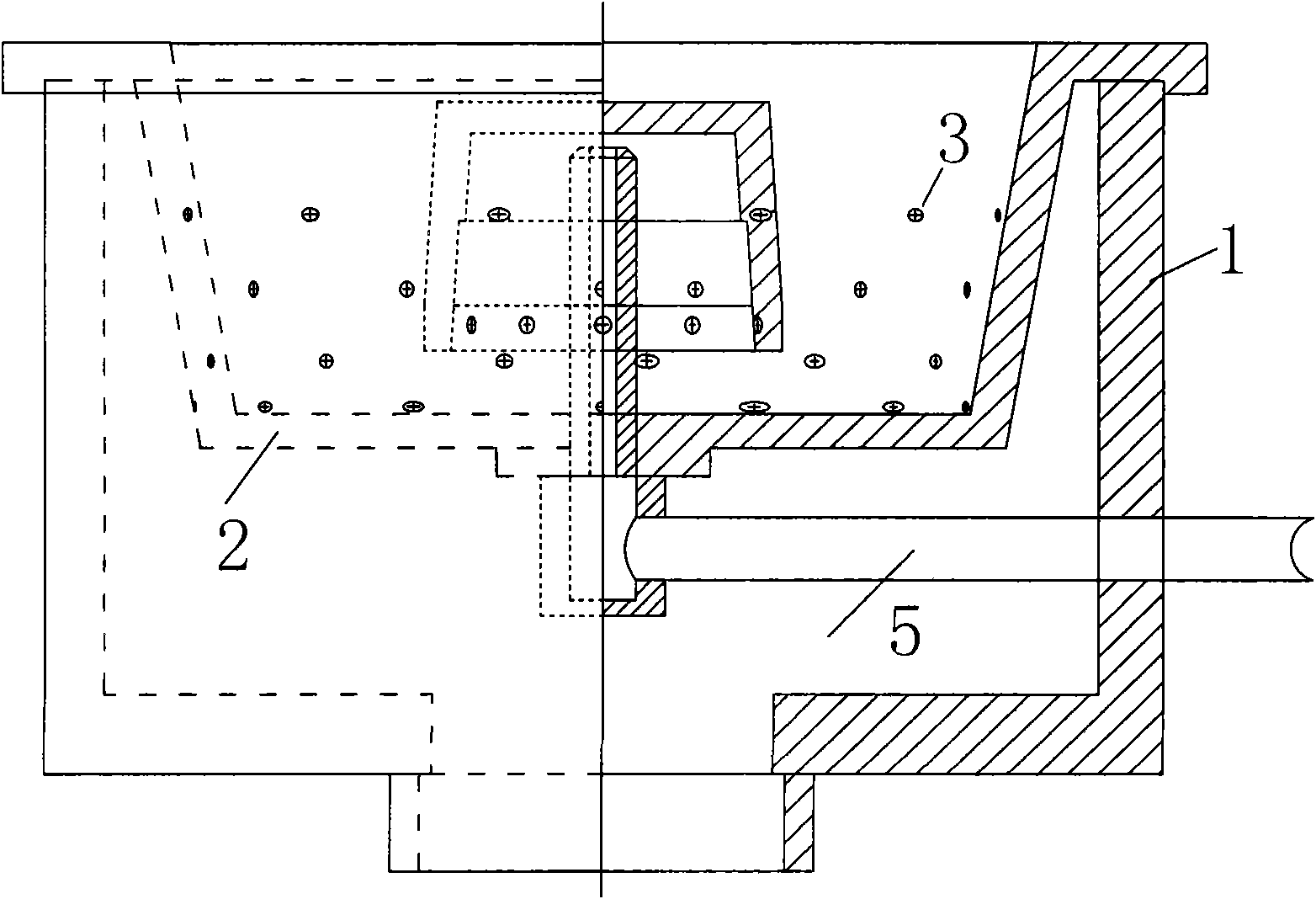

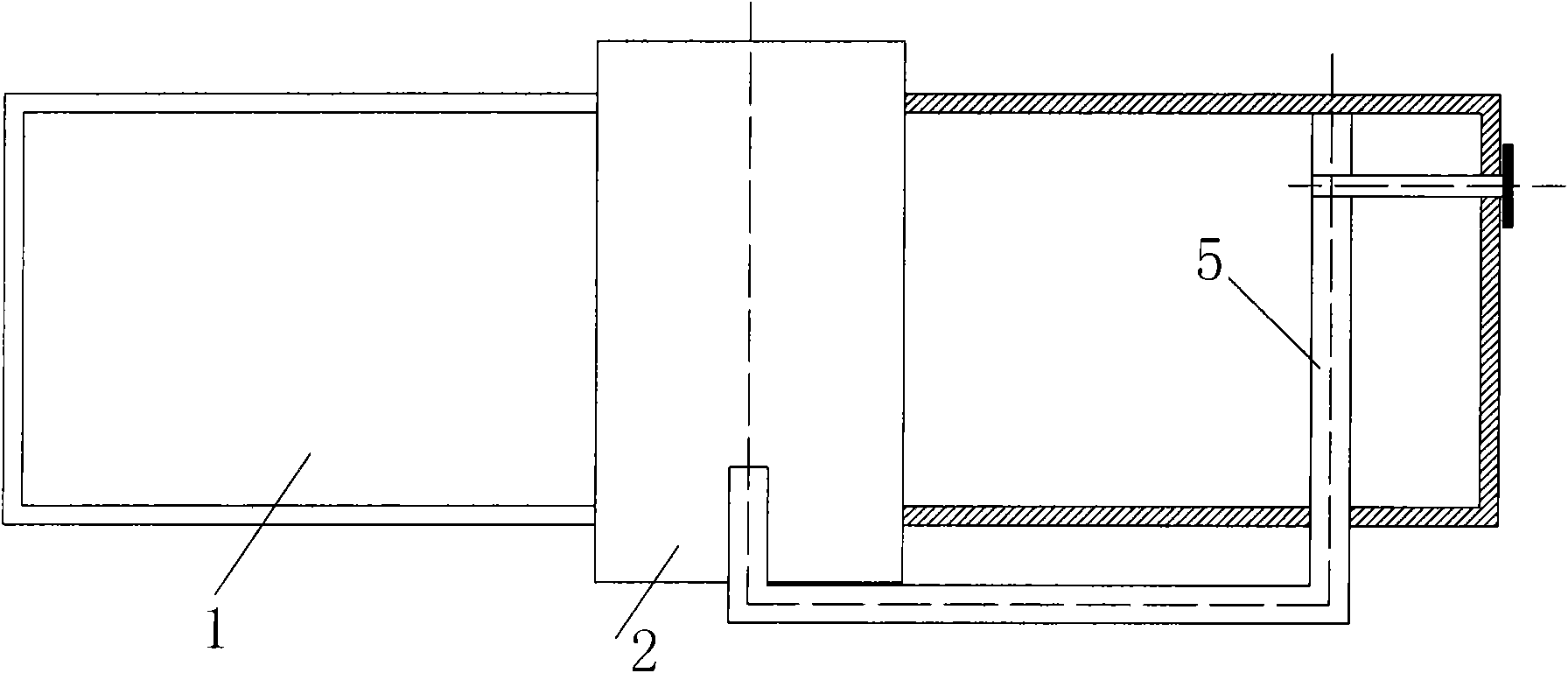

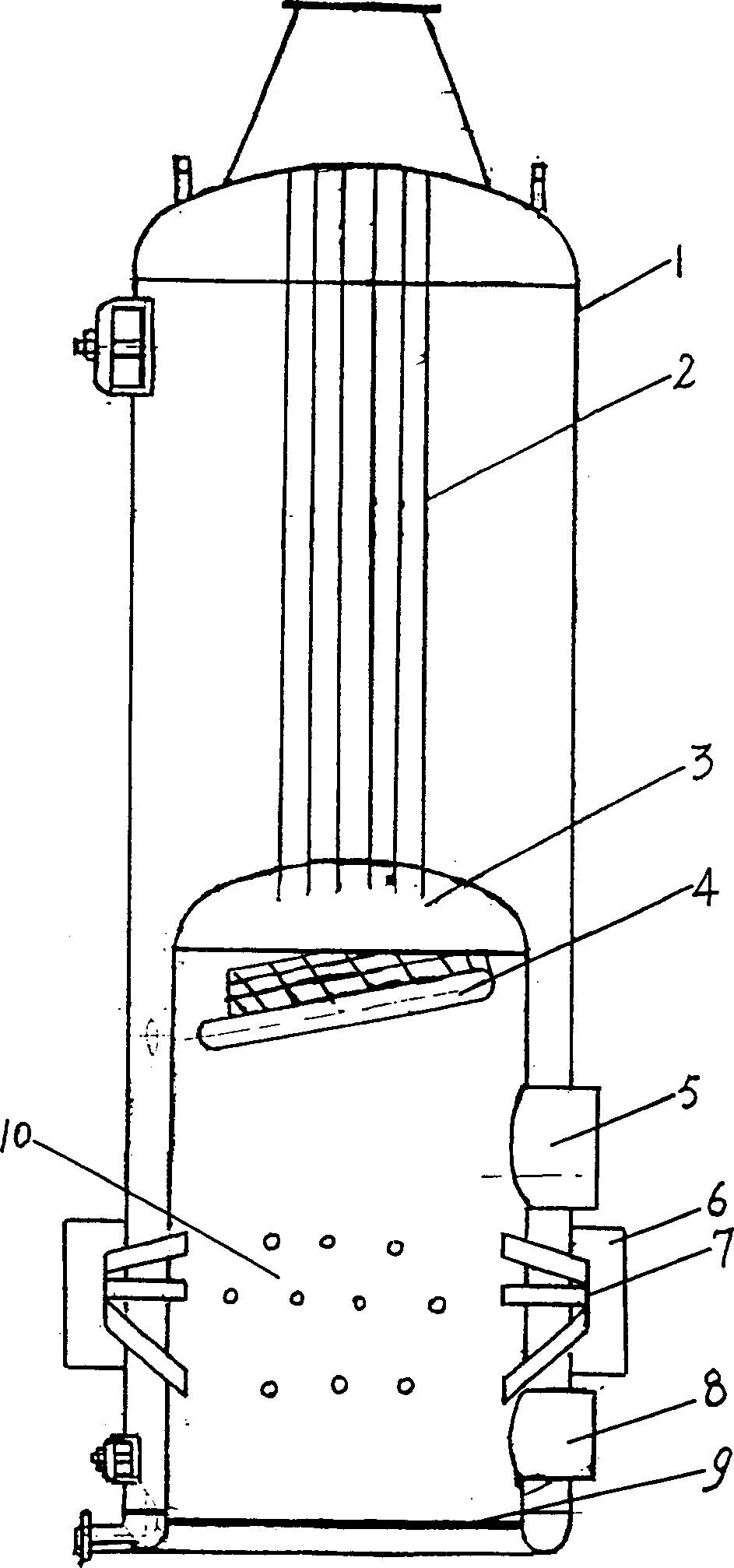

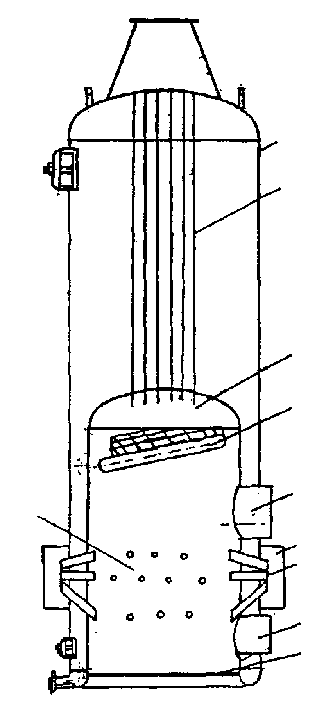

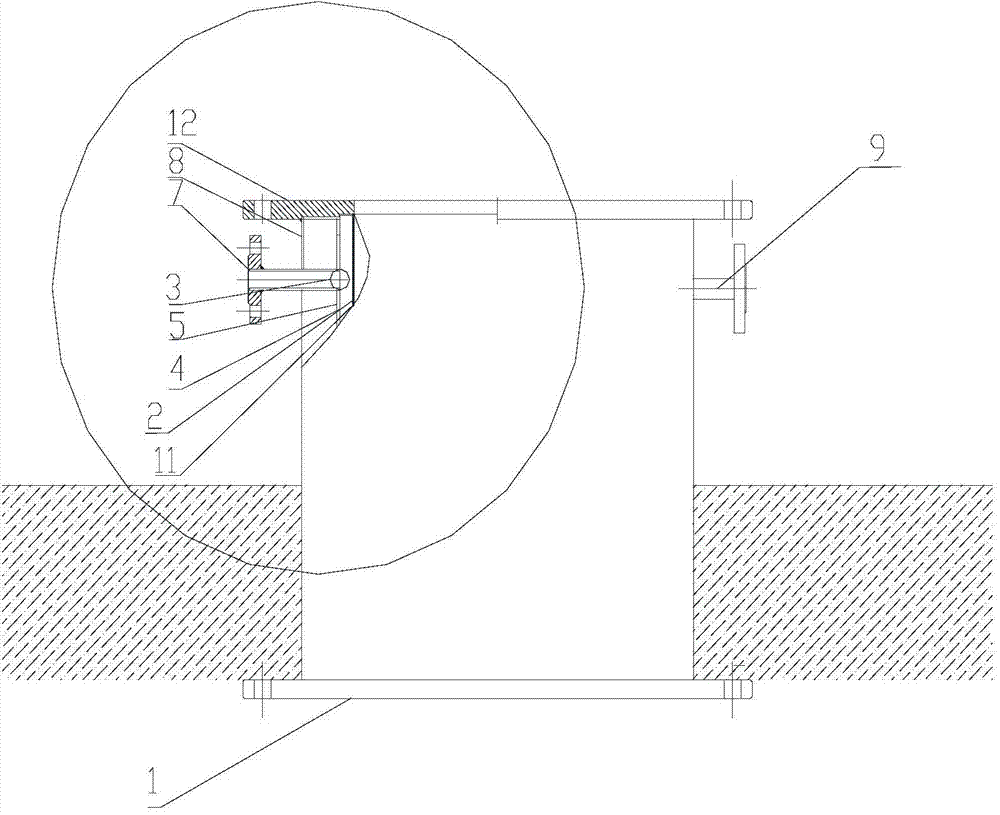

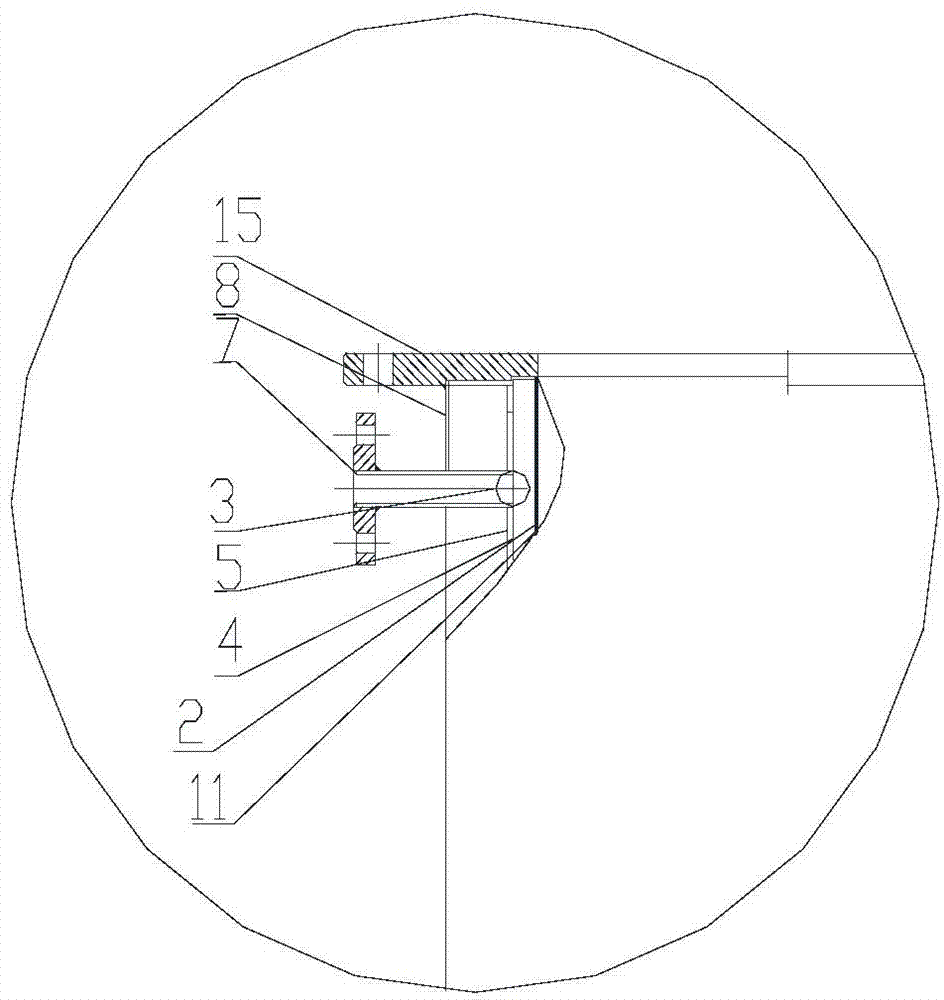

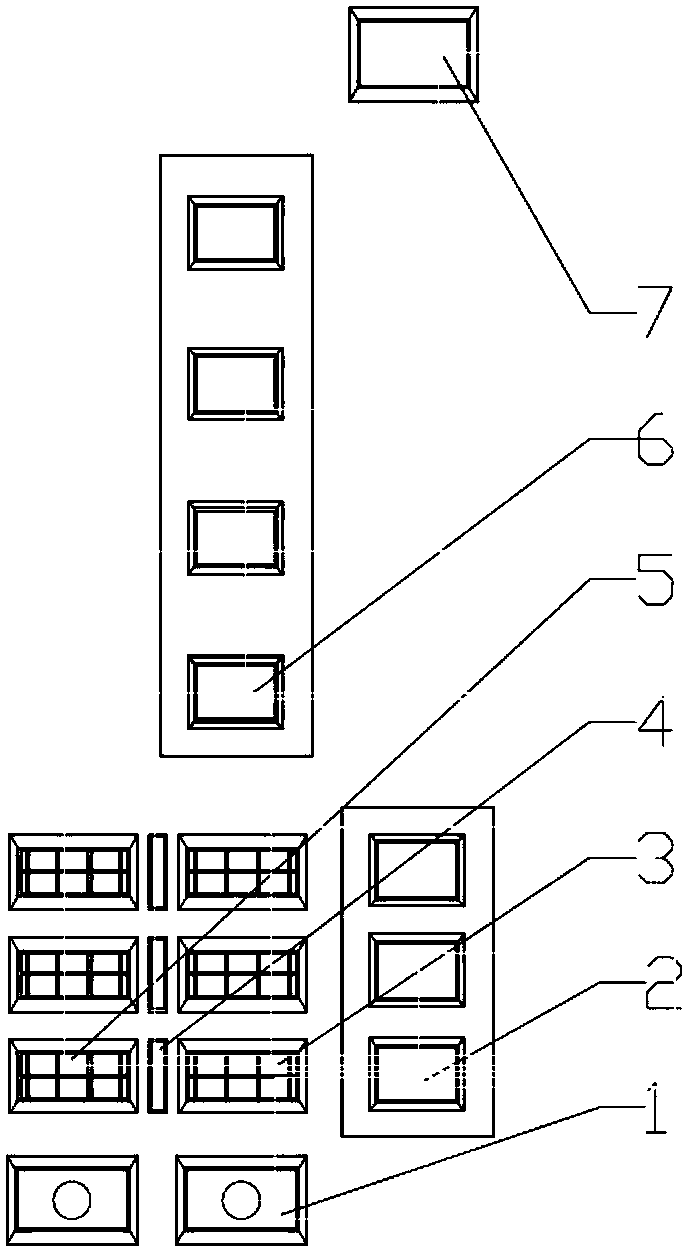

Batch feeder for boiler

InactiveCN101963361AReduce generationLow costLump/pulverulent fuel feeder/distributionEconomic benefitsEngineering

The invention discloses a batch feeder for a boiler. In the invention, a feed chamber (1) is internally provided with a blender (2) and one side surface of the feed chamber (1) is connected with one end of a charging hole (5); the other end of the charging hole (5) is connected with a charging pipe (8); the upper end of the charging pipe (8) is connected with a fan inlet (10) on a fan (11) through a charging hose (9); a discharging hole (12) on the fan (11) is connected with a nozzle (15) through a discharging hose (14); and the fan (11) is connected with a motor (13). The invention has the advantages of simple structure, low cost, low consumption, no pollution to environment and high economic benefit, can recycle the resources and reduce the discharge of the carbon dioxide, and is particularly suitable for the condition that the fuels such as peanut hulls, straws and sawdust are thrown in the boiler instead of the coal.

Owner:郭庆华

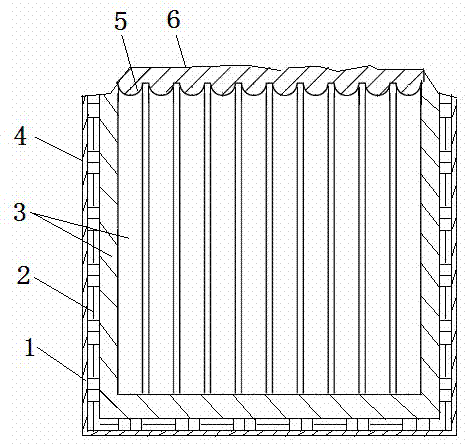

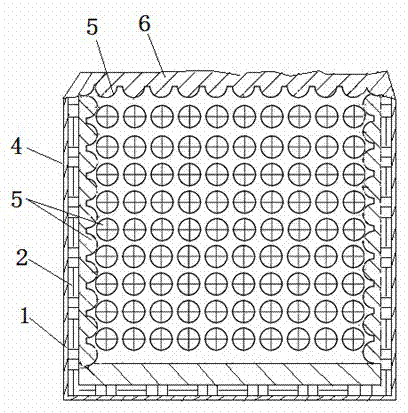

Industrial high-temperature kiln

InactiveCN103512358AIncreased wall surface areaExtended service lifeFurnace componentsSlagSpray coating

The invention provides an industrial high-temperature kiln. The industrial high-temperature kiln comprises a kiln body with a hearth arranged inside and hearth walls arranged at the periphery, and is characterized in that hemispherical bulges are arranged on the top wall of the hearth, and hemispherical bulges or semicircular convex pillars are arranged on the side wall of the hearth, so that the surface area of the inner wall of the hearth can be increased by 45% to 50%, and an active effect on reinforcing heat transfer by radiation is achieved; a black body spraying coating is arranged in a matching manner, so that the effect of heat transfer by radiation is relatively remarkable, and energy conservation and efficiency can be facilitated; according to different uses of the high-temperature kiln, the hearth adopting the structure that hemispherical bulges are fully arranged on the inner wall of the hearth is adopted to be applicable to a kiln of which the internal atmosphere is relatively clean and no dust exists; or a mixed hearth adopting the structure that hemispherical bulges are arranged on the top wall and semicircular convex pillars are arranged on the side wall is adopted to be applicable to kilns with more dust inside, so that the problem that dust accumulating on the hearth walls forms slag to be adhered to the hearth walls can be solved, the service life of the kiln can be prolonged advantageously, and the cost can be lowered.

Owner:云南天朗能源科技有限公司

A kind of production method of oxygen-enriched strengthened lignite calcined cement clinker

ActiveCN103496863BIncrease burn rateStrong disturbing effectClinker productionSocial benefitsBrown coal

Owner:INNER MONGOLIA UNIV OF TECH

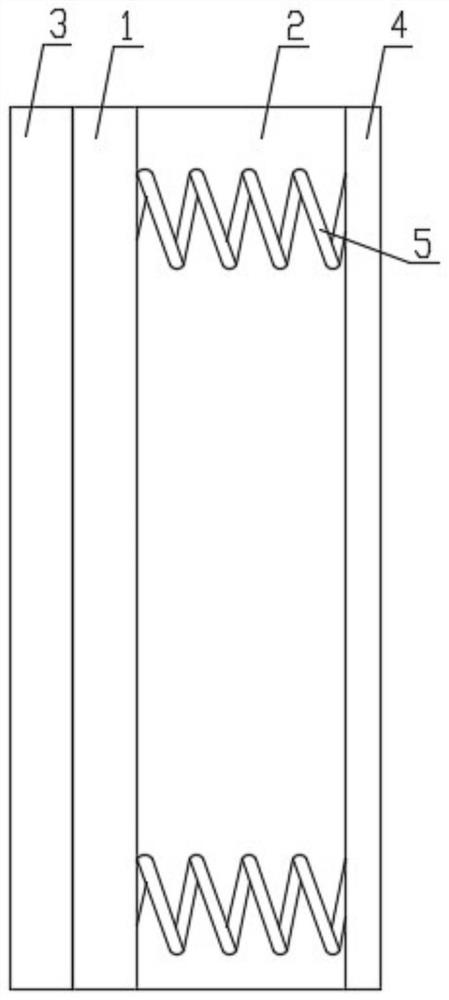

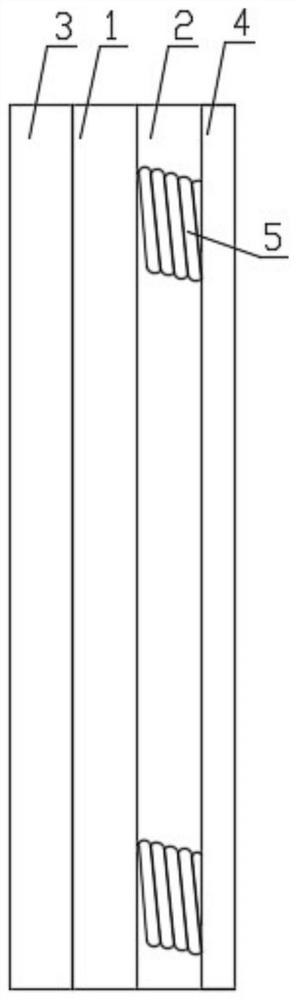

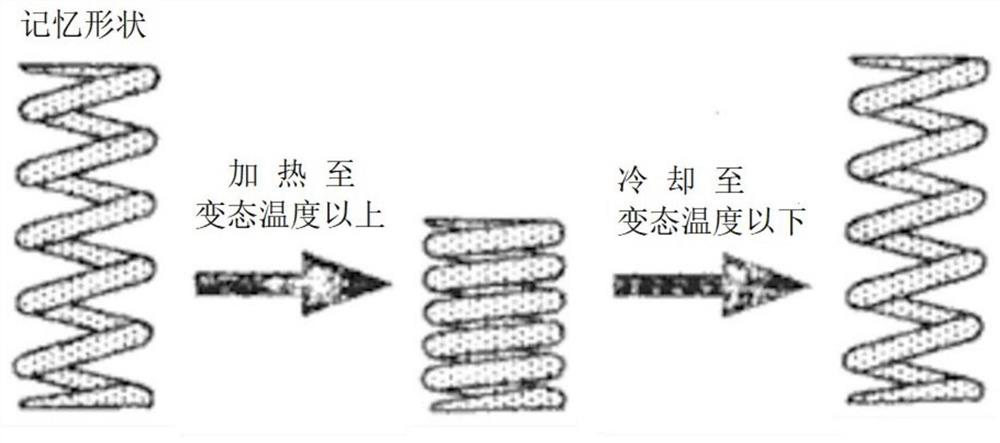

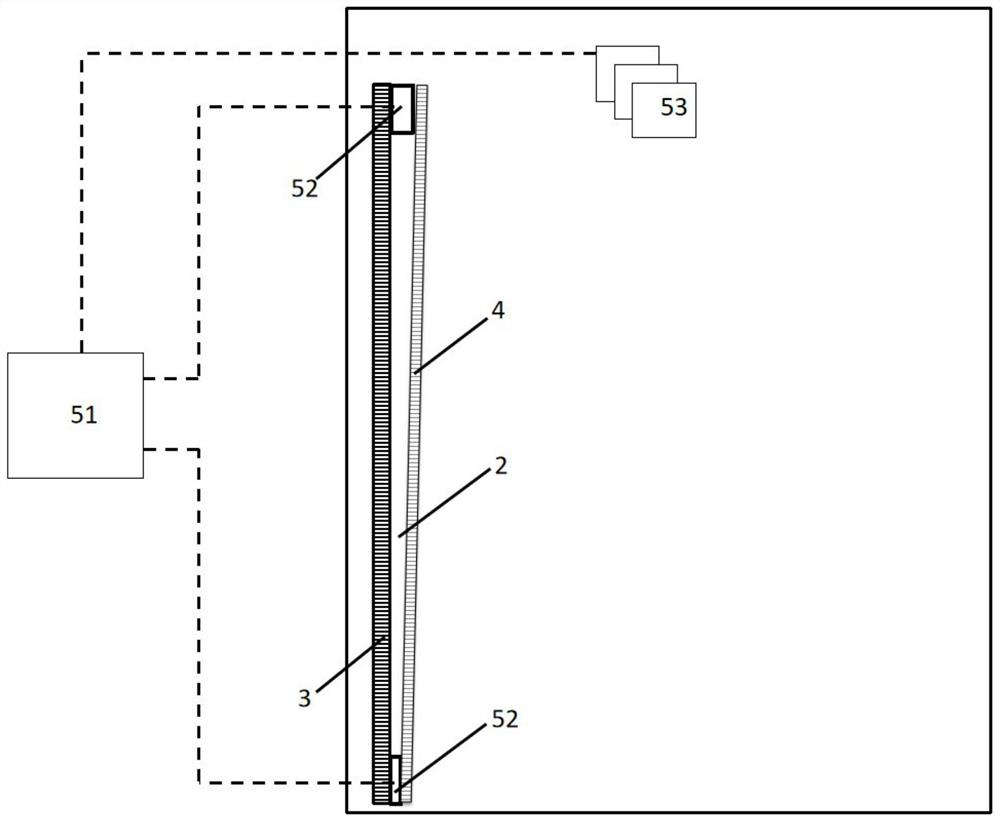

Radiating air-conditioner terminal self-adaptive to heat damping

ActiveCN111912065AAvoid condensationIncrease temperature differenceMechanical apparatusCondensate preventionThermal breakHeat resistance

The invention discloses a radiating air-conditioner terminal self-adaptive to heat damping. The terminal comprises a heat insulating layer, an energy conversion layer, a heat damping layer and a radiating panel which are arranged sequentially. The heat damping layer is an air layer formed between the energy conversion layer and the radiating panel. A self-adjusting supporting part used for adjusting the thickness of the air layer is arranged between the energy conversion layer and the radiating panel. Heat resistance of the heat insulating layer is larger than that of the heat damping layer. According to the terminal, a heat damping value of the heat damping layer can be adjusted dynamically, thus the panel face temperature of the radiating panel is adjusted dynamically, the panel face temperature of the radiating panel is lowered to the greatest extent to be always approximate to indoor temperature, and thus the radiating heat transfer ability is improved while the radiating panel iscontrolled not to condense.

Owner:WUXI FRESHAIR AQ TECH

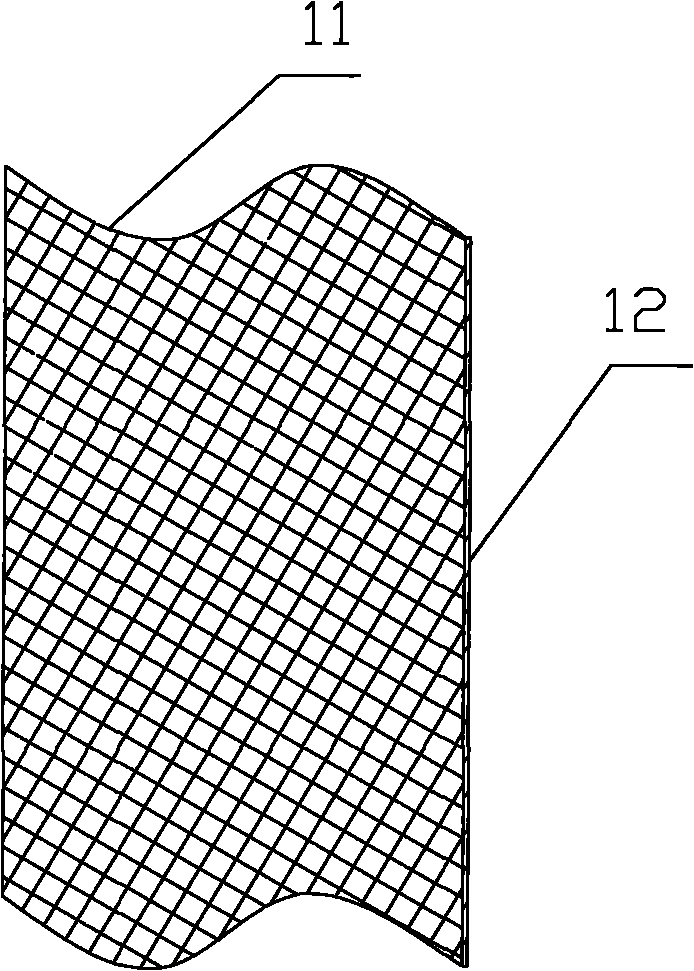

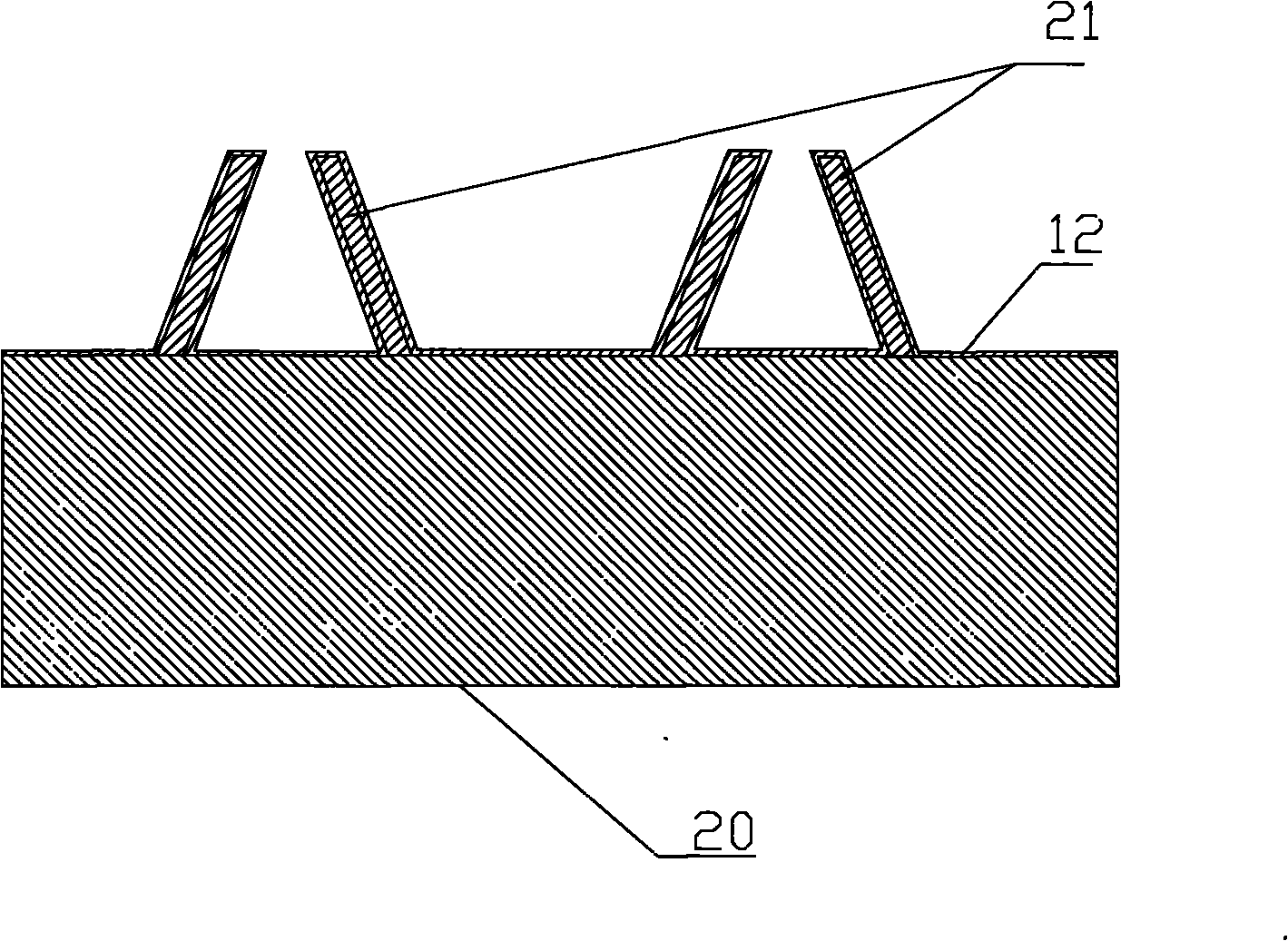

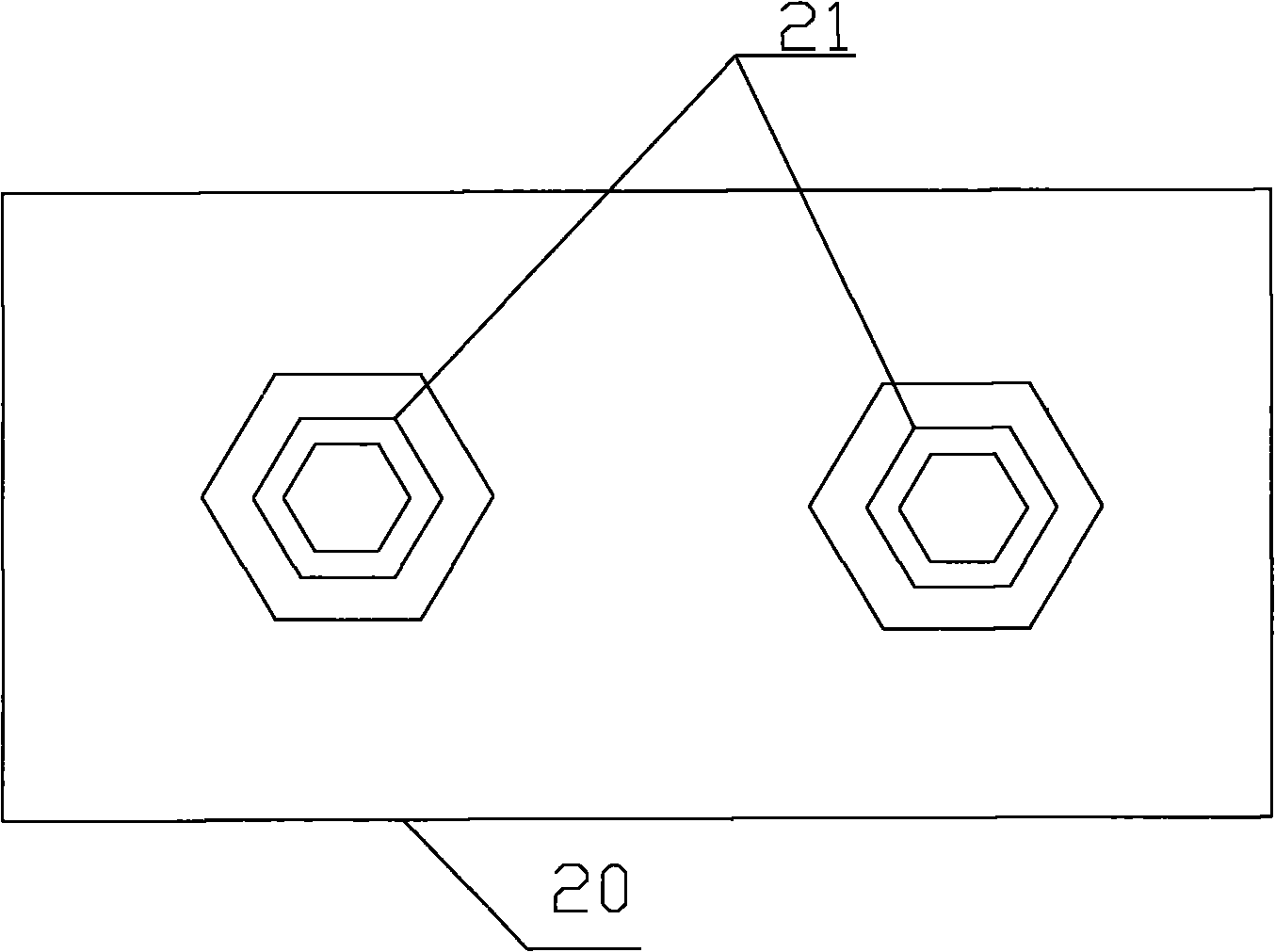

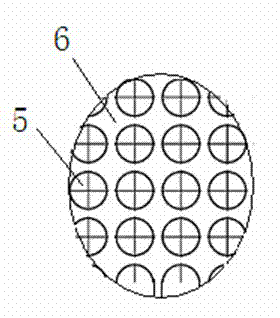

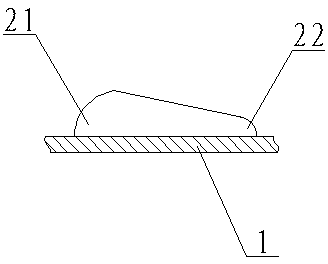

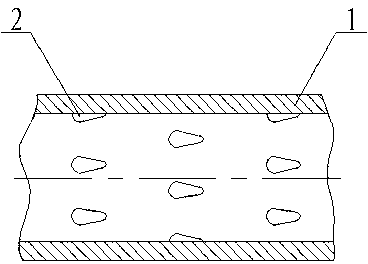

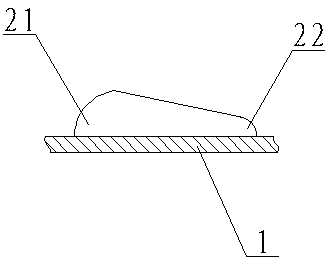

Inward convex spoiling tube and manufacture method thereof

InactiveCN103305256ASmall pressure dropSmall pressure drop increaseThermal non-catalytic crackingEngineeringAlloy

The invention relates to an inward convex spoiling tube and a manufacture method thereof. More than one circle of inward convex factor groups is uniformly arranged on in the inner hole of a smooth wall tube along the axial direction of the smooth wall tube, each circle of the inward factor group comprises a plurality of inward convex factors, a spiral line which takes the axial line of the smooth wall tube as the center is formed by two inward convex factors which are closest in two adjacent inward convex factor groups in the circumferential direction of the smooth wall tube; a laser facing nozzle extends into the smooth wall tube, high-temperature alloy powder and agglutinant are mixed and delivered to the laser facing nozzle through a powder delivery tube; and the laser facing nozzle is used for facing the inward convex factors in the smooth wall tube correspondingly. The inward convex factors are faced by adopting laser in the inner wall of a furnace tube, and the spiral line which takes the axial line of the furnace tube is formed by the inward convex factors, so that liquid in the tube is delivered in a spiral manner to realize stable delivery and effective heat transfer of cracking liquid. The structure of the inward convex spoiling tube is simple, the velocity field in the tube flows symmetrically, the delivery is stable, and the radiation heat transfer effect is good; and the invention is applicable to inward convex spoiling tubes with various tube diameter specifications, is simple in manufacture process and low in production cost, and is applicable to processing with various tube diameter specifications.

Owner:江苏久保联实业有限公司

Radiant air-conditioned ends with adjustable thermal damping

ActiveCN111912066BAvoid condensationLow temperature requirementMechanical apparatusCondensate preventionTemperature controlEngineering

The invention discloses a radiant air-conditioning terminal for adjusting thermal damping, which comprises a transducing layer, a thermal damping layer and a radiating panel arranged in sequence, and the thermal damping layer is an air layer formed between the transducing layer and the radiating panel; it also includes an adjusting component , the regulating assembly includes an actuator, at least one temperature and humidity sensor, at least one first temperature sensor and at least one second temperature sensor, the second temperature sensor monitors the temperature of the radiation panel, and the actuator monitors the temperature and humidity of the indoor air monitored by the temperature and humidity sensor and The water supply temperature monitored by the first temperature sensor is controlled by the actuator to adjust the distance between the transduction layer and the radiation panel, that is, to adjust the thickness of the thermal damping layer, so that the temperature of the radiation panel reaches the temperature threshold. The invention dynamically adjusts the thermal damping value of the thermal damping layer, thereby dynamically adjusting the temperature of the radiation panel, making the temperature of the radiation panel as close as possible to the indoor temperature, and improving the radiation heat transfer capability while controlling the radiation panel not to condense.

Owner:WUXI FRESHAIR AQ TECH

Alcohol-base fuel burner with radiant panel fuel nozzle

An alcohol-base fuel burner with radiant panel fuel nozzle comprises an air chamber, a mixed combustion chamber, an atomization injection pipe, wherein one end of the air chamber is opened, and the other end thereof is provided with an air inlet; the mixed combustion chamber is sleeved in the air chamber and is provided with air holes along the wall of the mixed combustion chamber; the center of the atomization injection pipe is a through hole, one end is provided with a radiant panel, the other end is installed on the soleplate of the mixed combustion chamber and is communicated with one endof a fuel supply pipe, and at least two fuel injection holes are uniformly distributed on the same cross section of the wall of the atomization injection pipe. The invention has high combustion efficiency, low energy consumption and less pollutant emission; compared with the existing technology, the discharge amount of CO and NOx is relatively reduced by 50% to 70%, and the heat efficiency reaches up to more than 40%. The burner is safe, environment-friendly, stable in combustion, high in combustion strength, easy and safe for combustion, good in fire adjustment, high-temperature and corrosion resistant, high impact resistant, mechanical impact resistant, low in thermal inertia and long in service life; and the burner is suitable for being applied to various special cookers in catering industry.

Owner:湖南中能力华新能源技术有限公司 +1

Inward convex spoiling tube

InactiveCN103305255ASmall pressure dropLiquidityThermal non-catalytic crackingEngineeringSpiral line

The invention relates to an inward convex spoiling tube. The inward convex spoiling tube comprises a smooth wall tube with a smooth inner hole, wherein more than one circle of inward convex factor groups is uniformly arranged in the inner hole of a smooth wall tube along the axial direction of the smooth wall tube, each circle of the inward factor group comprises a plurality of inward convex factors; and a spiral line which takes the axial line of the smooth wall tube as the center is formed by two inward convex factors which are closest in two adjacent inward convex factor groups in the circumferential direction of the smooth wall tube. The inward convex factors are faced by adopting laser in the inner wall of a furnace tube, and the spiral line which takes the axial line of the furnace tube as a center is formed by the inward convex factors, so that liquid in the tube is delivered in a spiral manner to realize stable delivery and effective heat transfer of cracking liquid. The structure of the tube is simple, the velocity field in the tube flows symmetrically, the delivery is stable, and the radiation heat transfer effect is good; and the invention is applicable to inward convex spoiling tubes with various tube diameter specifications. The inward convex spoiling tube disclosed by the invention is simple in manufacture process and low in production cost. The invention is applicable to processing of tubes with various tube diameter specifications.

Owner:江苏久保联实业有限公司

Waterborne heat-insulating flame-retardant multifunctional nano coating and preparation method thereof

InactiveCN101824270BImprove performanceSimple preparation processFireproof paintsPolyurea/polyurethane coatingsTin dioxideMicrosphere

The invention relates to a waterborne heat-insulating flame-retardant multifunctional nano coating and a preparation method thereof. The coating consists of the following components in part by weight: 48 to 52 parts of waterborne resin and 30 to 50 parts of nano pigment fillers (nano titanium dioxide, nano titanium dioxide-coated hollow glass microspheres, nano titanium dioxide-coated hollow ceramic microspheres and nano antimony-doped tin dioxide (ATO) particles), size and auxiliary materials such as film-forming additive and coupling agent. The preparation method includes the steps that: the nano fillers and the size are first dipped into the waterborne resin, the auxiliary materials are then sequentially added and stirred, and thereby the heat-insulating flame-retardant multifunctional nano coating is obtained. The processing technique is simple, the component proportion is reasonable, and the prepared coating has the advantages of high heat resistance, high reflectivity, high radiative heat conductivity, certain fire resistance, high-efficient heat insulation, excellent mechanical and chemical properties, environment-friendliness, stain resistance, flame retardance and energy saving. The coating can be coated on outside facilities such as outer walls and building roofs.

Owner:长沙新凯化工有限公司

Coke boiler with low sulphur discharge

InactiveCN1121573CReduce contentSignificant environmental benefitsSolid fuel combustionWater heatersCombustion chamberSulfur

The invention discloses a low-sulfur emission boiler for burning coke, which comprises a drum, a fire pipe, a furnace, a horizontal water pipe, a feeding hole, an air chamber, an air inlet pipe, a slag cleaning hole, a furnace bottom and a combustion chamber, wherein the boiler has no The grate and the air inlet pipe directly enter the coke layer, and there are three groups of air inlet pipes, one group is 45° downward, the other is tangentially parallel, and the other is 15° upward. The accumulation height of coke in the furnace is greater than 250mm. The boiler of the invention has a simple structure and low steel consumption, and can completely use coke as fuel, which not only achieves the purpose of environmental protection, but also greatly reduces the labor intensity of the fireman, and at the same time opens up a new broad sales market for coke.

Owner:阮赪燮 +1

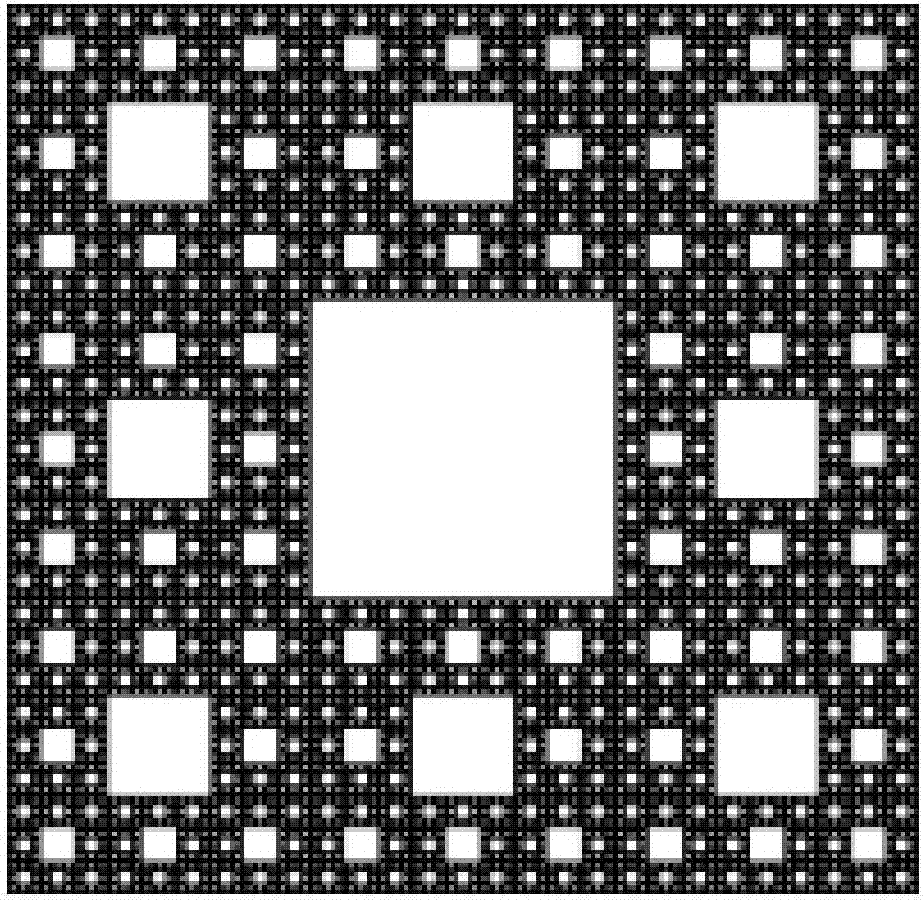

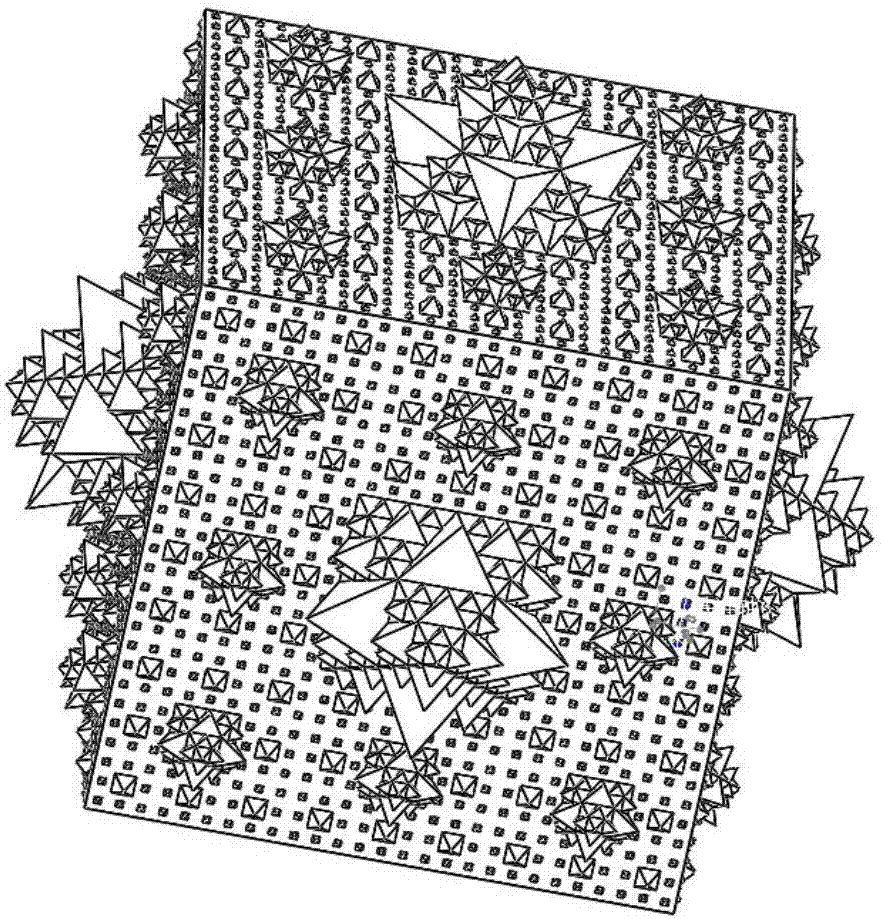

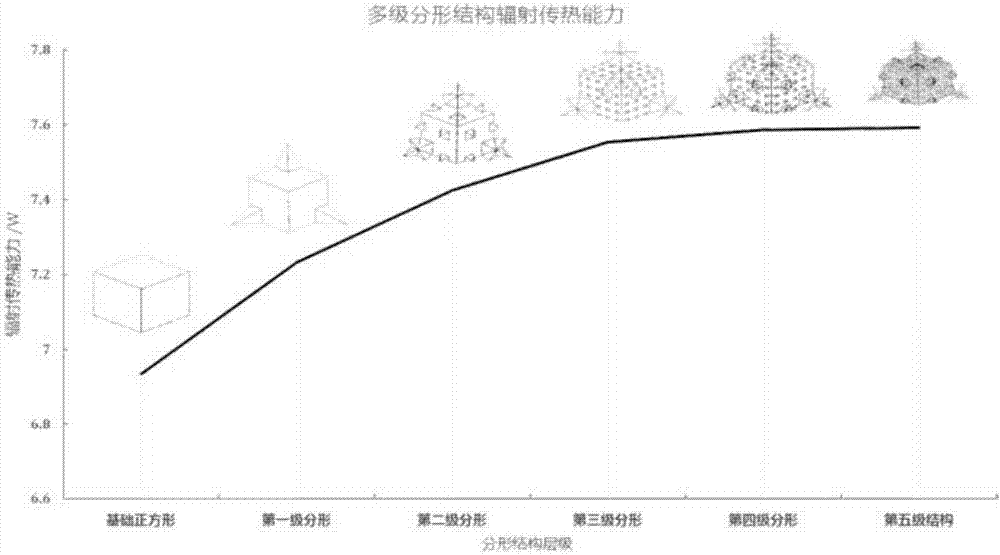

Fractal structure on satellite surface

The invention discloses a fractal structure on a satellite surface. A satellite body is a cube structure, and Sierpinski carpet patterns are created on any surface of the satellite body. The fractal structure comprises regular square pyramid protrusions taking squares in the middle of the Sierpinski carpet patterns as bottom surfaces.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

Rising pipe base heat exchange apparatus

InactiveCN104774624APrevent high temperature corrosionImprove heat transfer coefficientEnergy inputStationary tubular conduit assembliesFlue gasThermal insulation

The present invention relates to the field of heat exchangers, particularly to a rising pipe base heat exchange apparatus for being buried under the ground. The rising pipe base heat exchange apparatus comprises a vertically arranged vertical pipe section with the part buried under the ground, wherein the lower portion of the vertical pipe section is provided with a flue gas inlet, and the upper portion is provided with a flue gas outlet. The rising pipe base heat exchange apparatus is characterized in that a heat exchange pipeline is arranged in the vertical pipe section and comprises a heat exchange inner sleeve and a heat exchange outer sleeve, the side wall of the vertical pipe section is provided with a water inlet pipe communicated with the heat exchange outer sleeve, the place positioned on the other side of the vertical pipe section is provided with a water outlet pipe communicated with the heat exchange outer sleeve, the inner wall of the heat exchange inner sleeve is provided with a high temperature resistance heat conduction coating, and the outer wall of the heat exchange outer sleeve is provided with a thermal insulation layer. With the rising pipe base heat exchange apparatus of the present invention, the flue gas waste heat recovery is achieved, the energy source utilization rate is improved, and the energy source is saved.

Owner:常州江南冶金科技有限公司 +1

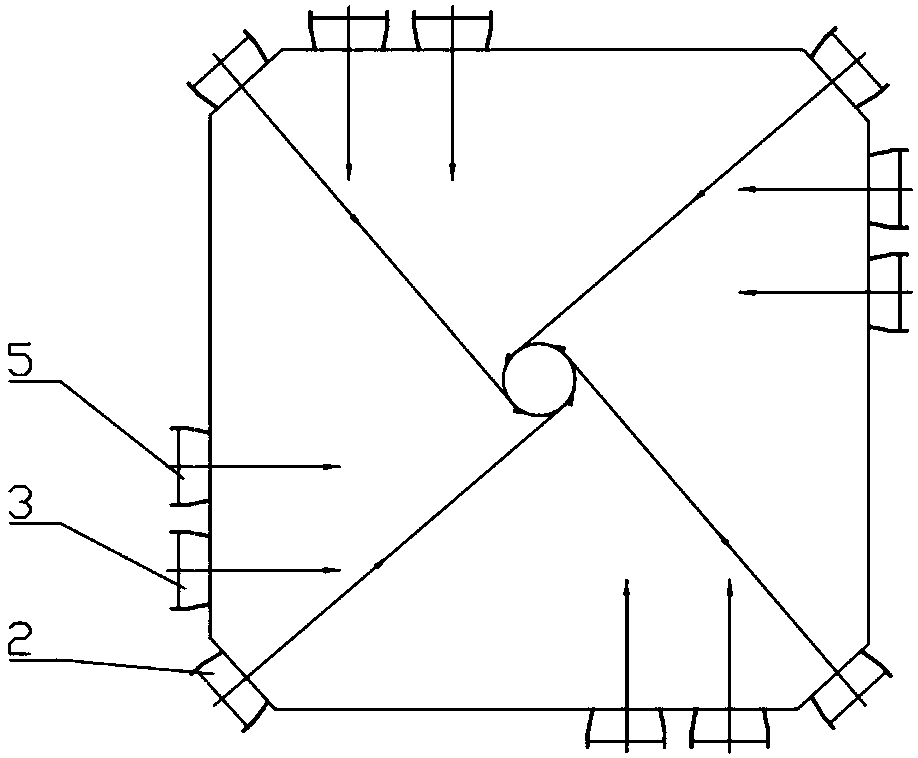

Low-nitrogen combustion device for coal powder gasification combustion and combustion method

PendingCN109458612ASuitable reducing atmosphereAchieve ultra-low emissionsCombustion using gaseous and pulverulent fuelFuel supply regulationNitrogenFuel type

The invention discloses a low-nitrogen combustion device for pulverized coal gasification combustion. The device comprises a multi-tangent-circle combustion hearth, wherein the multi-tangent-circle combustion hearth comprises a hearth angle wall and a hearth side wall, the furnace wall of the hearth is provided with one or more columns of nozzle groups which are arranged in the height direction, the nozzle groups comprise powder lower air nozzles, gasification nozzle groups, combustion-supporting air nozzles and top air nozzles, the gasification nozzle groups comprise first primary air nozzlegroups, second primary air nozzle groups and gasification air nozzle groups, and first primary air nozzles involved in the first primary air nozzle groups, second primary air nozzles involved in the second primary air nozzles groups and gasification air nozzles involved in the gasification air nozzle groups are sequentially arranged in the same direction or in the reverse directions according to the airflow horizontal rotating direction. The invention further discloses a method for performing low-nitrogen combustion based on the low-nitrogen combustion device for the pulverized coal gasification combustion. According to the low-nitrogen combustion device for the pulverized coal gasification combustion and the method, the generation of fuel type NOx and thermodynamic NOx can be fully inhibited; and the burnout stage is mainly the combustion of coal gas, and the amount of coke and the amount of fuel nitrogen in the coke are extremely low.

Owner:晋能电力集团有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com