Alcohol-base fuel burner with radiant panel fuel nozzle

A technology for fuel nozzles and alcohol-based fuels, applied in burners, combustion methods, combustion types, etc., can solve the problems of unstable combustion, high fuel quality requirements, and poor liquid vaporization, and achieve improved combustion performance and safety performance. , Strengthen the effect of radiation heat transfer and avoid the effect of tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

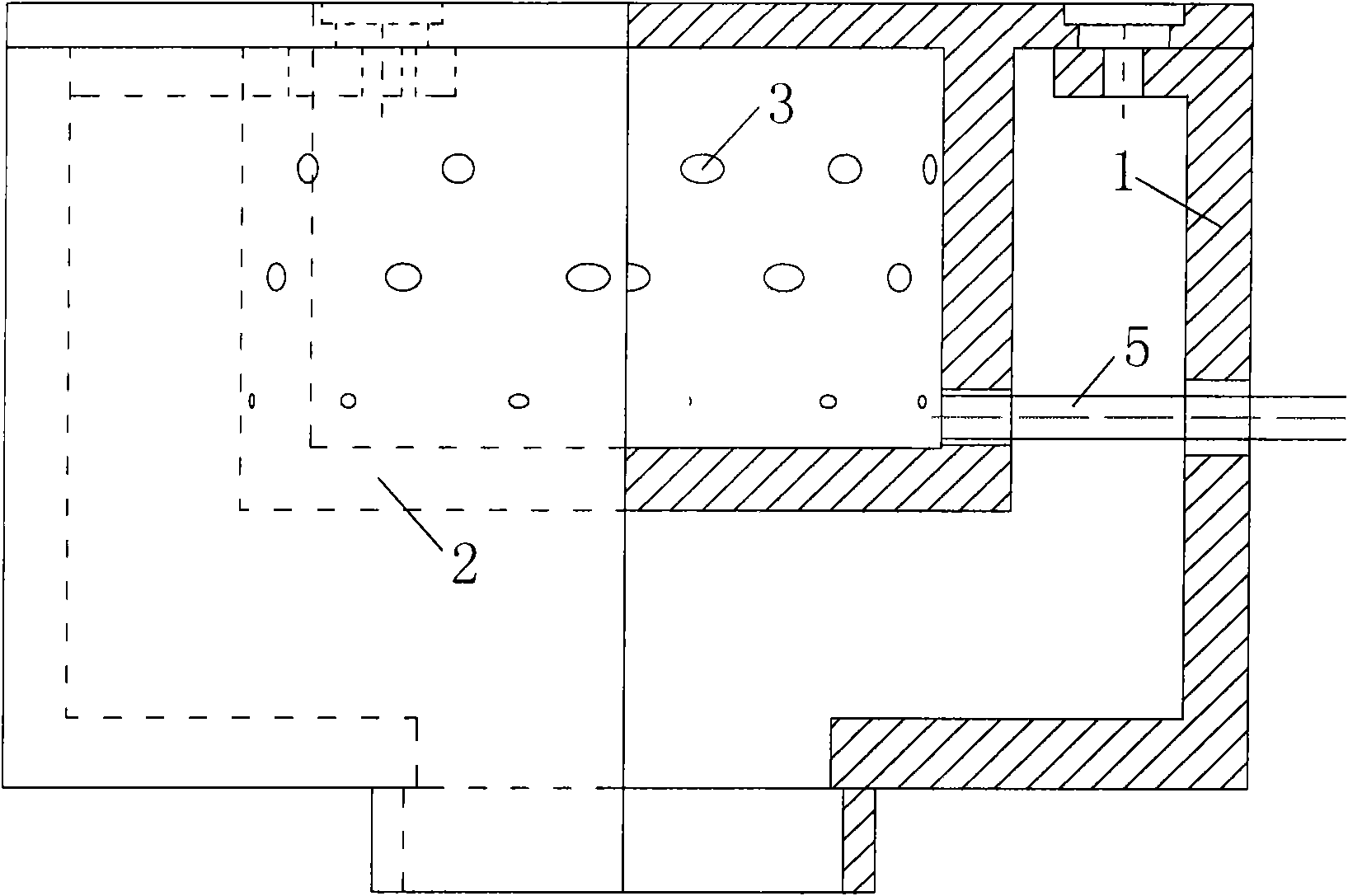

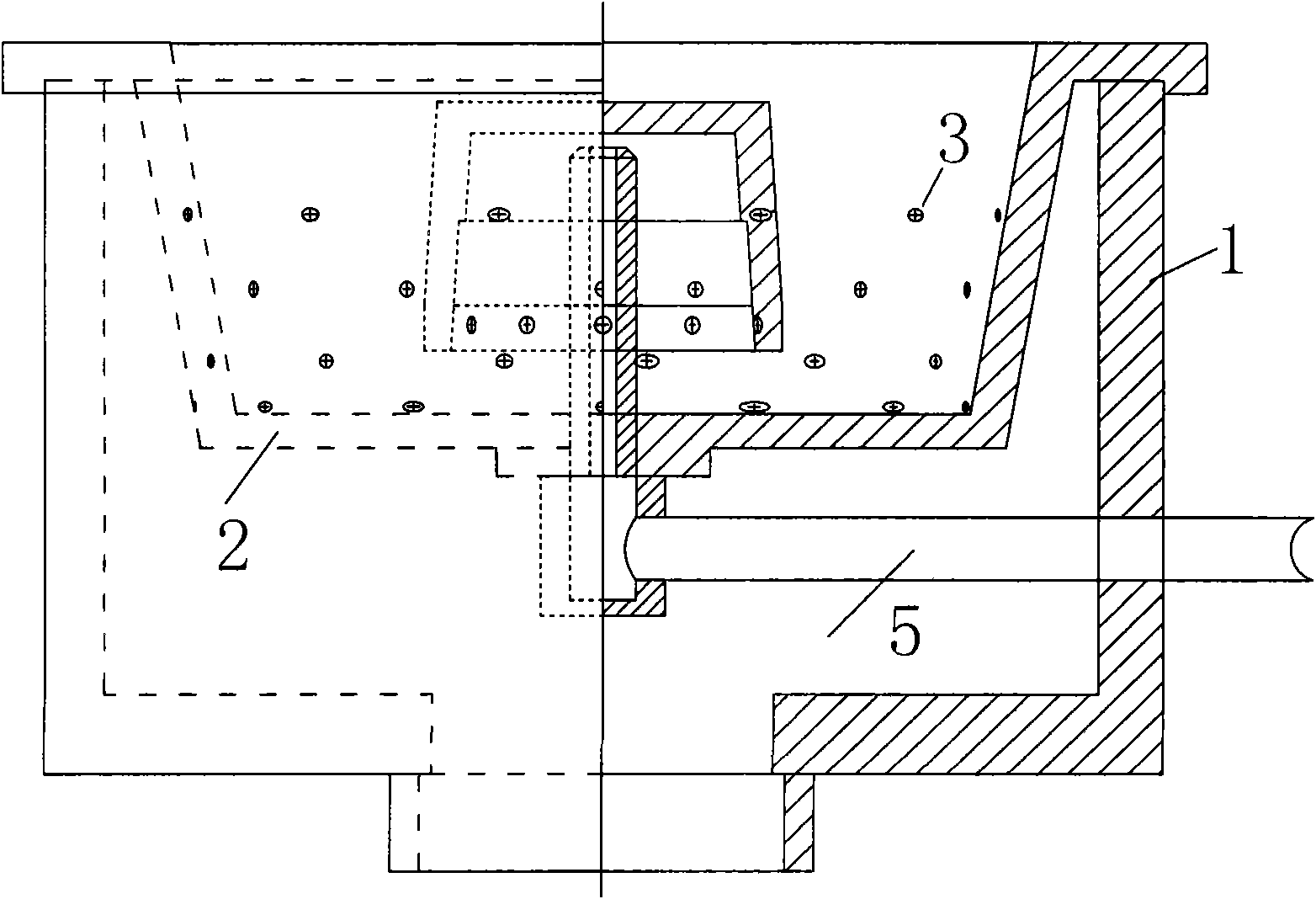

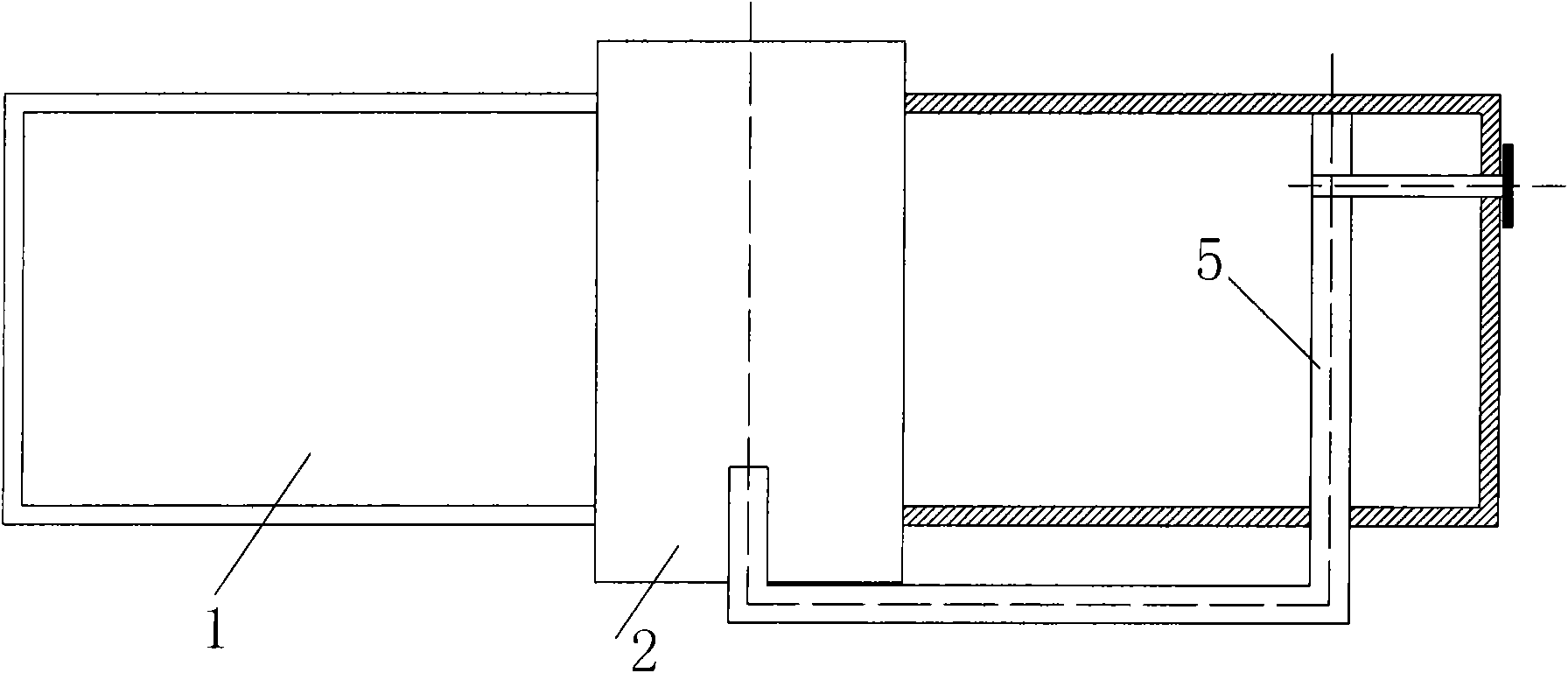

[0028] See attached Figure 4 , 5 , 6, 7, 8, the embodiment of the present invention, the alcohol-based fuel burner with radiant plate fuel nozzle, comprises air cavity 1, combustion mixing combustion chamber 2, atomizing injection pipe 4, and described air cavity 1 is opened at one end, and another One end is provided with a tuyere 8; the combustion and mixed combustion chamber 2 is a cylinder with a bottom plate at one end and an opening at the other end, and an air hole 3 is arranged on the cylinder wall, and the combustion and mixed combustion chamber 2 is set in the wind In the cavity 1, the open ends of the two are in the same direction and are fixedly connected and positioned through the open ends; the cylindrical wall of the combustion and combustion chamber 2 is evenly distributed with three circles of air holes 3, and between the two adjacent circles of air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com