High-efficiency porous media combustor for minitype heat optoelectronic system

A porous medium, micro-thermal photoelectric technology, used in burners, gas fuel burners, combustion methods, etc., can solve the problems of insufficient combustion, reduced energy ratio, and short residence time of pre-mixed gas, achieving easy observation, Improved temperature distribution, easy to manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

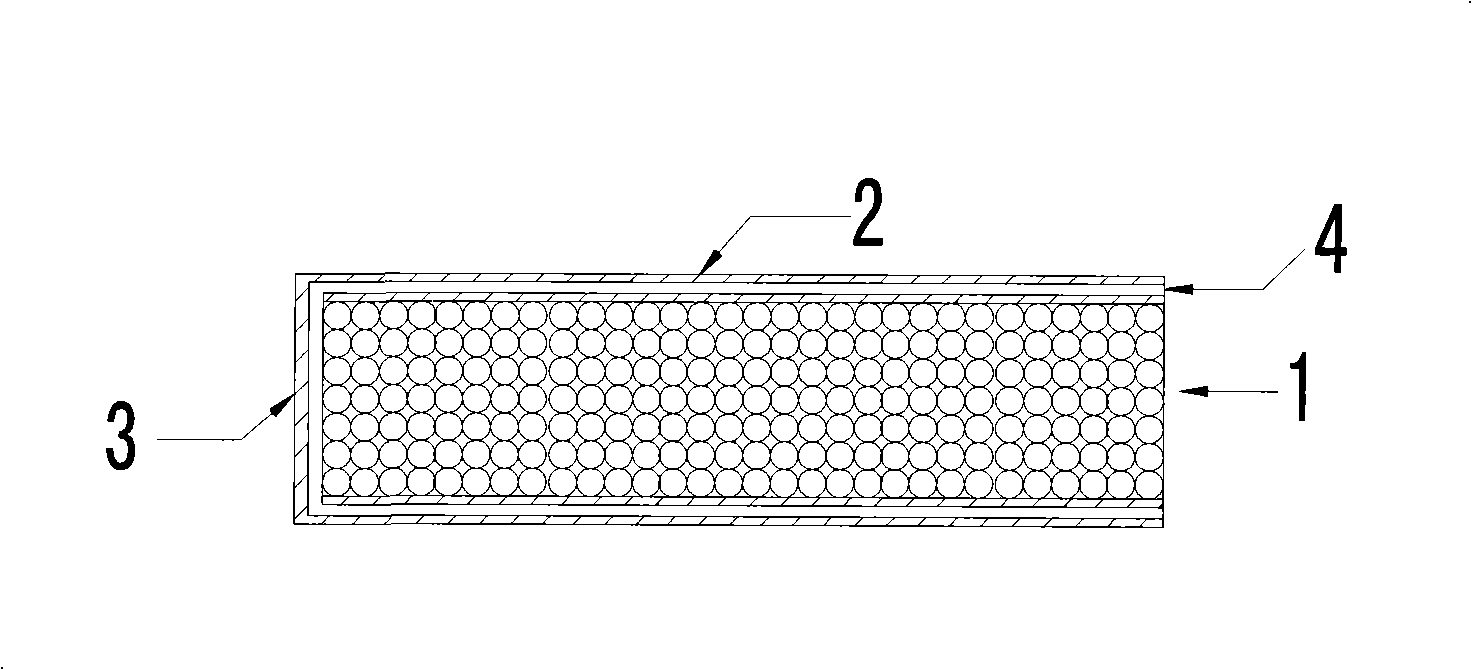

[0015] Example: Application of porous media burner in micro-hot spot system

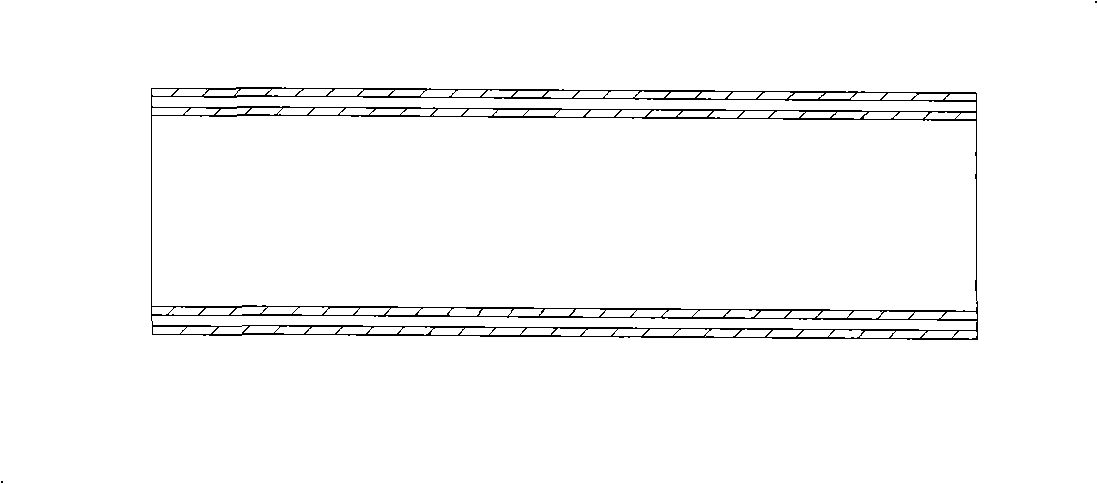

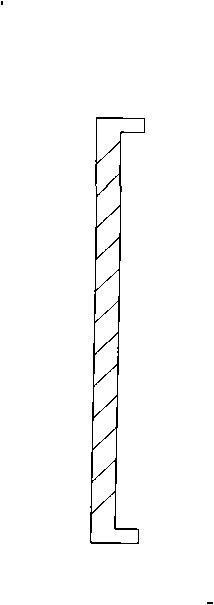

[0016] The working principle of the MTPV system is to release the heat generated by the combustion of fuel in the form of heat radiation, and convert it into electrical energy using photovoltaic cells. The micro-burner is the space where the fuel burns and releases heat energy in the MTPV. The distribution and height of its wall temperature are important factors that determine whether the MTPV system can work stably and efficiently. The burner has a tubular structure and the material is SiC ceramics with strong high temperature resistance. The physical parameters of SiC used are shown in the following table. The burner has an outer diameter of 3mm, an inner diameter of 2.4mm, and a length of 20mm. Ceramic balls with a diameter of 0.34mm are filled in the combustion tube in a slant hexahedron to form a porous medium structure with a porosity of ε=25.95%. At a standard atmospheric pressure and normal tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com