Coke boiler with low sulphur discharge

A technology of sulfur emission and coke, applied in the combustion chamber, combustion method, combustion equipment and other directions, can solve the problem that the boiler has not been published and has not been reported, and achieve the effect of huge economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

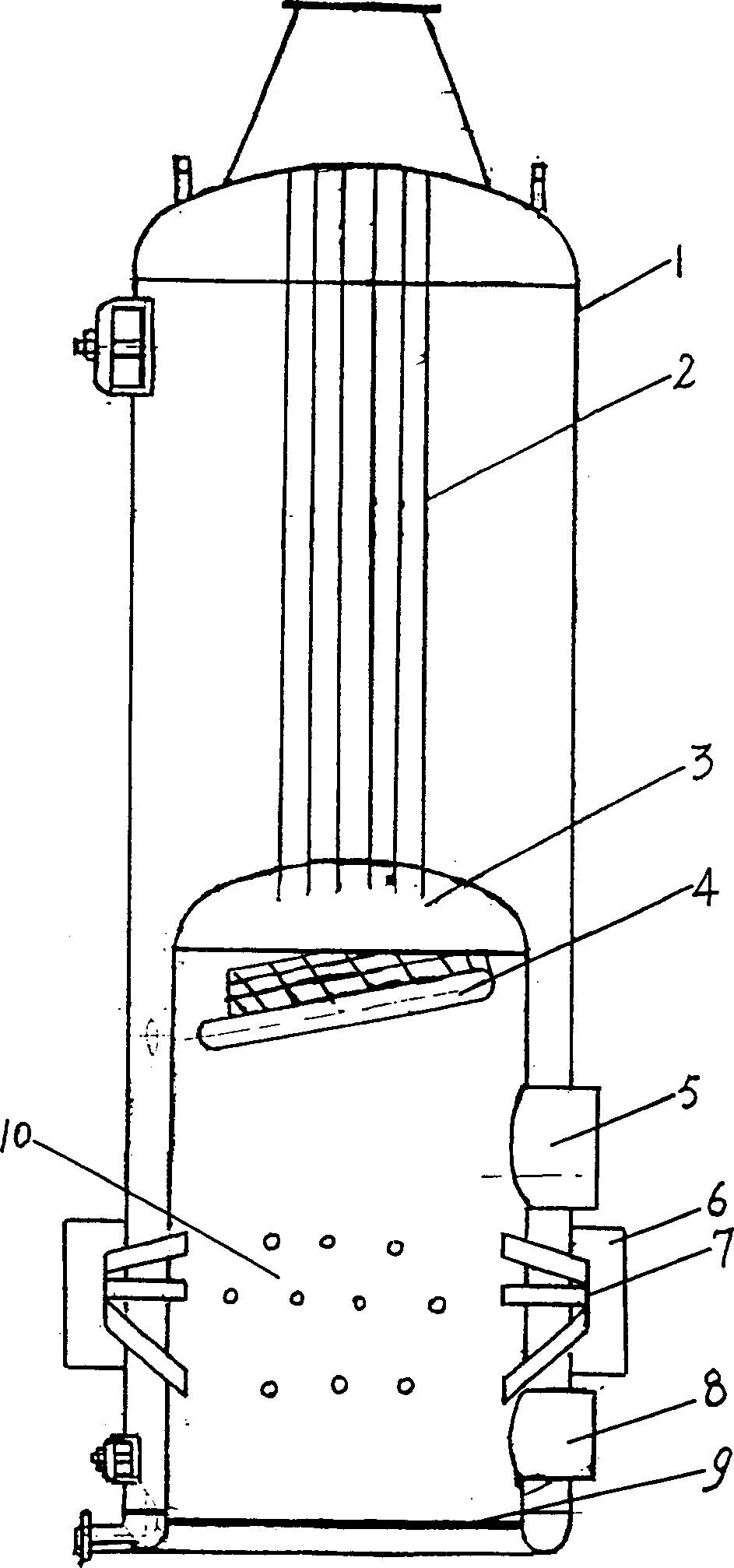

[0017] refer to figure 1 , the coke burning low-sulfur emission boiler of the present invention comprises a drum 1, a fire pipe 2, a furnace 3, a horizontal water pipe 4, a feeding hole 5, an air chamber 6, an air inlet pipe 7, a slag cleaning hole 8, a furnace bottom 9 and The combustion chamber 10, wherein the boiler has no grate, and the furnace 3 is provided with a slag cleaning hole 8 and a feeding hole 5, as a coke combustion chamber 10, an air chamber 6 is placed in the combustion chamber 10, and the air inlet pipe 7 directly enters the coke layer. , and there are three sets of air inlet pipes, one set is 45° downward, the other is tangentially parallel, and the other is 15° upward. The accumulation height of coke in the furnace is greater than 250 mm.

[0018] Further, in the coke-burning low-sulfur emission boiler of the present invention, the stacking height of coke in the furnace is preferably 800-1000 mm. At this time, the combustion situation is the best. Around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com